Plastic Injection Moulding Services

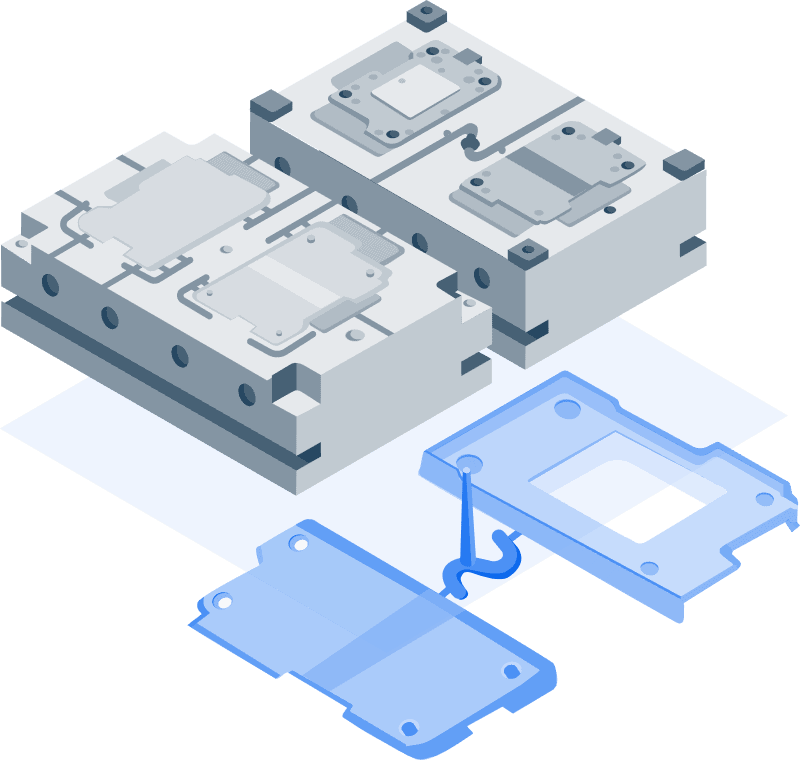

Custom injection moulding, insert moulding and overmoulding services with expert engineering evaluations and detailed design guidance. We offer full-service mould making and part production.

Ideal for serial manufacturing

Technical advice at all stages

AI-Powered Instant Quoting

Upload your CAD files and technical drawing to get an instant quote

STEP • STP • SLDPRT • IPT • 3DXML • CATPART • PTC • PRT • SAT

Quoting For Mid- & High-Volume Production

Want to get a custom quote for a complex project? Create your account, you can sign an NDA and talk to an account manager (only for corporate customers)

Our Injection Moulding Capabilities

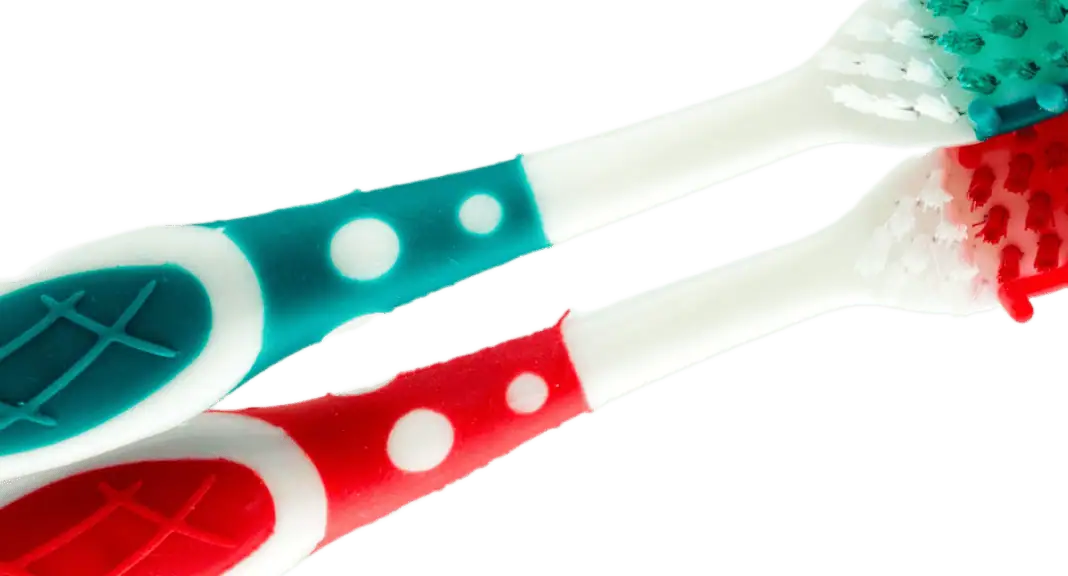

Insert Moulding

Overmoulding

Machines available

Quantity

Part tolerances

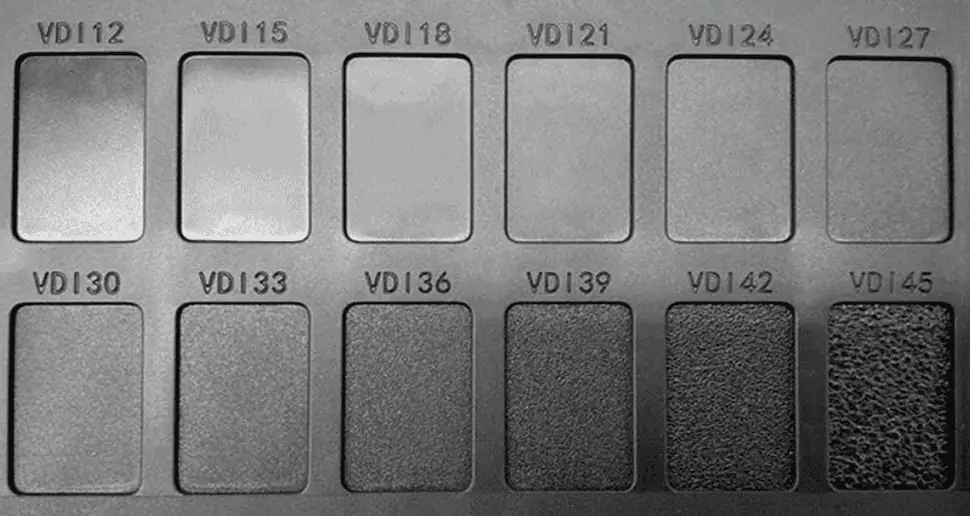

Finishes

Materials

Available mould types

Critical feature tolerances

Tool ownership

| Mould class | Cycles | Production level | Mould base | Minimum hardness (BHN) | Description |

|---|---|---|---|---|---|

| 101 | >1 million | High | Heat-treated stainless steel | 280 | Fast cycle times and very high production rate |

| 102 | <1 million | Medium-High | Heat-treated tool steel | 280 | Good for parts with abrasive materials and tight tolerances |

| 103 | <50,000 | Medium | P20 Steel | 165 | Widely used for low to medium production parts |

| 104 | <10,000 | Low | Mild steel, aluminium, or alloys | <165 | Good for limited-production parts especially with non-abrasive materials |

| 105 | <500 | Very low | Soft aluminum, epoxy, cast materials | <165 | Mostly used for prototype production |

Hızır Akbulut, Vivavis

“Xometry’s injection moulding expertise ensured our Octopus IoT device’s housing met stringent durability and IP68 standards, crucial for its performance in harsh environments.”

The Advantages of Our Digital Manufacturing Platform

Massive Network Capacity

Access the production capacity of over 2,000 qualified manufacturers in Europe and 10,000 worldwide, offering a wide range of production capabilities and certifications. Our extensive network enables the production of parts with any level of complexity, in almost any material, with precise tolerances and the required post-processing.

Intuitive Project Interface

Easily request parts at any scale, from AI-generated instant quotes for prototyping to comprehensive framework production projects.

Flexible Purchasing Solutions

Xometry offers flexible post-payment options for reliable corporate customers, a variety of payment methods to suit your needs, and the ability to establish framework agreements for specific prices and quantities, ensuring cost predictability and streamlined procurement processes.

Quality Assurance

Xometry is ISO 9001:2015 certified. Our seamless Manufacturing Supplier Network integration, in-house applications engineering team, and Xometry Quality Assurance Lab ensure we back every part we ship with top-notch quality.

Fast Delivery across Europe

Xometry delivers parts to all European countries, including the UK, Norway and Switzerland. See your delivery options for instant quotes right away or plan your custom shipments for complex projects.

Certifications & Inspection Reports

Xometry can provide various certificates (compliance with order types 2.1 and 2.2, raw material certificates for metals and plastics, heat treatment protocols, RoHS certificates, etc.) and inspection reports (CMM, First Article Inspection Report – FAIR, measurement reports, etc.).

Novag

“Partnering with Xometry for injection moulding has significantly enhanced our production efficiency and product quality, solidifying our position as a leader in conservation agriculture.”

Material Options: Unlimited Choice

Injection moulding supports an extensive range of plastics, making it suitable for diverse applications across nearly every industry. We can source thousands of materials upon request to meet your specific needs. Simply select “Custom” material on the part page and enter the name of your desired material.

Food grade

- ABS (POLYLAC® PA-757F)

- PA 12 (Grilamid® L 16 nat)

- PC (LEXAN™ RESIN 124R)

- PEEK glass-filled (30%) (APEXTECH-HT 330GL30)

- PMMA (POLYCASA® ACRYL G 55)

- PP (TAIRIPRO® K1011)

Glass-filled

- PA 6 (Kingfa PA6-G15 HSBK145)

- PA 66 (Kingfa PA66-G35 AHBK003)

- PC glass-filled (10%) (Makrolon® 9417)

- PC glass-filled (10%) (LEXAN™ FR Resin 500R)

- PC glass-filled (30%) (Bayblend® T88 GF-30)

- PEEK glass-filled (30%) (APEXTECH-HT 330GL30)

Biodegradable

- PLA (Anbio BG4400)

- PLA (GS Pla® AD92W)

UV-resistant

- ABS (CYCOLAC™ Resin FR15U)

- HDPE (DOW™ HDPE KT 10000 UE)

- HDPE (ExxonMobil™ HDPE HMA 016)

- PA 66 glass-filled (30%) (Zytel® 74G33W NC010)

- PC (Makrolon® 6557)

- PP (Kingfa AP-202W)

Flame retardant (UL 94 V-0 or higher)

- ABS (CYCOLAC™ Resin FR15U)

- ABS (POLYLAC® PA-765A)

- PA 66 glass-filled (35%) (Ultramid® A3X2G7)

- PC (Makrolon® 6557)

- PC glass-filled (10%) (Makrolon® 9417)

- PC glass-filled (10%) (LEXAN™ FR Resin 500R)

- PC-ABS (Bayblend® FR3008)

- PC-ASA (LUPOY EU5000FS)

- Teflon (PFA 440 HPB)

- TPV (SantopreneTM 251-70W232)

Heat-resistant

- ABS (Kingfa FW-612 TC)

- ABS (LG ABS LG703W)

- PA 6 (Kingfa PA6-G15 HSBK145)

- PEEK glass-filled (30%) (APEXTECH-HT 330GL30)

- PEI (LNP™ THERMOCOMP™ Compound EC006AQW)

Medical grade

- ABS (LNP™ STAT-KON™ Compound AX02747)

- PA 12 (Grilamid® L 16 nat)

- PBT (LNP™ ELCRIN™ W1000JiQ)

- PC (LEXAN™ HEALTHCARE RESIN HPS1)

- PEI (LNP™ THERMOCOMP™ Compound EC006AQW)

- PMMA (POLYCASA® ACRYL G 55)

- POM (LNP™ LUBRICOMP™ Compound KL004)

RoHS Compliant

- ABS (Axpoly® ABS52 1007)

- PA 12 (Grilamid® L 16 nat)

- PA 66 glass-filled (35%) (Ultramid® A3X2G7)

- ABS (POLYLAC® PA-757)

- PP (SEETEC PP H1500)

- TPV (SantopreneTM 101-64)

Clear/transparent

- ABS (Kingfa FW-612 TC)

- PA 66 (Kingfa PA66-G35 AHBK003)

- PC (LEXAN™ HEALTHCARE RESIN HPS1)

- PC (Makrolon® 6557)

- PMMA (POLYCASA® ACRYL G 55)

- PP (TAIRIPRO® K1011)

Biocompatible

- ABS (LNP™ COLORCOMP™ Compound A1000FXB)

- PBT (LNP™ ELCRIN™ W1000JiQ)

- PC (LNP™ ELCRIN™ HPH4504HB)

- PC-ABS (LNP™ COLORCOMP™ Compound N1000EXB)

- PEI (LNP™ THERMOCOMP™ Compound EC006AQW)

ESD

- ABS (ELIXTM ABS P2H-AT)

- ABS (LNP™ STAT-KON™ Compound AX02747)

- ABS (Novodur® P2H-AT)

- PC (LEXAN™ FR Resin SLD3000)

- POM (LNP™ STAT-LOY™ Compound K3000Z)

- PP (Borealis PP HG313MO)

Food grade

- ABS (POLYLAC® PA-757F)

- PA 12 (Grilamid® L 16 nat)

- PC (LEXAN™ RESIN 124R)

- PEEK glass-filled (30%) (APEXTECH-HT 330GL30)

- PMMA (POLYCASA® ACRYL G 55)

- PP (TAIRIPRO® K1011)

Clear/transparent

- ABS (Kingfa FW-612 TC)

- PA 66 (Kingfa PA66-G35 AHBK003)

- PC (LEXAN™ HEALTHCARE RESIN HPS1)

- PC (Makrolon® 6557)

- PMMA (POLYCASA® ACRYL G 55)

- PP (TAIRIPRO® K1011)

Heat-resistant

- ABS (Kingfa FW-612 TC)

- ABS (LG ABS LG703W)

- PA 6 (Kingfa PA6-G15 HSBK145)

- PEEK glass-filled (30%) (APEXTECH-HT 330GL30)

- PEI (LNP™ THERMOCOMP™ Compound EC006AQW)

Biodegradable

- PLA (Anbio BG4400)

- PLA (GS Pla® AD92W)

ESD

- ABS (ELIXTM ABS P2H-AT)

- ABS (LNP™ STAT-KON™ Compound AX02747)

- ABS (Novodur® P2H-AT)

- PC (LEXAN™ FR Resin SLD3000)

- POM (LNP™ STAT-LOY™ Compound K3000Z)

- PP (Borealis PP HG313MO)

RoHS Compliant

- ABS (Axpoly® ABS52 1007)

- PA 12 (Grilamid® L 16 nat)

- PA 66 glass-filled (35%) (Ultramid® A3X2G7)

- ABS (POLYLAC® PA-757)

- PP (SEETEC PP H1500)

- TPV (SantopreneTM 101-64)

Flame retardant (UL 94 V-0 or higher)

- ABS (CYCOLAC™ Resin FR15U)

- ABS (POLYLAC® PA-765A)

- PA 66 glass-filled (35%) (Ultramid® A3X2G7)

- PC (Makrolon® 6557)

- PC glass-filled (10%) (Makrolon® 9417)

- PC glass-filled (10%) (LEXAN™ FR Resin 500R)

- PC-ABS (Bayblend® FR3008)

- PC-ASA (LUPOY EU5000FS)

- Teflon (PFA 440 HPB)

- TPV (SantopreneTM 251-70W232)

Glass-filled

- PA 6 (Kingfa PA6-G15 HSBK145)

- PA 66 (Kingfa PA66-G35 AHBK003)

- PC glass-filled (10%) (Makrolon® 9417)

- PC glass-filled (10%) (LEXAN™ FR Resin 500R)

- PC glass-filled (30%) (Bayblend® T88 GF-30)

- PEEK glass-filled (30%) (APEXTECH-HT 330GL30)

Biocompatible

- ABS (LNP™ COLORCOMP™ Compound A1000FXB)

- PBT (LNP™ ELCRIN™ W1000JiQ)

- PC (LNP™ ELCRIN™ HPH4504HB)

- PC-ABS (LNP™ COLORCOMP™ Compound N1000EXB)

- PEI (LNP™ THERMOCOMP™ Compound EC006AQW)

Medical grade

- ABS (LNP™ STAT-KON™ Compound AX02747)

- PA 12 (Grilamid® L 16 nat)

- PBT (LNP™ ELCRIN™ W1000JiQ)

- PC (LEXAN™ HEALTHCARE RESIN HPS1)

- PEI (LNP™ THERMOCOMP™ Compound EC006AQW)

- PMMA (POLYCASA® ACRYL G 55)

- POM (LNP™ LUBRICOMP™ Compound KL004)

UV-resistant

- ABS (CYCOLAC™ Resin FR15U)

- HDPE (DOW™ HDPE KT 10000 UE)

- HDPE (ExxonMobil™ HDPE HMA 016)

- PA 66 glass-filled (30%) (Zytel® 74G33W NC010)

- PC (Makrolon® 6557)

- PP (Kingfa AP-202W)

Secondary Operations

Secondary operations enhance the functionality or aesthetics of your parts after production. You can specify these requirements in your technical drawing. Below are examples of the secondary operations we offer:

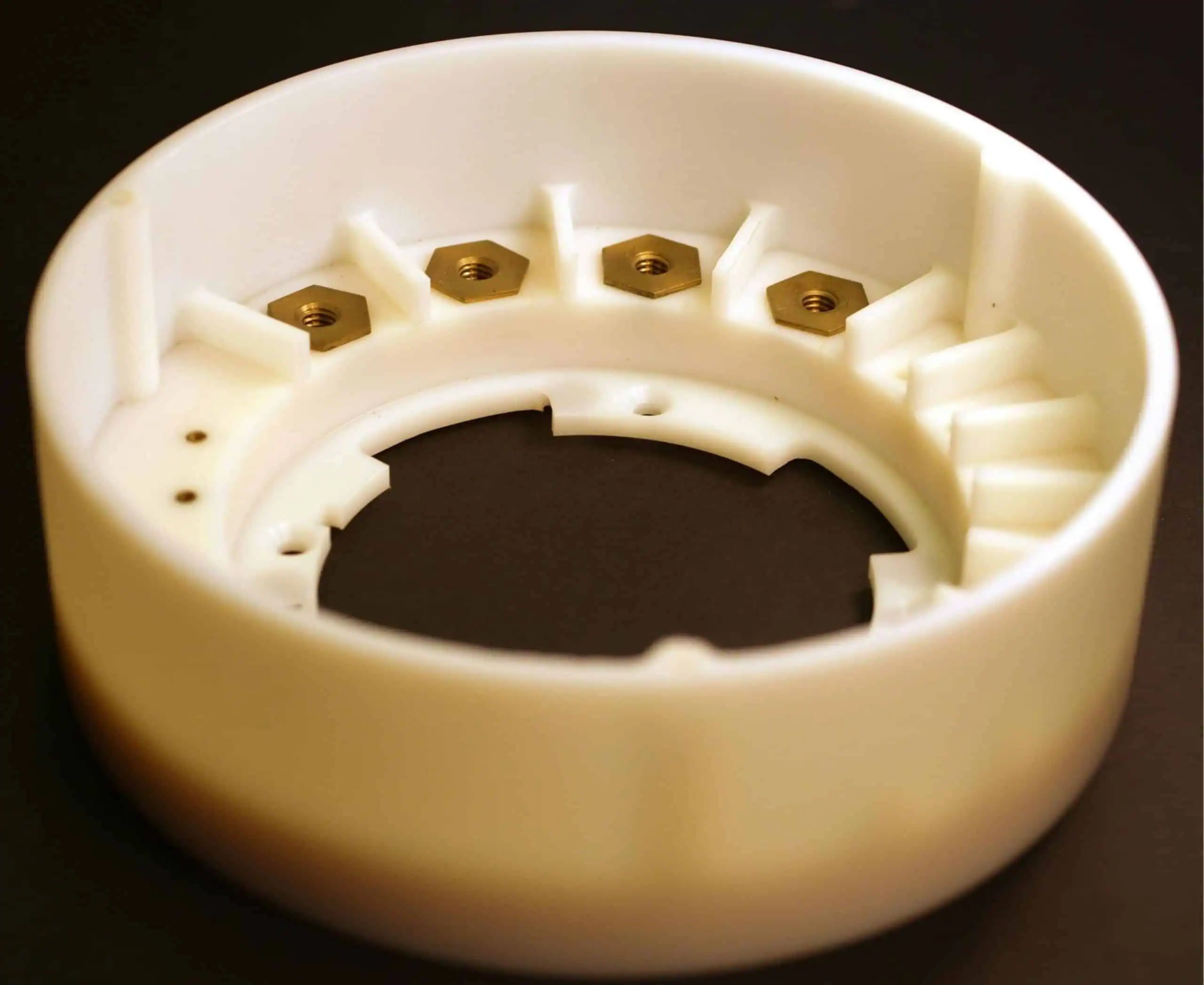

Inserts

We can install standard inserts in UNF and metric sizes, commonly used for creating durable threaded connections in plastic parts.

Pad printing

Transfer a 2D image onto a 3D part. All images are subject to review to ensure compatibility.

Laser engraving

Permanently engraves details such as part numbers, logos, or custom markings onto your parts, offering precision and durability.

Painting

Applies a custom-colour paint layer for aesthetics or functional purposes, such as improved durability or UV resistance.

Silk screening

Applies ink to a part through a stencil to create designs or text, ideal for flat or slightly curved surfaces.

Ultrasonic welding

Joins two plastic components together using high-frequency ultrasonic vibrations, creating a strong, seamless bond without additional fasteners.

UV coating

Adds a protective layer that enhances durability, scratch resistance, and UV stability while providing a glossy or matte finish.

Heat staking

Uses heat and pressure to embed metal inserts or form a joint in plastic parts, commonly used for durable assemblies.

Hot stamping

Applies metallic or pigmented foil to the part surface for decorative purposes, such as logos or text, with a high-end look.

Assembly

Xometry offers the assembly of injection moulded parts, including labelling and packaging services. Discuss your specific needs with your salesperson to tailor the process to your requirements.

Injection Moulding Compared With Other Processes

Use the dropdowns in each column to select and compare services side by side.

Use the dropdowns in each column to select and compare services side by side.

|

Mass production of highly detailed plastic parts Get a Quote

|

Small batches of detailed parts resembling production quality Get a Quote

|

Batches up to 5,000 pieces, often rubber, silicone or thermoset materials Get a Quote

|

|---|---|---|

Optimal quantity range50 – 1,000,000 | Optimal quantity range1 – 100 | Optimal quantity range1 – 5,000 |

Technology DescriptionHeats plastic resin, injects it into a mould cavity, and cools it to form precise and repeatable parts. | Technology DescriptionUses a silicone mould to create parts, ideal for prototypes or low-volume production. | Technology DescriptionInvolves placing material into a heated mould and compressing it to form the desired shape. |

Lead Time38 days | Lead Time20 days | Lead Time20 days |

Instant quote availabilityYes | Instant quote availabilityYes | Instant quote availabilityNo |

Maximum Part Size1,289×1,910×1,006 mm | Maximum Part Size2,500×2,200×1,800 mm | Maximum Part Size500x500x mm |

Mould life10,000 – 1,000,000 shots | Mould life1 – 20 shots | Mould life10,000 – 1,000,000 shots |

Material selectionAny thermosets/thermoplastics | Material selectionRigid plastics (ABS-like, PMMA-like, PP-like, PC-like), rubber-like plastics | Material selectionRubbers, silicone materials |

Prototyping | Prototyping | Prototyping |

High-volume production | High-volume production | High-volume production |

Part design complexity | Part design complexity | Part design complexity |

Standard surface finish | Standard surface finish | Standard surface finish |

Post-processingNo | Post-processingNo | Post-processingNo |

Cost of design mistakesHigh | Cost of design mistakesLow | Cost of design mistakesLow |

Advantages

| Advantages

| Advantages

|

Disadvantages

| Disadvantages

| Disadvantages

|

| Explore Injection Moulding Further | Explore Vacuum Casting Further | Explore Compression Moulding Further |

Frequently Asked Questions

Costs vary based on tooling complexity, materials, and production volume. Tool design and manufacturing lead times typically range from 20–30 business days, while part production can start as quickly as 8 days, depending on batch size and delivery requirements.

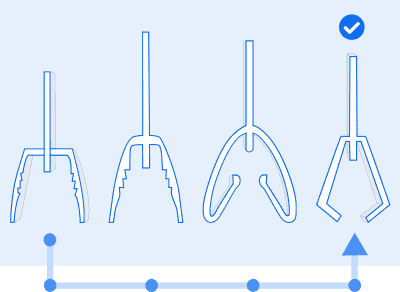

Yes, Xometry offers sample production (T1) before full-scale manufacturing. Feedback on samples may lead to further iterations (T2, T3, etc.).

Yes, Xometry provides DFM services and supports material selection.

Our standard is DIN 16742 tolerances, but we are capable of achieving tighter tolerances based on your requirements, depending on the specifics of the technical drawing and project.

We offer ISO 9001, AS9100, ISO 13485, and ISO 7/8 Medical Clean Room moulding certifications, ensuring high-quality standards for a range of industries.

We support an extensive range of materials, from standard plastics to customised options. With our network of manufacturing partners, we can source any material you need to meet your project requirements.

Yes, we can run multiple colours of the same material, even within the same order. Please note that using different colours may increase the cost due to purge.

At Xometry, customers retain full ownership of their injection mould tools. After production, the moulds remain securely stored at our facilities. Tools can be shipped to you upon request, with any associated shipping and packaging costs borne by you. Please confirm whether you have ordered an export or non-export mould to understand any potential additional costs.

We store your injection mould at our manufacturing partner facilities for at least two years, with the option for extended storage available upon request.

Reorders are seamless as moulds are stored and maintained. We provide quotes within 48 hours of your request, and lead times vary based on batch size and production schedules.

Start a new Instant Moulding Quote With Xometry Now

Need a small production batch?

Try our AI-powered Instant Quoting! Upload your design to get an online quote for your project.

Need mid- or high-volume production batches or a complex production project?

Proceed with describing your project requirements through our platform.

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط