HP Multi Jet Fusion (MJF) 3D Printing Services

- Free Delivery

- PA 12, PA 11, TPU 95A

- Manufacturing From 3 Business Days

Start A New 3D Printing Quote

STEP | STP | SLDPRT | STL | IPT | 3DXML | CATPART | PTC | PRT | SATS

HP MJF 3D Printing Capacities

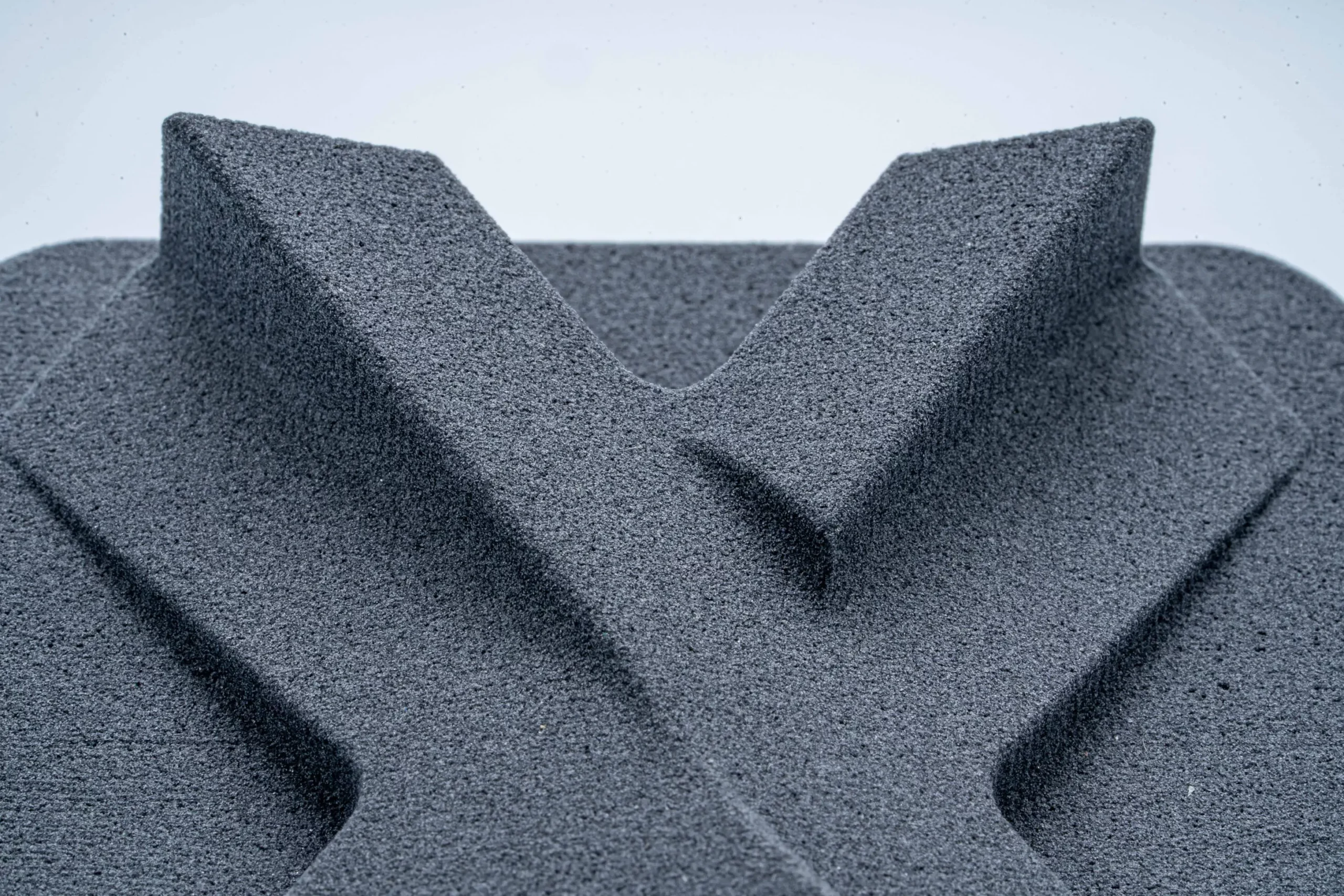

HP Multi Jet Fusion is a powerful 3D printing technology that produces highly accurate and durable parts at fast speeds, especially compared to other powder bed fusion technologies. Multi Jet Fusion parts are great for end-use, low-to-mid volume production, rapid prototyping, or as a bridge process to injection moulding. MJF printed parts can be post-processed by dyeing, sanding and plating.

- Lead time: 3 days

- Build volume: up to 380 x 284 x 380 mm, while we normally recommend the maximum size of 356 x 280 x 356 mm

- Layer thickness: ~0.08 mm

- Minimum feature size: 0.5 mm

- Minimum wall thickness: 0.6 mm (supported), 0.7 mm (unsupported)*

- Tolerance: ±0.3% (± 0.2 mm)

*Please note that parts with a wall thickness above 7 mm will be hollowed

Try Xometry Out Now In Just A Few Steps

Multiple designs for different parts can be imported at the same time to produce a single quote. In less than a minute, a detailed cost estimation appears on the screen.

First, select the manufacturing process you require. You can then choose from over 70 materials, both metals and plastics, and from a wide range of finishes and certifications.

Once you have selected the required options, all you need to do is confirm the order and pay for it on the secure payment platform. Your design will be analysed by engineers.

Within a short amount of time, you will receive the parts you ordered directly to your shipping address. You can track your package at any time in your personal account.

Advantages of HP MJF with Xometry

Massive Capacity

We can quickly produce both prototypes and large batches thanks to the largest manufacturing network in Europe, with over 2,000 vetted partners

Fast Production

You will get your 3D printed parts fast delivered in as fast as 3-5 days.

Quality Assurance

We have strong QA procedures, controlled by an in-house team of QA engineers, which allows us to deliver high quality parts.

Engineering Check & Status Updates

All designs are checked by engineers before they’re sent for 3D printing. After confirming your order, you will receive status updates on your production.

HP MJF 3D Printing Materials

- Nylon 11 (PA 11)

- Nylon 12 (PA 12) glass-filled

- Nylon 12 / PA 12 (SLS, MJF)

- Nylon 12 full-colour / CB PA 12

- Polypropylene (PP)

- TPU (Thermoplastic Polyurethane)

Pros & Cons of MJF 3D Printing

| Advantages | Considerations |

|---|---|

| Free form design: doesn’t need support features | Limited material and colour choice |

| Versatile, durable, flexible and chemical resistant material (Nylon) | Surface roughness (however, could be reduced by media tumbling) |

| Scalable into series | Warping issues for large feature |

| Fast: Xometry can deliver them in just 3 days | |

| Cheap, especially for small series |

HP MJF Manufacturing Specifications & Capabilities

| HP MJF | SLS | SLA | FDM | Carbon DLS | DMLS | Polyjet | |

|---|---|---|---|---|---|---|---|

|

Lead time |

3 days |

3 days |

7 days |

8 days |

5 days |

10 days |

7 days |

|

Build volume |

up to 380 x 284 x 380 mm, while we normally recommend the maximum size of 356 x 280 x 356 mm |

up to 340 x 340 x 605 mm, but usually, we recommend the maximum size of 320 x 320 x 580 mm |

• 145 × 145 × 185 mm (Standard) |

• 350 x 350 x 350 mm (Standard) |

up to 119 x 189 x 300 mm. Recommended size: Within 100 x 100 x 150 mm |

400 x 400 x 400 mm |

up to 490 mm x 391 mm x 200 mm |

|

Layer thickness |

~0.08 mm |

~0.1 mm and for water-tight parts 1.5 mm, when wall thickness is higher |

min 0.02 |

~0.05-0.3 mm |

~0.1 mm |

0.02 – 0.08 mm depending on the material |

0.04 mm |

|

Minimum feature size |

0.5 mm |

0.5 mm |

0.2 mm |

up to 0.2 mm |

0.5 mm |

0.75 mm for cosmetic features, 1.5 mm for structural features |

1.2 mm or greater for rigid. 2 mm or greater for rubber-like |

|

Tolerance |

±0.3% (± 0.2 mm) |

±0.3% (± 0.3 mm) |

• ±0.5% (±0.2 mm) (Standard) |

±0.5% (±0.5 mm) (Standard & Industrial) |

±0.1% (±0.1 mm). However, tolerances are not guaranteed on the first attempt at a new design. |

±0.2% (±0.1 – 0.2 mm) |

±0.1 mm for the first dozens of mm is typical, plus ±0.05 mm for every mm thereafter |

|

Description |

A technology that produces highly accurate and durable parts at fast speeds, especially compared to other powder bed fusion technologies |

One of the most popular and inexpensive technologies for industrial 3D printing |

A technology that produces extremely accurate and high-resolution parts |

Widely known for a great material selection, accuracy, and possibility to print large parts |

A breakthrough technology that uses digital light projection, programmable liquid resins, and oxygen-permeable optics to produce parts with exceptional durability, resolution, and surface finish |

Metal 3D printing technology. Selectively fuses a fine metal powder in aluminium or stainless steel |

Polyjet is a rigid photopolymer 3D printing technology that produces high-detailed models |

|

Support structures |

No |

No |

Yes, for overhanging features |

Yes, for overhanging features |

Yes, for overhanging features |

Yes, for overhanging features |

Yes, for overhanging features |

Xometry Also Offers These Services

Order 3D Printed Parts Online

All uploads are secure and confidential.

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط