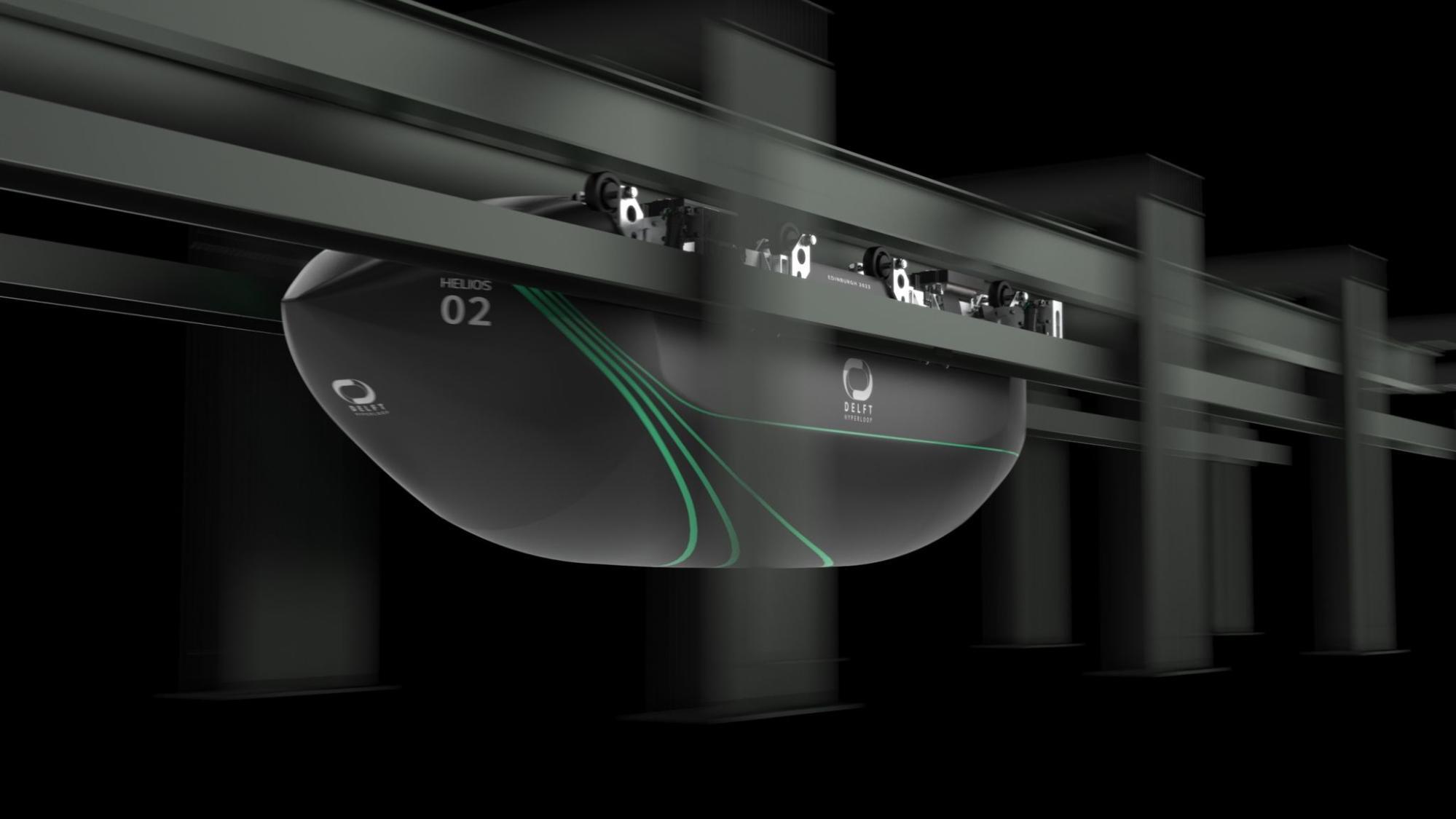

Video case

Video case

Alemania

Automation robotics for assembly tasks

Franka Robotics, formerly known as Franka Emika, is a leading robotics company based in Munich. Their Franka Production 3 robot system demonstrates the immense capabilities through an automated assembly line process. In order to successfully demonstrate the robots’ potential during the exhibitions and trade shows, they designed an automated assembly line with 2 robotic systems performing a custom engraving operation and assembling a bottle opener from 2 parts.

Showcasing Robotics Through Real-World Demonstrations

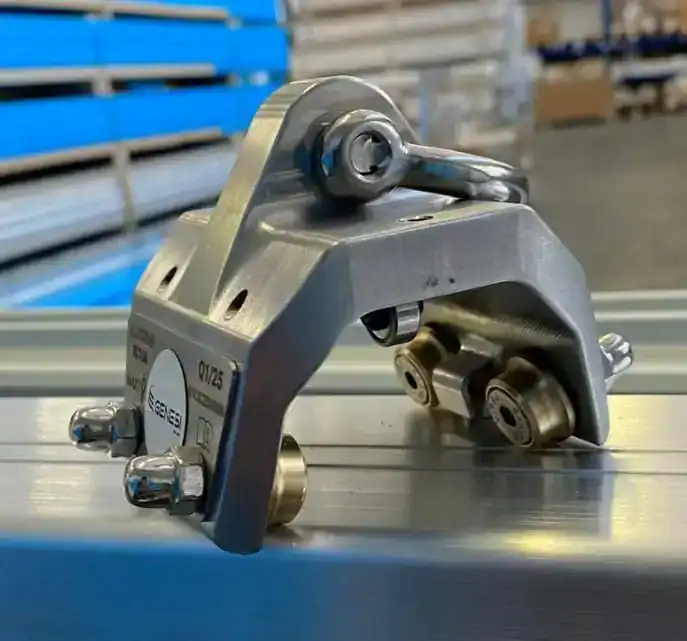

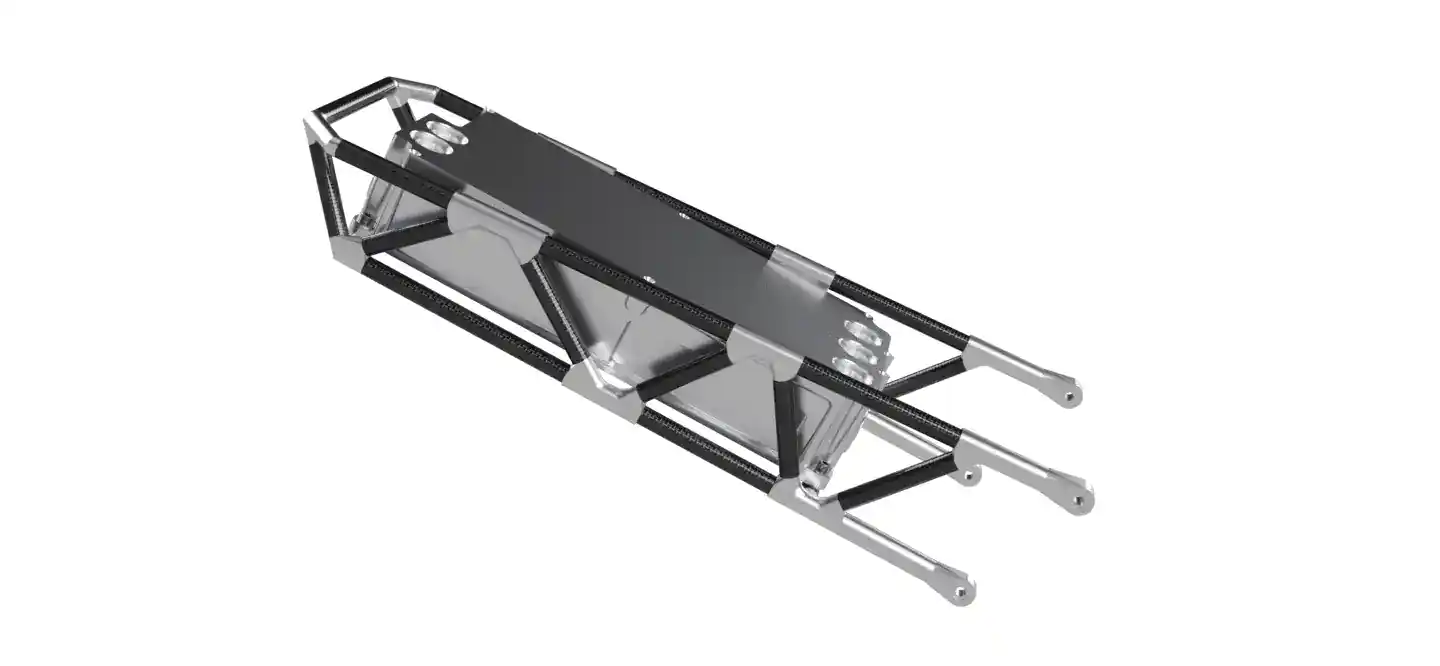

Partnering with Xometry, Franka Robotics sought to produce two essential metal parts for their demos: CNC machined handle with a cosmetic anodised finish and thin sheet metal inlay for a bottle opener assembly. Both components were manufactured in quantities of 3000 pieces each.

Watch this interview conducted by Nick Chambers, Director of Portfolio Business Strategy at Franka Robotics, with Nikolaus Mroncz, Head of Sales Engineering at Xometry, at the exhibition where Franka Robotics showcased their the Franka Production 3.

Engineering Support for High-Quality Components

Xometry’s engineering support team provided invaluable guidance on material selection, particularly for the 2 mm inlay sheet metal part. It was crucial for this component to be thin, cost-effective, yet strong enough to withstand repeated use without bending. The team initially navigated through numerous iterations and material options, including plastic and steel.

Following Xometry’s recommendation, Franka Robotics team chose aluminium 7075, renowned for its strength and durability. As a result, after successful prototyping, they ordered several thousand parts directly via Xometry’s Instant Quoting Engine® for a bottle opener assembly.

Learn more about Franka Robotics: https://www.franka.de/

Europa

Europa  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط