Sferasol, a family-owned company, has driven innovation in the Green Economy by developing the first spherical solar thermal collector. Xometry has supported this innovation by manufacturing critical steel components.

Italie

Spherical solar thermal collector

Xometry helped us in speeding up our supply chain: we found certified suppliers for steel parts at a very competitive price, in a very short time.

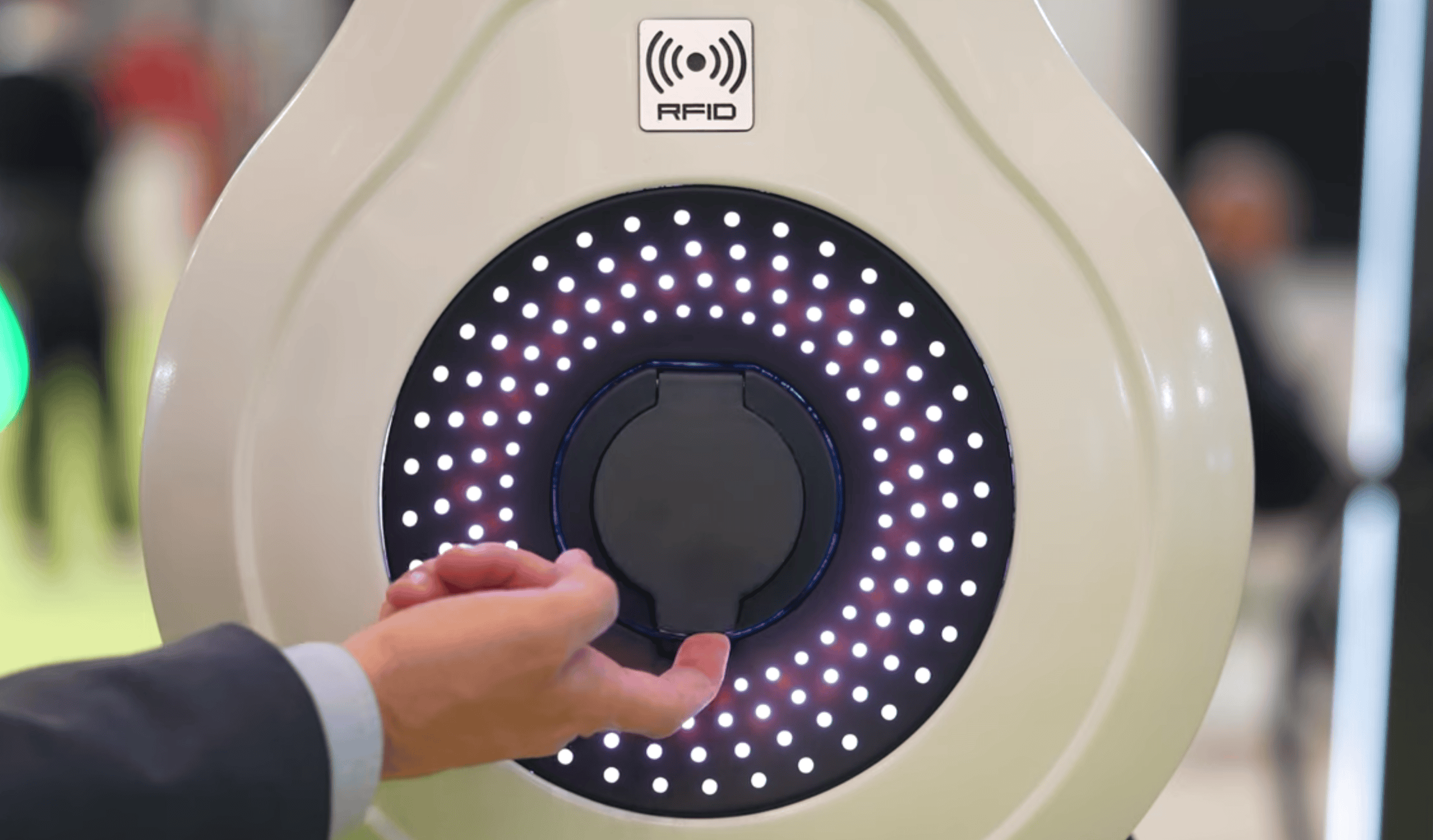

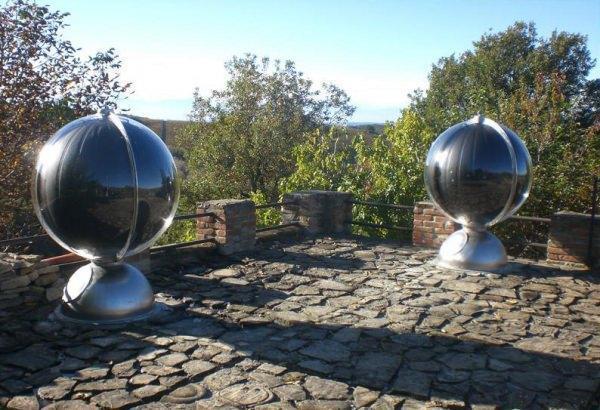

When aesthetics meets functionality, the product becomes instantly iconic. This is the story of Sferasol, which has developed and patented the first spherical-shaped solar thermal collector, capable of harnessing a larger surface area compared to traditional flat modules and, at the same time, integrating into homes as a true design object.

A Family Business Fueled With Innovation

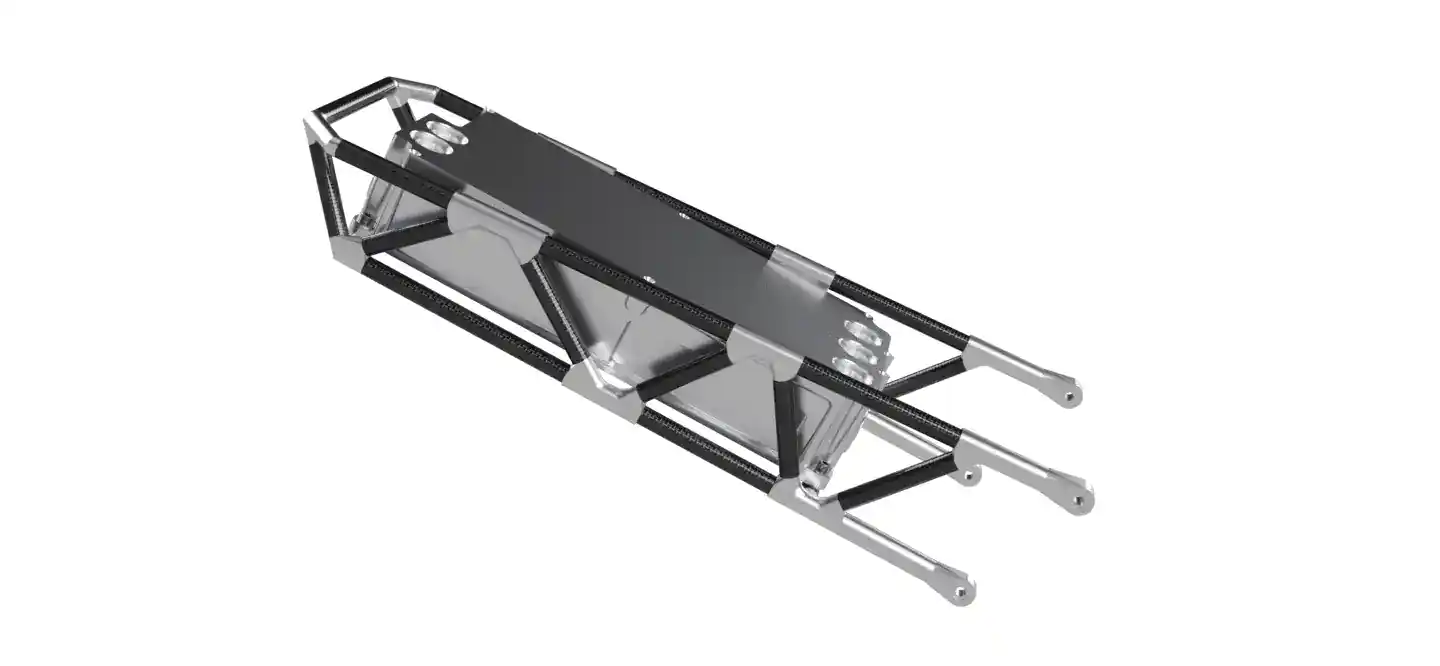

Today, Sferasol is a company that combines two brands, Sferasol Ecology and Sferasol Energy. Sferasol Ecology originates from a family business established in 1978, specializing in strip presses and sludge and water treatment. Sferasol Energy stems from the idea of a spherical-shaped solar thermal collector, dating back to the late ’80s.

In the early 2000s, the company participated in a StartCup with the Polytechnic University of Turin with this energy project, immediately generating a lot of interest because it was both innovative and design-oriented. The next step was to obtain the patent and the certifications required by market standards.

A Brand New Form of Thermal Solar Collector

We asked Sferasol CEO Mario Boaglio what makes his product unique: “First and foremost, the aesthetics. As a small business, we couldn’t compete with giants in the photovoltaic and ‘traditional’ solar thermal (the classic flat panel) sectors. We had to find a new, specific market segment with a different, innovative product. Sferasol has an aesthetic – and emotional, I would say – impact different from the solutions we are accustomed to. Moreover, it is a product suitable for a family of 5-6 people, easy to install in the garden or on the balcony; I could say it’s almost like an appliance because it doesn’t require a connection system”.

Working With Xometry to Produce High-quality Steel Parts

It can be said that it was the change of material that led Sferasol to collaborate with Xometry. The company started using galvanized iron but in the last years, they decided to abandon this material for stainless steel, used for standardizing the production for both collectors and strip presses.

The material change led to a change in processing and the need to find new suppliers. This happened at a time when steel, in 2022, reached very high values. Sferasol’s priority was immediately to find a quality partner with competitive prices, so they were fortunate to find Xometry.

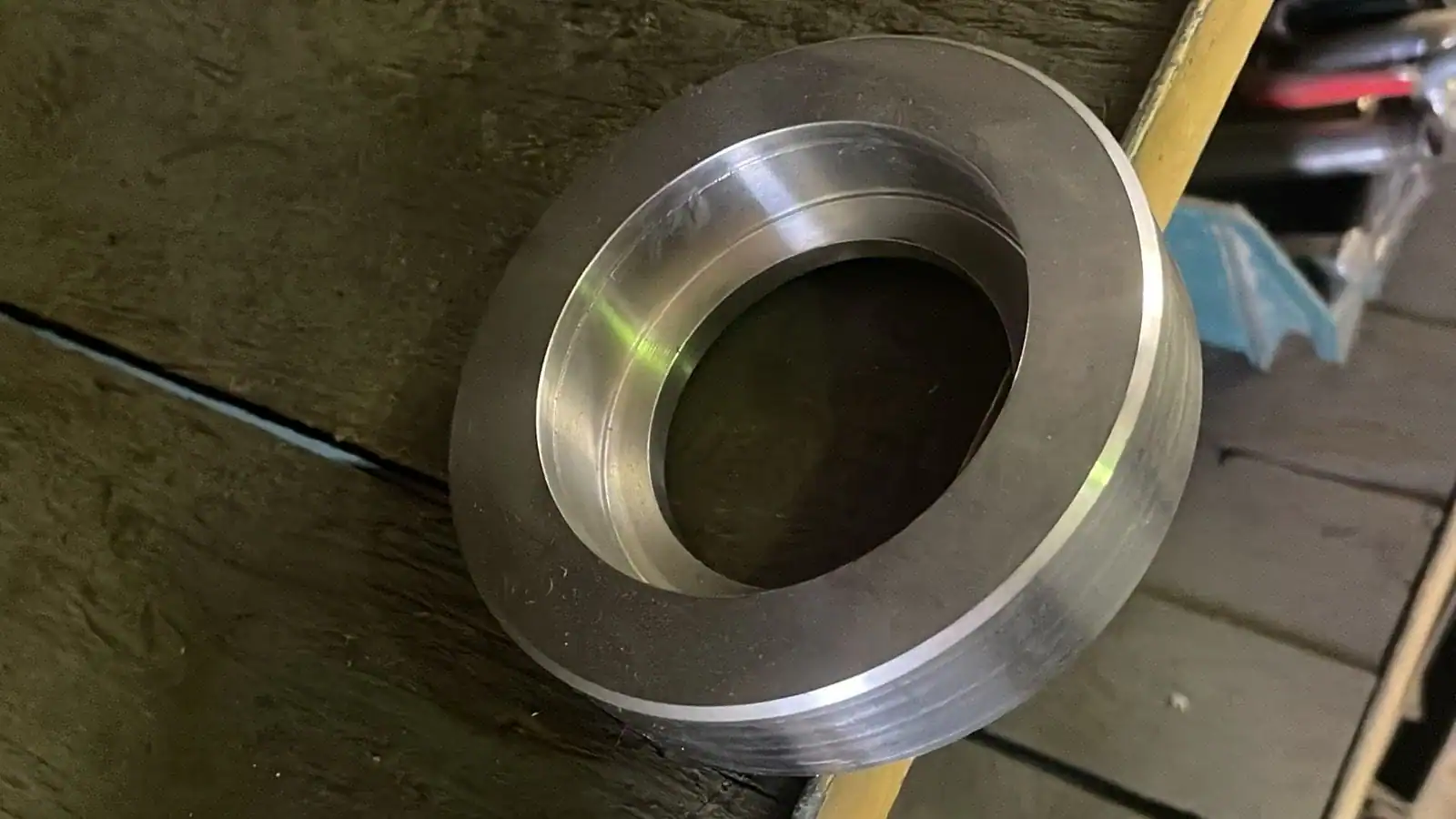

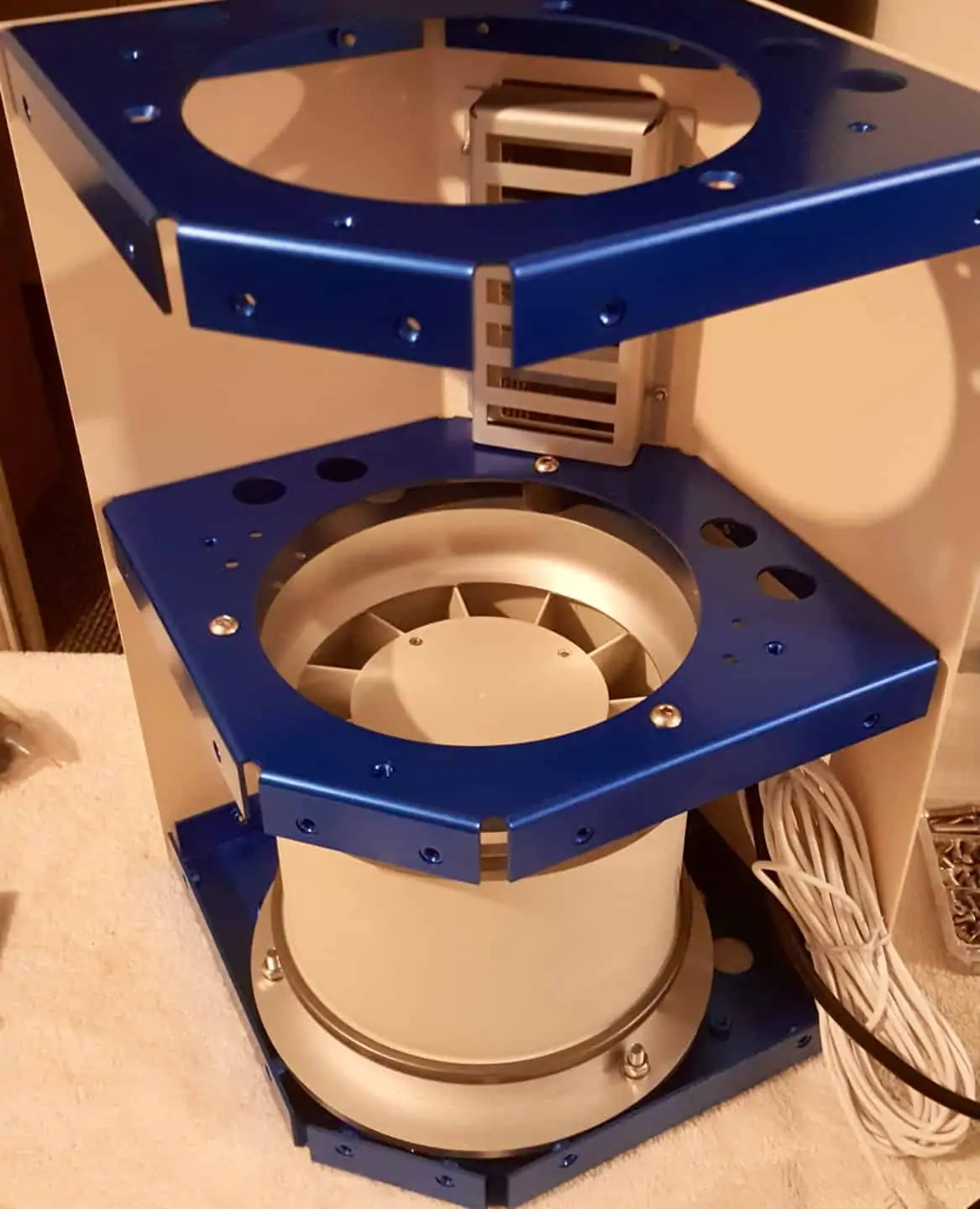

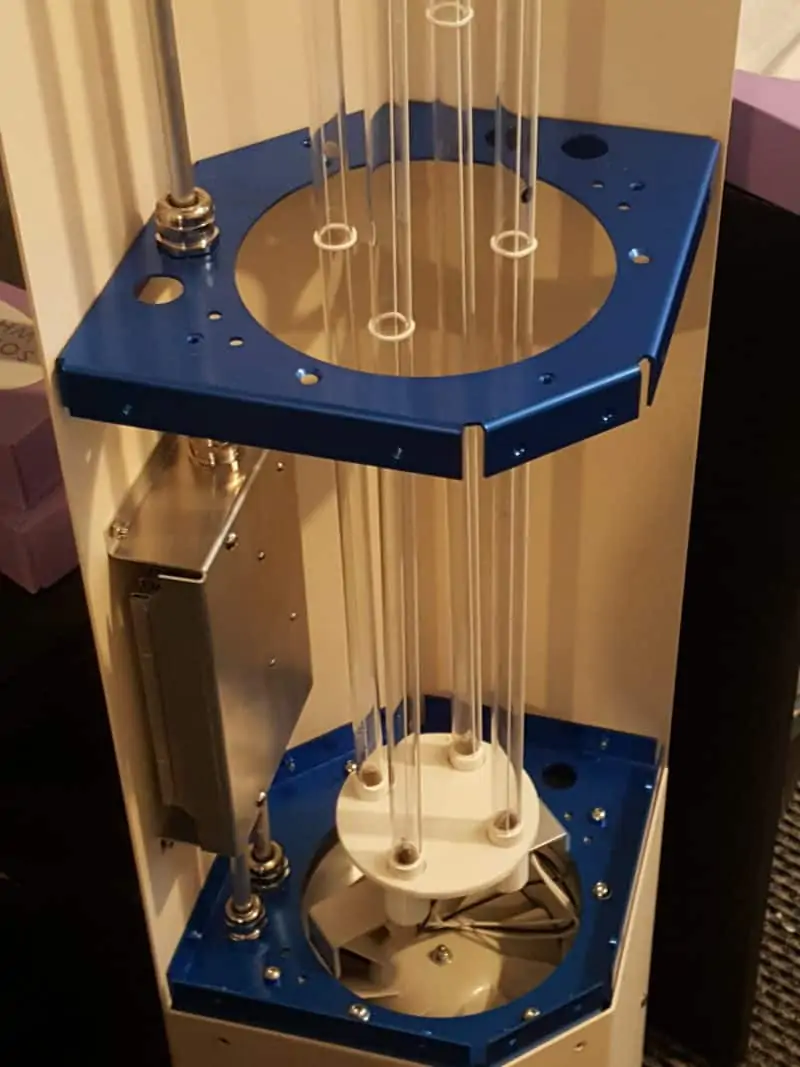

The company started with a test of small batches of steel pivots (around 50 per piece), and then went on to produce batches of hundreds of pistons and bottoms as well, always with CNC turning and milling. Now, they are making early steps to utilising injection moulding as a prospective technology for their parts.

How Xometry Accelerated Supply Chain

Here’s what Mario Boaglio said about his cooperation with Xometry: “What amazed me about Xometry is a very empathetic approach, almost ‘micro-business style’, despite being a multinational: the ability to adapt to customer needs, with great responsiveness, and to immediately create a relationship of mutual trust. I must be honest: I don’t feel treated only as a customer. Technically speaking, Xometry helped us in speeding up our supply chain: we found certified suppliers for steel parts at a very competitive price, in a very short time”.

For product development, he confirmed that it will depend a lot on the evolution of technologies in the market, because Sferasol is still working on optimizing the production cycle. His goal is to increase the presence of their products in the market more and more, focusing on the mix that makes Sferasol unique in the Green Economy landscape: aesthetics and functionality.

For further information: https://www.sferasolenergy.com/

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط