More than $10 billion in cryptocurrencies have been lost due to improperly secured seed phrases — and the number keeps growing. One simple mistake can mean losing everything. Yoseyomo set out to change that with a physical vault engineered to safeguard digital assets with the same strength and permanence as a traditional safe.

Spain

Titanium Grade 5, Stainless Steel 316L, Copper C1100

Stainless steel components with passivation and sanding finishes, titanium parts with fine surface prep for punch engraving

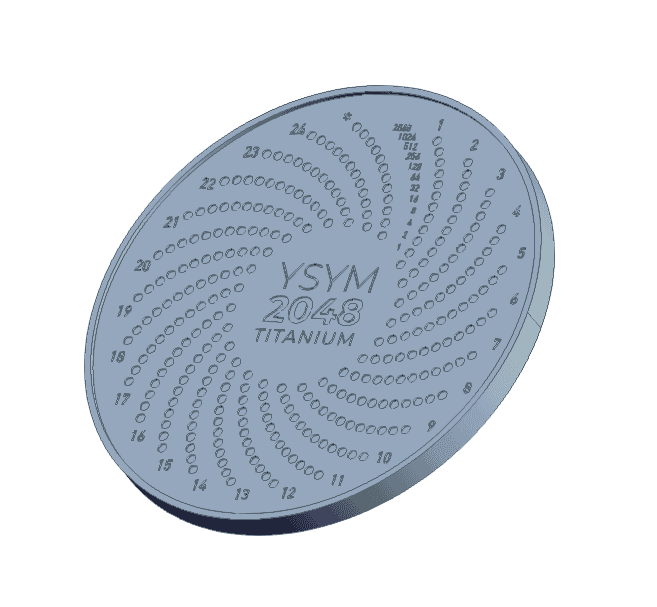

A 50 mm round, minimalist encrypted vault made from high-performance metals, designed as a physical, offline, fire-, water-, and tamper-resistant storage device for crypto seed phrases.

We’re particularly proud of our binary sum encryption system—engraved into a 50 mm plate. It’s not just a backup—it’s a shield.

By combining encryption, premium materials, and minimalist design, the team developed a tamper-proof and fire-resistant device that redefines what secure crypto storage looks like. With help from Xometry, Yoseyomo transformed their concept into a durable, precision-engineered product that’s now reaching customers across Europe.

From Shared Frustration to a New Standard in Crypto Security

Álvaro Campos and Iñaki Zubeldia were trading school colleagues who connected over Discord—driven by a shared interest in digital privacy and crypto security. Frustrated by the lack of elegant and robust ways to secure crypto seed phrases, they began developing the concept in late 2023, officially founded Yoseyomo in March 2024, and brought their first product to market by May. Yoseyomo is a brand dedicated to building encrypted, tamper-proof, and indestructible crypto vaults for the modern investor—one inspired by samurai values, premium craftsmanship, and encryption technology.

What is a Seed Phrase—and Why It Matters

Every crypto wallet is protected by a seed phrase: a series of 12 to 24 randomly generated words that act as the master key to your digital assets. Unlike a password, your seed phrase can’t be recovered if it’s lost. If someone else gets access to it, they can take your funds. If you lose it, your funds are gone forever—no reset, no customer service.

That’s why secure seed storage is critical. Many users rely on paper, text files, or metal plates—but these methods often lack tamper protection, encryption, or resistance to fire, water, and time. Yoseyomo set out to build a better alternative.

Building a Vault with Zero Compromises

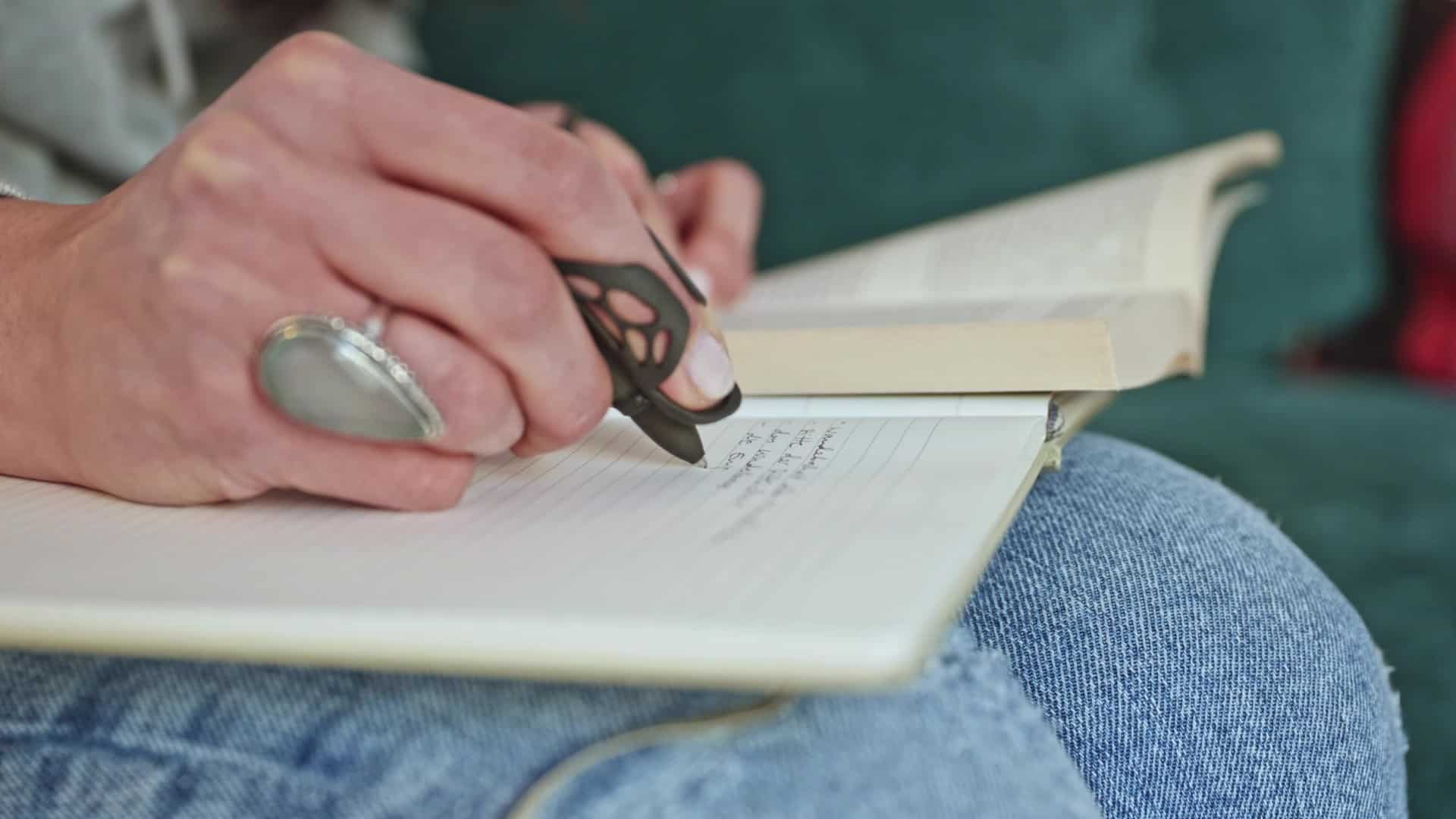

Yoseyomo’s vision was clear: create a physical storage device that could protect digital wealth for decades—if not generations.The result is a minimalist, 50 mm round vault made from high-performance metals like titanium, stainless steel, and copper. Its design is completely offline, requiring no batteries or electronics. Seed phrases are recorded manually using a guided punch tool, following a binary encryption method based on BIP39 and SLIP39 standards.

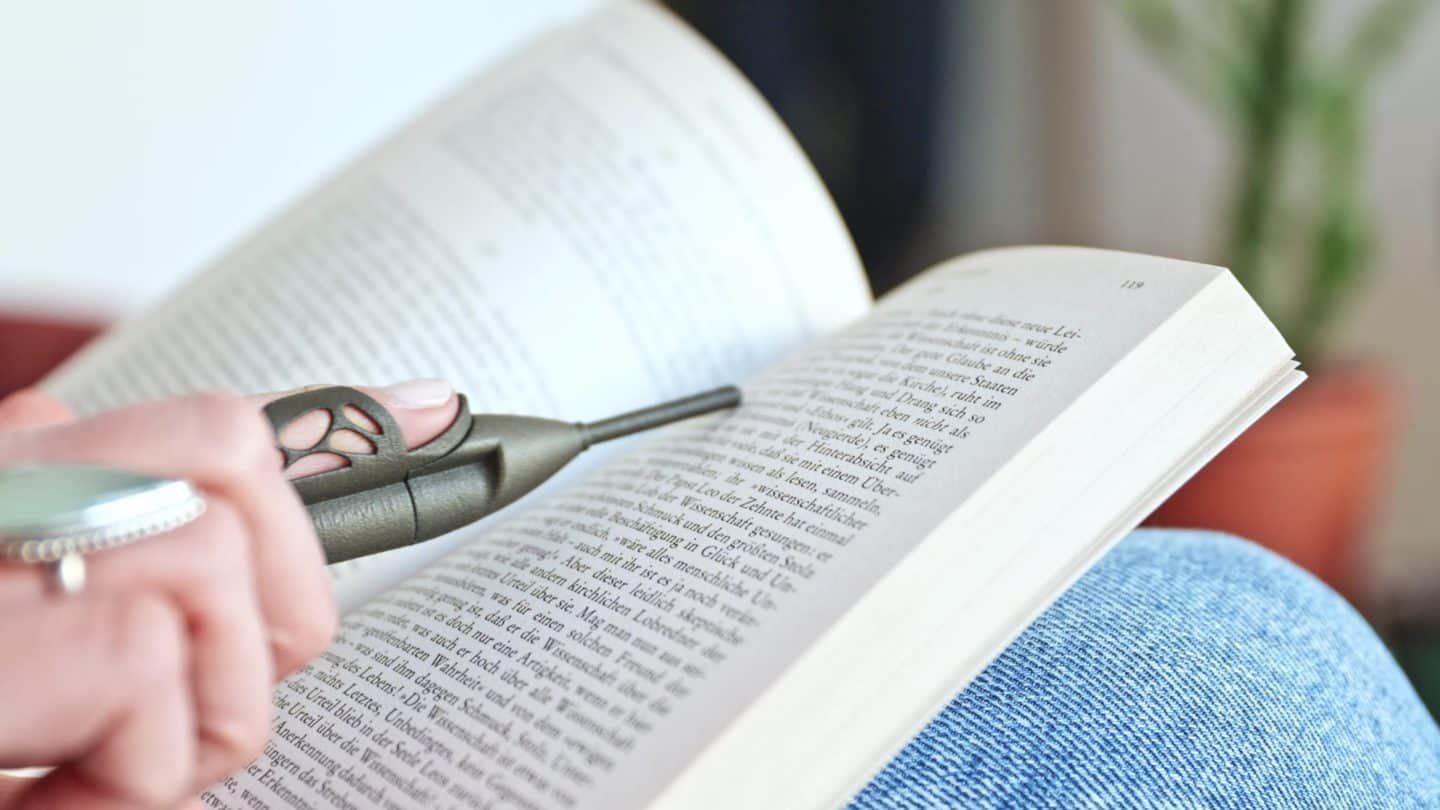

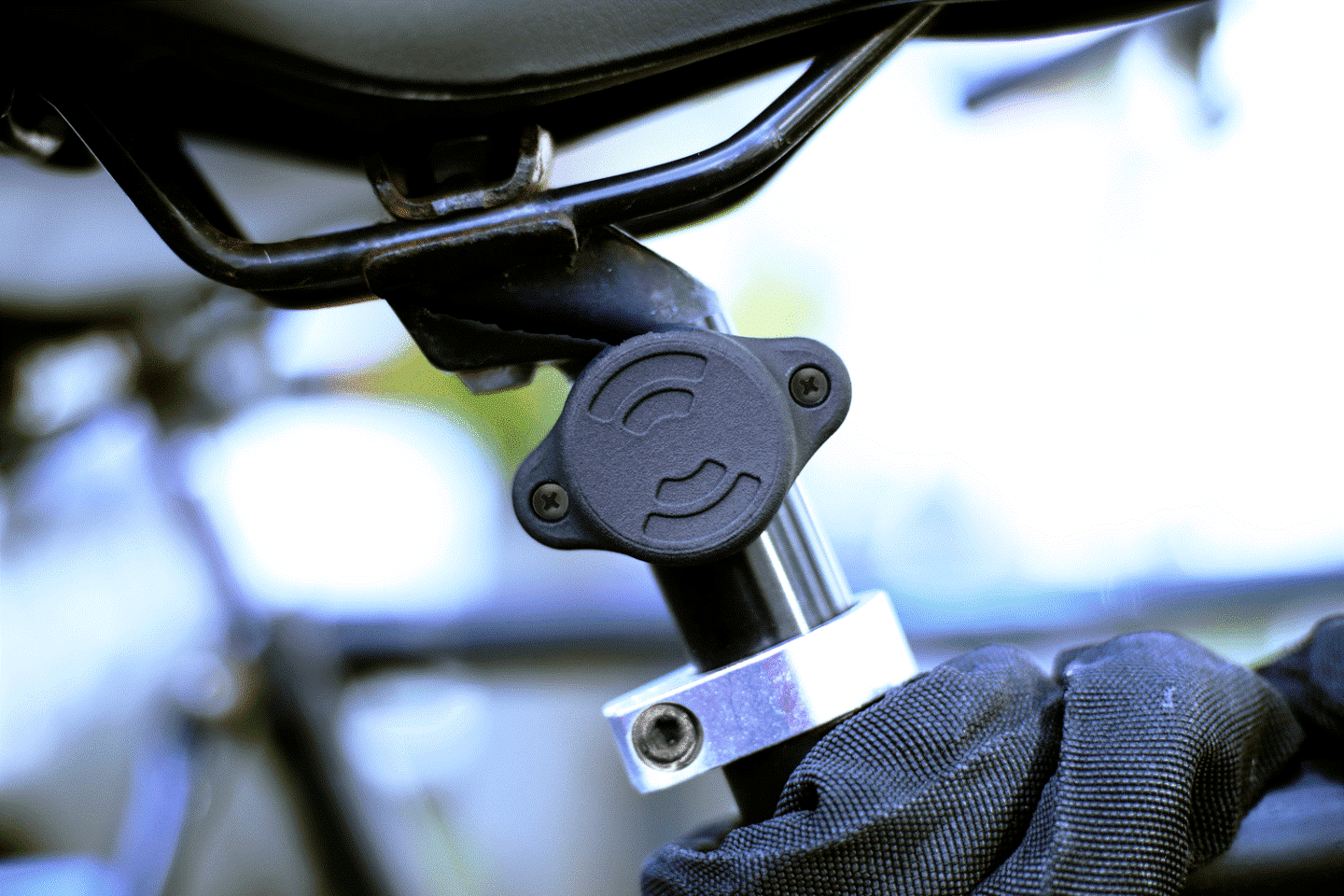

Instead of writing down words in plain text, users convert each one into a numerical value, punch it into the vault, and seal it with an NFC-enabled tamper-evident sticker. The sticker links to Yoseyomo’s app, allowing for verification of ownership without ever exposing the actual seed.

Every detail of the vault was considered—not just for functionality, but for emotion. From the mechanical tolerance of the fit to the engraving readability under low light, each element demanded high-end materials and micron-level machining. The result is not just a security device, but a sculpted object you’d be proud to own, display, and even pass on. Yoseyomo believes security should feel meaningful—like holding your legacy in your hands.

Designed for Those Who Take Security Seriously

Yoseyomo’s customers range from high-net-worth individuals to early adopters and tech-savvy newcomers. Internally, they’ve defined user personas like:

- The Security Freak – who wants maximum protection

- The Premium Guy – who appreciates quality and design

- The Full-Equip Newbie – who wants to get it right from the start

- The Crypto Purist – who seeks total control and privacy

Yoseyomo’s vaults are rated to resist extreme conditions. The team performed internal stress and burn tests, and even designed the geometry to limit hotspots that could deform the vault under fire exposure. The binary system also ensures seed phrases aren’t easily guessed or extracted without the punch alignment guide.

A Look Inside the Vault

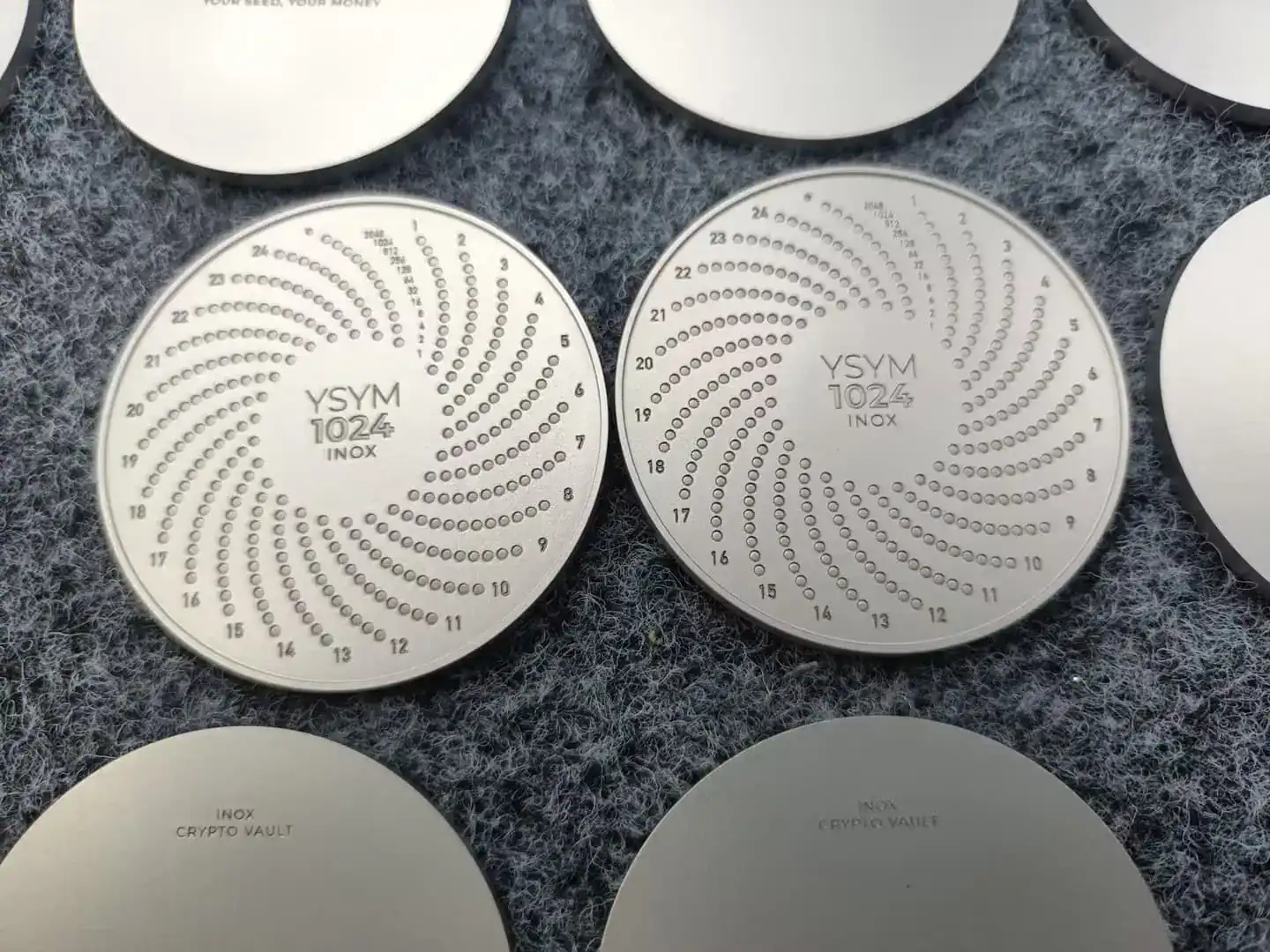

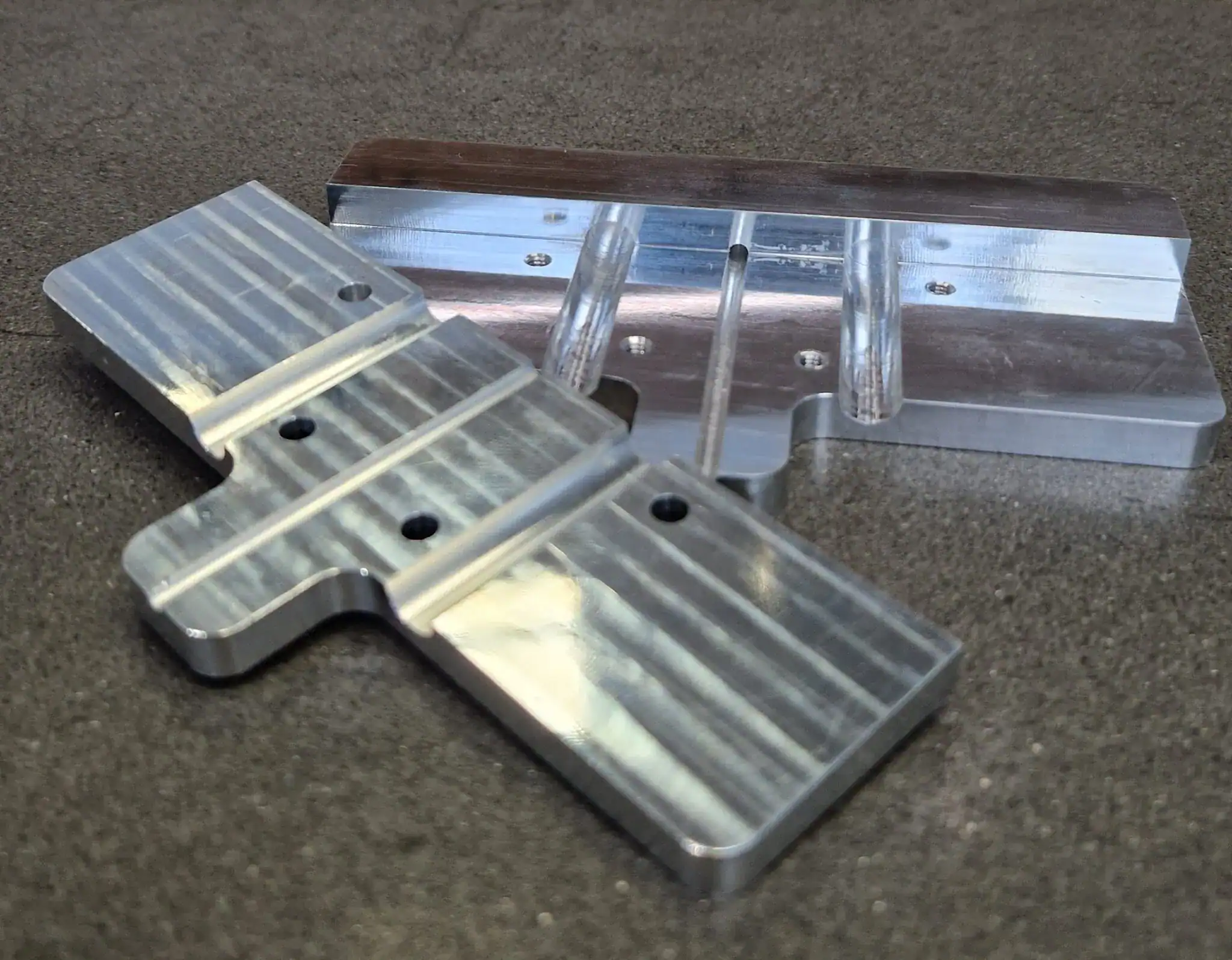

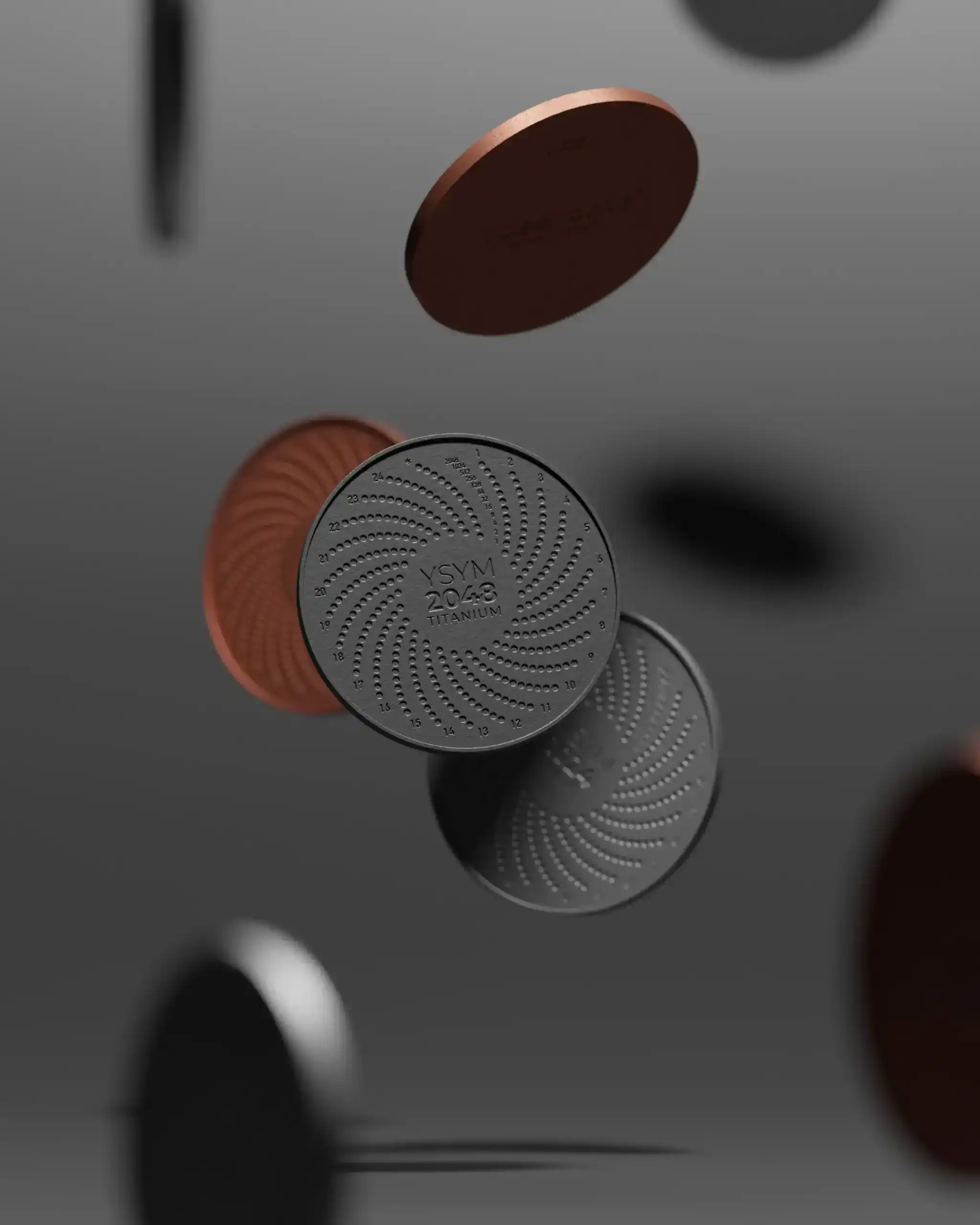

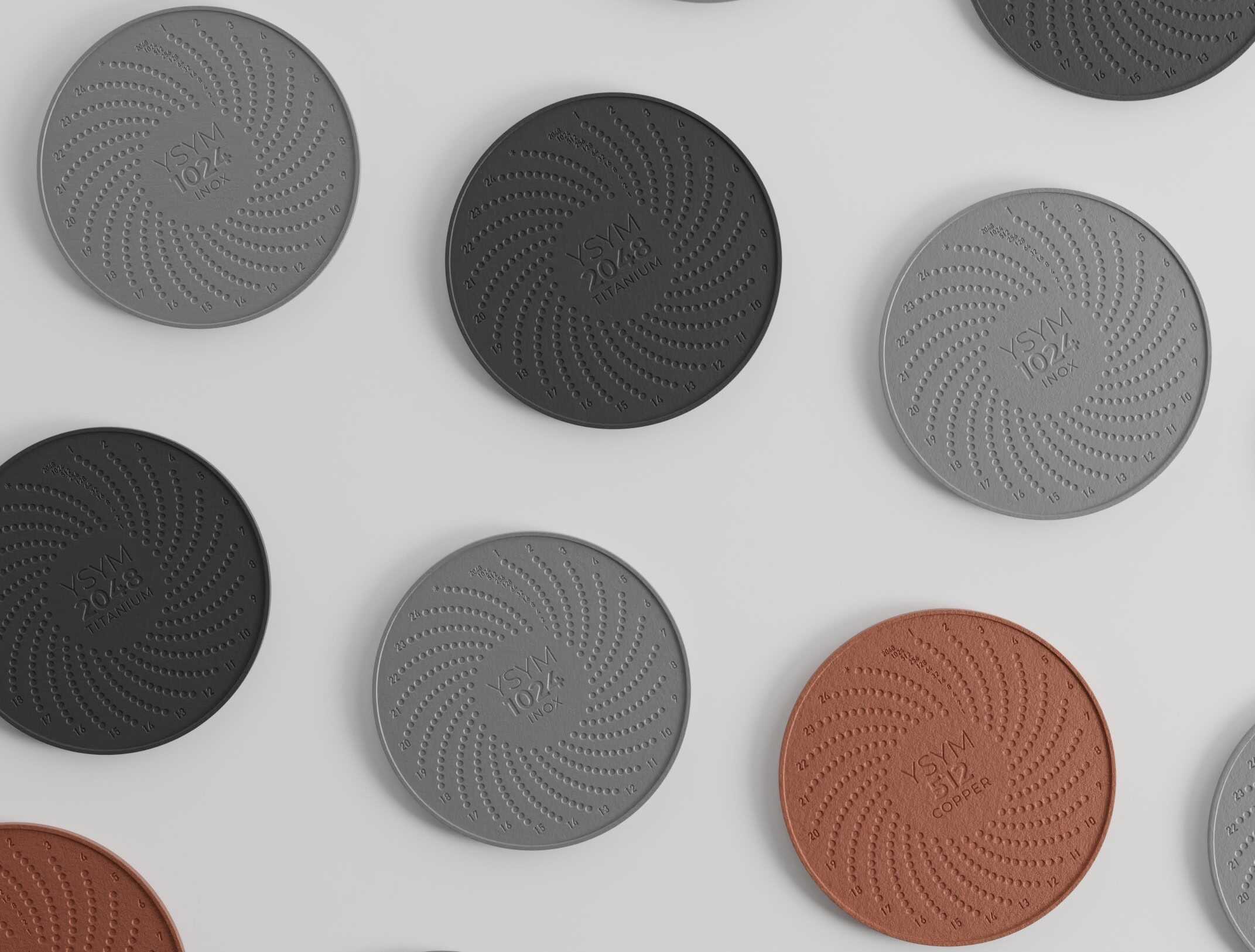

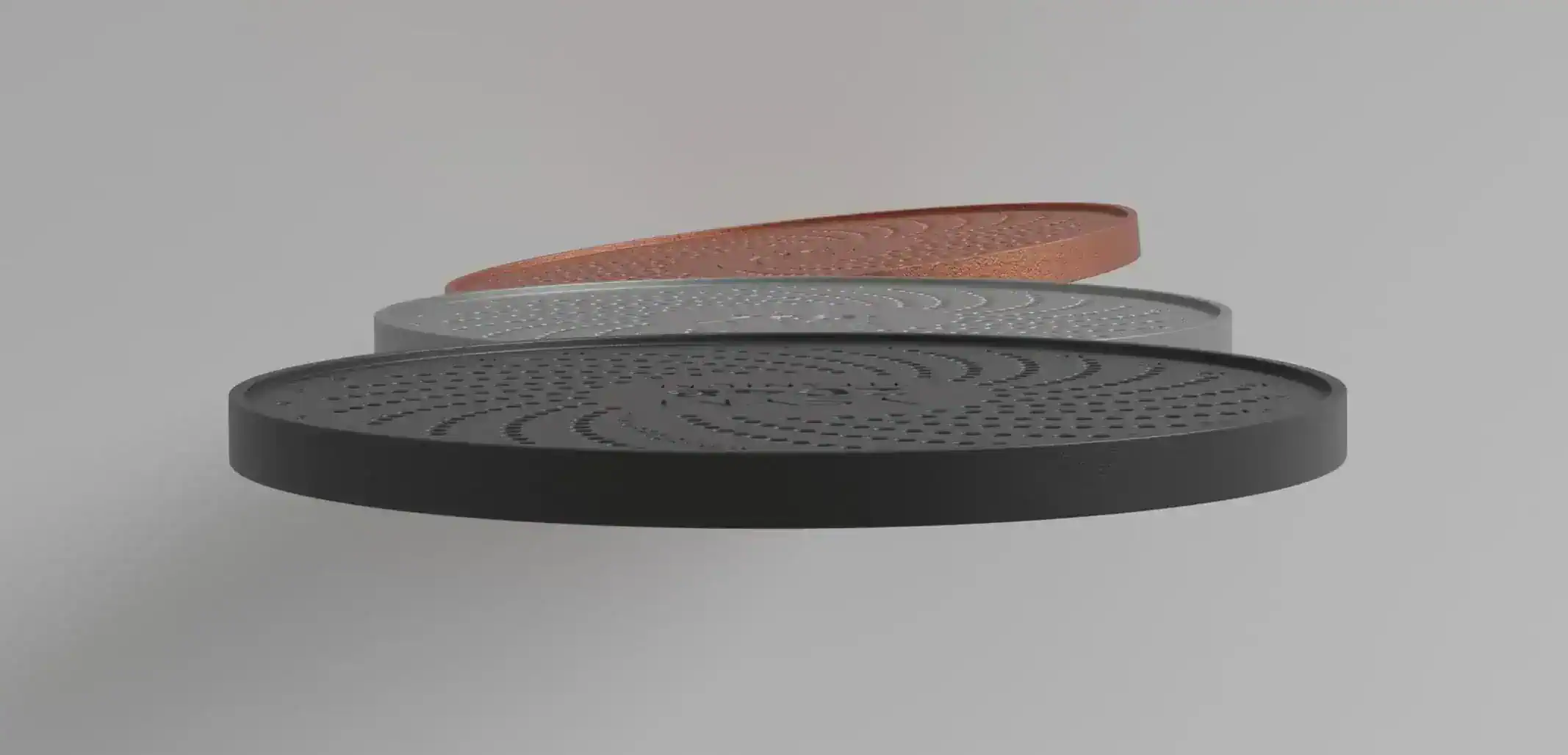

Yoseyomo currently offers three material variants of its encrypted vault—each engineered to the same uncompromising standard.

The YSYM_2048, machined from aerospace-grade Titanium Grade 5, is ultra-light, corrosion-resistant, and nearly indestructible. Designed for those who want the most advanced materials in the most compact format, it offers maximum durability without added weight.

The YSYM_1024, crafted from 316L stainless steel, brings a satisfying heft and smooth satin finish that emphasises its premium, analog feel. While slightly heavier, it offers the same extreme resistance to fire, water, and time—ideal for secure storage in vaults or safes.

The YSYM_512 is made from high-purity copper, chosen for its conductivity, symbolic richness, and artisanal appearance. It brings an elegant warmth to the vault’s aesthetic while preserving Yoseyomo’s robust security promise.

Each vault includes a guided punch tool and template for precise engraving, an NFC-enabled tamper-evident sticker that links to Yoseyomo’s mobile app, and a protective pouch made with long-lasting, plastic-free materials. The components are neatly packaged in minimalist boxes that reflect the brand’s aesthetic values and commitment to longevity.

Each variant combines durability with precision. While the copper edition adds an aesthetic warmth, it’s built to the same encrypted standard and tested against heat, corrosion, and physical tampering.

From Idea to Launch: How Xometry Made It Possible

In early development, Yoseyomo tested several manufacturing suppliers—but most failed to deliver the required quality. The tolerances were inconsistent, surface finishes too rough, or materials didn’t meet spec.

What they needed was a partner who could machine Grade 5 Titanium and 316L stainless steel with high precision and offer finishing processes that protected the aesthetics without compromising on durability.

Xometry stepped in to support both prototyping and production, delivering:

- Titanium vault parts with fine surface prep suitable for punch engraving

- Stainless steel components with passivation and sanding finishes

- Tolerances tight enough to ensure a perfect fit between layers of the vault

- Consistent batch production at scale

A Partnership Built on Precision, Speed, and Trust

Yoseyomo’s journey from prototype to product relied heavily on the ability to test, iterate, and launch within tight timelines—without sacrificing quality. That’s where Xometry came in. With Xometry, the team received design for manufacturability (DFM) feedback that improved tolerancing and fit, as well as guidance on surface finishing to enhance clarity and corrosion resistance. Lead times remained reliable even for small batches, and the consistent quality across production runs helped Yoseyomo maintain its premium positioning. A dedicated project manager also ensured quick turnaround and support during every iteration.

Xometry didn’t just deliver parts—they helped validate material choices, fine-tune the mechanical design, and streamline Yoseyomo’s path to market. And throughout, the Instant Quoting Engine played a key role.

That speed gave the team a strategic edge during launch preparation, where every week counted.

Red Dot Recognition: Design Meets Security

In 2025, Yoseyomo was awarded the prestigious Red Dot Award for Innovative Design—becoming the first crypto product in the world to receive this honour. With over 70 years of history, the Red Dot celebrates excellence in product design, previously recognising iconic brands like Apple, Bose, and SEAT. For Yoseyomo, this marked a pivotal moment: a confirmation that a security device could be both technically uncompromising and emotionally resonant—a product with soul.

Built for the Future — Together

Yoseyomo has bold plans for the future. Their upcoming products will include SLIP39-compatible vaults, modular accessories, and a full rollout of Inheritans®, their digital inheritance service for crypto holders. And with each product iteration, precision manufacturing will remain a core need. For that, they plan to continue partnering with Xometry.

We see Xometry not just as a vendor, but as an extension of our team. Their consistency, flexibility, and quality allow us to stay lean while delivering world-class hardware.

From a shared frustration between two classmates to a physical product now shipping across Europe, Yoseyomo’s story shows how design vision, engineering precision, and the right manufacturing partner can turn complex ideas into enduring products.

About Yoseyomo

Yoseyomo is a Spanish hardware startup focused on secure self-custody solutions for the crypto community. Their flagship product is a tamper-evident, encrypted vault designed to physically store seed phrases using binary encoding—offline, permanent, and resilient against fire, water, and theft. Founded in 2023, the company combines precision engineering with minimalist design, offering long-term protection for digital assets. Yoseyomo is currently expanding its product line and developing Inheritans®, a platform for secure digital inheritance.

Website: www.yoseyomo.com

Contact: support@yoseyomo.com

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط