DocCheck specialises in the development and production of medical products and has grown into a leading supplier and trading platform for medical and practice supplies in Europe. It focuses on redesigning medical devices (stethoscopes, diagnostic lights, reflex hammers) with a strong emphasis on functionality and design aesthetics.

Vokietija

Medical devices redesigned and mass‑produced, including: Clôppe reflex hammer, tulip stethoscope, Lûx rechargeable diagnostic light, auris anatomical ear model.

If it’s not close enough to the reference model, Xometry is very helpful and we get a new one based on our feedback until we’re completely sure that’s the right quality we want. Xometry is always there to help us and is focused on delivering the best possible solution.

puts great emphasis on improving the functionality and efficiency of medical devices such as stethoscopes, diagnostic lights, and reflex hammers without compromising on design and aesthetics. DocCheck Thïngs is the company’s own-brand range that specifically concentrates on the product design of its own medical products. We spoke to David Marshall, Head of Product Design at DocCheck, who oversees the development of innovative medical products.

DocCheck Was Looking for an Efficient Way to Implement New Designs & Quality Standards

Rethinking medical products in terms of both functionality and design is a major challenge in the healthcare sector. It’s important that products aren’t just aesthetically pleasing, but also meet the strict medical requirements. Full of ideas and with a strong desire to introduce its own products to the market, the company created.

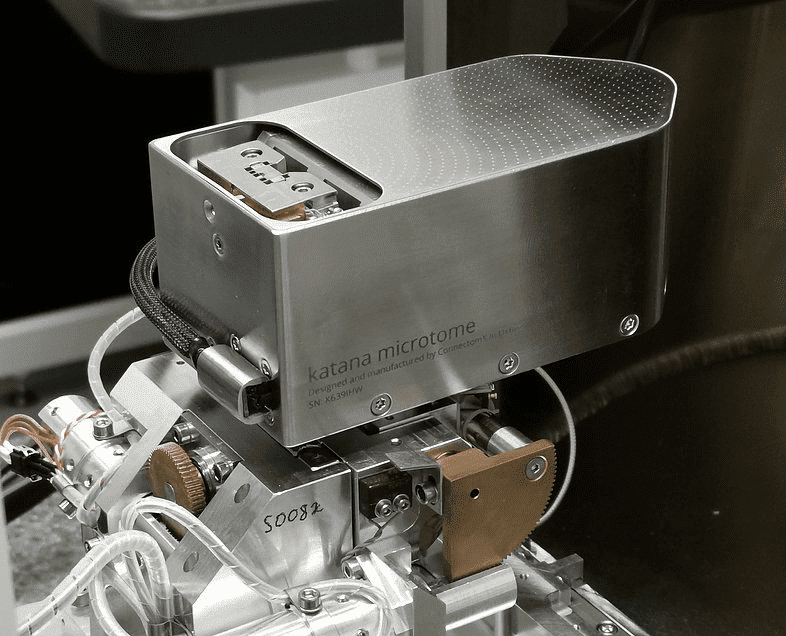

DocCheck is in a perfect position to do this since it already knows exactly what bothers customers about certain products via the platform, giving the team an ideal basis for building an optimal product based on this feedback. They first started with the “Clôppe” percussion hammer for triggering reflexes. Not only did this reflex hammer need to be more robust, it also had to stand out from the rest of the market in terms of design. This particular product, which was created in collaboration with Xometry, was awarded the prestigious Red Dot Design Award in 2022.

Marshall says: “…it was an instant success, a real head-turner!”

A Collaborative Partnership for Other Products

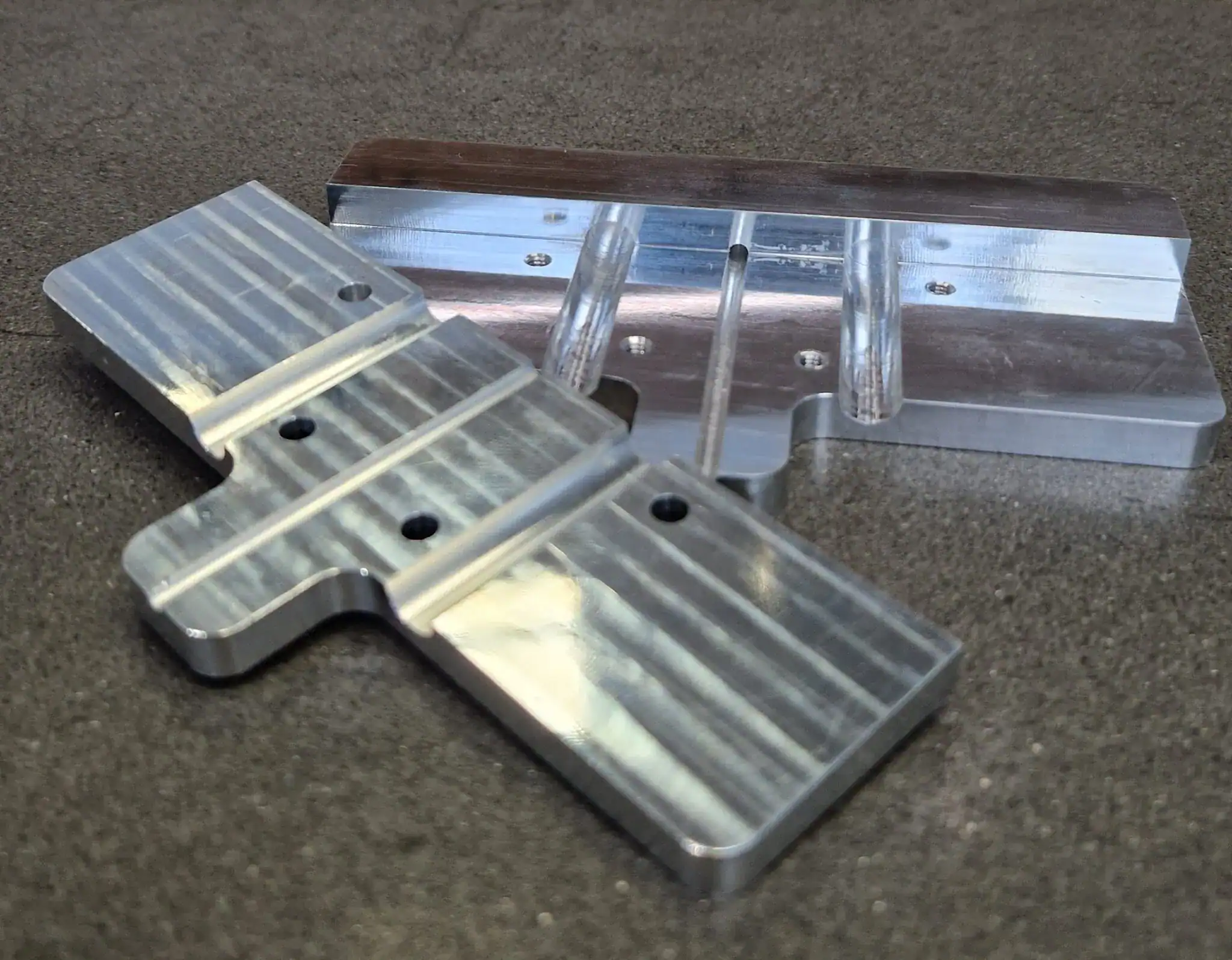

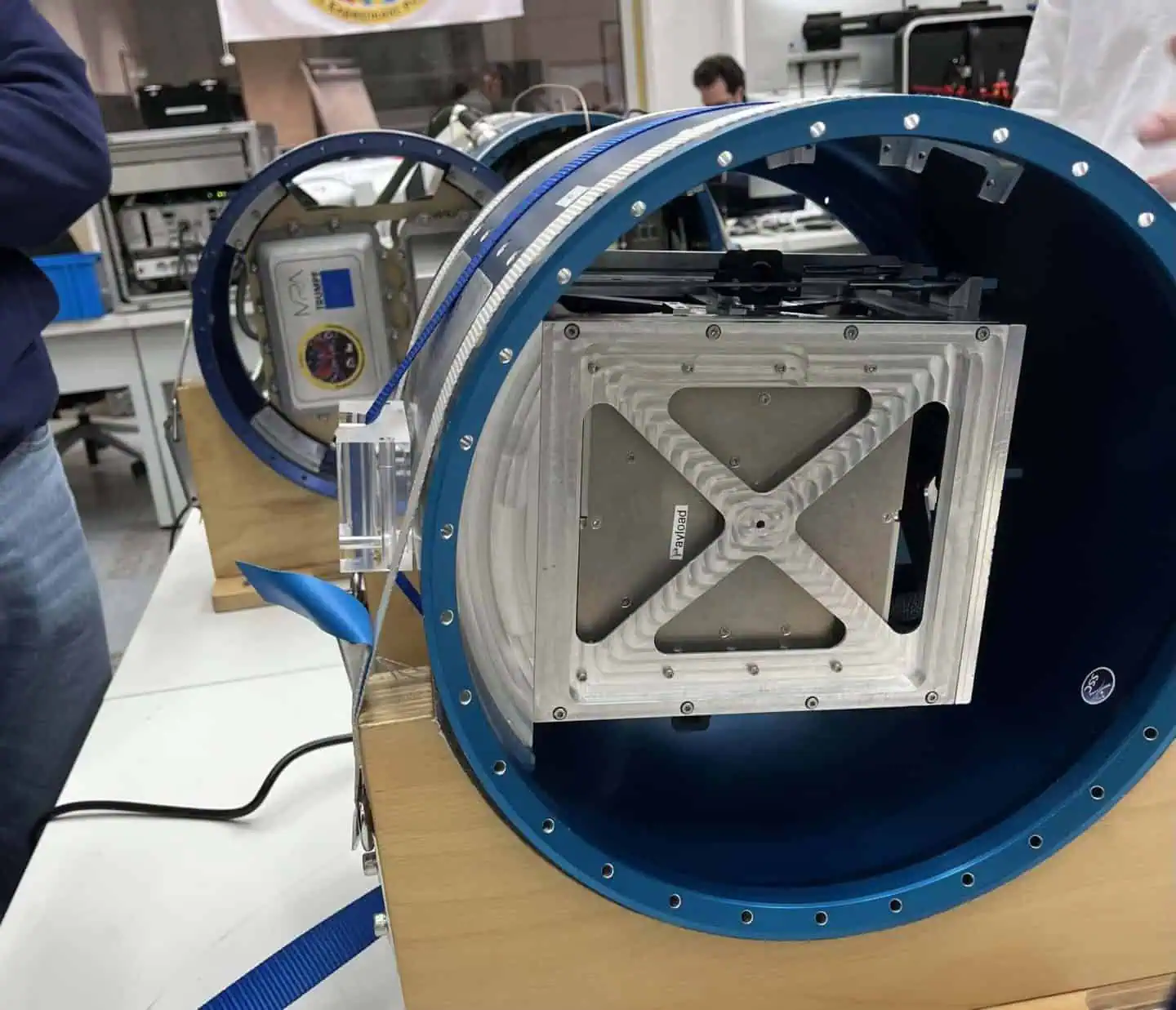

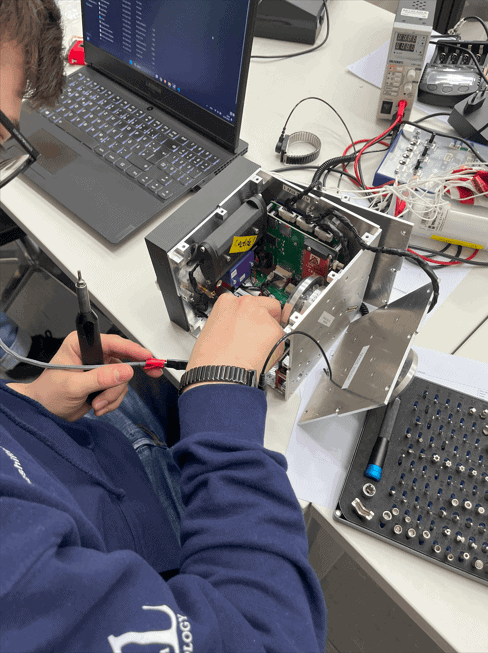

The tried-and-tested approach for the Clôppe reflex hammer is now being used to develop other products. DocCheck can create in-house prototypes itself using FDM 3D printing and high-precision CNC machines, which gives it quick access to reference models. Once a reference model is completed, the step file can simply be uploaded to Xometry and a sample is then sent from Xometry. Because DocCheck has such good facilities on site to produce a reference model, they can judge exactly how good the quality of the sample from Xometry is.

“If it’s not close enough to the reference model, Xometry is very helpful and we get a new one based on our feedback until we’re completely sure that’s the right quality we want. Xometry is always there to help us and is focused on delivering the best possible solution,” says Marshall.

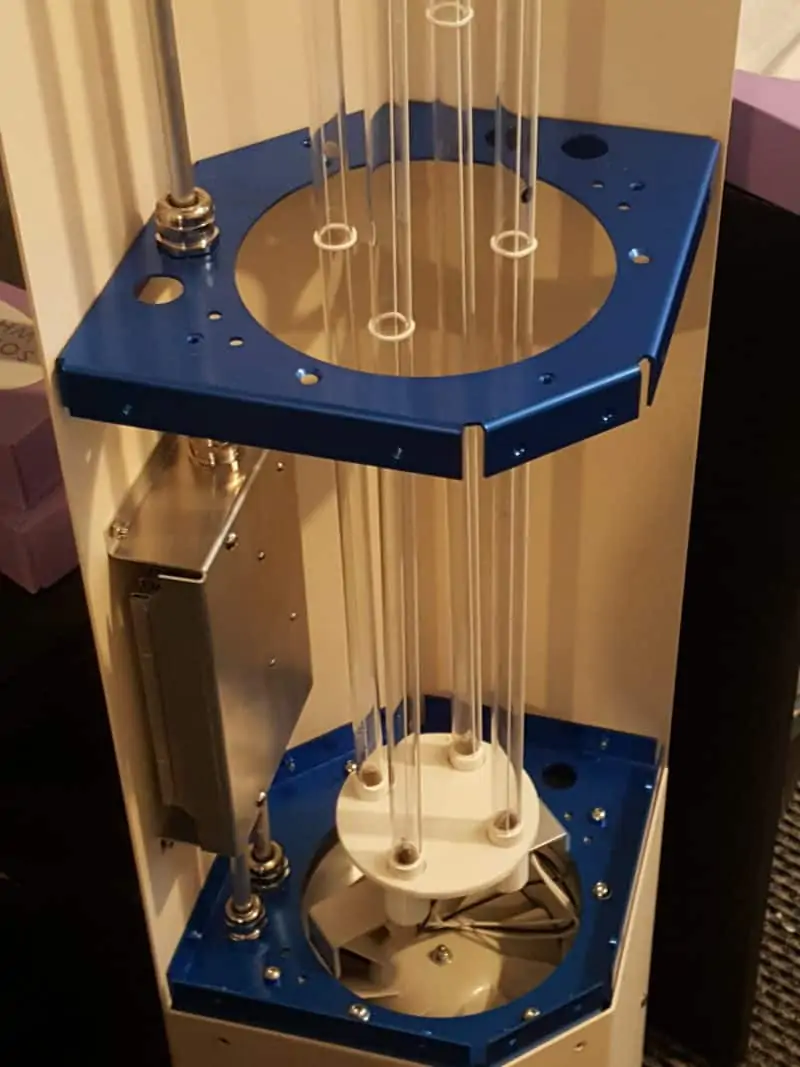

DocCheck uses a variety of manufacturing processes to produce their products, including CNC machining and injection molding. For example, they have developed their own stethoscope, “Tulip”, where both the mounting ring and the stethoscope itself are produced via Xometry.

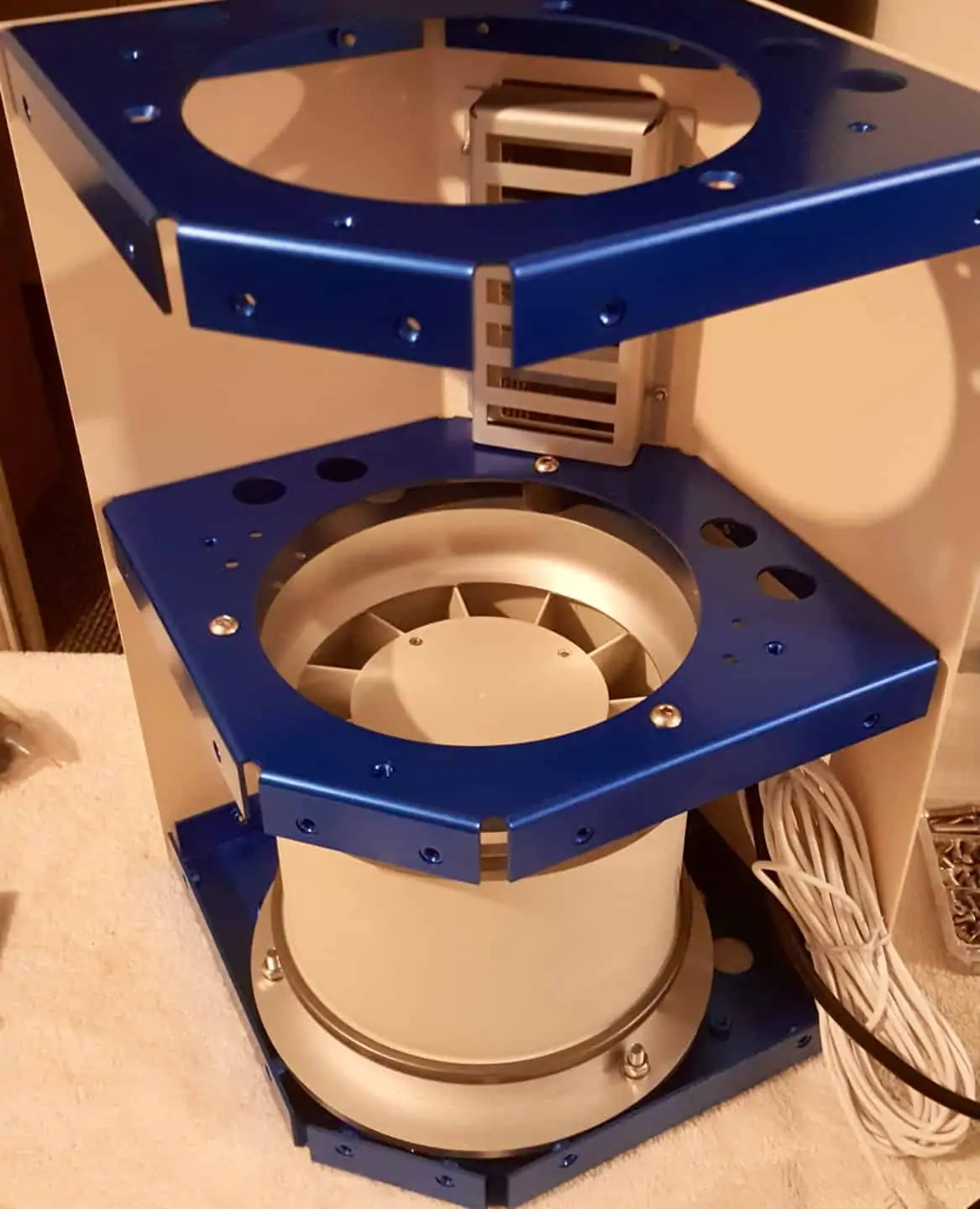

Another example of DocCheck and Xometry working closely together is the “Lûx” diagnostic light. Similarly to other products, DocCheck analysed exactly how the product could be improved, which resulted in a rechargeable diagnostic light made from injection moulded and CNC parts.

Marshall reports: “We designed the product in-house, uploaded the model to Xometry’s Instant Quoting Engine and, with the help of our personal contact Oleg Ermakov, we received the samples. So apart from the batteries, you can say that this product is a complete collaboration between us and Xometry—we provide the design and Xometry makes it!”

The feedback from DocCheck employee Azad Ahmad illustrates the success of the collaboration to date: “Despite our extremely demanding design requirements, we have successfully implemented several projects in close collaboration with Xometry. Working with Xometry has enabled us to overcome the challenges of our complex design requirements while maintaining our quality standards.”

An Extension of the in-house Team

In addition to injection molding and CNC machining, DocCheck has also used other processes to produce its products. For example, the Auris product, an anatomical ear model, is 3D printed using the MJF process. Once again, this product followed the same established process used for others. DocCheck has the in-house capability to manufacture this product and so a perfect reference model had also been created already, which served as the basis for Xometry.

DocCheck once again decided to rely on Xometry because, although they can easily produce prototypes, they are not able to mass-produce the product internally at low cost.

In addition to the excellent quality of the products, the crucial element of this close collaboration between DocCheck and Xometry is the relationship that has developed and strengthened over time.

Marshall explains: “I always have the same contact person, I always work with the same engineer and this has also resulted in friendship. It feels like I’m not just a Xometry customer, it’s more like Xometry is part of my team through this relationship!”

What the Future Holds

The partnership between DocCheck and Xometry remains strong and promising. The team is already implementing a new version of the reflex hammer with an interchangeable head. DocCheck also plans to develop and manufacture other innovative medical products in which Xometry will play a key role in manufacturing. For example, there will probably also be a gold-plated variant of the stethoscope in the future. In short, the combination of DocCheck’s creative product design and Xometry’s manufacturing expertise will continue to deliver outstanding results in medical & practice supplies.

This is also illustrated by the feedback from DocCheck employee Annalena Stolte, who adds: “The collaboration with Xometry simplifies many steps in the development of our products. The reasons for this include the expertise of their engineers and the fact that their team supports us in development by helping us choose the right material, for example. The communication with Xometry is also great, so we always find the best solution together. Not only do we buy the finished components from Xometry, but we also test our prototypes at Xometry, meaning their team supports us throughout the development of a product and has done so for multiple products now. The quality of the parts is always very pleasing, so we will continue to work with Xometry in the future.”

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط