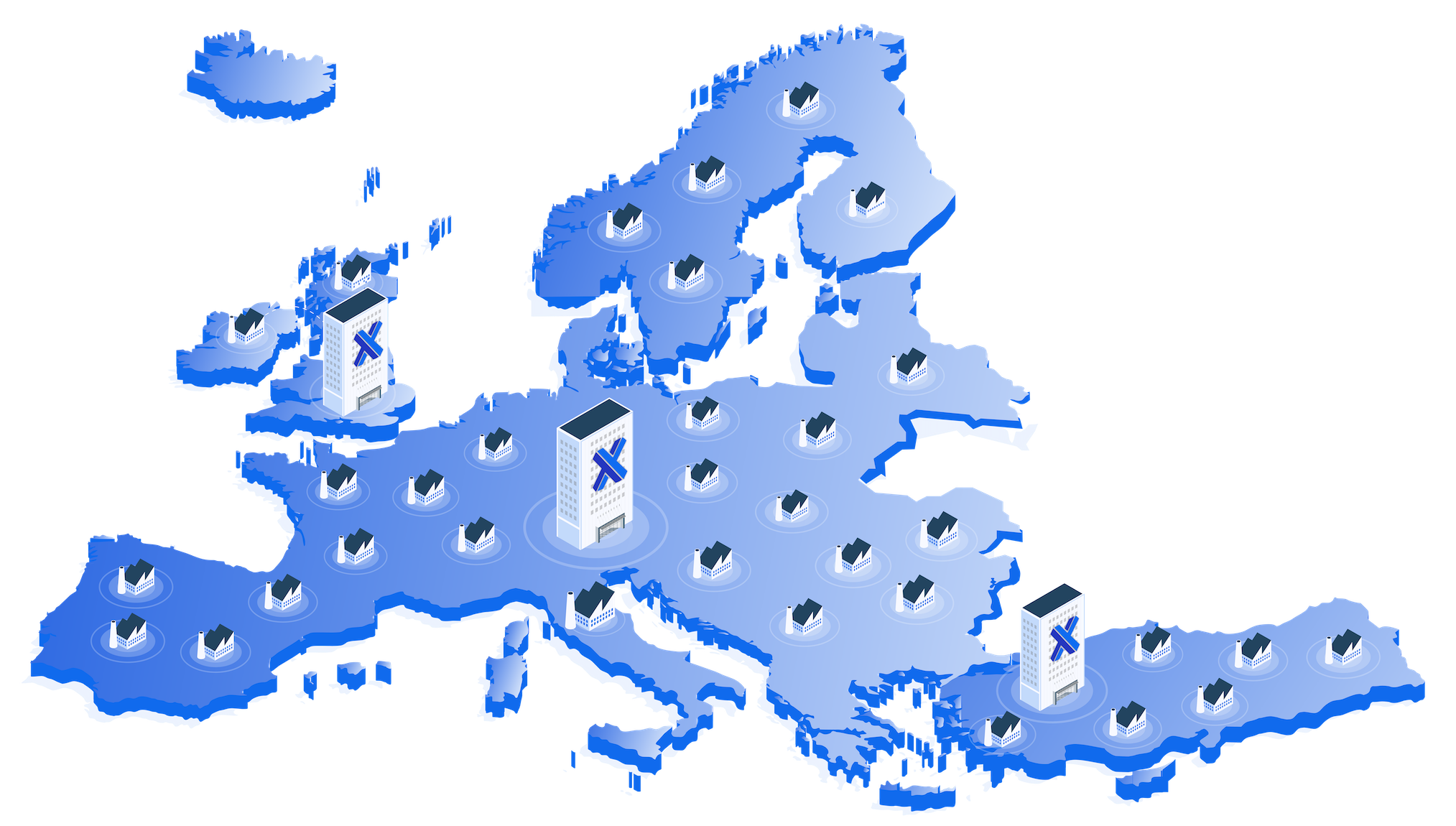

Massive Capabilities Of World’s Largest Manufacturing Platform

Working with Xometry Europe gives you access to the production capacity of over 10,000 manufacturing workshops from more than 25 European countries. In this pool of workshops and professionals, there is always available capacity for a quick production start.

25+

EU Countries With Partners

2000+

Top-Notch Manufacturers

5000+

CNC Machines & 3D Printers

All manufacturing processes and materials on a single platform

More than 100 metal and plastic materials

Aluminium

- Aluminium 2007 / 3.1645 / Al-CuMgPb

- Aluminium 2017A / 3.1325 / Al-Cu4Mg

- Aluminium 46100 / ADC12 / A383 / Al-Si11Cu3

- Aluminium 46500 / A380 / Al-Si8Cu3

- Aluminium 5052 / 3.3523 / Al-Mg2,5

- Aluminium 5083 / 3.3547 / Al-Mg4.5Mn

- Aluminium 5754 / 3.3535 / Al-Mg3

- Aluminium 6060 / 3.3206 / Al-MgSi

- Aluminium 6061 / 3.3211 / Al-Mg1SiCu

- Aluminium 6082 / 3.2315 / Al-Si1Mg

- Aluminium 7075 / 3.4365 / Al-Zn6MgCu

- Aluminium Al-Si10Mg

Steel

- Steel 1.0038 / S235JR

- Steel 1.0044 / S275JR

- Steel 1.0117 / S235J2 / S235J2G4

- Steel 1.0117 / S235J2 / S235J2G4, pickled and oiled

- Steel 1.0330 / DC01

- Steel 1.0503 / C45

- Steel 1.0511 / C40

- Steel 1.0570 / S355J2G3

- Steel 1.1191 / XC48H1 / C45E

- Steel 1.2379 / X153CrMo12 / SKD11, annealed

- Steel 1.2510 / 100MnCrW4 / SKS3, annealed

- Steel 1.2842 / 90MnCrV8

- Steel 1.7131 / 16MnCr5

- Steel 1.7218 / 25CrMo4

- Steel 1.7225 / 42CrMo4

- Tool steel 1.2709 / MS1

Stainless Steel

- Stainless Steel 17-4PH / 1.4542 / X5CrNiCuNb16-4

- Stainless Steel 303 / 1.4305 / X10CrNiS18-9

- Stainless Steel 304 / 1.4301 / X5CrNi18.10

- Stainless Steel 304L / 1.4307 / X2CrNi18-9

- Stainless Steel 316L / 1.4404 / X2CrNiMo17-12-2

- Stainless Steel 316Ti / 1.4571 / X6CrNiMoTi17-12-2

Copper, Brass & Cobalt

- Brass Ms58 / 2.0401 / CuZn39Pb3

- Cobalt chrome / CoCr

- Copper E-Cu57 / 2.0060 / E-Cu58 / 2.0065

Titanium

- Titan Grade 2 / 3.7035

- Titan Grade 5 / 3.7164 / 3.7165 / Ti-6Al-4V

Zinc

- Zamak 2

- Zamak 3

- Zamak 4

- Zamak 5

- Zamak 7

Plastics

- ABS

- ABS (PU8150)

- ABS (PU8260)

- ABS (PU8263)

- ABS (PX100)

- ABS (PX1180)

- ABS (PX215)

- ABS (UP4280)

- ABS-ESD7

- Acrylic

- Acrylic (PMMA)

- Alumide® / Nylon 12 (PA 12) filled with aluminium

- ASA

- CE 221 (Cyanatester)

- DPR 10

- EPU 40

- EPX 82

- Flex TPU

- FPU 50

- HDPE

- Inconel 718

- Industrial Black, ABS-Like

- Industrial Grey, ABS-like

- Industrial Heat resistant, PC-like

- Industrial Transparent, ABS-like

- Industrial White, ABS-like

- LDPE

- Nylon 11 / PA 11

- Nylon 12 (PA 12) glass-filled

- Nylon 12 / PA 12

- Nylon 12 flame retardant / PA 2241 FR

- Nylon 12 full-colour / CB PA 12

- Nylon 12CF / PA 12 carbon-filled

- Nylon 6 / PA 6

- Nylon 66 / Nylon 6/6

- PA 11 food grade

- PA 12 food grade

- PBT

- PC (Polycarbonate)

- PC (PU8098)

- PC (PX510)

- PC (UP6160)

- PC ISO (Polycarbonate ISO 10993 USP Class VI)

- PC-ABS (PX223HT)

- PC-ABS Polycarbonate

- PC-PBT

- PEEK

- PEEK glass-filled

- PEI (Ultem)

- PET

- PETG

- Photopolymer, rigid

- PLA

- PMMA / Acrylic (PX5210HT)

- PMMA / Acrylic (UPX5210)

- PMMA / Acrylic (X522HT)

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- POM / Delrin acetal

- PP (8550)

- PP (PU8570)

- PP (UP5690)

- PPE-PS

- PPS

- PSU

- PTFE / Teflon

- PVC

- PVDF / Polyvinylidene fluoride

- RPU 70

- Rubber (PU8400)

- Rubber (T0387)

- SIL 30

- Silica Glass

- Silicone

- Standard Black, ABS-like

- Standard Durable, PP-like / Pliable

- Standard ESD, ABS-like

- Standard Flexible 80A, Silicone-like

- Standard Head resistant, PC-like

- Standard Transparent, ABS-like

- Standard White, AB-like

- TPE (Elastomer)

- TPU (Polyurethane)

- TPV (rubber)

- True Silicone

- UHMW PE / Ultra-high-molecular-weight polyethylene

- ULTEM 1010

- ULTEM 9085

- UMA 90

Various post-processing options

Coating services

Galvanic Zinc

- Purpose: Zinc coating (galvanisation) protects parts from rusting.

- Materials: This method is suitable for steel and iron.

Nickel & Chrome

- Purpose: Nickel and chrome coatings (plating) are often used for decoration, anti-corrosion purposes or to increase surface hardness.

- Materials: these methods are suitable for parts out of all metals.

Anodising: Hard & Colour

- Purpose: Anodising protects parts from corrosion, provides durability, and makes parts non-conductive. Parts can be dyed upon anodising.

- Materials: anodising is suitable only for aluminium and titanium.

- Available colours: black hard coat, black, blue, gold, grey hard coat, green, natural hard coat, Natural, Orange, Red).

Surface finishes

Polishing

- Purpose: polishing is used to remove marks left from CNC-machining, contamination and oxidation and improve the appearance of the parts.

- Materials: applicable for all materials.

Blasting

- Purpose: bead blasting is used mainly for improving the appearance characteristics of ready parts.

- Materials: applicable for all materials.

Painting & Powder coating

- Purpose: powder coating is used to increase the smoothness of surfaces and make parts resistant to corrosion. Powder coating can be also used for colouring purposes.

- Materials: applicable for all materials.

Heat treatment

Quenching and tempering

- Purpose: quenching is used to increase the surface hardness of parts. Tempering reduces the brittleness of the parts.

- Materials: this method is suitable mainly for steel alloys.

Normalizing and tempering

- Purpose: normalization or annealing process eliminates stresses from CNC machined parts, which stabilises the mechanical properties of the parts, while tempering reduces the brittleness of the parts.

- Materials: stress-relieving is suitable for all alloys. Tempering is suitable for only steel alloys.

Ready to Use the Capacity of the Largest Manufacturing Network?

Customers

70,000+

Parts Quoted

1 Million+

Get an Instant Quote

All uploads are secure and confidential.

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط