Video case

Video case

Turkiet

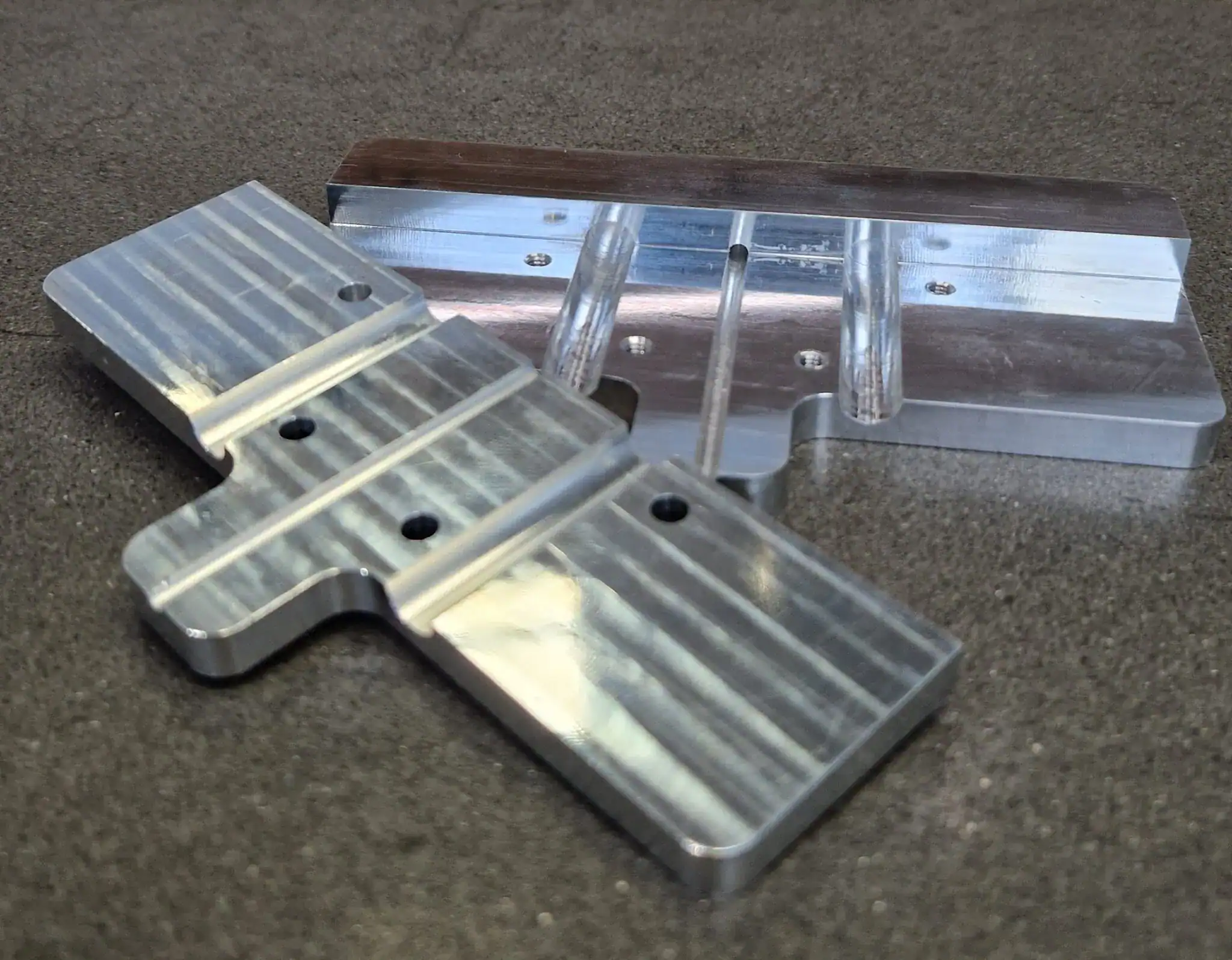

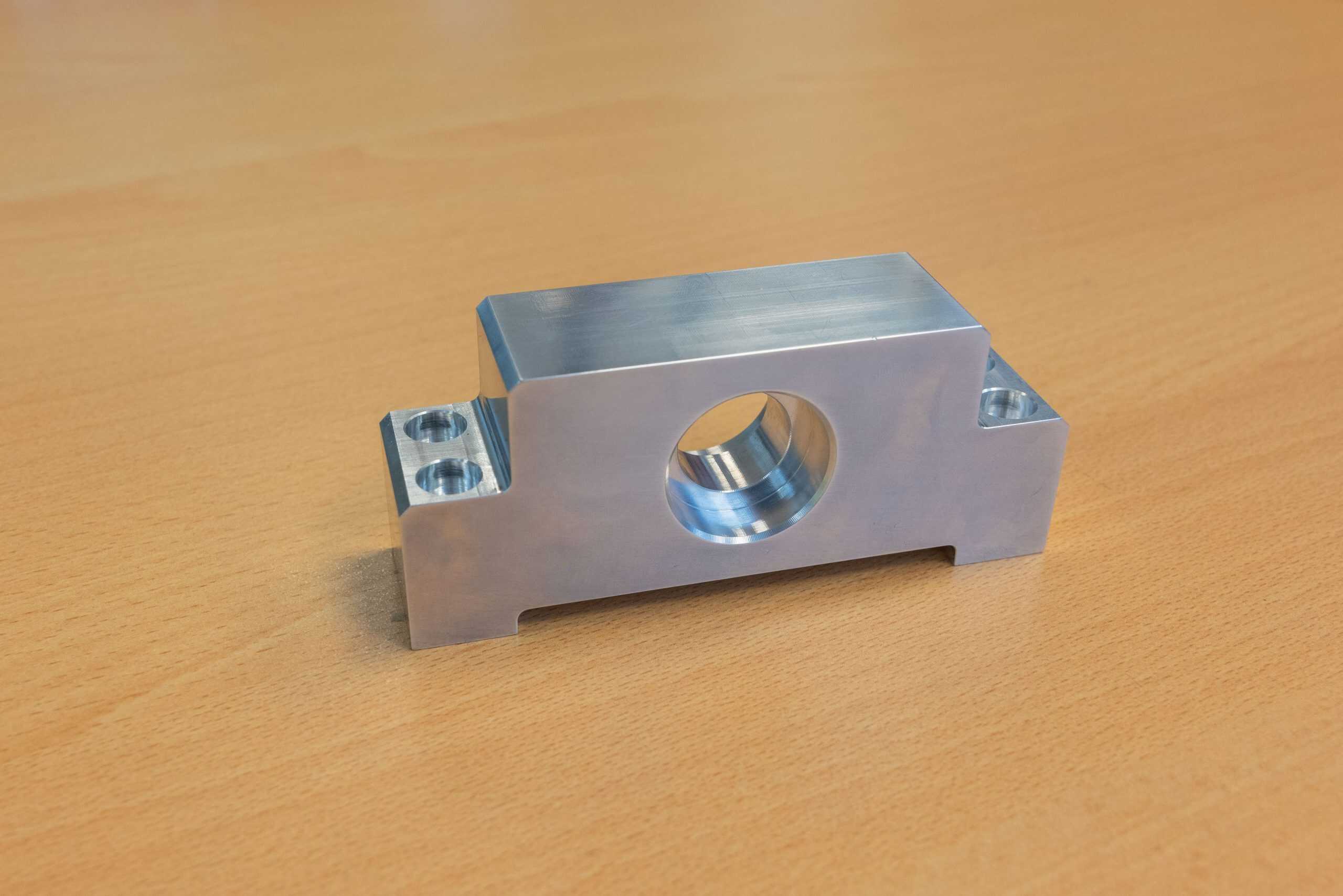

Aluminum 7075, 5083, 6082, 6061, and Steel C45, C40

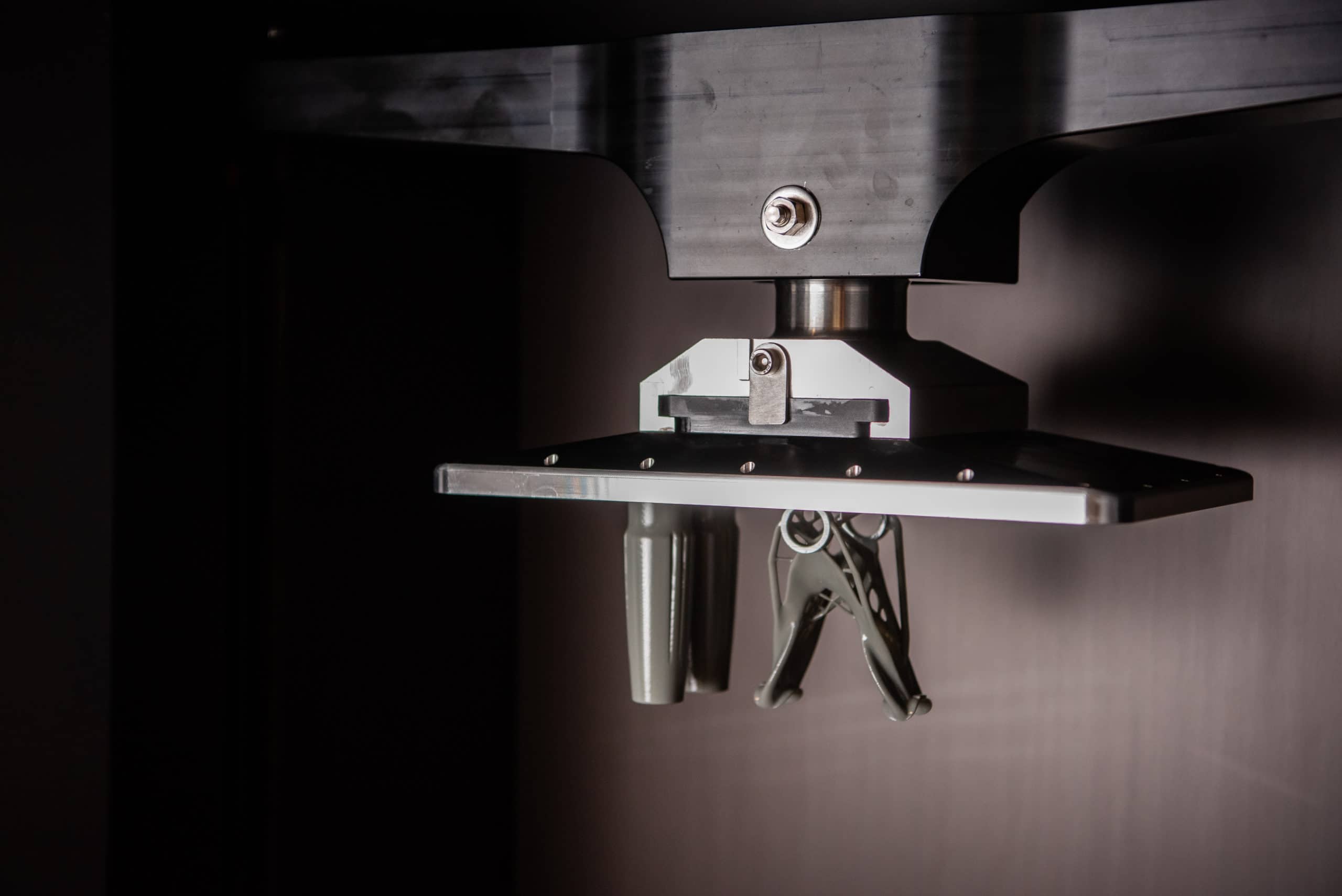

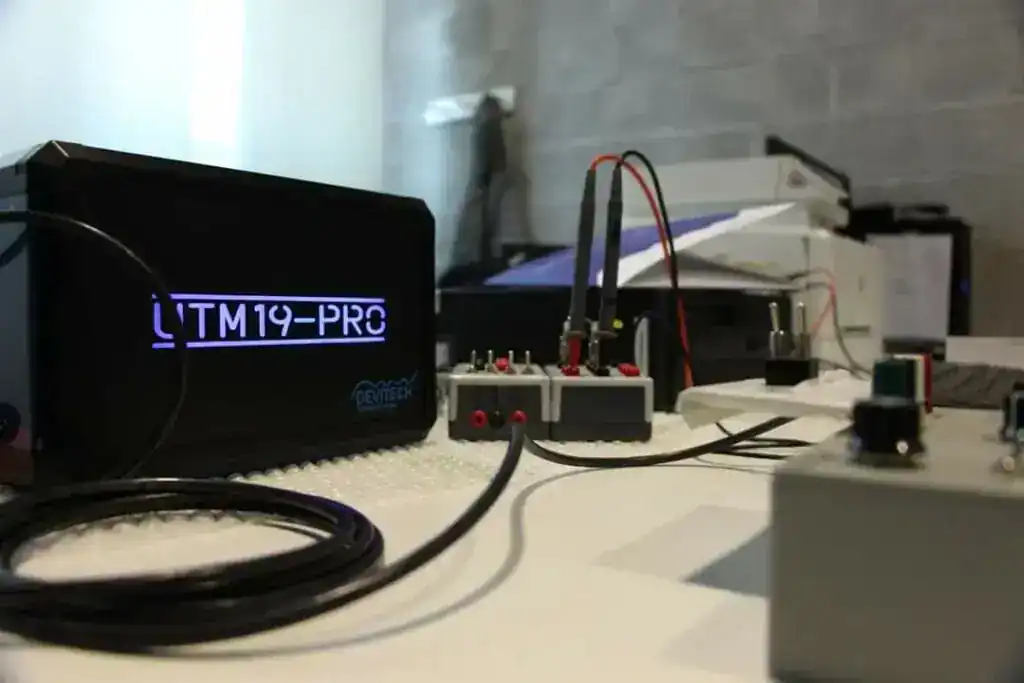

High-precision measurement machines

Thanks to your wide supplier network, we received the parts quickly and smoothly, and since then, we’ve collaborated on various projects.

Gökser Vision Measurement Systems, based in Gebze Technopark, specializes in designing and manufacturing optical devices, measurement machines, and metrology systems. Known for innovative products like the Easy Shaft Series, the company prioritizes local production and technological advancement.

We spoke with Gökser Vision founders Serkan Safi and Gökhan Hankolu to learn how they utilized Xometry’s on-demand manufacturing services to streamline their production processes, reduce costs, and accelerate their journey from prototyping to mass production.

Challenges in Manufacturing High-Precision Equipment

Founded in 2017 by Serkan Safi and Gökhan Hankolu, former technical service engineers at a prominent national company, Gökser Vision caters to corporate clients in industries such as automotive and defense, where high-precision measurement devices are essential.

The company faced significant challenges in its production and supply processes, including long lead times and quality issues. While working on a brake disc control machine, Xometry’s ability to deliver laser-cut parts quickly and seamlessly for a revision strengthened Gökser Vision’s confidence in their services.

Managing multiple R&D and prototyping projects simultaneously, Gökser Vision had to rely on various suppliers, some of whom were based abroad. This introduced challenges such as customs delays, communication barriers, extended lead times, and occasional quality inconsistencies. These issues led to both time losses and additional costs.

Reflecting on their first experience with Xometry, co-founder Serkan Safi shared:

This initial collaboration marked the beginning of a partnership that would encompass numerous prototyping and mass manufacturing projects.

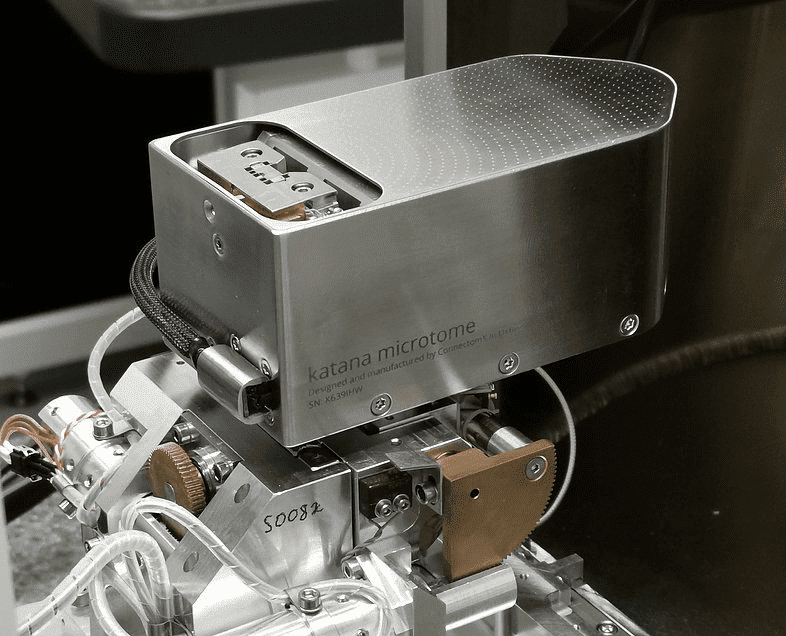

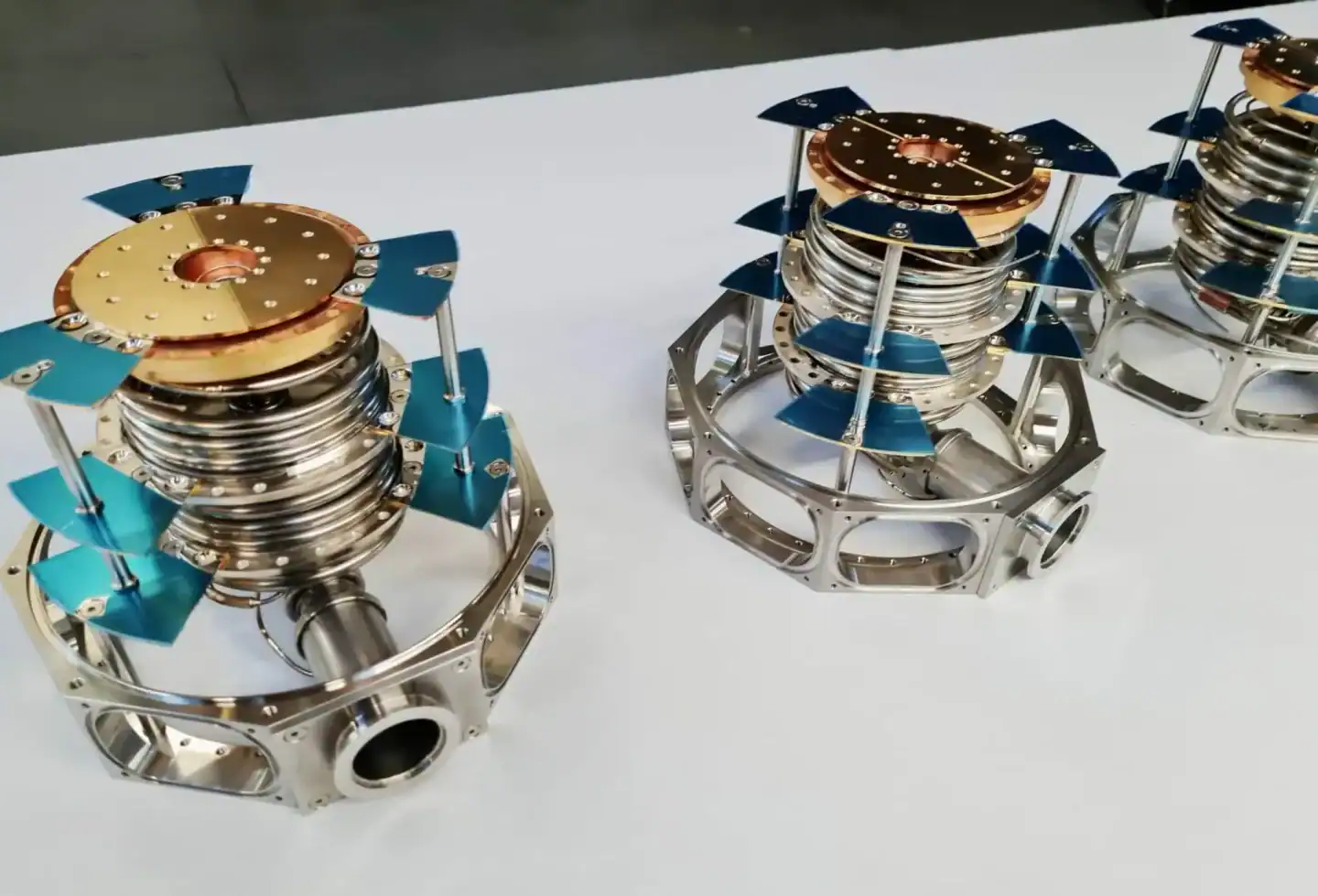

Easy-Shaft Series: Precision Redefined

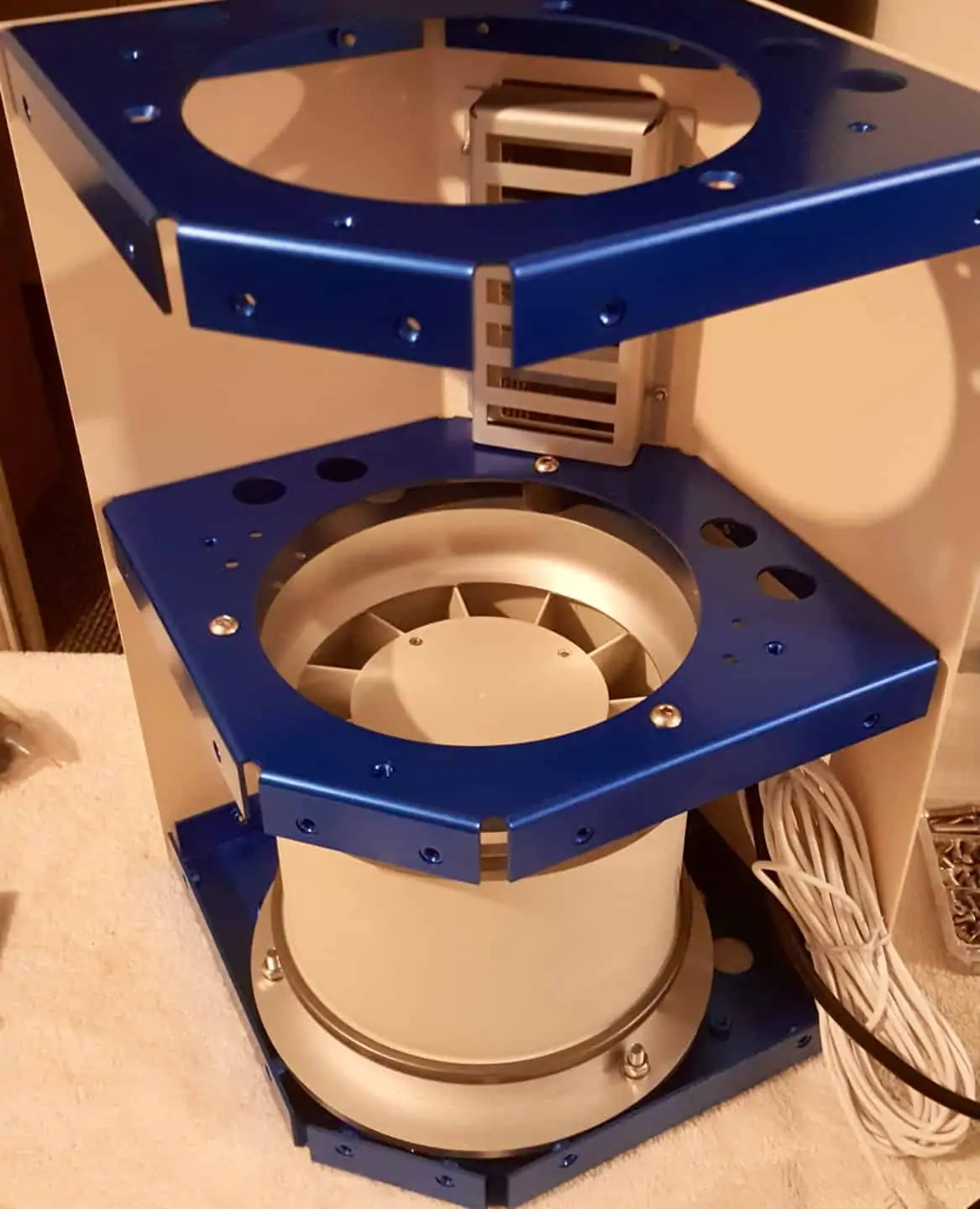

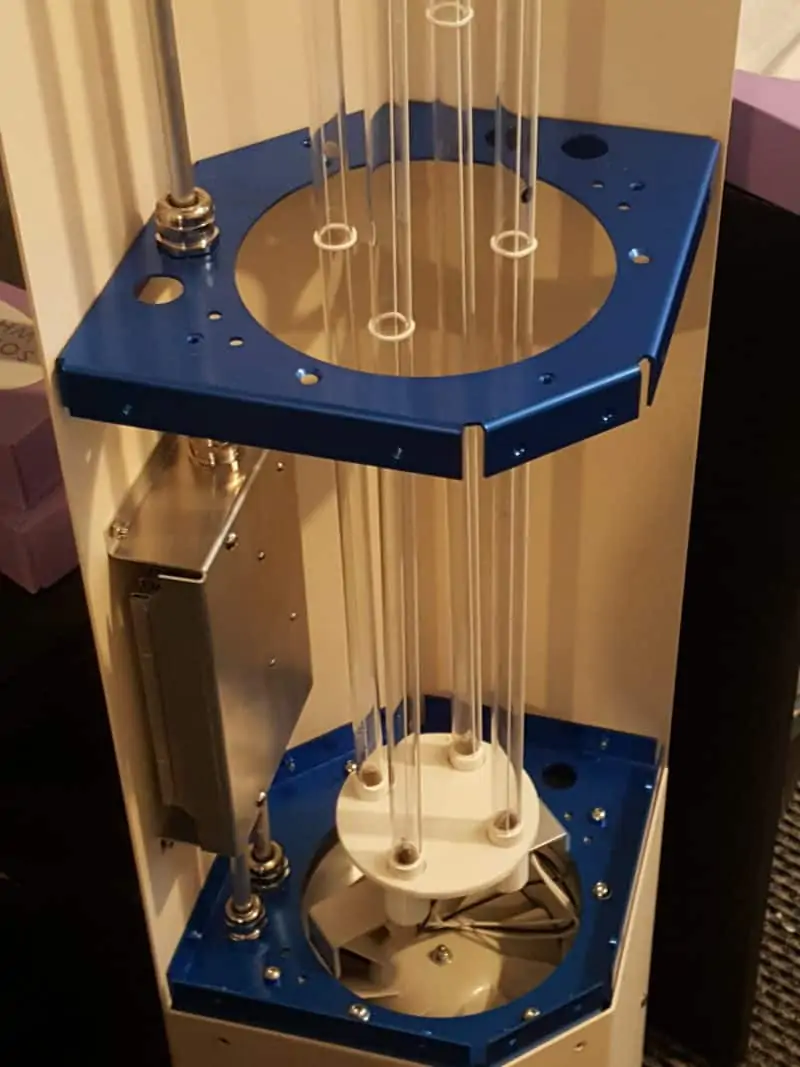

The Easy Shaft Series is one of Gökser Vision’s most advanced technological innovations. In addition to this, the company manufactures a wide range of products, including optical devices, industrial cameras, machine vision lenses, lighting systems, filters, and measurement equipment. Since its founding, Gökser Vision has developed numerous camera-based measurement devices, producing electronic circuit boards and software in-house to ensure complete control over quality and functionality.

The Easy Shaft Series includes various machines tailored to specific applications. The Easy Shaft Nano is designed for small parts, such as dental implants, while the Easy Shaft 350 and 550 are high-precision measurement devices for industrial applications. Xometry’s expertise has been instrumental in producing critical components for these models, including shaft spindles, sleeve mounts, engine bearings, and moving tailstocks.

Currently, Gökser Vision is preparing to launch the Easy Shaft 750 Series, a machine capable of measuring up to 750 mm. This cutting-edge product places Gökser Vision among only three companies globally that produce such advanced measurement devices. Once again, Xometry is playing a key role in the production of essential components for the Easy Shaft 750 right now.

From Prototyping to Mass Production

While Gökser Vision had extensive experience with prototyping, their collaboration with Xometry became more intensive as they transitioned to mass production. Some of their projects required the production of numerous parts and the management of complex supply chain solutions. To address these needs, Xometry’s manufacturing partners in Turkey and China handled the production of intricate components.

Co-founder Gökhan Hankolu explained that, before partnering with Xometry, the company considered investing in CNC machines and hiring additional staff.

However, they ultimately decided against it due to the comprehensive solutions offered by Xometry’s digital platform:

Flexibility and Cost Optimization with the Framework Model

Serkan Safi highlighted that one of the most significant advantages of collaborating with Xometry was the framework model they offered. This service enabled Gökser Vision to receive Easy Shaft components in stages, helping them reduce stock costs and optimize production planning.

Serkan further elaborated on how Xometry’s solutions contributed to cost optimization:

Looking Ahead: Local Innovation and Global Ambition

Gökhan Hankolu outlined the company’s future vision:

The company aims to provide locally manufactured measurement machines and equipment to all manufacturing workshops across Turkey while also expanding into the global market.

For more information about Gökser Vision’s innovative products and vision, visit https://www.gokservision.com/

To learn more about Xometry’s manufacturing capabilities, explore our production and supply solutions.

Europa

Europa  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط