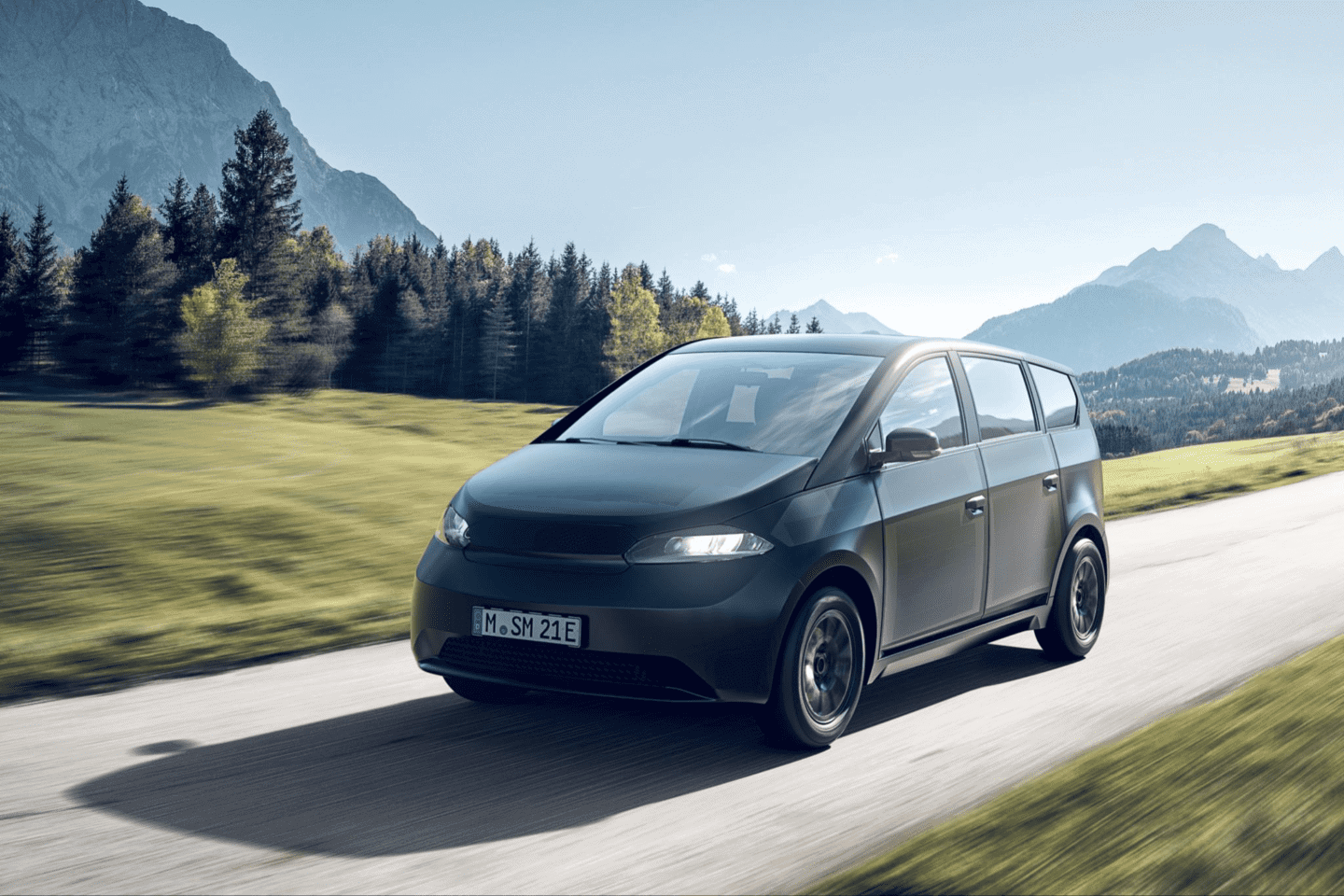

Black Tea Motorbikes, a Munich-based startup, builds retro-inspired electric motorcycles with a sustainable twist. To produce them in small series, they rely on complex, high-precision metal parts—without compromising on cost or flexibility. See how Xometry helps speed up production and simplify the process.

Vidéo

Vidéo

Allemagne

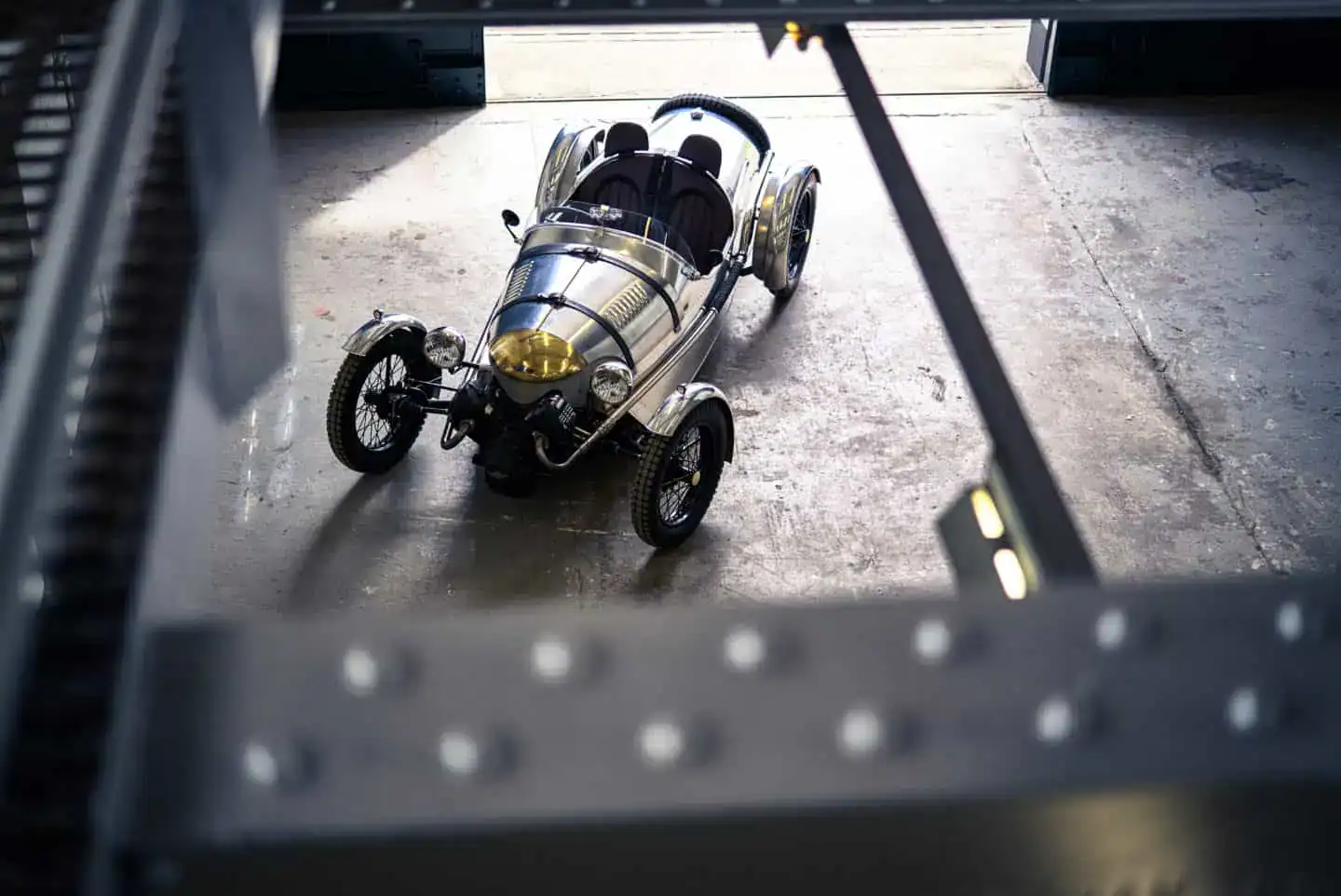

Retro-inspired electric motorcycles.

Xometry was more affordable than other providers. We upload the parts, review pricing and feasibility, and get started right away.

About Black Tea Motorbikes

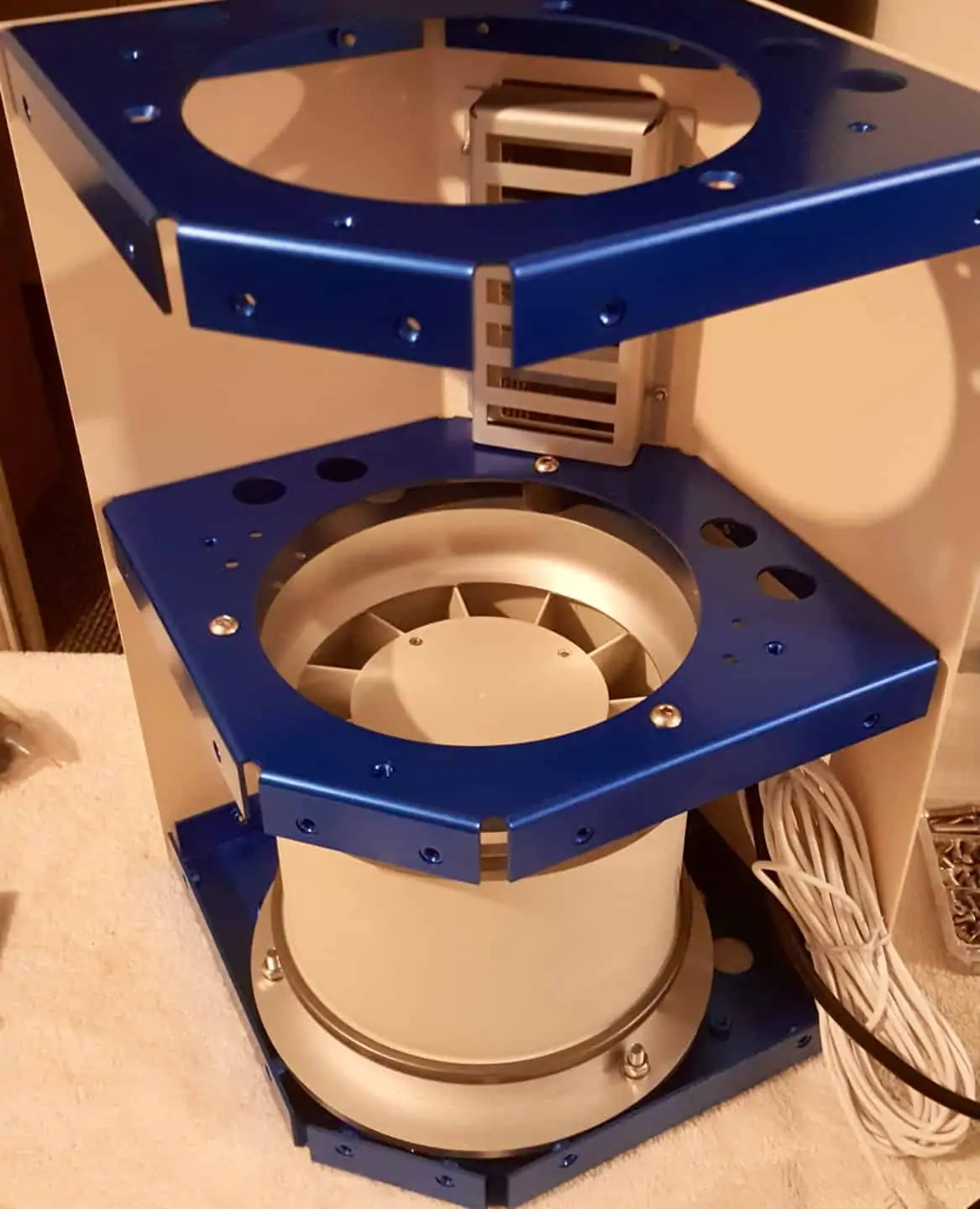

Founded in 2020, Black Tea Motorbikes merges classic motorcycle design with sustainable electric mobility. The startup specializes in lightweight electric motorcycles modeled after “Café Racers.” All production and assembly takes place in Bavaria, in close collaboration with their own rider community.

Sourcing Complex Metal Parts Efficiently

To build their motorcycles, Black Tea Motorbikes relies on precision sheet metal parts, frame components, and structurally critical assemblies. These parts must meet exacting design requirements and offer mechanical stability—yet be available on-demand, tailored to the production schedule. With limited internal resources, managing manufacturing in-house or through a network of small suppliers wasn’t feasible.

Instant Quotes, Precision Manufacturing, and Streamlined Ordering

Working with Xometry as their manufacturing partner, Black Tea Motorbikes uploaded all CAD files directly to the platform and received a reliable, instant quote—including price, lead time, and feasibility. Parts were ordered in small batches of 20 units, precisely aligned with their assembly timeline. Even intricate components requiring multiple bends and meeting tight design tolerances were produced cost-effectively.

From Prototype to Market: Faster Production, Less Risk

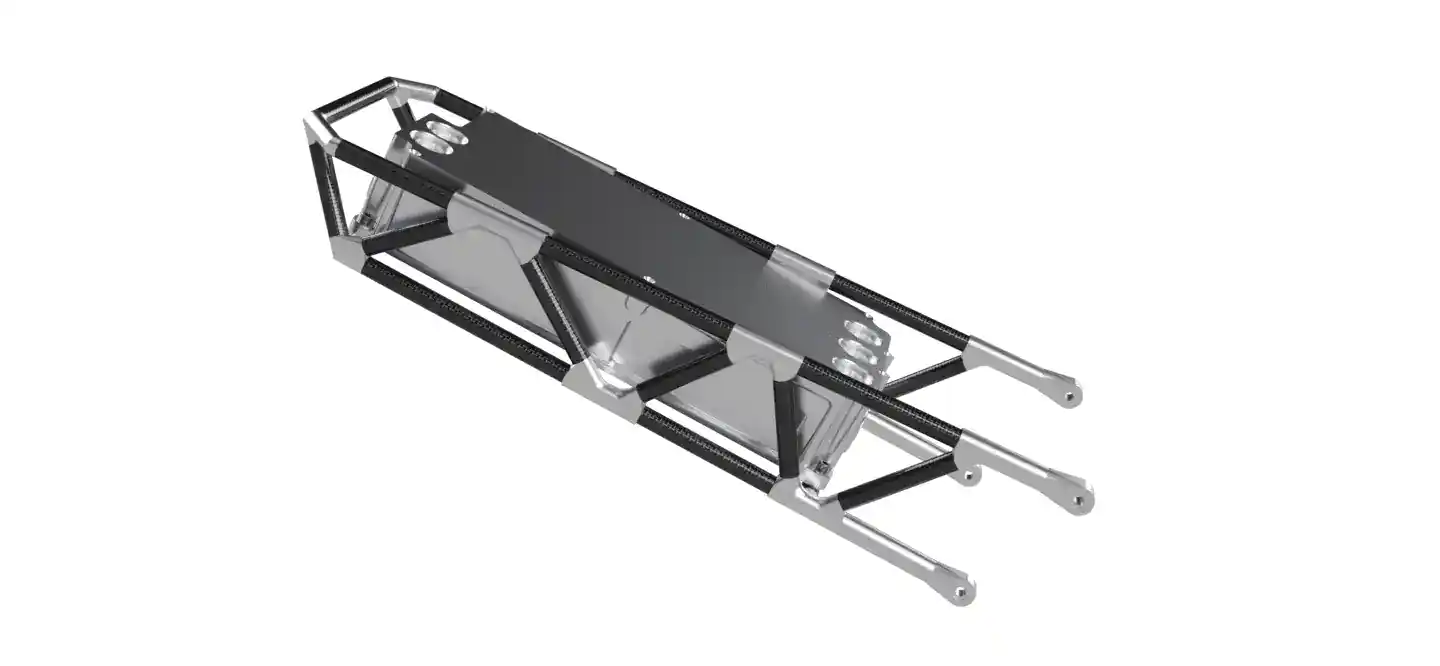

- Highly complex frame components delivered with precision and ready to install

- Flexible call-off quantities, with startup-friendly payment terms

- Time savings in procurement enable full focus on product and customer

- Cost advantage over conventional suppliers

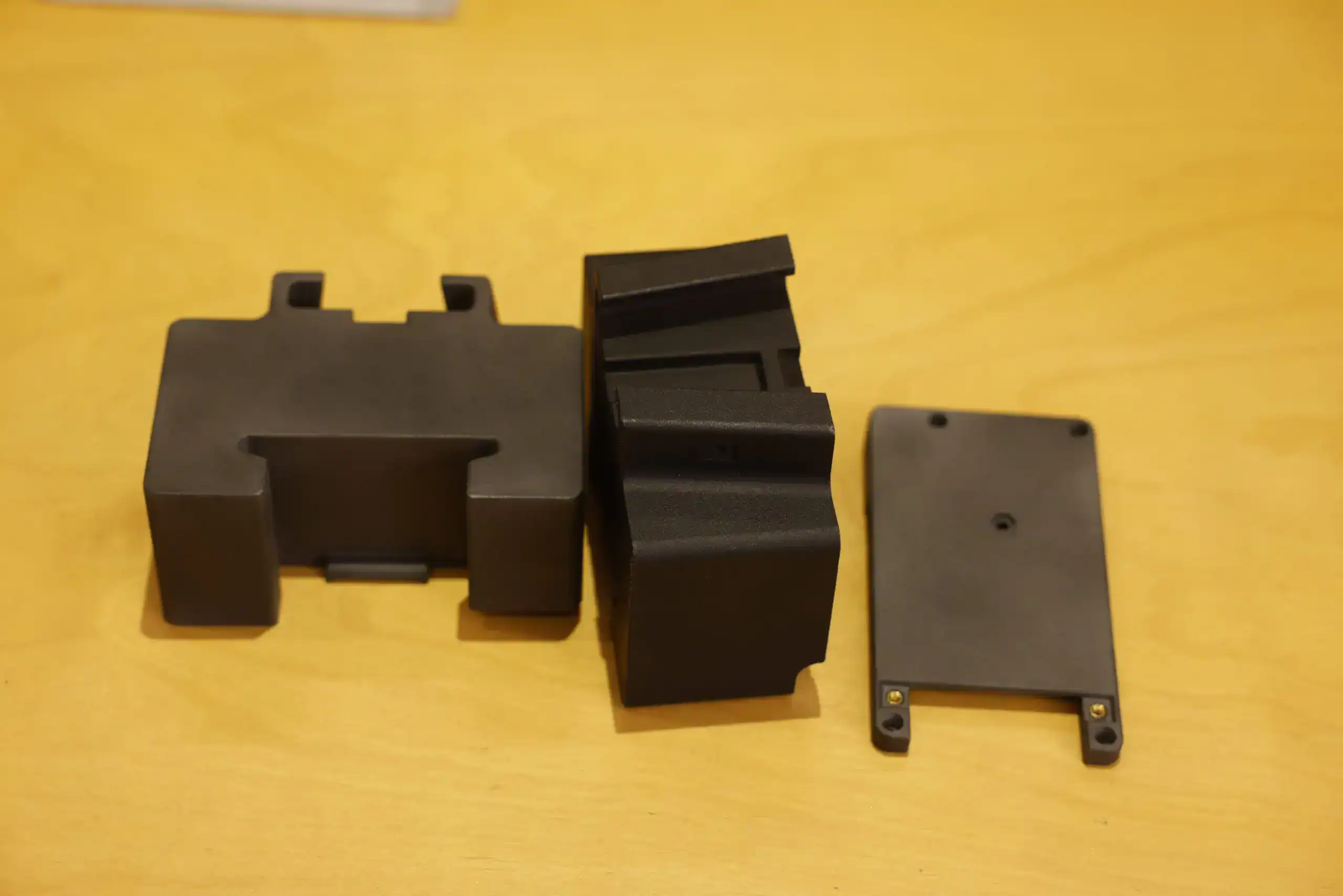

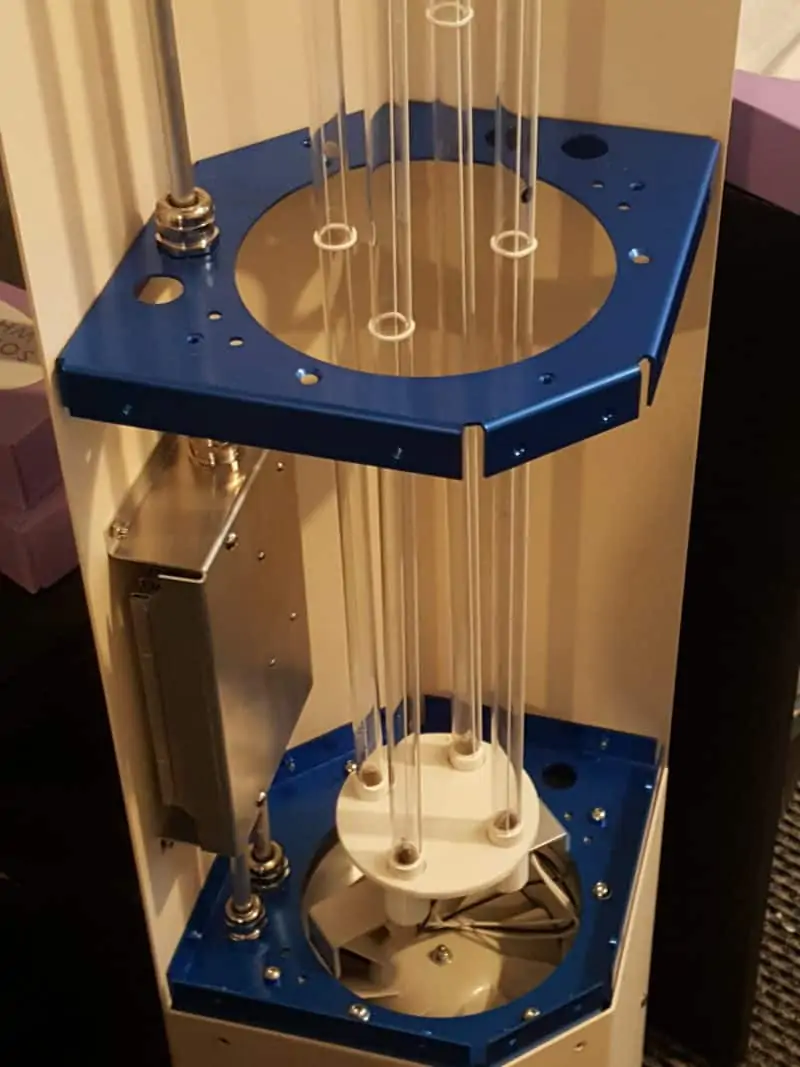

Multi-Bend Frame Component – Manufactured by Xometry

Efficiency That Startups Rely On

Xometry empowers startups like Black Tea Motorbikes to manufacture production-grade parts with agility, cost-efficiency, and precision planning. From complex sheet metal parts and CNC-machined components to small-batch series, Xometry is the ideal partner for emerging industrial companies that demand high standards in design, quality, and on-time delivery.

Learn more about Black Tea Motorbikes: https://www.blackteamotorbikes.com/

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط