Cyfac has been handcrafting bicycle frames for 40 years and recently enjoyed success at Concours de Machines with an all-carbon bike. This distinctive two-wheeler stood out thanks to its 3D printed titanium suspensions produced using Xometry.

France

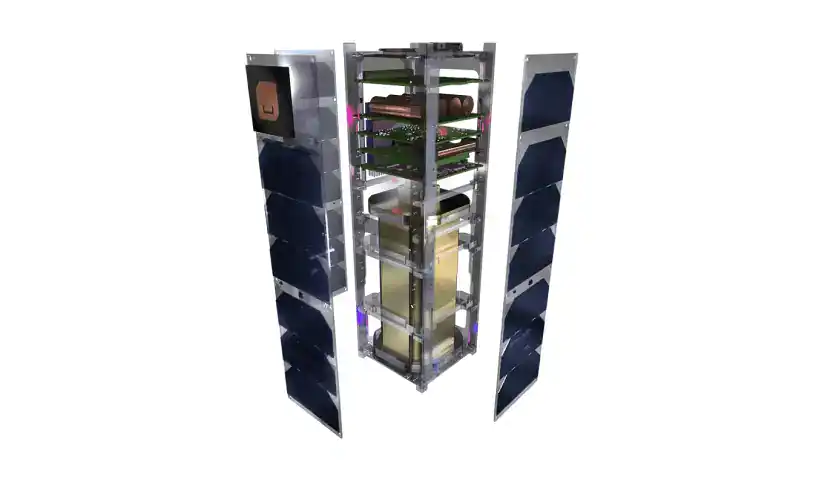

Full-carbon gravel bike with 3D-printed titanium suspension

Having a partner we could rely and deliver high-quality parts was essential… If things had gone wrong, we wouldn’t have won the competition.

It all began when the Cyfac team decided to take part for the fourth time in the Concours de Machines. For the 2022 edition, lightness, resistance and versatility were the key attributes for tackling a route that is as feared as it is challenging.

The riders had to contend with the “Paris-Roubaix” route, which includes gravel and cobbled sections that are usually quite painful to ride on. That’s why the focus was on suspension in the Paradox specifications, the name given to the bike designed and created by Cyfac.

A Bold Choice: a Full-carbon Gravel Bike

Although carbon is still very much in the minority in the handmade bike segment, Cyfac put its faith in this material when designing its latest innovative model. The company had already planned to produce a carbon model for its 40th anniversary—and what better time than the competition to introduce it to the general public?

But why carbon? For Aymeric Le Brun, Director of Cyfac, it was an opportunity to remind people of their unique expertise, especially with this high-grade material that they already use to produce tandem frames. It was also an excellent opportunity to demonstrate that a carbon frame can be just as, or even more, comfortable than steel.

Not to mention that carbon also has excellent mechanical properties and is extremely light. Weighing in at 10.7 kg, the Paradox was more than a match for the competition and allowed Cyfac to win the competition with the expert guidance of the rider, Sophie Gateau.

The Titanium Suspensions: Key Parts of the Bike

Paul Riegel, Head of Production and R&D at Cyfac, reveals that the suspension components were at the heart of the bike’s design. Damien Leclerc, a designer and frame builder, came up with the basic idea. With years of experience under his belt and after spending many hours on Adobe Illustrator, he showed up one morning with an innovative concept.

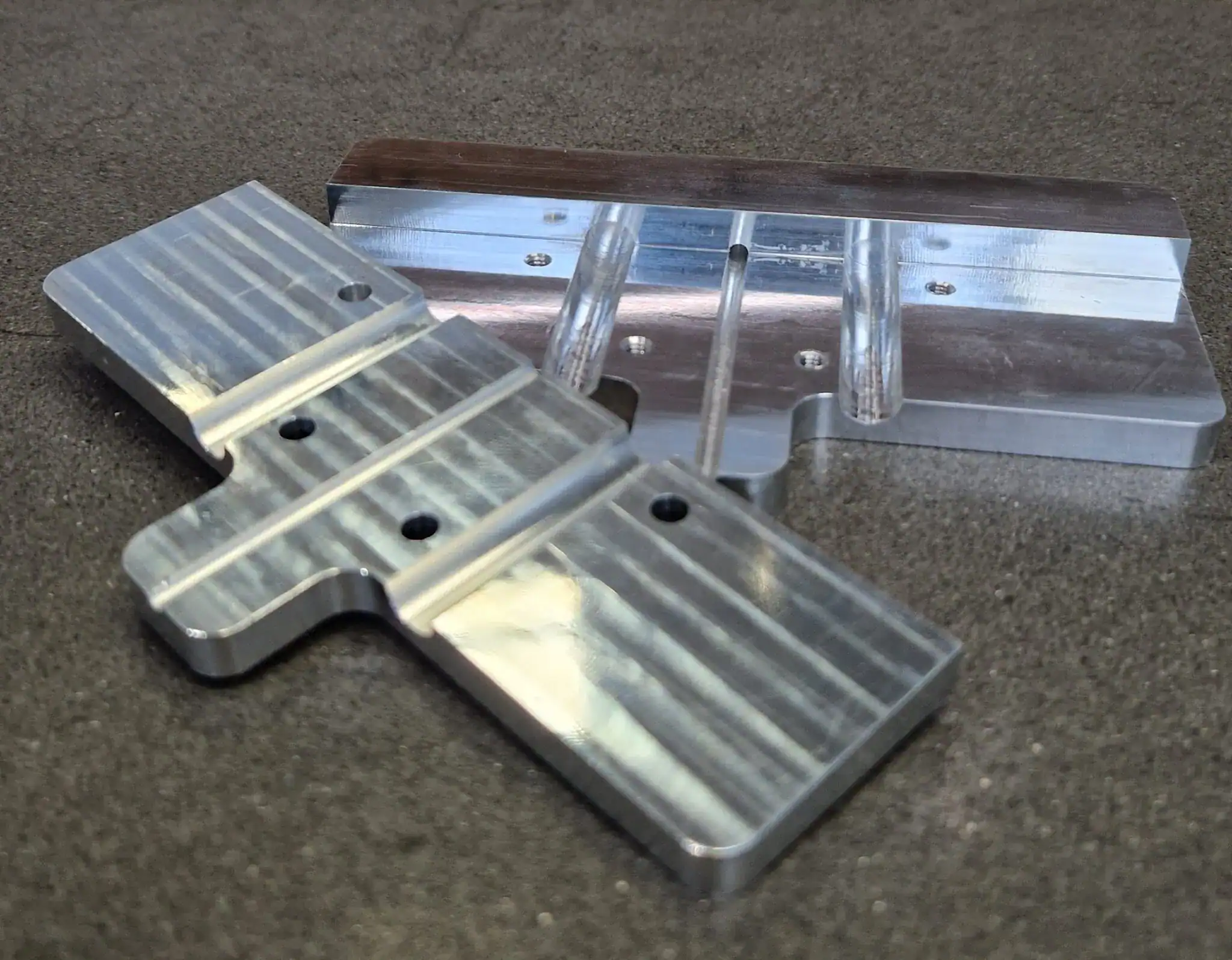

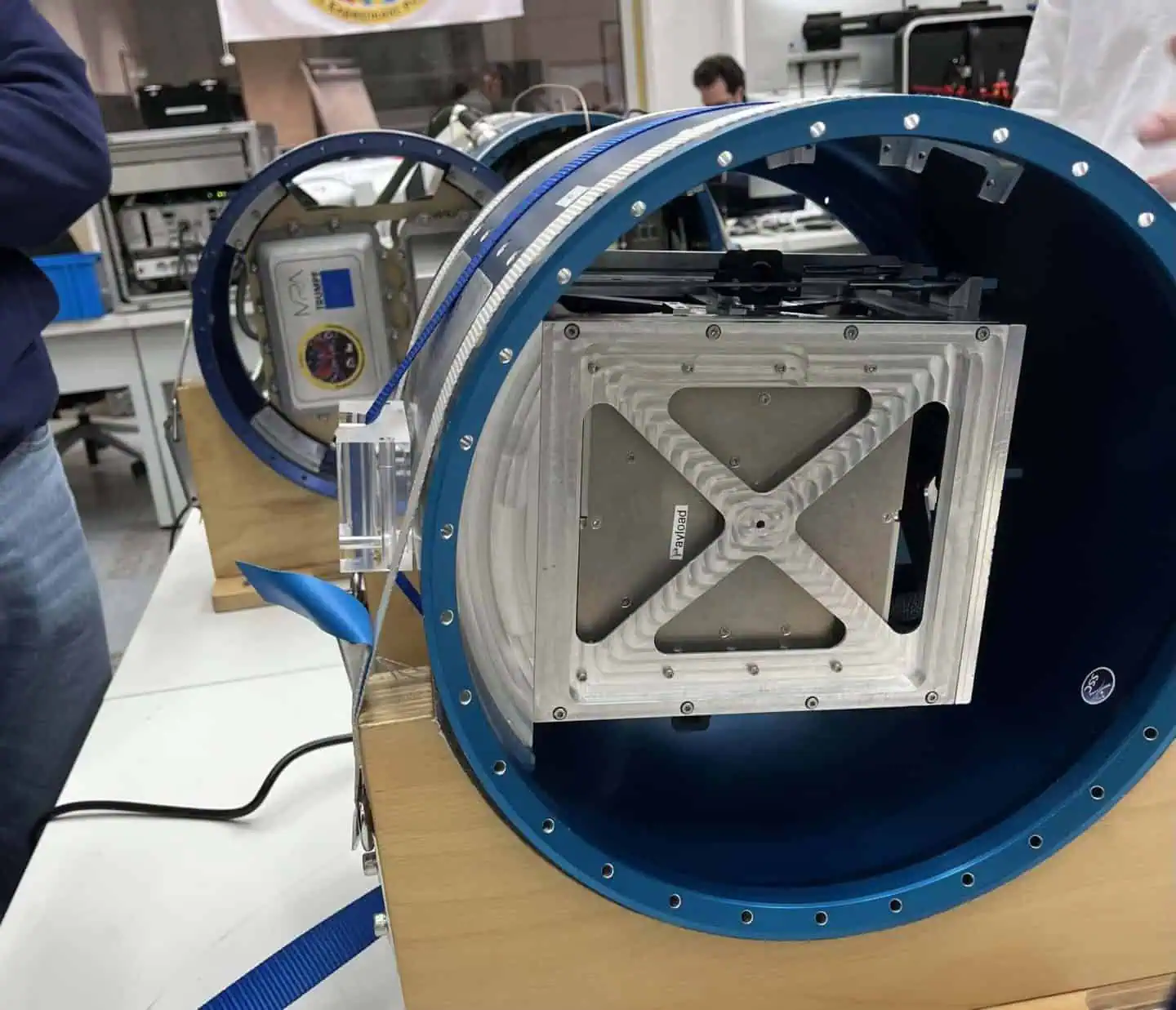

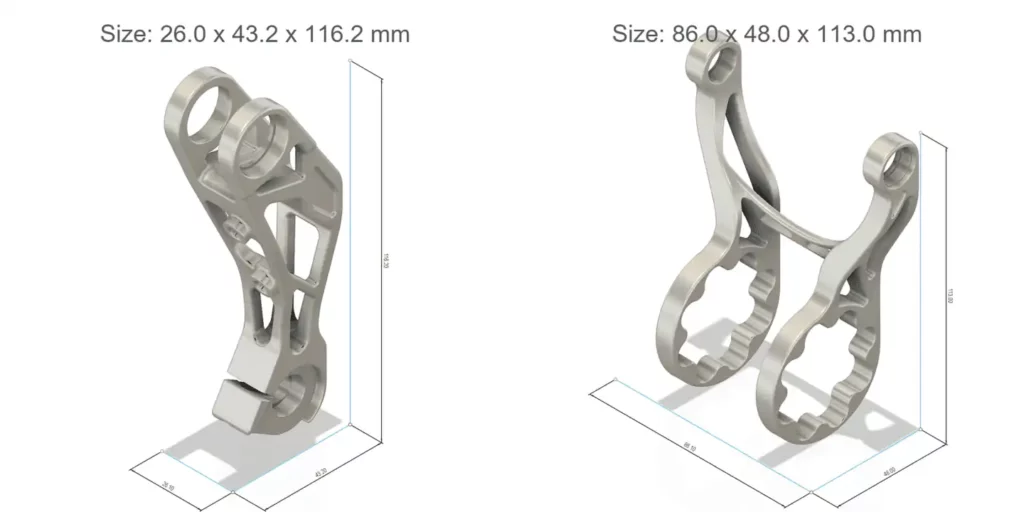

The engineer suggested fitting the bike with flexible titanium blades and to pivot through the front fork with the help of two small swingarms, also made of titanium. These parts are also combined with an elastomer component to dissipate energy and a spring made of carbon blades.

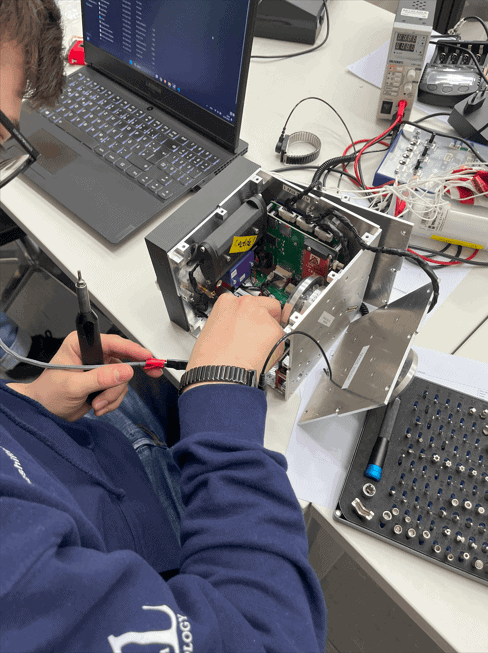

Once the designs have been completed, it’s time to have the parts produced.

The complexity of the final geometry of the suspension parts meant that 3D printing was an obvious choice for manufacturing the parts. Partly inspired by the use of additive manufacturing by competitors, the Cyfac team decided to try it out. Riegel believes that 3D printing helped them optimise the part designs by fully freeing themselves from the limits imposed by traditional machining.

Titanium proved to be the right choice of material for the team ,as they wanted to obtain the lightest possible parts and use a top-quality material. Cyfac’s desire to be innovative is made abundantly clear by the use of a wide range of different materials in the right places to best meet the specifications.

The titanium suspension parts attracted the most attention and were a great success when the Paradox was unveiled at the competition. “A lot of people didn’t even know that 3D printed titanium existed,” says Riegel.

Xometry: a Fast and Reliable Solution for Custom Parts

Cyfac turned to Xometry to get these impressive custom titanium parts manufactured. In light of current supply problems, the bike frame manufacturers had to streamline the purchasing of certain parts so they could meet demand and deadlines. This was a major problem that Xometry was able to help them overcome.

With the competition in mind, it was out of the question for Cyfac to wait almost a year—as with other suppliers—for the parts to be delivered. For the Cyfac team, one of Xometry’s strengths was the speed with which they sourced the various parts, ensuring that any possible supply difficulties were avoided and the very tight deadlines were met.

“Having a partner we could rely and deliver high-quality parts was essential.” There was so much at stake financially. We needed to be certain that we would have top-quality parts on time for the competition,” says Le Brun. “If things had gone wrong, we wouldn’t have won the competition.”

Cyfac also feel that the personal touch is another of Xometry’s strengths. “Hadrien Comsa, our dedicated account manager at Xometry, contacts me every time I create an online quote to fully understand what I need and in what quantities,” says Riegel. “It’s brilliant to have someone available to answer all my questions.”

Xometry coordinated production of the 3D printed parts (swingarms for the suspension, connecting rods, inserts at the end of the seatstays), but also for some machined parts (two closing half-caps, a small brake adapter).

Quotes and orders were processed directly online using Xometry’s instant quoting platform. “This tool is really useful for us since we occasionally need small series or even one-off parts. Without it, we’d have to wait a solid week just for a quote,” explains Riegel.

“It’s an invaluable tool that helps us streamline the process even more with Xometry. We quickly get information on prices and deadlines, which is an important factor for confirming our choice. On top of that, we have the personal touch that really strengthens the collaboration.”

Series Production of a Carbon Bike to Celebrate 40 Years

To celebrate its 40th anniversary, Cyfac will unveil a new model in November that expertly combines innovation and tradition as always. This series production model will initially be more geared towards the road with thinner tyre sections.

The good news is that it will use the same tube series as the Paradox, winner of the 2022 Concours de Machines, to add modern twist to their carbon frame range.

About Cyfac

Cyfac has been producing custom bicycle frames for 40 years. The cycling enthusiasts at Cyfac made frames for some of the greatest riders in the pro peloton in the 1990s. Cyfac was awarded the “Living Heritage Company” (EPV) label by the French government in 2012 and strives every day to preserve its expertise and the made in France quality. That’s why Cyfac continues to produce its frames entirely in France, and always by working closing with their customers.

Discover the Cyfac site https://www.cyfac.fr/

Get in touch contact@cyfac.fr

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط