The FaceDip case study highlights Nicole Jeffery’s journey in developing a convenient solution for cold water face immersion. Facing challenges like finding suitable manufacturing for prototyping and navigating design iterations for series production, Nicole partnered with Xometry.

United Kingdom

Xometry is the company that made it the easiest. I talked to a few different companies, and Xometry felt like the best fit for me. A lot of these decisions do come down to who do I want to work with long term, so who do I get the best feeling from and who feels like they understand the product and are excited about it and want to be involved as well.

Xometry’s on-demand manufacturing services, including 3D printing and injection molding, facilitated the creation of the Facedip bowl. This collaboration enabled Nicole to refine her design, test material variations, and move towards mass production. Xometry’s support proved crucial in overcoming manufacturing hurdles and bringing this innovative product to the health and wellness market.

The Challenge: Creating a Convenient Solution for Cold Water Face Immersion

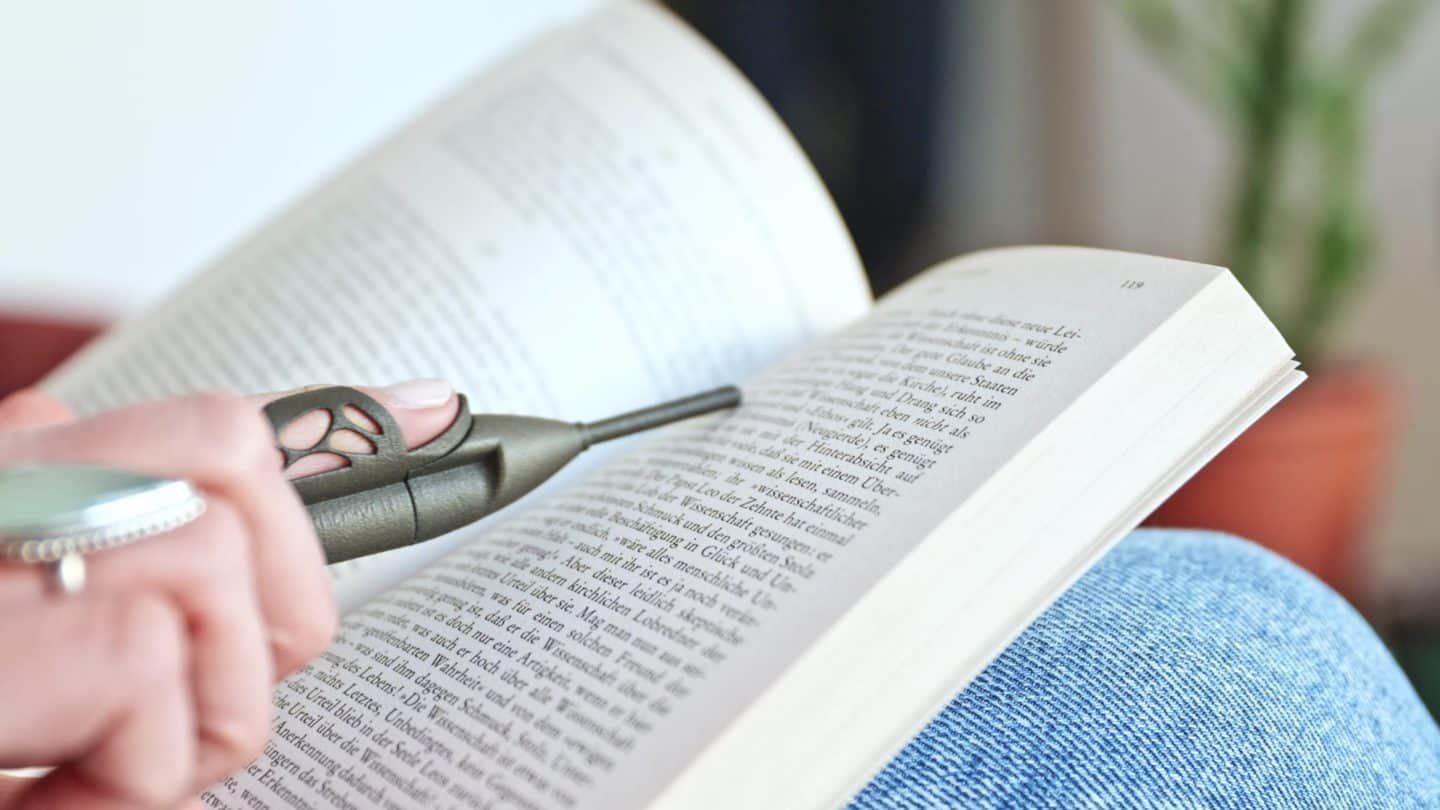

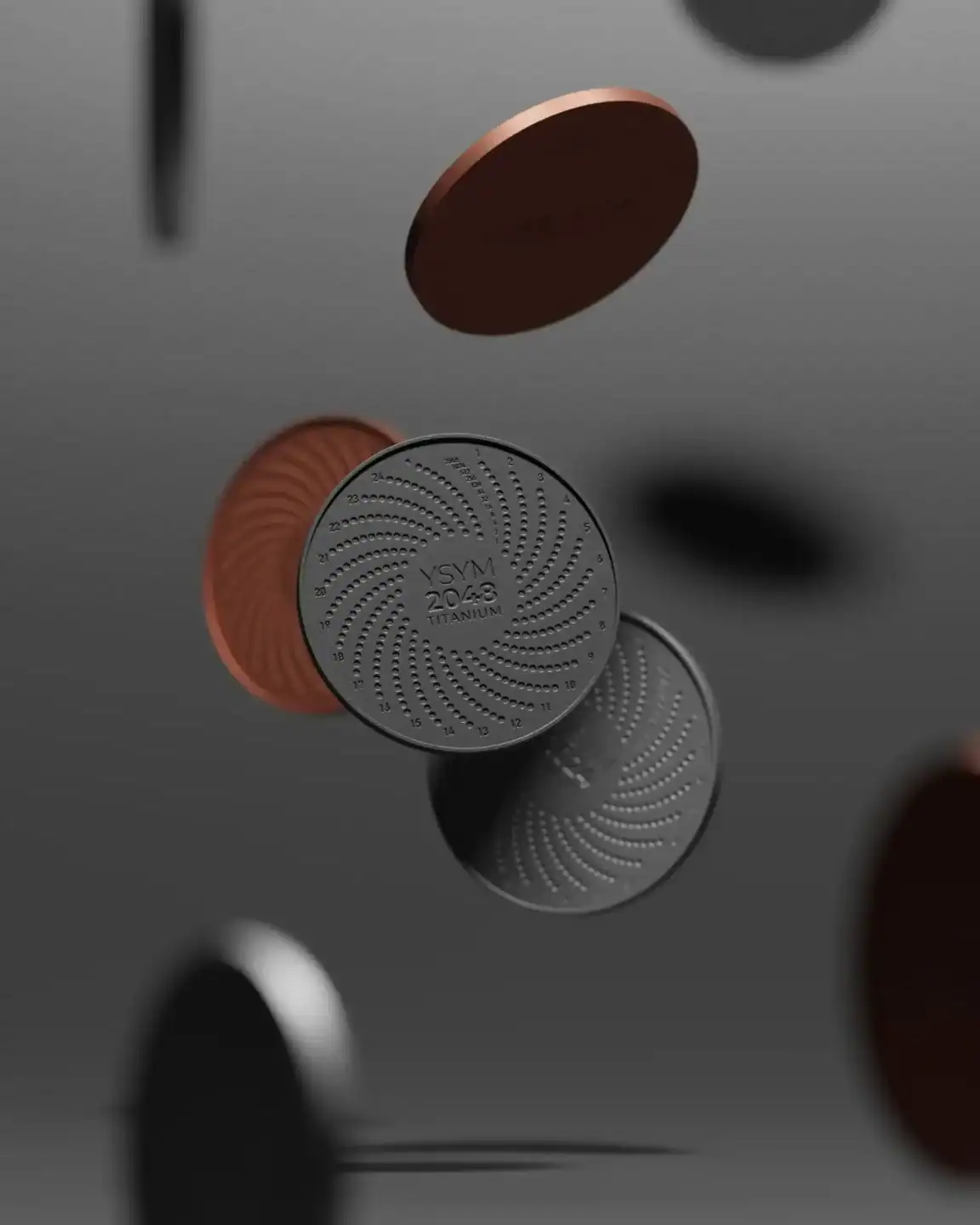

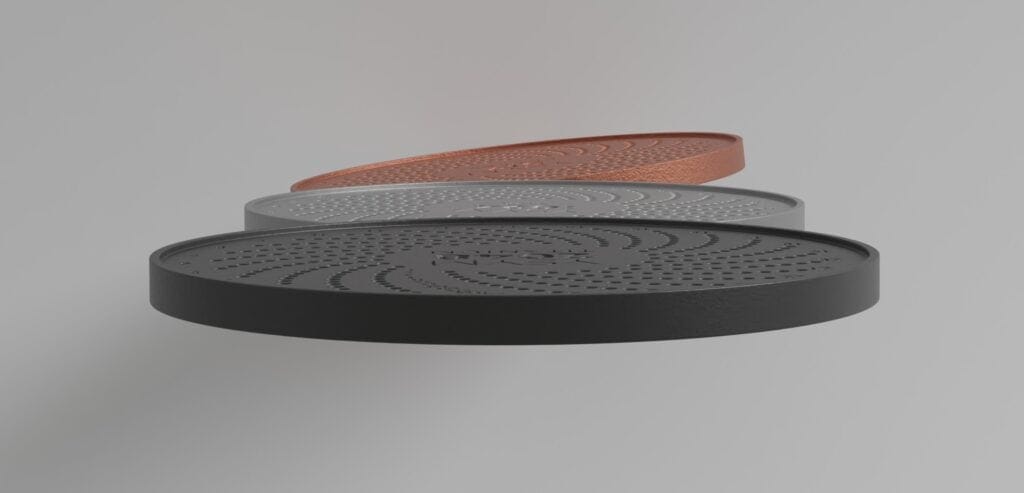

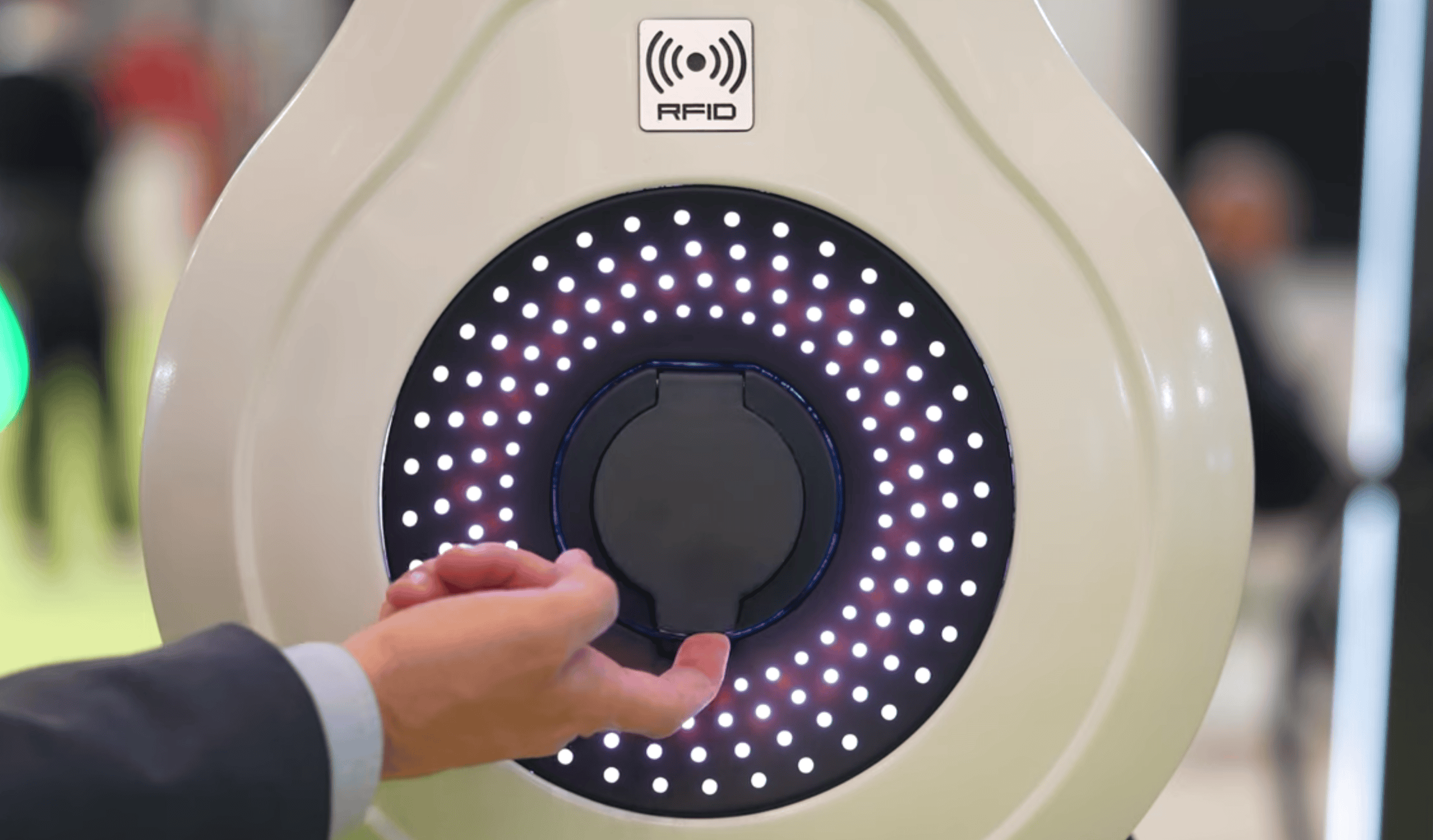

Nicole Jeffery, the founder of Facedip, recognised a growing trend in the health and wellness community: cold water face immersion. This practice, often seen on social media, involves submerging the face in ice-cold water for various skincare and well-being benefits like reducing redness, tightening pores, and providing a refreshing sensation. However, the existing methods – using salad bowls filled with ice – presented inconveniences, especially for those with limited freezer space or shared household items.

Living in the UK with a small fridge freezer, Nicole sought a more practical and dedicated solution. “I wanted to continue my routine, but to be able to do it in an easier way,” she explains. This desire led to the concept of Facedip, a collapsible silicone bowl designed specifically for cold water face immersion, making the practice more accessible to a wider audience.

From Concept to Prototype: Navigating the Design and Manufacturing Landscape

Nicole initially collaborated with a design agency to create initial product drawings, which helped gauge public interest on social media. While the design consultancy provided valuable initial support, the ongoing costs led Nicole to explore alternative manufacturing options. Her search for a manufacturing partner eventually led her to Xometry through a Google search.

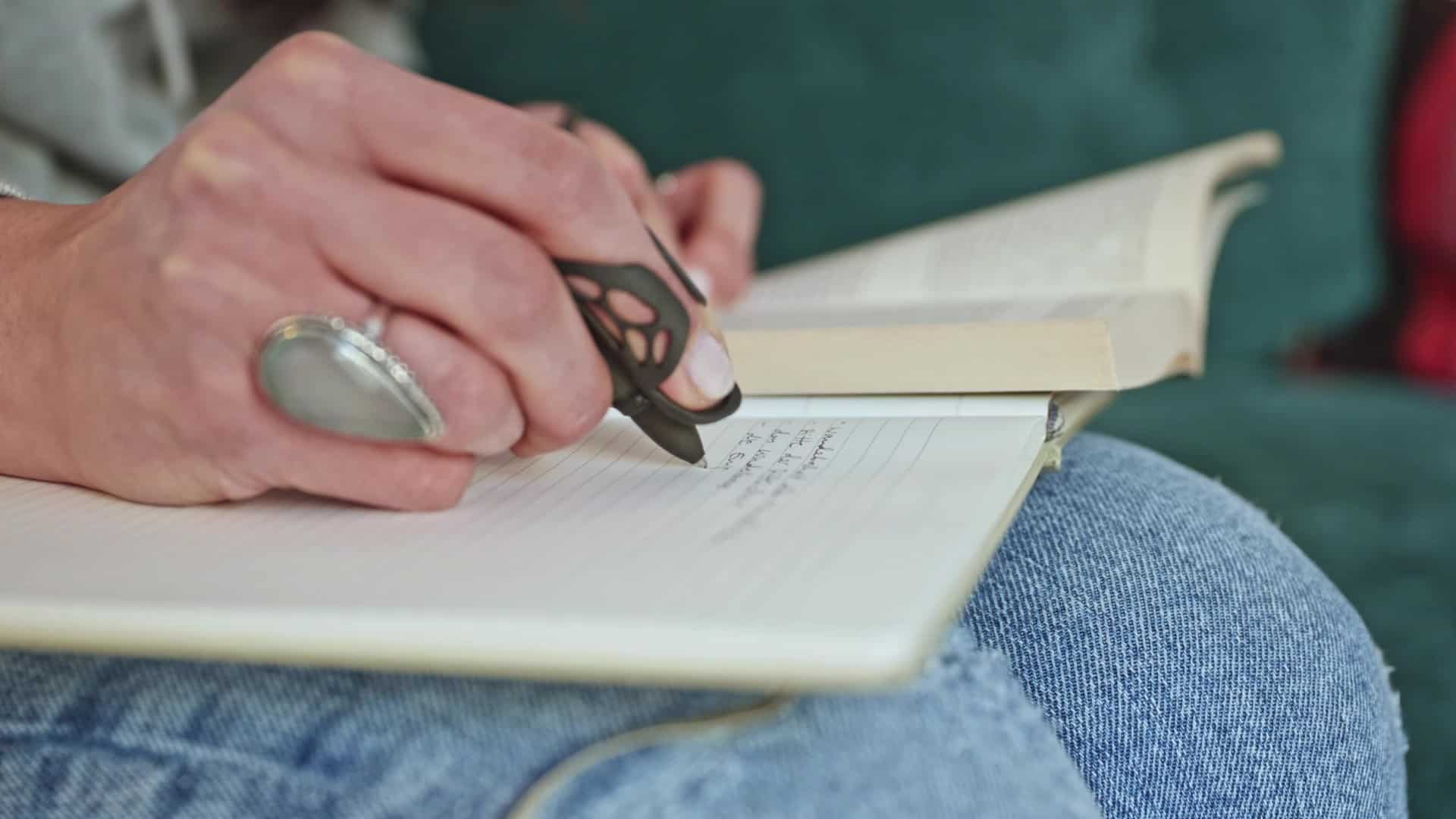

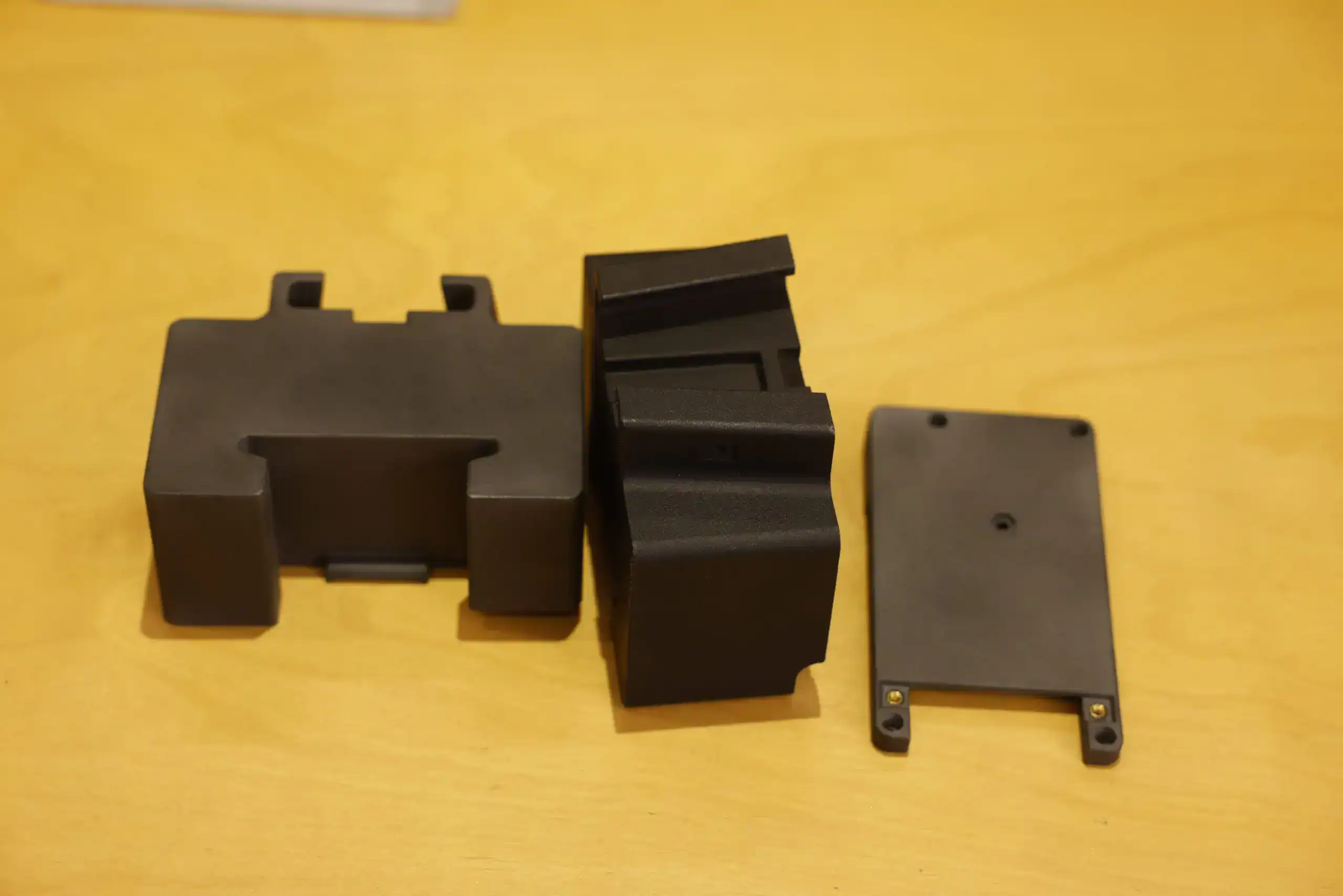

“The first thing that Xometry did for me was a 3D print“, Nicole recalls. The initial manufacturer she consulted had specified a 60A shore hardness for the silicone to ensure the bowl’s flexibility for collapsing and expanding. Finding a 3D printing service that could meet this specific requirement and the desired size proved challenging.

Xometry’s extensive network of partners provided the solution. Nicole connected with Chris, UK Key Account Manager at Xometry, who facilitated the 3D printing of the Facedip prototype. Impressed with the print quality and the collaborative relationship built with Chris, Nicole also decided to explore manufacturing quotes for different shore hardnesses with Xometry.

Xometry’s Solution: Flexible Prototyping and Design for Manufacturing Support

Nicole leveraged Xometry’s on-demand manufacturing services for both prototyping and tooling.

- 3D Printing: Xometry efficiently produced the initial prototypes in the specified 60A shore hardness, allowing Nicole to test the functionality and feel of the Facedip bowl.

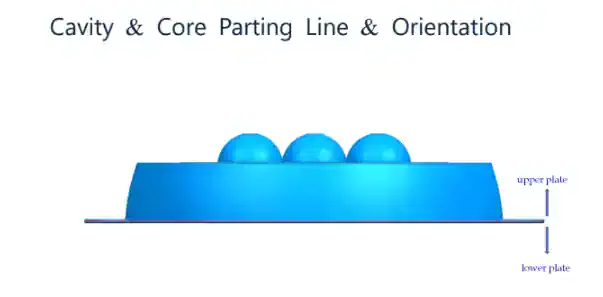

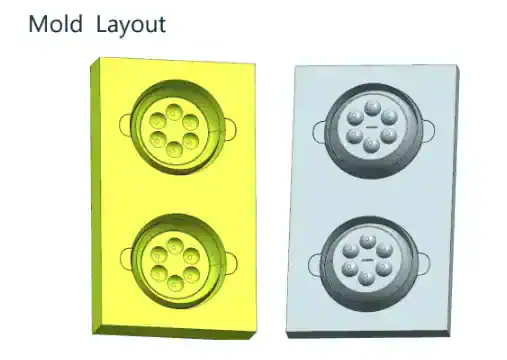

- Material Testing: To ensure the optimal user experience, Nicole requested molds with different silicone hardnesses (60A, 70A and 80A). Initial attempts with an 80A hardness resulted in fracturing due to shrinkage during the injection molding process. This flexibility in testing different materials highlighted the importance of prototyping in refining the final product.

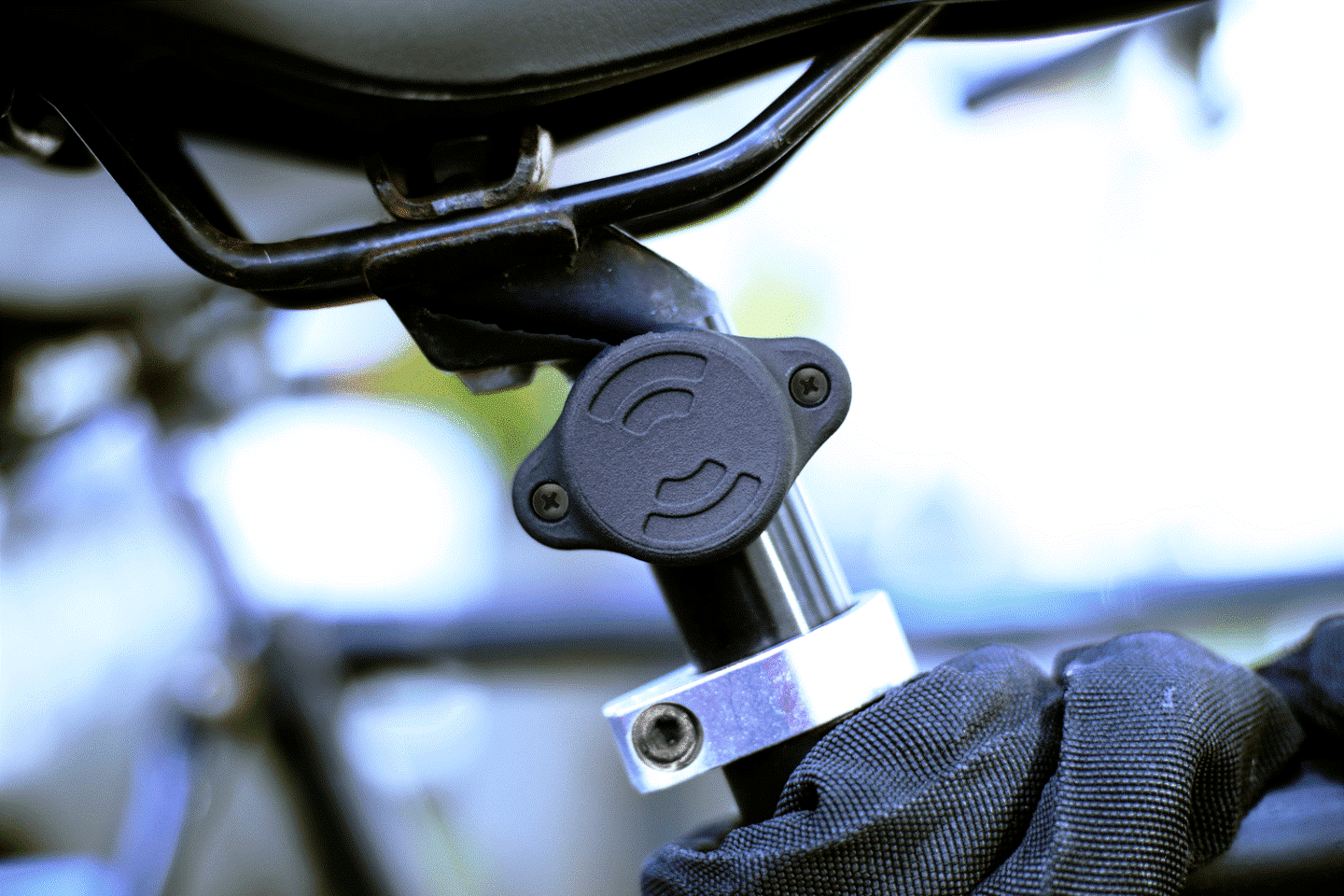

- Injection Molding Tooling: Recognising that injection molding would be the most efficient method for mass production, Nicole entrusted Xometry with the tooling creation.

Nicole appreciated Xometry’s flexibility and support throughout the process, especially as a solo entrepreneur navigating the complexities of product development. This approach was particularly helpful in the early stages when Nicole was still solidifying her production plans.

Launching Facedip: A Pre-Order Driven Approach

With the final prototypes approved, Nicole is gearing up for the official launch of Facedip. The launch will be on social media, leveraging the interest generated by the early product renders. With packaging, product, and website ready, Nicole is excited to bring Facedip to the health and wellness community.

Ready to elevate your skincare routine? Pre-order your Facedip today and experience the refreshing benefits of cold water face immersion!

Website: https://facedip.co.uk/

Instagram: https://www.instagram.com/facedipuk/

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط