Paul Byrne developed Viralink® that removes pathogens in the air and SARS-CoV-2 directly to 99.9999% Log6. «Let us disinfect your next breath… so it won’t be your last».

Reino Unido

Air-sanitisation device destroying airborne viruses using UVC radiation

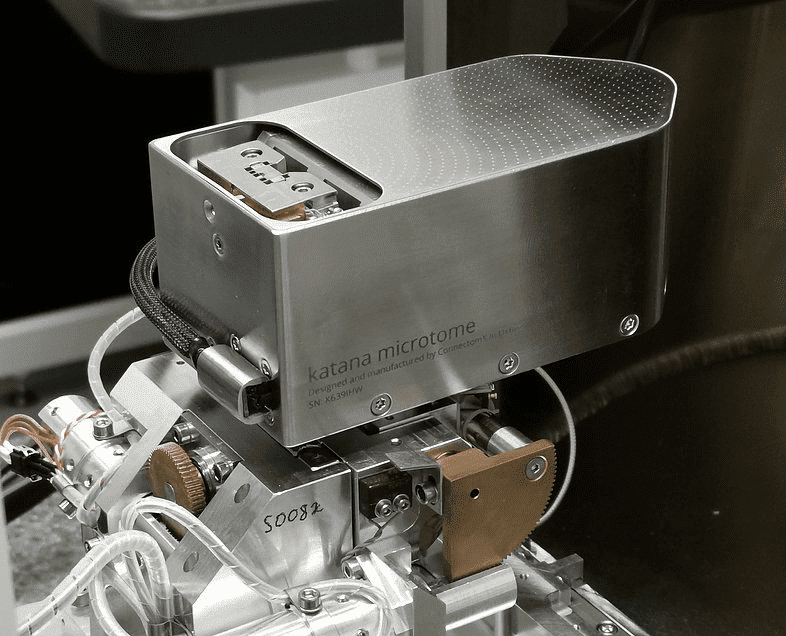

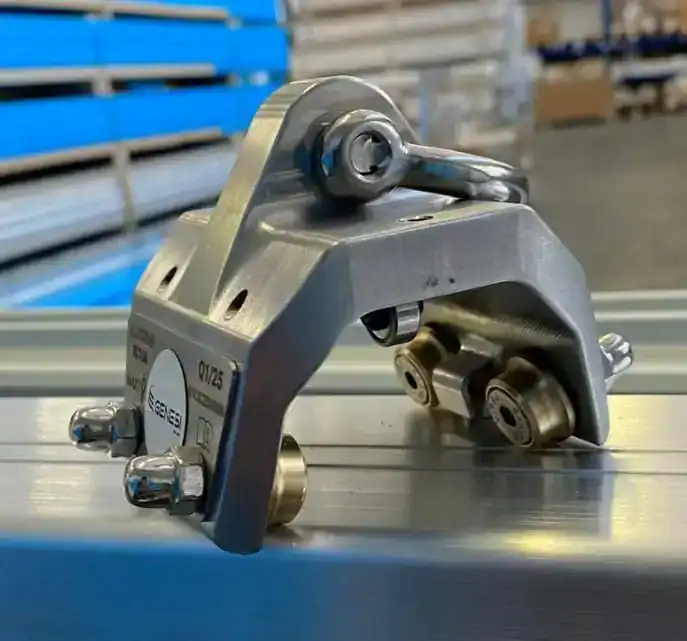

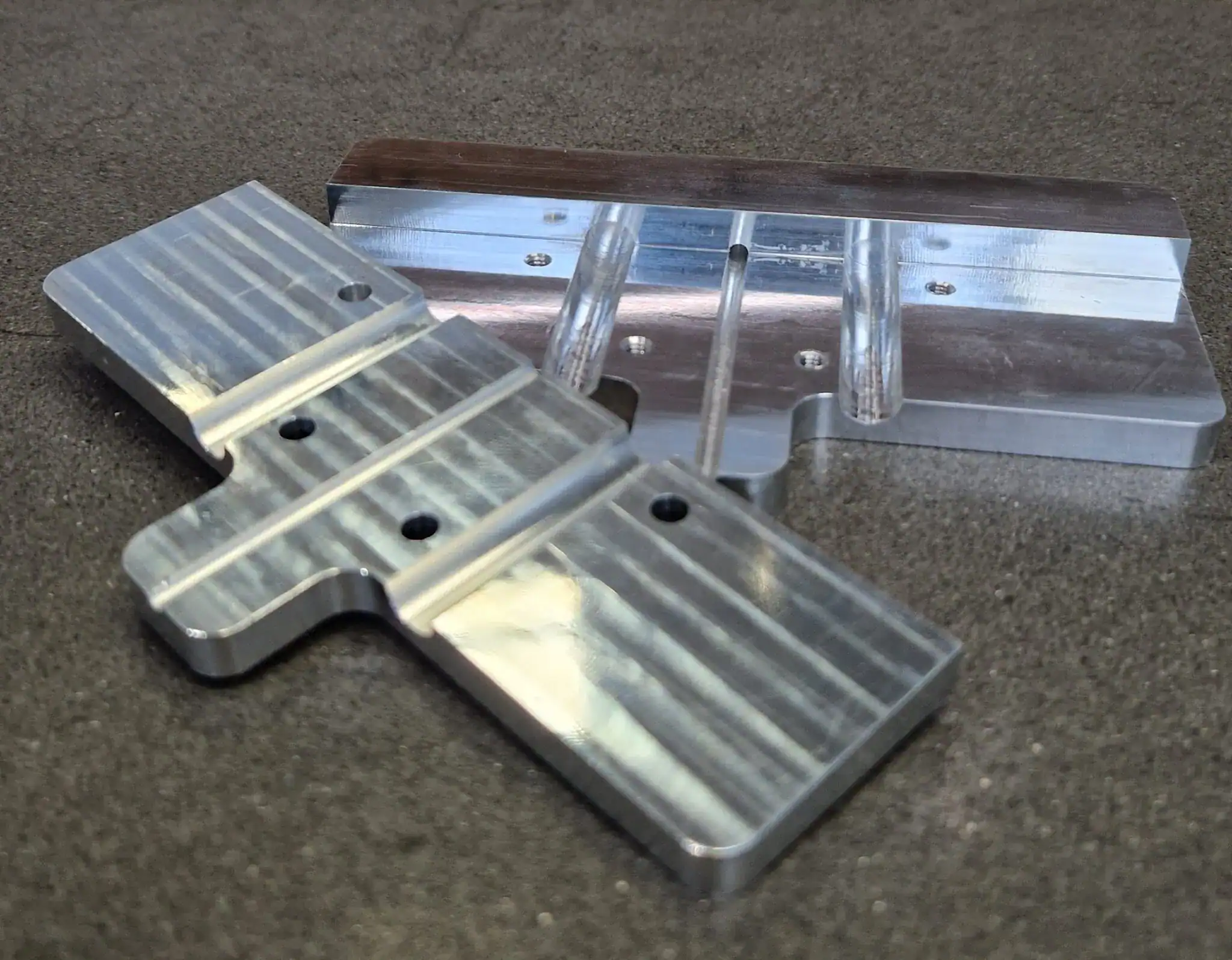

When I put it together, you simply can’t imagine how accurate it was … With Xometry as my supplier, we’re certainly ready for mass production.

developed a fully functional device that removes viruses such as SARS-CoV-2 from the air indoors.

News just in: Viralink destroys SARS-Cov-2 directly. Boston University has lab tested it and found conclusively that UVC Radiation destroys SARS-CoV-2 to 99.9999% which is Log6 efficiency.

Here’s the interview with Mr. Byrne on how he designed VIRALINK®, made its first functional prototypes, and how he plans to bring the device to the mass-market.

R&D Started Just as the Pandemic Hit the World

Xometry: How did it all start?

Paul Byrne: In January 2020, it became evident that the world was heading towards a pandemic from the infections of the SARS-CoV-2 virus leading to COVID-19. I decided to investigate what could be developed that would assist in reducing the impact of this pandemic.

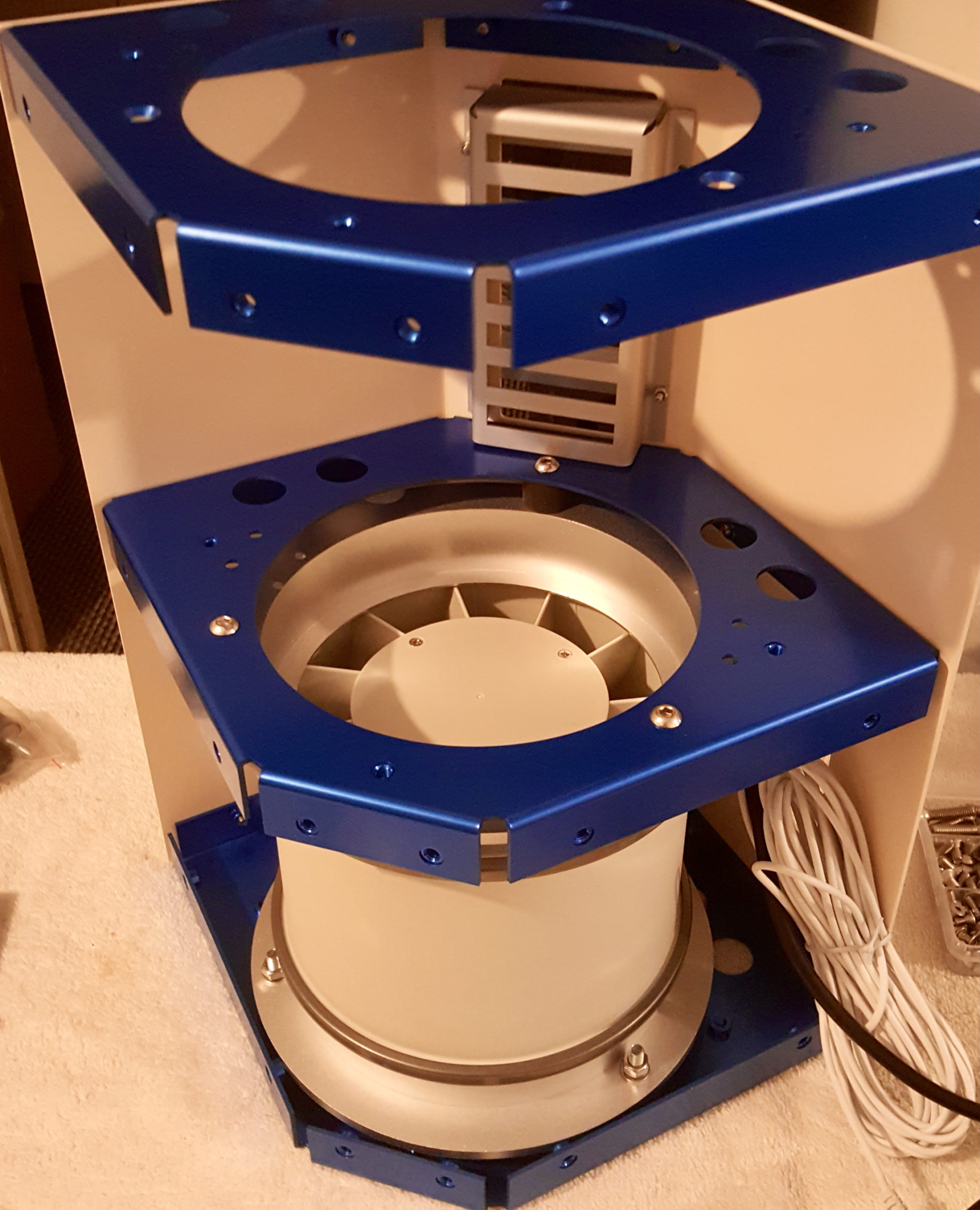

I initially started researching Invasive Mechanical Ventilators. I quickly realised that this would only treat the already infected people, which was rather too late. I then started researching how to get rid of the airborne Pathogens through Germicidal Sterilisation using UVC Radiation. This led to the current series of VIRALINK-UVC300A/E Air Sanitization machines.

Uvc to Destroy Viruses Inside a Chamber

X: Can you please explain what the basic principle behind the Viralink is?

PB: Since the Earth is shielded by the atmosphere against UVC ultraviolet light, no organisms or pathogens have ever evolved to protect themselves against it; so all organisms are very susceptible to destruction by UVC at the DNA level. It is a well-known fact, so ultraviolet lamps have been in use for a while, especially in hospital rooms. However, this approach has two big disadvantages:

- Direct exposure to UVC light is very dangerous for the skin, so you can’t be in the room, when the lamp is on;

- Even though such lamps effectively destroy the viruses in the areas directly under the lamp, pathogens still remain in the corners of the room as well as in the other less accessible areas.

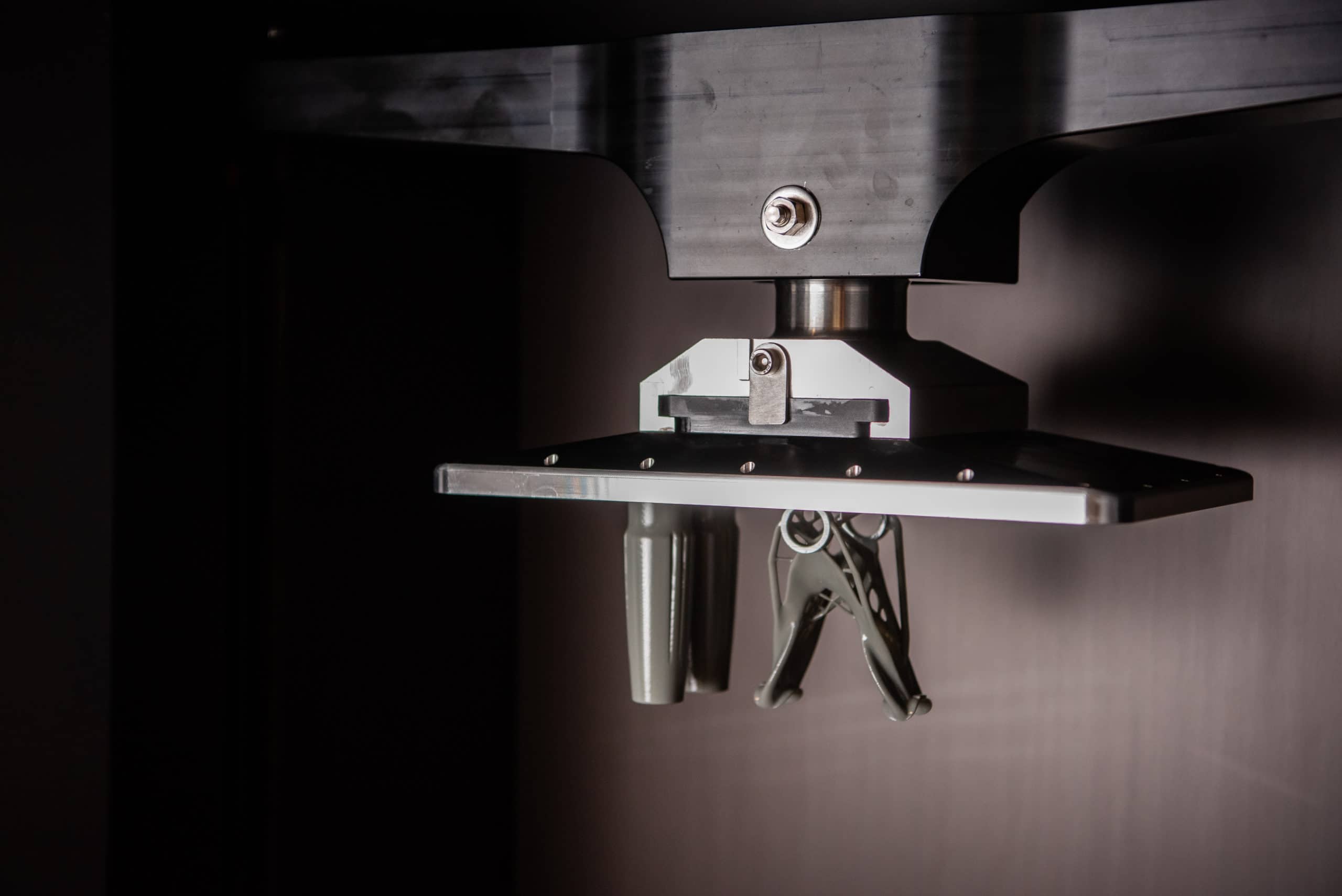

I started looking for a different way to remove viruses from air. This is how the concept of Viralink was born. It draws in the air from the room and brings it very close to an intense radiation area of UVC that destroys all the pathogens (as long as the ‘dose’ is large enough) and then releases the treated air into the room again.

Why Hire 4 Engineers When You Can Hire Just Me?

X: You’ve had a very interesting career: you’re a mechanical engineer, you worked on NASA projects, you studied for a PhD in the field of Nuclear Reactor Design. What expertise did it take to create the Viralink?

PB: First of all, you need to be a bit of a scientist to understand the biology and technology that this involves, you need expertise in mechanical engineering to build the actual structure, analogue and digital electronics in order to build controllers and circuit boards, you need to be able to program and develop an operating system to make it all work. Since I had to design my own circuit boards, I also needed to use PCB CAD systems… and you need a really good manufacturing company to supply you with the parts you need!

X: So, do you have a dedicated team for all that?

PB: Not, it’s only me.

X: Oh, wow! That’s really impressive.

PB: I had to develop the company website as well. As a consultant engineer my slogan was “Why hire 4 engineers when you can hire just me?”.

Safe and Silent

X: Are there any similar products on the market?

PB: No, almost every product that I’ve seen exposes the room directly to the UVC light, which is dangerous for the skin and eyes. There are no systems that perform the destruction of viruses using Viralink Algorithms within the unit and no UVC escapes the chamber. These machines are completely safe.

X: Is it loud?

PB: No, it is very quiet, around 45 db. The system can also be programmed to turn on and operate on a powerful mode, let’s say, an hour before the school class starts so the air is treated several times. When the class starts, it can slow the air flow into a whisper-quiet phase which also increases the Lethality of the Radiation Chamber.

Viralink Can Be Used Anywhere

X: Apparently, this device can be very useful in hospitals and in classrooms.

PB: Not just in these locations, Viralink treats a room…how many rooms are there on the planet? It could be in hospitals, schools, offices, anywhere people are breathing, even on trains or buses.

X: Are there any size limitations?

PB: There are several units that can be adjusted to any room size, even very large spaces like airports. It’s just a matter of how much energy you need to support the units environment. There is a trade-off between the energy of the system and the volume of air you can effectively treat.

What’s Next?

X: Are you going to launch the product on the mass-market now?

PB: Yes, that’s the plan. I always put myself in the position of being an investor. I put together solutions for every question that an investor would ever want to ask: “how does it all work?”, “can it be built?”, “will the electronics work?”, “where do you get all the custom parts?”. What I was a little afraid of was if I were to contact a school district and they ordered 1000 units and I didn’t have the resources to produce all the parts quickly and then they went somewhere else. However, luckily, I have Xometry now that has proved that you can produce spectacular parts on-demand. I’ve been so impressed with the quality of the parts I received. With Xometry as my supplier, we’re certainly ready for mass production.

X: Do such devices require special licensing?

PB: I’ve been told that the hospital system might have stringent requirements but look: it is just a fan and a light. How much certification do you need to operate a light in a room? The important considerations is that there is no exposure to any of the internal UVC Radiation whatsoever. With no high voltage near where the user has contact, so it’s completely safe.

Viralink® is a Registered Trademark, patented filing in the UK and in the USA.

You Simply Can’t Imagine How Accurate It Was

X: What’s been your experience with Xometry?

PB: Finding a competent European supplier was a key requirement for me, so I started looking around and found Xometry that seemed to cater for absolutely everything I was looking for, but I couldn’t believe they could produce all the parts I needed so well and so inexpensively. When the first boxes arrived in January, I was afraid to open them, because if the quality wasn’t good enough I wouldn’t have anywhere else to go to. But when I put it together, you simply can’t imagine how accurate it was. It is a wonderful experience to use Xometry as a supplier, I don’t have to worry about the quality anymore. I’ve done my job as an engineer, you’ve done yours as a supplier, we are ready to assist in fighting this terrible pandemic.

X: If someone were to order VIRALINK tomorrow, are you already in a position to start supplying?

PB: Thanks to Xometry, you can supply me with any quantities of CNC-machined parts and sheet metal very quickly. I already have a few units here that can be used as test units by my customers and we could supply a large number of VIRALINK Machines within 4-6 weeks. These machines need to be sold now because unfortunately, this pandemic is not going away.

More Information About Asepsis Products and Viralink

Product Designations and Specifications

These products have been given the designation: VIRALINK Model Numbers U300A ,B, C, D, E. The lettering denotes the level of UVC Radiation intensity. All units can achieve a remarkable Radiation Intensity Density Flux of over 5,000,000 µj/cm2 which achieves a Log 6 efficiency (99.9999%) in destroying pathogens.

As the strongest Pathogen currently observed requires 800,000 µj/cm2, these devices can easily cope with the infections seen in the current coronavirus pandemic.

Further Information to Review

- Website of Asepsis Air Products Ltd: https://www.asepsisairproducts.com

- Paul Byrne’s CV

- Product Catalogue

Contact Details for further information:

admin@asepsisairproducts.com

UK Mobile: +44 7523 437 725

UK Land: +44 1792 937 632

US Freephone: +1 214-646-3257

Europa

Europa  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط