Industrial 3D Printing Service Online

Source all your 3D printing jobs, from prototyping to high-volume production projects, reliably in one place. Advanced AI technology, combined with attentive customer care, ensures a seamless experience from instant quotes to order tracking.

Express Manufacturing Within 3 Days

Seven 3D Printing Technologies

Free Delivery

AI-Powered Instant Quoting

Upload your design – Get an online quote – Place your order and get parts.

Quoting For Mid- & High-Volume Production

Quote & source your large & complex projects.

Our 3D Printing Capabilities

Xometry offers massive capabilities with 10,000 manufacturers across Europe and worldwide. With the

flexibility of 3D printing and the ability to support complex, intricate designs, we provide everything from

functional and visual prototypes in plastic and metal to high-quality end-use parts.

Not sure what process or material to choose for your 3D printing project?

Use our interactive 3D Printing Decision Guide

How it works

Intuitive Platform, Expert-Backed Projects

Prototypes & small-to-mid sized batches

Get Instant Quotes with the AI-Powered Quoting Engine

Quoting

Instant online quotes

Additional Capabilities

- Lead times starting from 3 days

- Over 60 materials and 10+ finishes quoted instantly

- Dedicated account manager and engineering support for corporate customers

- Certifications & inspection reports available

- Highest standards of data protection

Design Feedback & Audit

Automated DFM Feedback and audit after order placement to ensure manufacturability

Technical Support

Live chat support for quick assistance, similar to online stores

More complex projects

Seamlessly Manage Mid-to-High Volume Projects

Quoting

Manual quotes within 24-48 hours

Additional Services Possibilities

- Lead times according to high-volume projects schedule

- Any custom materials and finishes

- Dedicated account manager and engineering support for corporate customers

- Certifications & inspection reports available

- Highest standards of data protection

- Framework agreements with scheduled batch shipments

- Possibility of sourcing parts at your target prices

- Post-payment possibilities for reliable corporate customers

Design Feedback & Audit

Manual design review and audit after order placement to ensure manufacturability

Technical Support

Dedicated account manager and engineering support at every stage. Direct contact for questions, problem-solving, design improvements, and feedback

Tooling Design Engineer, BMW

“Xometry delivers professionalism and ease. They take care of fulfillment so I don’t need to juggle or manage suppliers. We buy the quote and Xometry takes care of the rest.”

The Advantages of Our Digital Manufacturing Platform

Massive Network Capacity

Access the production capacity of over 2,000 qualified manufacturers in Europe and 10,000 worldwide, offering a wide range of production capabilities and certifications. Our extensive network enables the production of parts with any level of complexity, in almost any material, with precise tolerances and the required post-processing.

Human Expertise Behind Every Order

Our experienced team ensures smooth order management at every step. From initial design checks to seamless communication with manufacturing partners, we provide personalised feedback and suggest design improvements to optimise your parts and production processes.

Flexible Purchasing Solutions

Xometry offers flexible post-payment options for reliable corporate customers, a variety of payment methods to suit your needs, and the ability to establish framework agreements for specific prices and quantities, ensuring cost predictability and streamlined procurement processes.

Quality Assurance

Xometry is ISO 9001:2015 certified. Our seamless Manufacturing Supplier Network integration, in-house applications engineering team, and Xometry Quality Assurance Lab ensure we back every part we ship with top-notch quality.

Fast Delivery across Europe

Xometry delivers parts to all European countries, including the UK, Norway and Switzerland. See your delivery options for instant quotes right away or plan your custom shipments for complex projects.

Certifications & Inspection Reports

Xometry can provide various certificates (compliance with order types 2.1 and 2.2, raw material certificates for metals and plastics, heat treatment protocols, RoHS certificates, etc.) and inspection reports (CMM, First Article Inspection Report – FAIR, measurement reports, etc.).

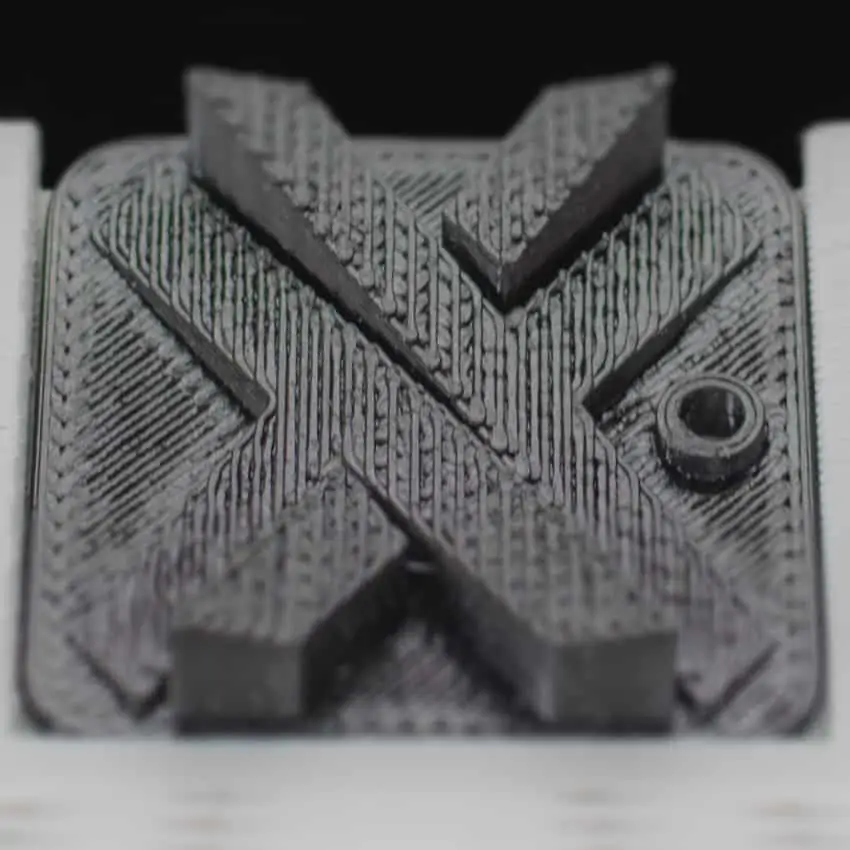

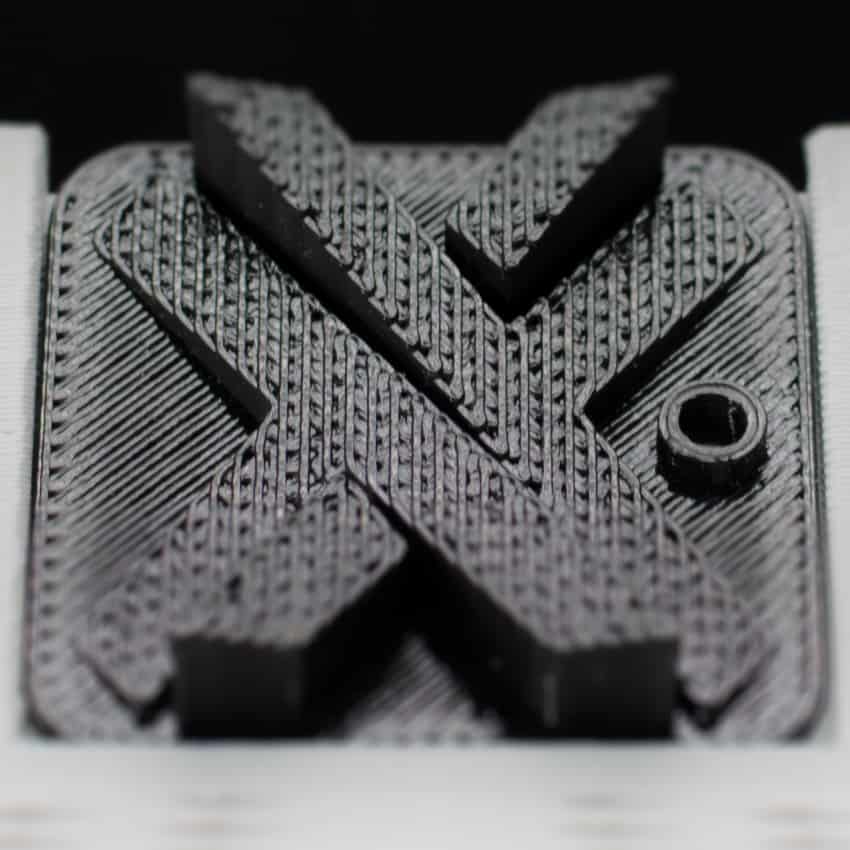

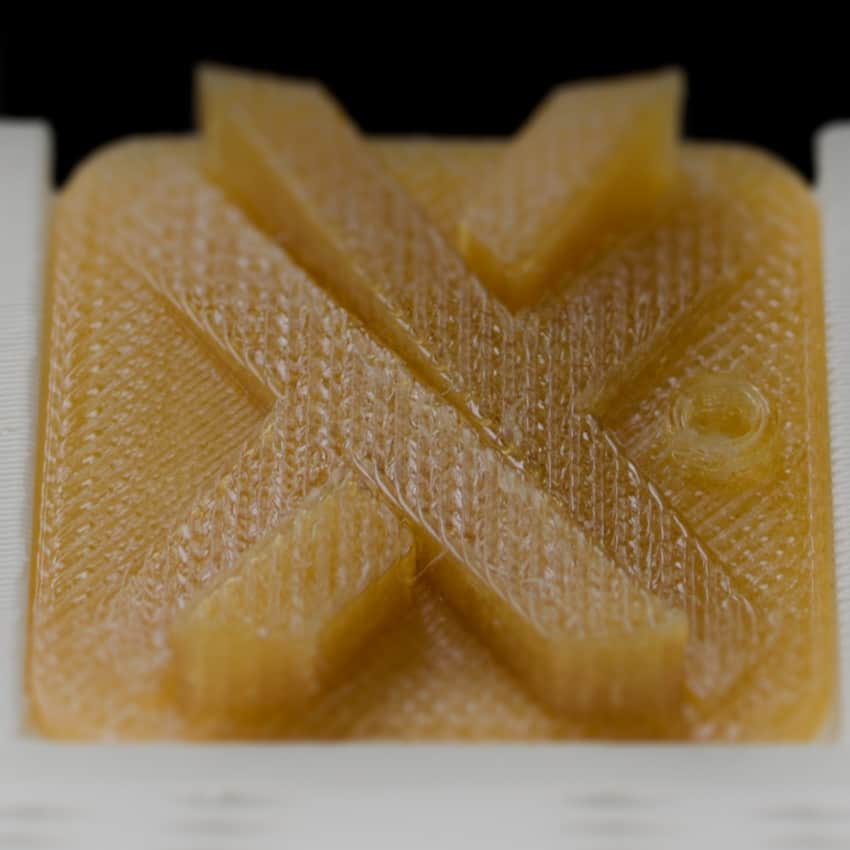

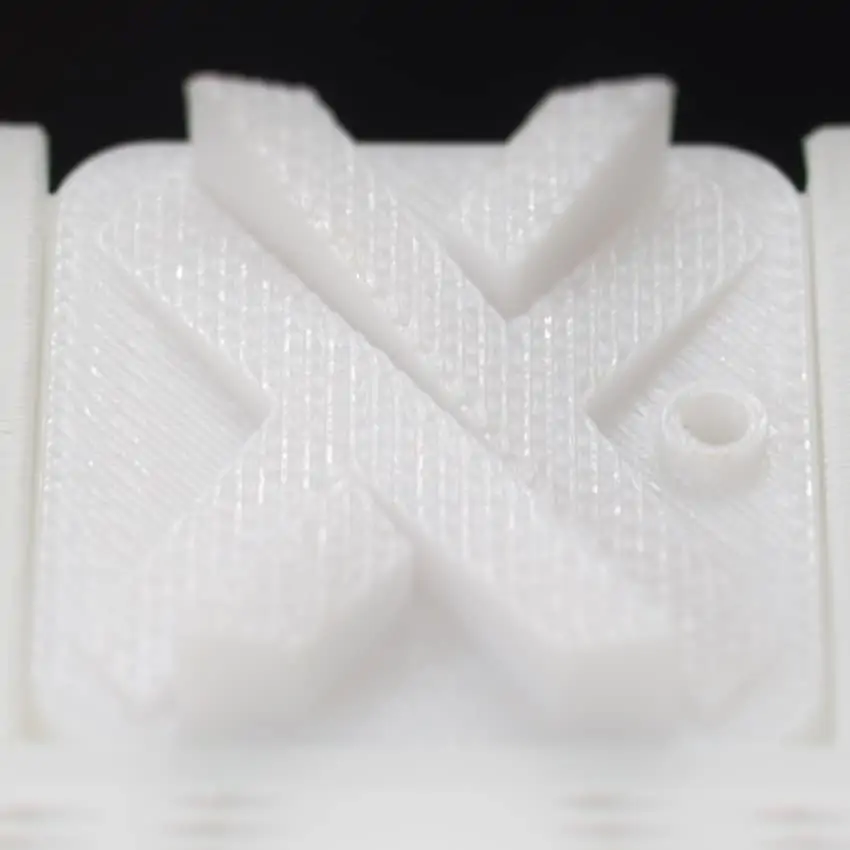

3D Printing Materials Quoted Instantly

Plastics

50 materialsOur range of 3D printing plastics offers lightweight, durable options perfect for prototyping and production. Choose from versatile materials like ABS, nylon, and more to meet your project needs.

Elastomers

8 materialsElastomers bring flexibility and resilience to your 3D printed parts, ideal for creating rubber-like components that need to withstand repeated bending and compression. Common elastomers include TPU (Thermoplastic Polyurethane) and TPE (Thermoplastic Elastomer).

Metals

7 materialsAchieve exceptional strength and precision with our selection of 3D printable metals. From stainless steel to aluminium, our materials are well-suited for both functional prototypes and end-use parts.

Plastics: SLS

Get a Quote9 materials quoted instantly*

- Rubber-like TPU (Industrial grade)

- Flex TPU

- Nylon (7 types)

Lead time

5 days

Build volume

340 x 605 x 340 mm

Technology description

Plastics: MJF

Get a Quote5 materials quoted instantly*

- Nylon (4 types)

- Polypropylene (PP)

Lead time

5 days

Build volume

380 x 380 x 284 mm

Technology description

Plastics: FDM

Get a Quote16 materials quoted instantly*

- TPU 85

- Nylon 12 / PA 12 (FDM)

- PEEK (2 types)

- ABS and ABS-like (3 types)

- ULTEM (2 types)

- PETG

- PLA

- PC and PC-Like (2 types)

- PC-ABS Polycarbonate

- Nylon 12CF / PA 12 carbon-filled

- ASA

Lead time

6 days

Build volume

900 x 900 x 600 mm

Technology description

Plastics: SLA

Get a Quote14 materials quoted instantly*

- ABS and ABS-like (9 types)

- PC and PC-Like (2 types)

- Standard Durable, PP-like / Pliable

- Silica Glass

- True Silicone

Lead time

6 days

Build volume

736 x 533 x 635 mm

Technology description

Plastics: Carbon DLS™

Get a Quote8 materials

- EPU 40

- SIL 30

- UMA 90

- CE 221 (Cyanatester)

- DPR 10

- EPX 82

- FPU 50

- RPU 70

Lead time

8 days

Build volume

119 x 300 x 189 mm

Technology description

Plastics: PolyJet

Get a Quote0 materials quoted instantly*

Lead time

7 days

Build volume

490 x 200 x 391 mm

Technology description

Plastics: DMLS

Get a Quote0 materials quoted instantly*

Lead time

8 days

Build volume

400 x 400 x 400 mm

Technology description

Elastomers: SLS

Get a Quote2 materials quoted instantly*

- TPU (2 types)

Lead time

5 days

Build volume

340 x 605 x 340 mm

Technology description

Elastomers: MJF

Get a Quote1 materials quoted instantly*

- TPU (Thermoplastic Polyurethane)

Lead time

5 days

Build volume

380 x 380 x 284 mm

Technology description

Elastomers: FDM

Get a Quote1 materials quoted instantly*

- TPU 85

Lead time

6 days

Build volume

900 x 900 x 600 mm

Technology description

Elastomers: SLA

Get a Quote2 materials quoted instantly*

- Silicone and silicone-like (2 types)

Lead time

6 days

Build volume

736 x 533 x 635 mm

Technology description

Elastomers: Carbon DLS™

Get a Quote1 materials

- SIL 30

Lead time

8 days

Build volume

119 x 300 x 189 mm

Technology description

Elastomers: PolyJet

Get a Quote1 materials quoted instantly*

- Photopolymer, rigid

Lead time

7 days

Build volume

490 x 200 x 391 mm

Technology description

Elastomers: DMLS

Get a Quote0 materials quoted instantly*

Lead time

8 days

Build volume

400 x 400 x 400 mm

Technology description

Metals: SLS

Get a Quote0 materials quoted instantly*

Lead time

5 days

Build volume

340 x 605 x 340 mm

Technology description

Metals: MJF

Get a Quote0 materials quoted instantly*

Lead time

5 days

Build volume

380 x 380 x 284 mm

Technology description

Metals: FDM

Get a Quote0 materials quoted instantly*

Lead time

6 days

Build volume

900 x 900 x 600 mm

Technology description

Metals: SLA

Get a Quote0 materials quoted instantly*

Lead time

6 days

Build volume

736 x 533 x 635 mm

Technology description

Metals: Carbon DLS™

Get a Quote0 materials

Lead time

8 days

Build volume

119 x 300 x 189 mm

Technology description

Metals: PolyJet

Get a Quote0 materials quoted instantly*

Lead time

7 days

Build volume

490 x 200 x 391 mm

Technology description

Metals: DMLS

Get a Quote7 materials quoted instantly*

- Cobalt chrome / CoCr

- Tool steel 1.2709 / MS1

- Stainless steel (2 types)

- Inconel 718

- Aluminium Al-Si10Mg

- Titan Grade 5 / 3.7164 / 3.7165 / Ti-6Al-4V

Lead time

8 days

Build volume

400 x 400 x 400 mm

Technology description

David Marshall, DocCheck

“Despite our extremely demanding design requirements, we have successfully implemented several projects in close collaboration with Xometry. Working with Xometry has enabled us to overcome the challenges of our complex design requirements while maintaining our quality standards.”

Comparison of our 3D printing capabilities

Use the dropdowns in each column to select and compare services side by side.

Use the dropdowns in each column to select and compare services side by side.

|

Strong and functional prototypes & low-volume production Get a Quote

|

Affordable & large format prototypes and end-use parts Get a Quote

|

Visual prototypes with high resolution Get a Quote

|

|---|---|---|

Technology DescriptionMulti Jet Fusion (MJF) 3D printing is one of the most widely used industrial additive manufacturing processes. Like SLS, MJF is used to produce strong, functional plastic parts. | Technology DescriptionFused Deposition Modeling (FDM) 3D printing is cost-effective and widely known for its great material selection, accuracy, and the possibility to print large, functional plastic parts. | Technology DescriptionStereolithography (SLA) 3D printing utilizes light-curable thermoset resins to build highly accurate, high-resolution parts. Its surface finish is one of the highest standards in the industry and recommended for aesthetic prototypes. |

Lead Time3 days | Lead Time4 days | Lead Time6 days |

Instant quote availabilityYes | Instant quote availabilityYes | Instant quote availabilityYes |

Maximum Part Size380x380x284 mm | Maximum Part Size900x900x600 mm | Maximum Part Size736x533x635 mm |

General Tolerance0.3% | General Tolerance0.5% | General Tolerance0.2% |

Standard Layer Thickness0.08 mm | Standard Layer Thickness0.05 – 0.3 mm | Standard Layer Thickness0.02 mm |

Minimum Feature Thickness0.50 mm | Minimum Feature Thickness0.20 mm | Minimum Feature Thickness0.20 mm |

Minimum Wall Thickness

| Minimum Wall Thickness

| Minimum Wall Thickness

|

Requires Support StructuresNo | Requires Support StructuresYes | Requires Support StructuresYes |

Advantages

| Advantages

| Advantages

|

Disadvantages

| Disadvantages

| Disadvantages

|

| Explore MJF Further | Explore FDM Further | Explore SLA Further |

Not sure what process or material to choose for your 3D printing project?

Use our interactive 3D Printing Decision Guide with advanced filtering options like functional or visual material properties, colors and certifications.

Frequently Asked Questions

Selecting the right 3D printing process depends on your project’s requirements, such as material, part complexity, mechanical properties, and desired surface finish. Explore our 3D Printing Decision Guide to help you compare technologies to ensure the ideal match for your application.

Yes, Xometry specializes in both rapid prototyping and scalable mass production. For mass production, 3D printing is used to create complex geometries, reduce tooling costs, and enable efficient on-demand manufacturing. Suitable technologies include Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) for high-volume plastic parts.

We offer flexible quoting options for different project volumes. Use our AI-Powered Instant Quoting Engine for immediate estimates on prototypes and small-to-mid-sized batches (up to 1,000 pieces or €10,000). For larger volumes, including over 1,000 pieces or €10,000, we provide manual quotes within 24–48 hours.

Yes, we offer support at multiple stages to ensure the best outcome for your project:

- Automated DFM feedback: Our instant quoting engine provides automated Design for Manufacturability (DFM) feedback, highlighting potential issues with your design and selected 3D printing process.

- Preliminary Manufacturability Check: Before production begins, we conduct a detailed review of your design. If any changes are necessary, we’ll reach out to collaborate on adjustments.

- Expert Guidance for corporate customers: Our 3D printing experts are available to help optimise your design and guide material selection based on your project’s specific needs.

Yes, Xometry can produce multi-color objects using technologies like PolyJet and Multi Jet Fusion (MJF). Additionally, we offer post-processing options (painting and dyeing) to achieve custom colors and refine the finish of your 3D printed parts. Upload color-supported file formats like OBJ or 3MF to get started.

We offer 35 plastics, elastomers, and metals for instant quoting, each with unique properties such as strength, heat resistance, flame retardancy, flexibility, and more.

If you need a custom material, we can provide a quote within 24–48 hours. In most cases, if the material is supported by one of the 3D printing technologies we offer, we can produce it through our manufacturing network.

Xometry offers instant quotes for post-processing options such as bead blasting, media tumbling, vapor smoothing, dyeing in various colours, and spray painting with custom RAL colour options. These enhancements improve the appearance and functionality of your 3D-printed parts.

For any custom post-processing needs, we can provide a quote within 24–48 hours upon request.

The maximum size of a 3D-printed object depends on the technology used. For example, with Fused Deposition Modeling (FDM), we can print parts up to 900x900x600 mm, while Stereolithography (SLA) supports maximum dimensions of 736x533x635 mm.

We maintain the standards of quality through ISO 9001:2015 certified processes, a network of vetted manufacturing partners, and rigorous inspections. Upon request, we can provide detailed inspection reports, including analyses from in-house and external labs.

For more information about our quality assurance processes, visit our Quality Assurance page.

Yes, Xometry offers metal 3D printing using Direct Metal Laser Sintering (DMLS) technology. We provide a variety of metals, including aluminium, stainless steel, tool steel, titanium, and inconel, suitable for creating prototypes and end-use parts.

Yes, transparent and translucent parts can be printed using SLA (Stereolithography) technology with desktop and industrial transparent ABS-like materials, Flexible 80A Resin, and Silica Glass. These materials provide options for high resolution, smooth surfaces, stiffness, flexibility, and chemical resistance, catering to diverse applications.

Start Your 3D Printing Project With Xometry Now

Need prototypes or a small production batch?

Try our AI-powered Instant Quoting! Upload your design to get an online quote for your project.

Need mid- or high-volume production batches or a complex production project?

Proceed with describing your project requirements through our platform.

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط