Foam Moulding Services

Source your custom structural foam moulding projects with Xometry, from lightweight yet durable components to complex geometries. Our foam molding process produces lightweight parts with a rigid outer skin, combining strength, design flexibility, and suitability for large panels, enclosures, and ergonomic supports. Our expert support at every stage, combined with attentive customer care, guarantees a seamless experience from quoting to order tracking.

Cost-effective production with lower tooling and material costs

Ideal for large, lightweight parts with high strength-to-weight ratio

Enhanced design flexibility for intricate shapes and long flow lengths

Trusted by over 81,000+ engineers & purchasing leaders worldwide

Low tooling and material costs

What is Foam Moulding?

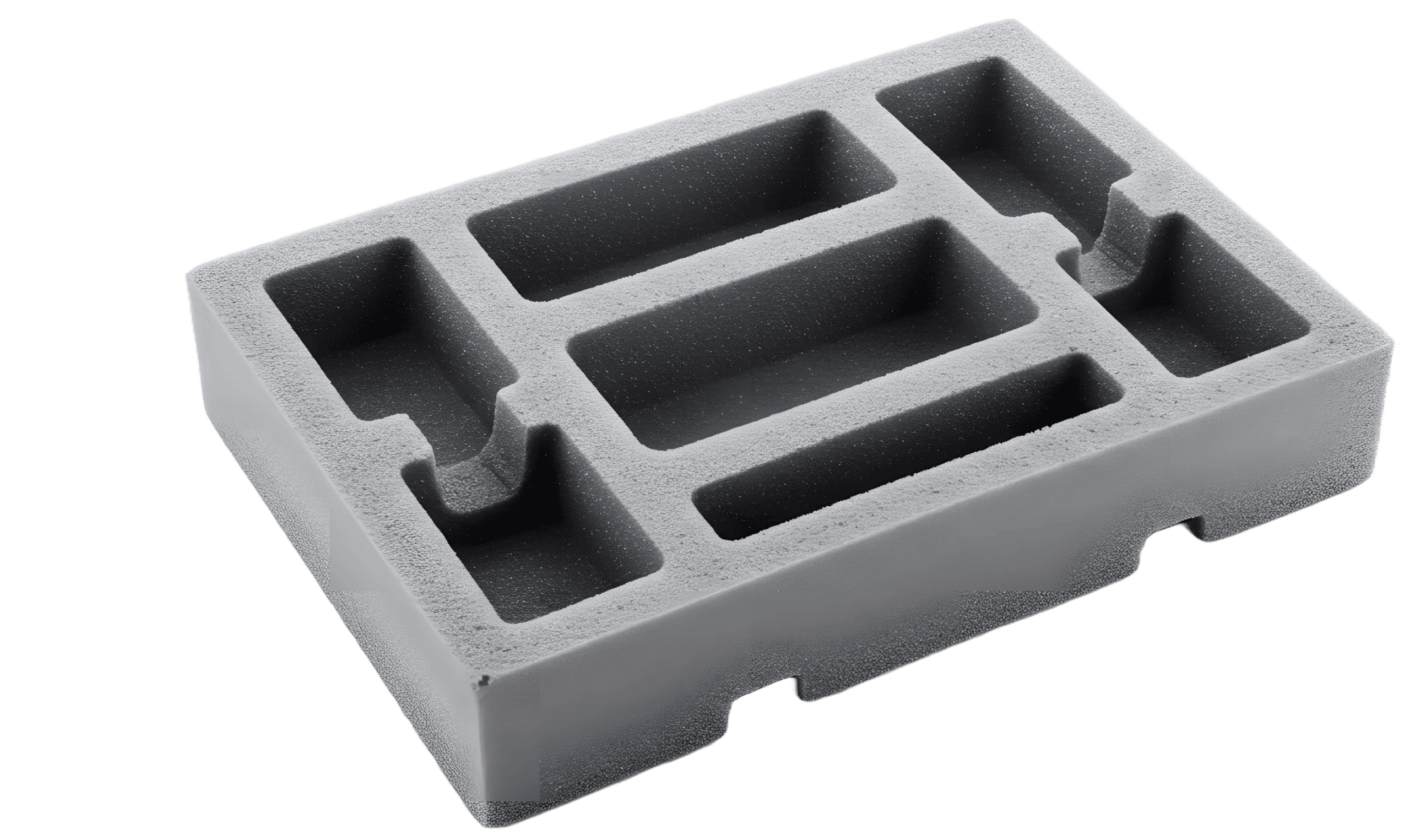

Foam moulding is a manufacturing process that injects gas-impregnated plastic into a mould, creating parts with a lightweight foam core and a dense, rigid outer skin. This process delivers high strength-to-weight ratios, excellent durability, and design flexibility, making it ideal for large, complex components that traditional injection moulding cannot achieve. Foam moulding is widely used in industries such as automotive (lightweight panels, enclosures), construction (insulated panels, durable housings), medical (equipment casings, ergonomic supports), and industrial applications (storage containers, machine housings).

Technology Specifications

Our Manufacturing Capabilities

- Quantity: From 200 parts (minimum total weight: 500 kg)

- Materials: EPP (Expanded Polypropylene), EPS (Expanded Polystyrene), EPO (Expanded Polyolefin)

- Finishes: As moulded

- Tolerance: Depend on a part density and part design. Should be discussed during the DFM stage of a project

Tooling Design Engineer, BMW

“Xometry delivers professionalism and ease. They take care of fulfillment so I don’t need to juggle or manage suppliers. We buy the quote and Xometry takes care of the rest.”

Tooling Design Engineer, BMW

The Easiest Way To Manage Your Projects

1. Submit Your Foam Moulding Enquiry

Upload your designs, select the quantity, materials, surface finish, and other parameters, then submit a quote request.

2. Review and Quoting

A Xometry engineer reviews your enquiry within 24-48 hours to ensure all requirements are met. You receive an initial quote. Upon your approval, our engineers match your project with the most suitable manufacturer based on skills, availability, and other criteria. We then send you a final quote.

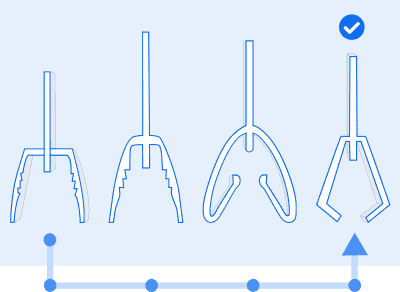

3. Project Kick-Off and DFM

Once you approve the final quote, you receive an order confirmation and an invoice for 50% of the mould costs. After that we start the Design for Manufacturability (DFM) process. Xometry works with you to clarify and finalise all technical details before proceeding.

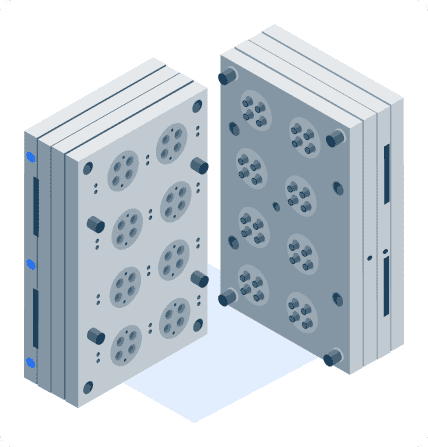

4. Mould Building and Sample Production

After finalising DFM, we set deadlines for mould building and first sample production (T1). Our project manager oversees logistics and communication. You receive the T1 samples with a measurement report for approval. Feedback on the T1 samples should be received within 10 days and if further improvements might be required, further iterations (T2, T3, etc.).

5. Full Production and Delivery

Once samples are approved, Xometry manages full-scale production, quality control, and part delivery. You pay the production costs upon receiving the parts.

6. Mould Ownership and Re-Orders

The mould lifespan is between 10,000 to 1,000,000 shots. The mould is owned by you and maintained by Xometry. The customer can easily re-order parts whenever required.

The Advantages of Our Digital Manufacturing Platform

Massive Network Capacity

Access the production capacity of over 2,000 qualified manufacturers in Europe and 10,000 worldwide, offering a wide range of production capabilities and certifications. Our extensive network enables the production of parts with any level of complexity, in almost any material, with precise tolerances and the required post-processing.

Human Expertise Behind Every Order

Our experienced team ensures smooth order management at every step. From initial design checks to seamless communication with manufacturing partners, we provide personalised feedback and suggest design improvements to optimise your parts and production processes.

Flexible Purchasing Solutions

Xometry offers flexible post-payment options for reliable corporate customers, a variety of payment methods to suit your needs, and the ability to establish framework agreements for specific prices and quantities, ensuring cost predictability and streamlined procurement processes.

Quality Assurance

Xometry is ISO 9001:2015 certified. Our seamless Manufacturing Supplier Network integration, in-house applications engineering team, and Xometry Quality Assurance Lab ensure we back every part we ship with top-notch quality.

Fast Delivery across Europe

Xometry delivers parts to all European countries, including the UK, Norway and Switzerland. See your delivery options for instant quotes right away or plan your custom shipments for complex projects.

Certifications & Inspection Reports

Xometry can provide various certificates (compliance with order types 2.1 and 2.2, raw material certificates for metals and plastics, heat treatment protocols, RoHS certificates, etc.) and inspection reports (CMM, First Article Inspection Report – FAIR, measurement reports, etc.).

Available Materials for Foam Moulding

Plastics

- EPP (Expanded Polypropylene)

- EPS (Expanded Polystyrene)

- EPO (Expanded Polyolefin)

Finishes Available for Foam Moulding

As-formed

As-formed parts retain the natural surface texture and appearance that results from the mould.

Final result:

- Uniform surface texture, depending on the mould

- Smooth and glossy surface finish

Sand blasting

Sand blasting is a surface preparation technique involving high-velocity abrasive particles to remove contaminants and roughen surfaces.

It’s commonly used for cleaning, texturing, or preparing plastics for processes like painting.

Final result:

- Matte surface

- Enhanced paint adhesion

Custom

If you select a custom finish in the Instant Quoting Engine it will require manual review. Manual quoting usually 1-2 business days.

Submitting for manual review with a custom request does not guarantee a quote.

Stefano Grigis, Asitech

Stefano Grigis, Asitech

“We very much appreciated the speed of the platform: in zero time, I can get a quote for 1, 10 or 100 pieces, and test how much it might cost to produce with one material over another, which is crucial in the design phase but also to make realistic proposals for our customers.”

Frequently Asked Questions

Foam moulding is a manufacturing process that uses gas or chemical blowing agents to create lightweight, durable, and impact-resistant foam parts. This method is commonly used for protective packaging, insulation, cushioning, and structural components. Foam moulding is widely applied in industries such as automotive, aerospace, construction, medical, and consumer goods.

Products made through foam moulding include packaging inserts, insulation panels, automotive seating, and custom-shaped cushions. This process is ideal for producing lightweight components with excellent shock absorption, thermal insulation, and sound-dampening properties.

Common materials used in foam moulding include polyurethane (PU), expanded polystyrene (EPS), expanded polypropylene (EPP), and polyethylene foams. Each material offers different benefits, such as flexibility, rigidity, or high impact resistance.

Yes, we specialize in custom foam moulding, allowing us to create parts with unique shapes, densities, and mechanical properties tailored to your specific application. We can also provide design assistance to optimize your parts for cost and performance.

The maximum part size depends on the material and moulding method. Large-format foam moulding is possible for applications such as protective packaging, insulation, and structural components. Contact our team to discuss your specific size requirements.

Other Clients Reviews

“What amazed me about Xometry is a very empathetic approach, almost ‘micro-business style’, despite being a multinational: the ability to adapt to customer needs, with great responsiveness, and to immediately create a relationship of mutual trust.”

Mario Boaglio, Sferasol

“Discussions with my Key Account Manager about the gear knob were crucial in finding the best manufacturing process and achieving a result that was as close as possible to a production part. Unlike other companies and suppliers, I actually got to deal with a human contact.”

Stephane Develter, Develter

“With Xometry, it helps that there is an algorithm to instantly provide a price and a binding quote when you upload your part design. I thought that was amazing. Then you just complete your order and get a delivery date, which was met in our case. Wow, what a great process to work with!”

Thomas Kern, Atmos

“Collaborating with Xometry has put us in a strong position to make progress, particularly with mass production. Being able to outsource has significantly reduced our workload and we can still easily maintain quality and meet deadlines.”

Vincent Dufour, Neocean

“Xometry has provided us with great support in the CNC manufacturing of our MCU prototype enclosures, for both very small and medium-sized batches. Xometry’s customer support also ensures the right high-quality parts are delivered to the right location in record times on a very direct and personal basis.”

Christian Hornschuch, Sono Motors

Start Your Foam Moulding Project with Xometry Now

Xometry Newsletter

Don’t Miss Out on Our Content & Discounts

Learn more about Xometry Newsletter.

By entering your contact information, you are agreeing to receive email communications about Xometry products and services. You may update your subscriptions or unsubscribe from these communications at any time using the link at the bottom of every marketing email or by contacting support. For more information, review our Data Protection Policy.

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  APAC

APAC  الشرق الأوسط

الشرق الأوسط