AADS, a leading provider of mobility solutions for defence and security sectors, partnered with Xometry to overcome critical manufacturing challenges, accelerating the product development and build for their militarised ambulance vehicle conversions.

Spojené království

Ambulance vehicles for defence applications

Partnering with Xometry made perfect sense for us. Their model freed us from supply chain worries so we could focus on our core work. Knowing they had all the necessary fabrication and manufacturing links meant we didn’t have to find suppliers ourselves – that was key.

About AADS

AADS established in 1904, specialises in custom vehicle conversions for military and government organisations. Born out of the Jeep J8 project in 2007, AADS transforms standard off-the-shelf vehicles into bespoke solutions, including troop carriers, ambulances, patrol vehicles, and command vehicles.

Their mission is to provide comprehensive mobility solutions, encompassing integrated logistical support, parts supply, and extensive training for end-users, covering mechanical and driving skills, as well as after-sales support and warranty services through local partnerships. With a team of fifty, AADS delivers high-mobility, robust vehicles tailored to specific customer requirements, primarily for the US Department of Defence and direct government sales.

The Challenge: Accelerating Production for a New Model of Their Militarised Ambulance Vehicle

AADS faced a significant challenge with a new project involving the conversion of an ambulance for the new Jeep J8 Wrangler model. While ambulance conversions were a standard offering, this was the first time they were applying it to the updated vehicle model. This meant all designs and engineering had to be redone from scratch, including the body extension, fibreglass roof, and internal ambulance pod. The biggest hurdle was the tight timeframe: approximately 12 months from order to delivery, with vehicles needing to be ready for logistics within eight months. AADS’s engineering team was already heavily committed to other large orders, so finding a manufacturing solution was critical to the rapid production of the vehicle roof frame for these ambulance vehicles.

The Solution: Xometry’s On-Demand Manufacturing Expertise

AADS originally discovered Xometry through a search for manufacturing partners capable of providing rapid prototypes. The instant quoting engine, allowing for quick iteration on designs and cost implications, immediately stood out. AADS rapidly expanded their use of Xometry’s manufacturing services to include metal fabrication, which supported their need for high-volume series parts.

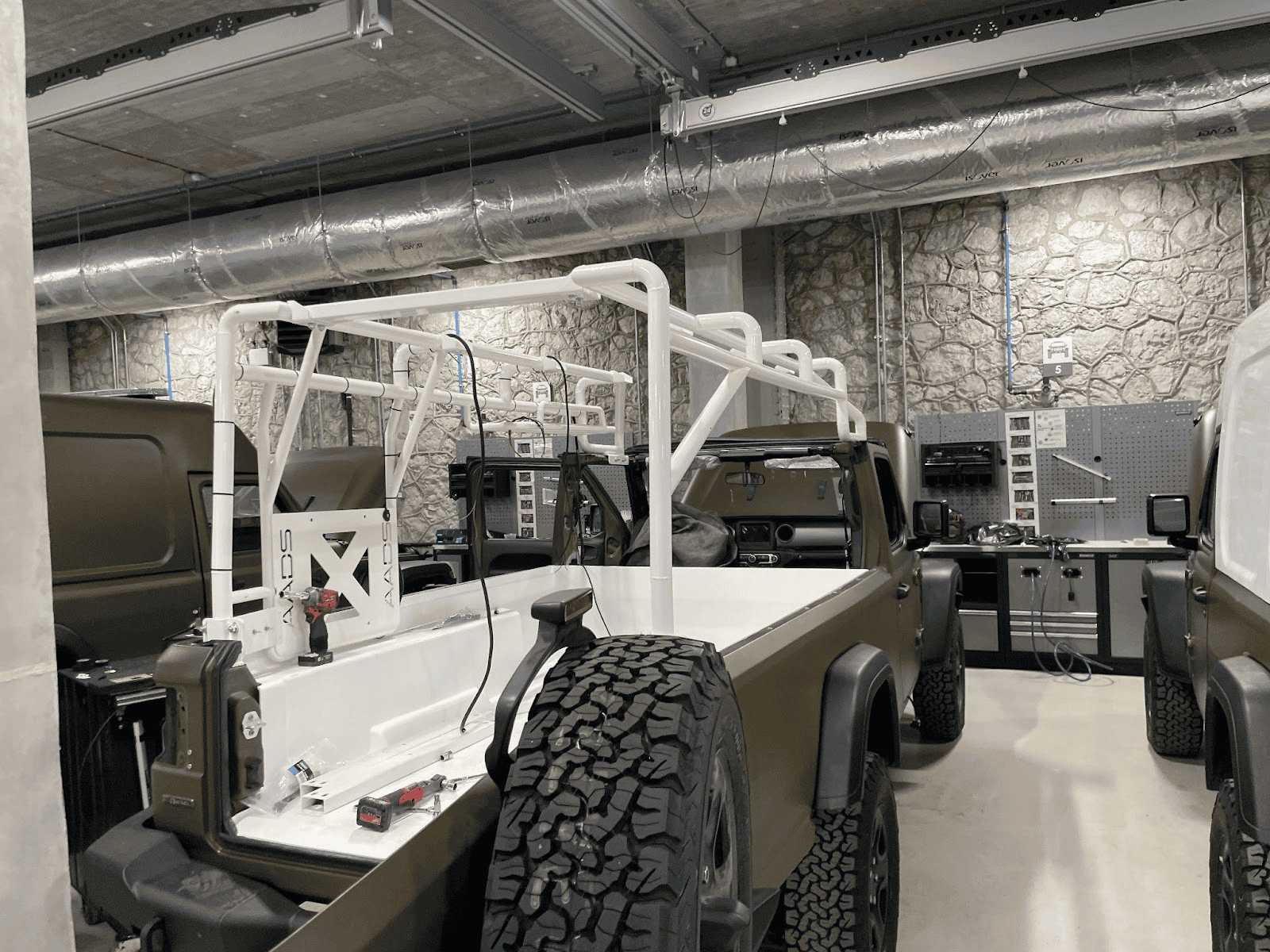

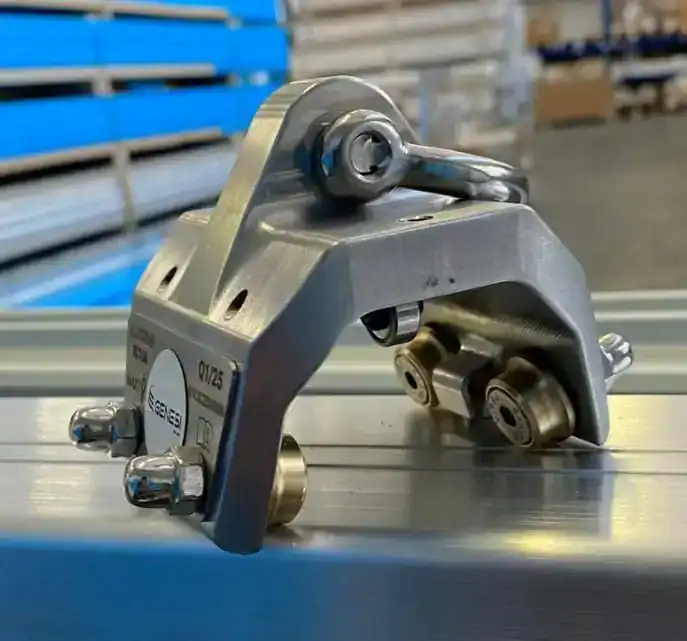

For the militarised J8 Jeep Wrangler ambulance vehicle fleet, Xometry manufactured two main steel-fabricated components:

- Body Extension: A 550mm steel extension to the vehicle’s body, crucial for creating the necessary space for the ambulance conversion.

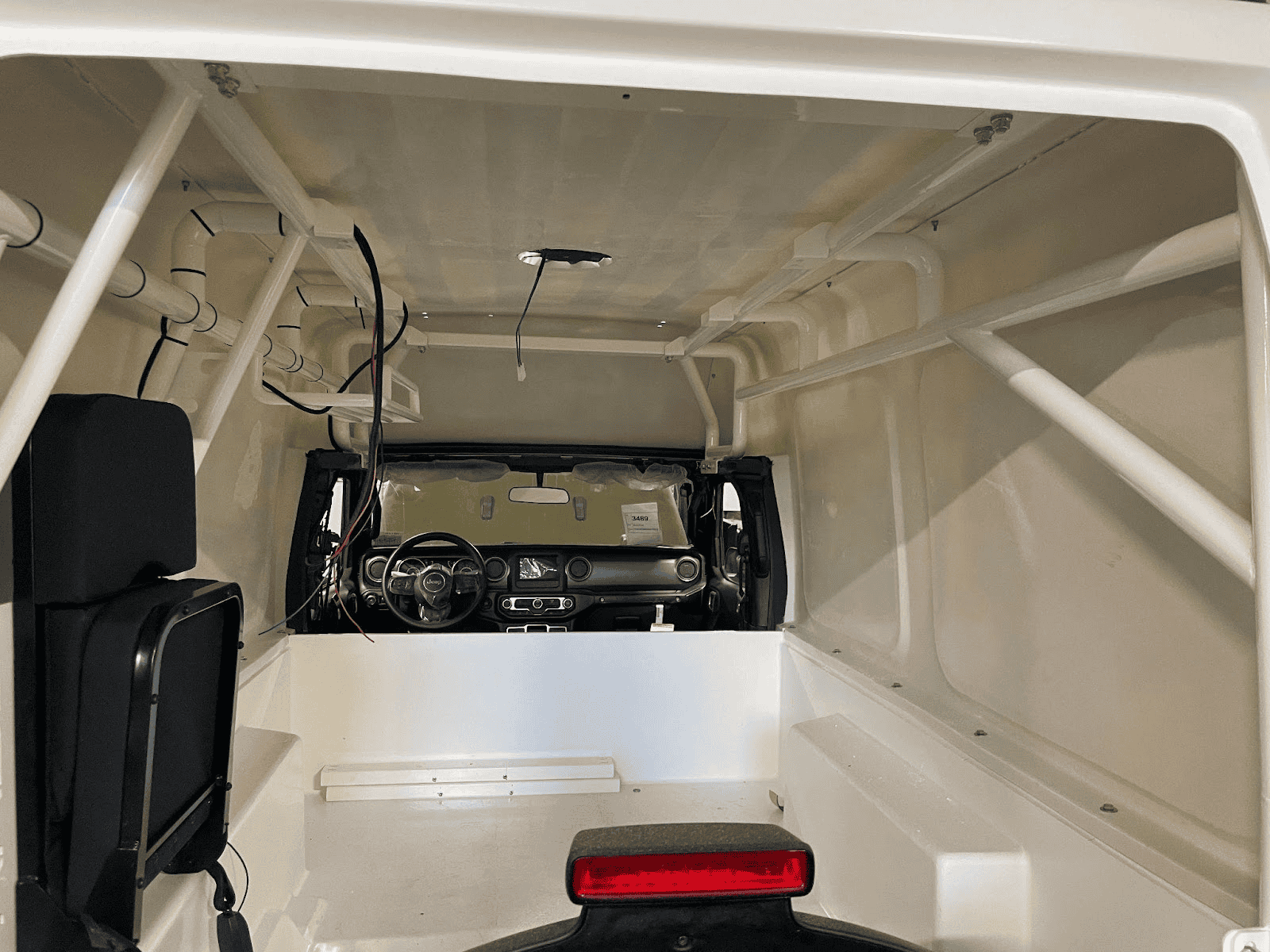

- Safety Cage Structure: A tubular steel framework providing additional rigidity to the body, supporting the patient attendant seat, and helping to support the fibreglass roof structure.

The steel tubular vehicle roof frame, finished in a white powder coating durable paint, was used as a safety cage structure to provide additional rigidity to the body, support the patient attendant seat, and help support the fibreglass roof structure.

From a manufacturing perspective, this was a significant component in the ambulance vehicle, being a structural element of the build. AADS received a first-off sample from Xometry to ensure accuracy against drawings and tolerances.

Mark Jensen, Head of Technical and Production at AADS, commented on their initial experience: „The Xometry website was fantastic; just dragging and dropping a CAD model gave us instant pricing feedback. Being able to instantly change materials or manufacturing processes was incredibly useful.“

Xometry’s capacity to deliver a comprehensive solution—ranging from manufacturing the steel frame, to connecting AADS with a network of qualified suppliers and managing logistics—proved to be invaluable. This support relieved AADS of the burden of sourcing and managing multiple suppliers, allowing their engineering team to concentrate on core design and development. Importantly, Xometry’s high-volume manufacturing capabilities in steel fabrication and welding ensured that AADS could meet the demanding production quotas for these essential components within tight deadlines.

The Results: Quality, Speed, and Flexibility

AADS was highly satisfied with the quality of the parts supplied by Xometry. The process involved initial samples for test fitting and minor tweaks, ensuring that the final production parts met their exact specifications.

„Partnering with Xometry made perfect sense for us. Their model freed us from supply chain worries so we could focus on our core work. Knowing they had all the necessary fabrication and manufacturing links meant we didn’t have to find suppliers ourselves – that was key.“ – Mark Jensen, Head of Technical and Production, AADS.

Key advantages of partnering with Xometry for AADS included:

- Instant Quoting Engine: Enabled engineers to quickly iterate on designs and understand cost implications during the development phase.

- Expanded Supplier Base: Provided access to a wide range of manufacturing capabilities, particularly for metal fabrication, which was crucial for their high-volume production needs. Xometry’s capacity for high-volume steel welding was instrumental in delivering the necessary components efficiently.

- Streamlined Procurement: Xometry’s platform simplified the procurement process, reducing the laborious task of engaging with numerous individual suppliers.

AADS on The Future: Diversification and Continued Partnership

AADS is focused on diversifying its product portfolio and customer base, leveraging new vehicle platforms from the wider Stellantis group. They aim to expand into additional products to service a broader market and provide more value to their customers. AADS anticipates continuing their partnership with Xometry, viewing them as a valuable supplier for their ongoing and future manufacturing needs.

Visit the AADS website to learn more: aads-gib.com

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط