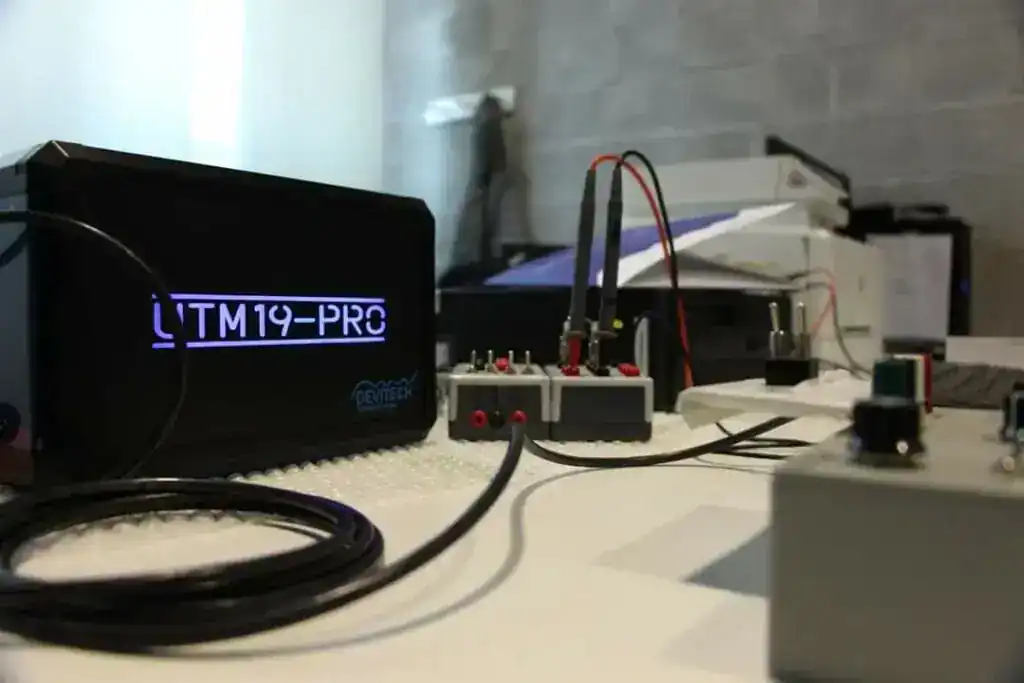

Devitech is an Italian start-up specialised in ‘revamping’, i.e. reconditioned industrial machinery: through the experience of its founders and their patented software, the company can increase the performance of obsolete machines with savings of up to ⅕ compared to buying new. How? By making customised parts with Xometry. Let’s discover more about this economically and environmentally sustainable choice with Pierpaolo Bassani.

Italie

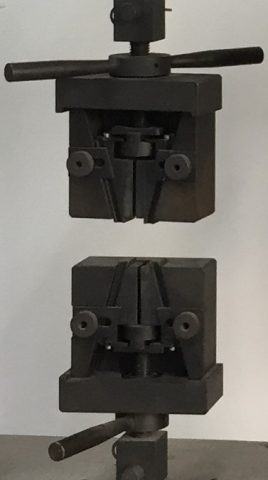

Steel

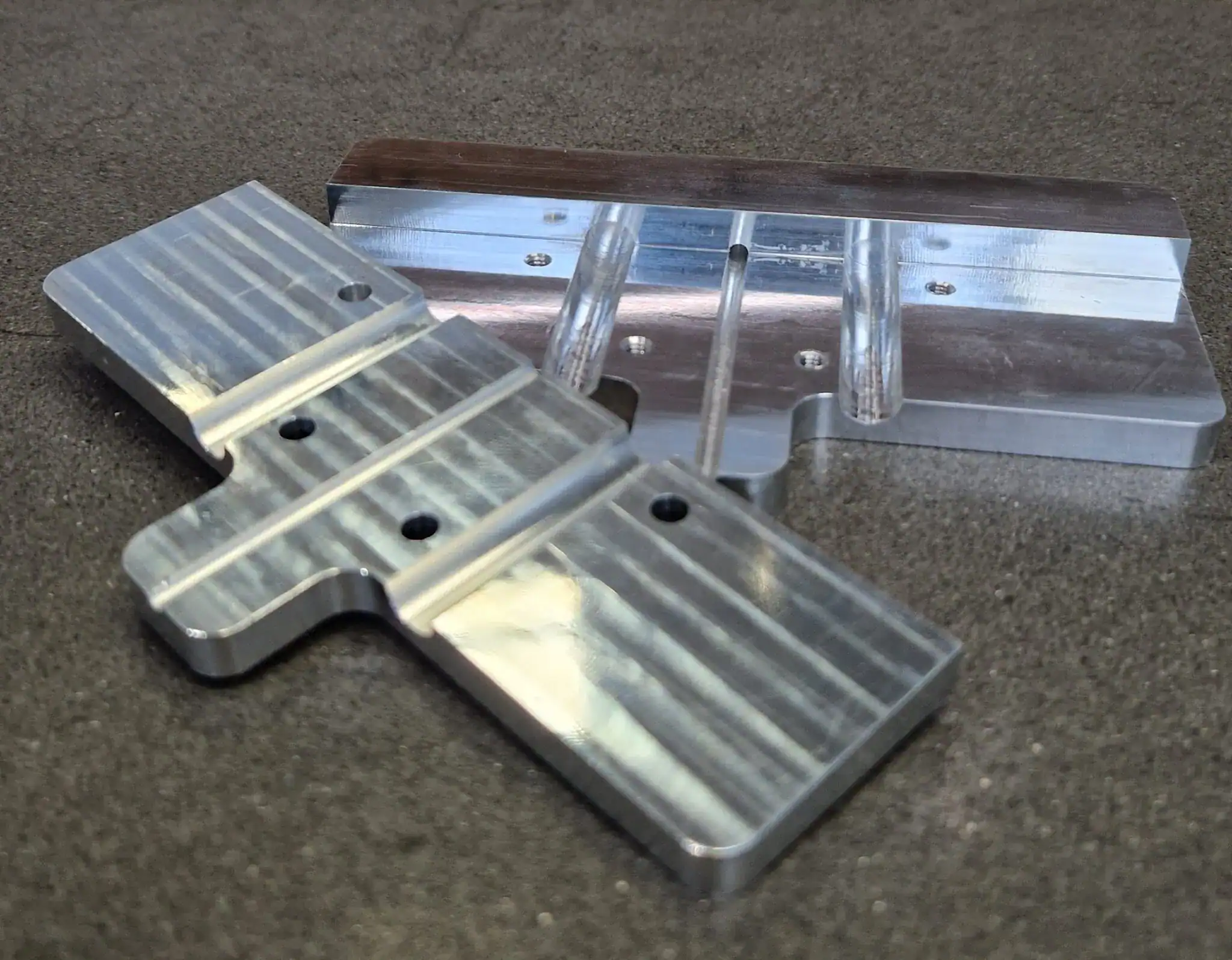

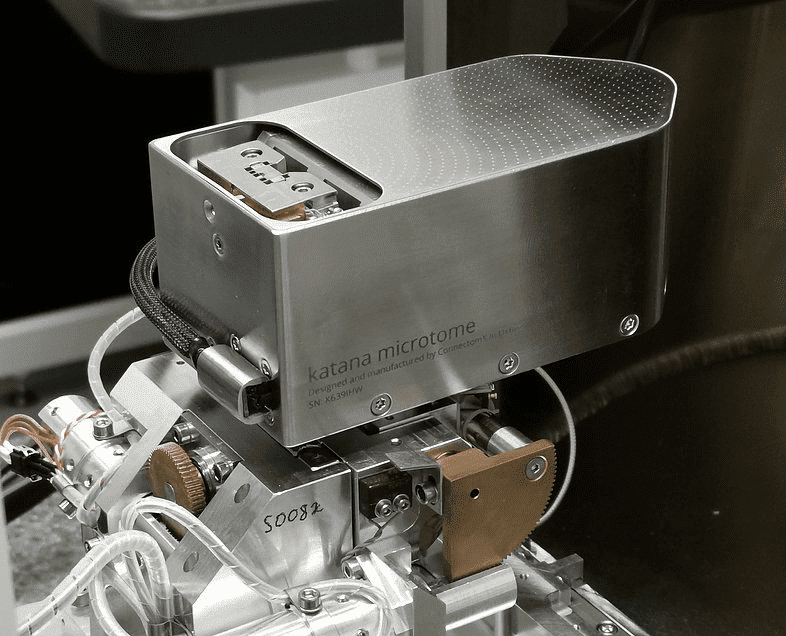

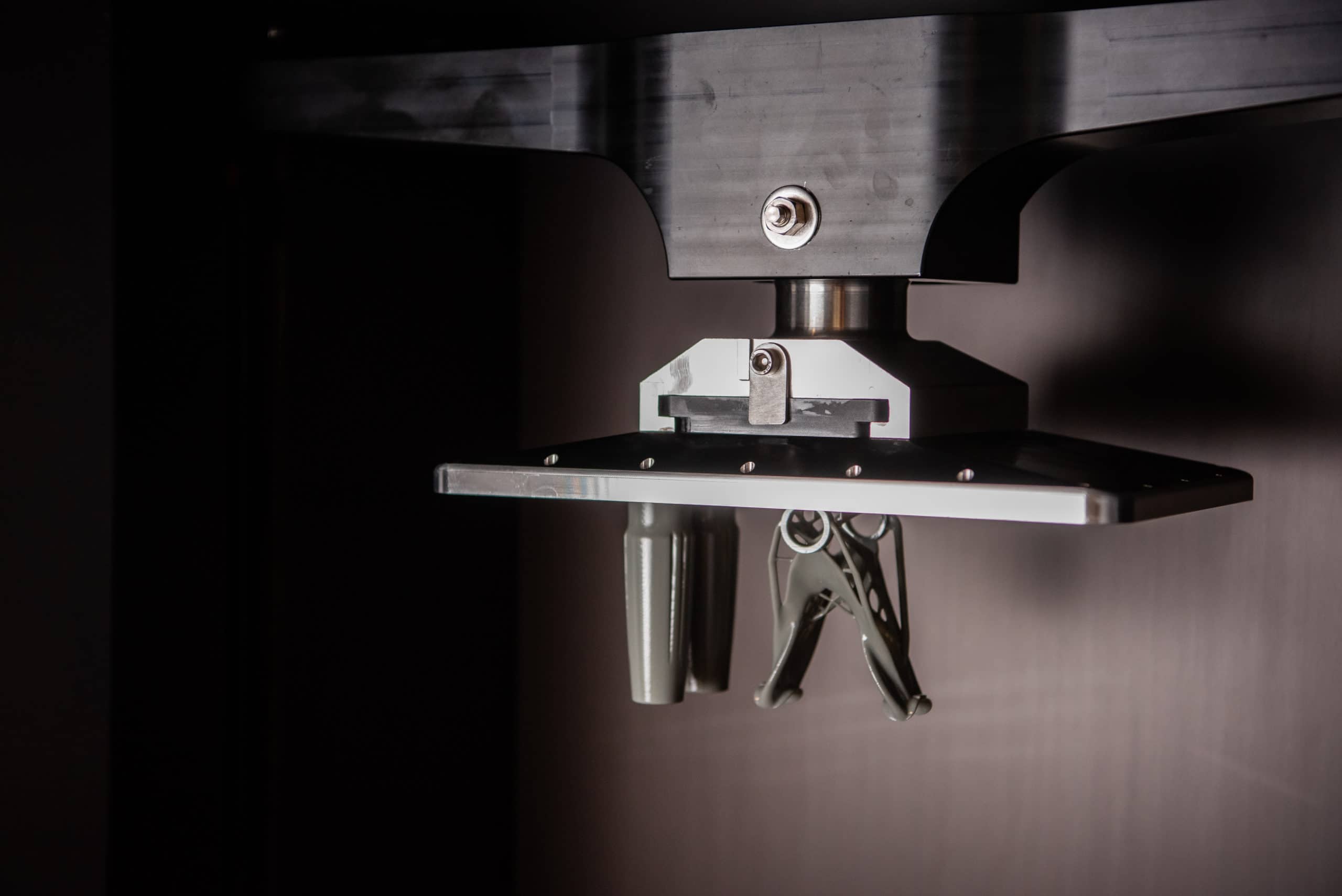

Custom spare parts (e.g. gripper jaws) produced via CNC machining to refurbish and upgrade obsolete materials test machines, extending lifecycle and performance

Finding a valid partner in Xometry was crucial for us, both for the parts’ precision and the price/quality ratio. Your service has also been truly valid: the sales department has always been available to solve problems and listen to our requests?

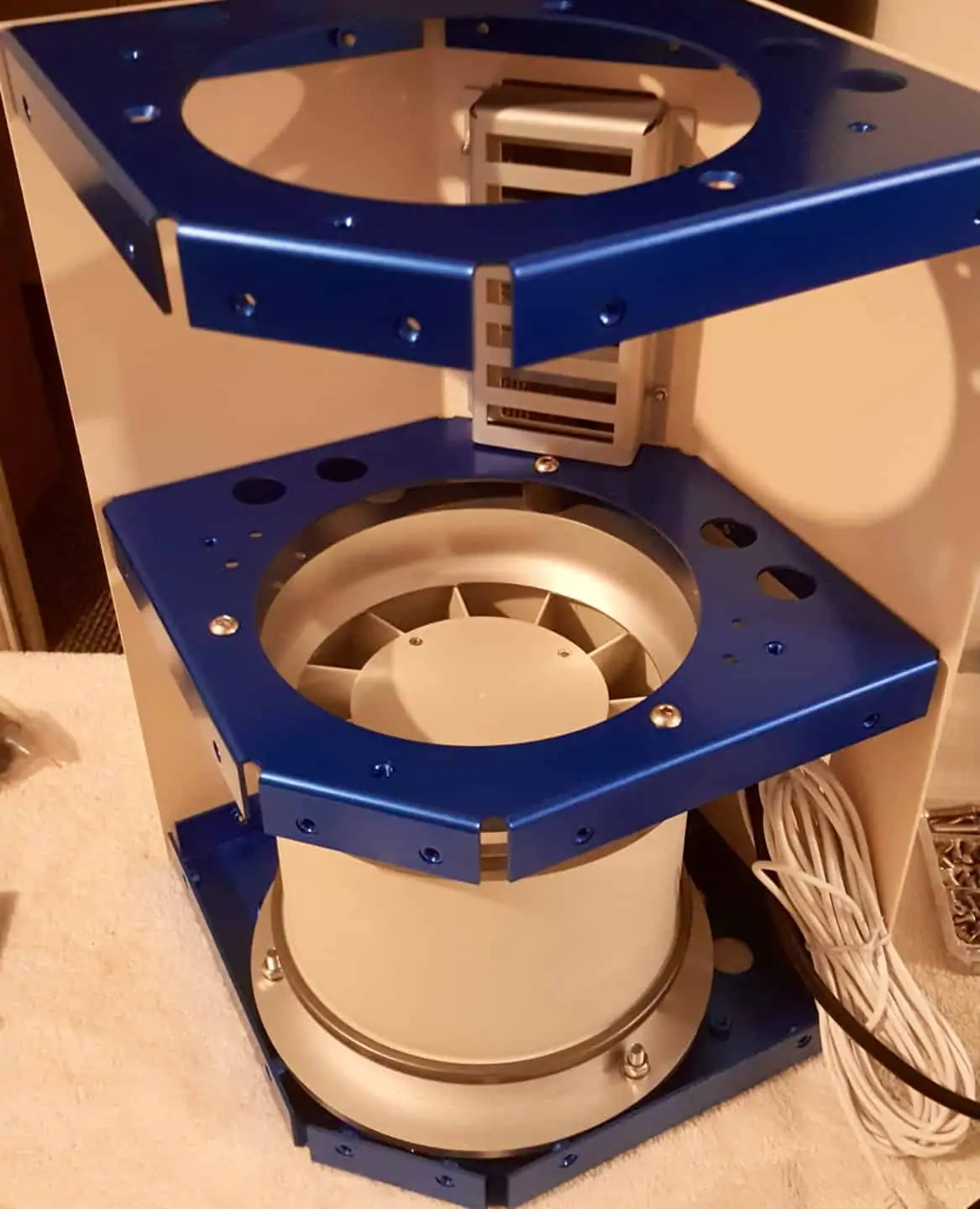

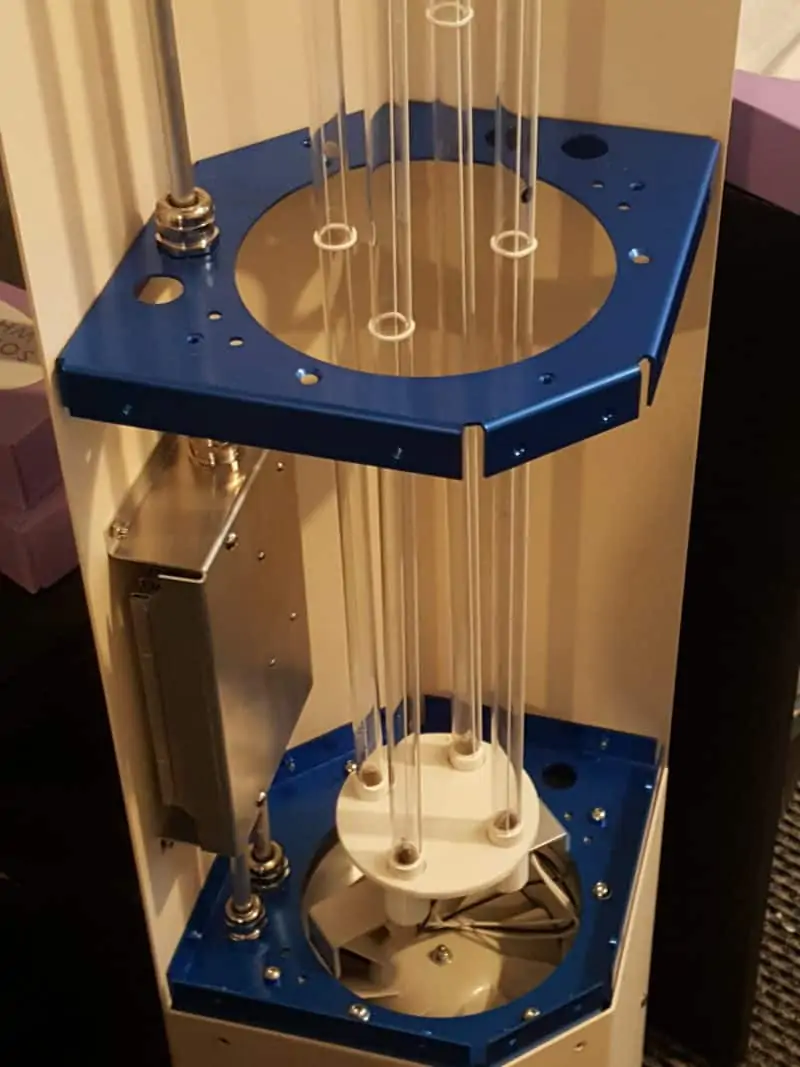

Breathe new life into the machines, even 30-40-year-old ones, and update them to the latest regulations, whilst improving their performance.

The phenomenon of “revamping” is becoming increasingly widespread in Italy, but there are still a mere handful of truly competent specialised companies capable of providing certifications. One of the most authoritative at the national level is Devitech, a young startup that starts from afar.

“The company was founded in 2020, with 30 years of personal experience in the testing sector”, confirms Pierpaolo Bassani, founder and specialist in test machines. “And it is precisely from this sectorial know-how concerning its pitfalls, that we started to find a solution. After creating an innovative software system for the management of test machines, we created this startup, consisting of four partners with other internal and external professionals. Today we can handle the requests of highly assorted customers, from the aeronautical to the automotive to the steel industry”.

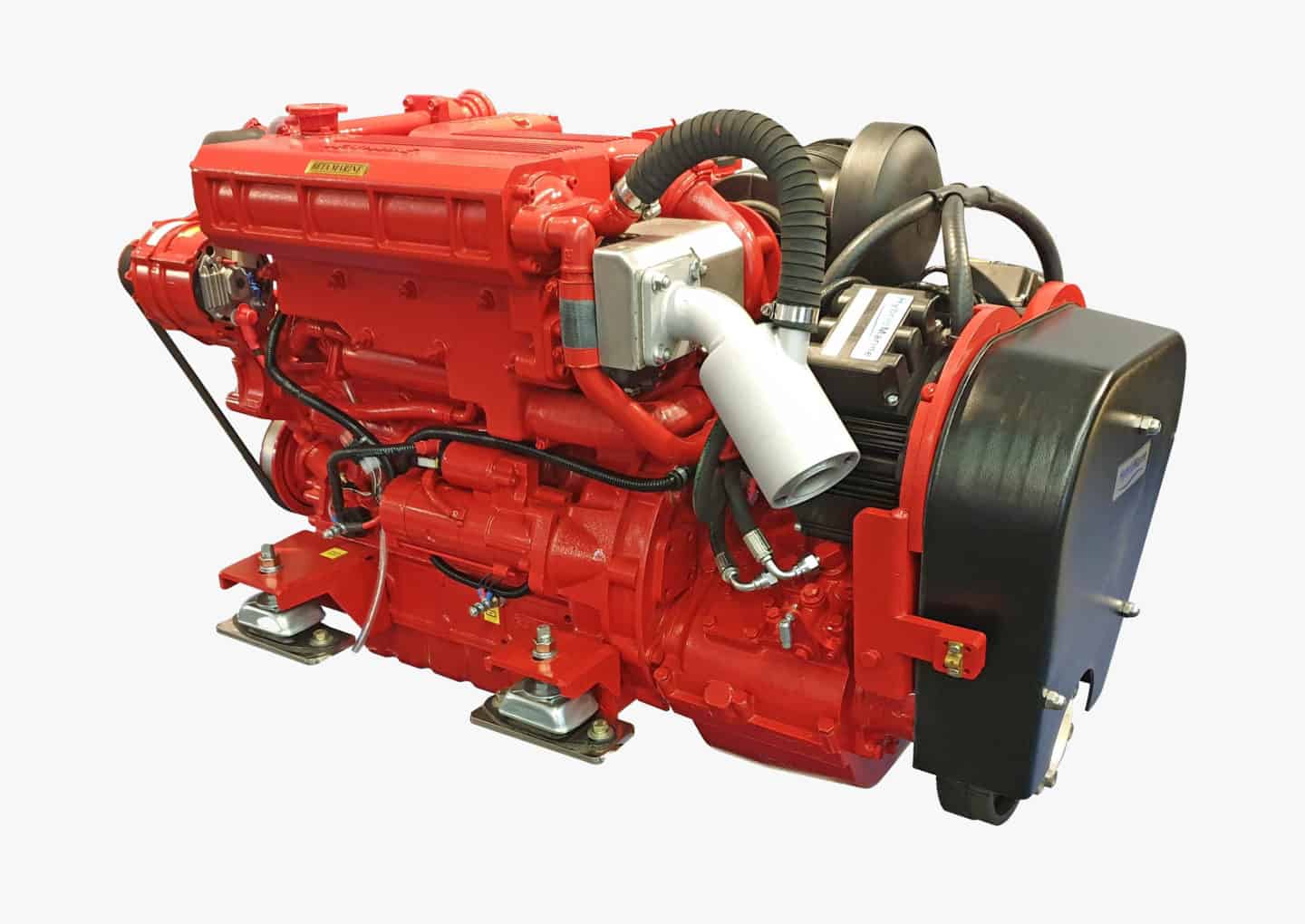

The main problem that Bassani and his team have faced is the difference in interests between machine manufacturers and manufacturing companies: “The big manufacturers push incessantly to buy new equipment. However, if the machine is still mechanically working and there is only the control system to be renewed, the customer company should hang onto it and simply modify those parts. Hence, revamping becomes a perfect solution for them”.

The Three Advantages of Revamping for Small and Large Companies

“Italian companies are usually advised to buy a machine and keep it for life, as long as the regulations do not oblige them to change. Our business objective is to allow these companies to keep the machine compliant and performing instead of buying a new one or choosing to keep two, with no advantage to production”.

The advantages for companies are very concrete: “The first benefit of our business is to their bottom line. Obviously, we must first analyse the machine’s condition and evaluate the cost/benefit together with the company. The bigger the machine, the more the revamping is profitable. You can save up to ⅕ of the cost of a new machine”.

The second advantage is operational: “Devitech customers can continue to use the machine they know perfectly well with all its accessories and, through our proprietary software, take advantage of an updated system to improve the overall performance and also the safety of operators”.

Finally, an advantage that involves all of us: “Reusing what has already been produced compared to producing from scratch, also considering all the difficulties that machine manufacturers have had to face in recent periods, is also good for the ecosystem. Therefore, the choice is economically advantageous and even sustainable”.

Xometry: Bespoke Spare Parts to Upgrade Machines

The collaboration with Xometry began with the creation of spare parts for gripper jaws for testing machines. The search for a non-traditional partner, who shared the same innovative vocation with the startup, was decisive:

“Building a spare part to design specifications with traditional methods is impossible, despite being in an area packed with mechanical workshops. These suppliers work on large numbers, we focus on individual specificities”.

That’s where Xometry steps in: by uploading custom projects based on the machines to be reconditioned, Devitech tested instant quotes and decided to produce on-demand steel parts with CNC machining.

“We started to produce unique parts in small quantities with Xometry, as spare parts for items subject to depreciation or obsolescence”.

And the results met expectations: “Finding a valid partner in Xometry was crucial for us, both for the parts’ precision and the price/quality ratio. Your service has also been truly valid: the sales department has always been available to solve problems and listen to our requests”.

Creating the Future Starting From Revamping

What are Devitech’s future plans?

“We are increasingly focusing on the production of sensor accessories for testing machines. Perhaps in the future, we will dedicate ourselves to the production of complete machines. We currently deal with projects on request: if the company needs a machine that is no longer available on the market, we can study the entire project from scratch and execute it within 60 days. At the moment, we are contemplating our original mission: to create innovative original machines, poles apart from those of large manufacturers”.

Further Info About Devitech

Devitech S.r.l. was founded in 2020 and specialises in the reconditioning of test machines through proprietary software.

Website: https://www.devitech.it/

Contact us: commerciale@devitech.it

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط