Xometry helped the Rocketry Department from Aristotle Space & Aeronautics Team (ASAT) manufacture key components for a high-power rocket, enabling participation in international competitions.

Grieķija

Aluminium grade 6061 (aerospace-grade)

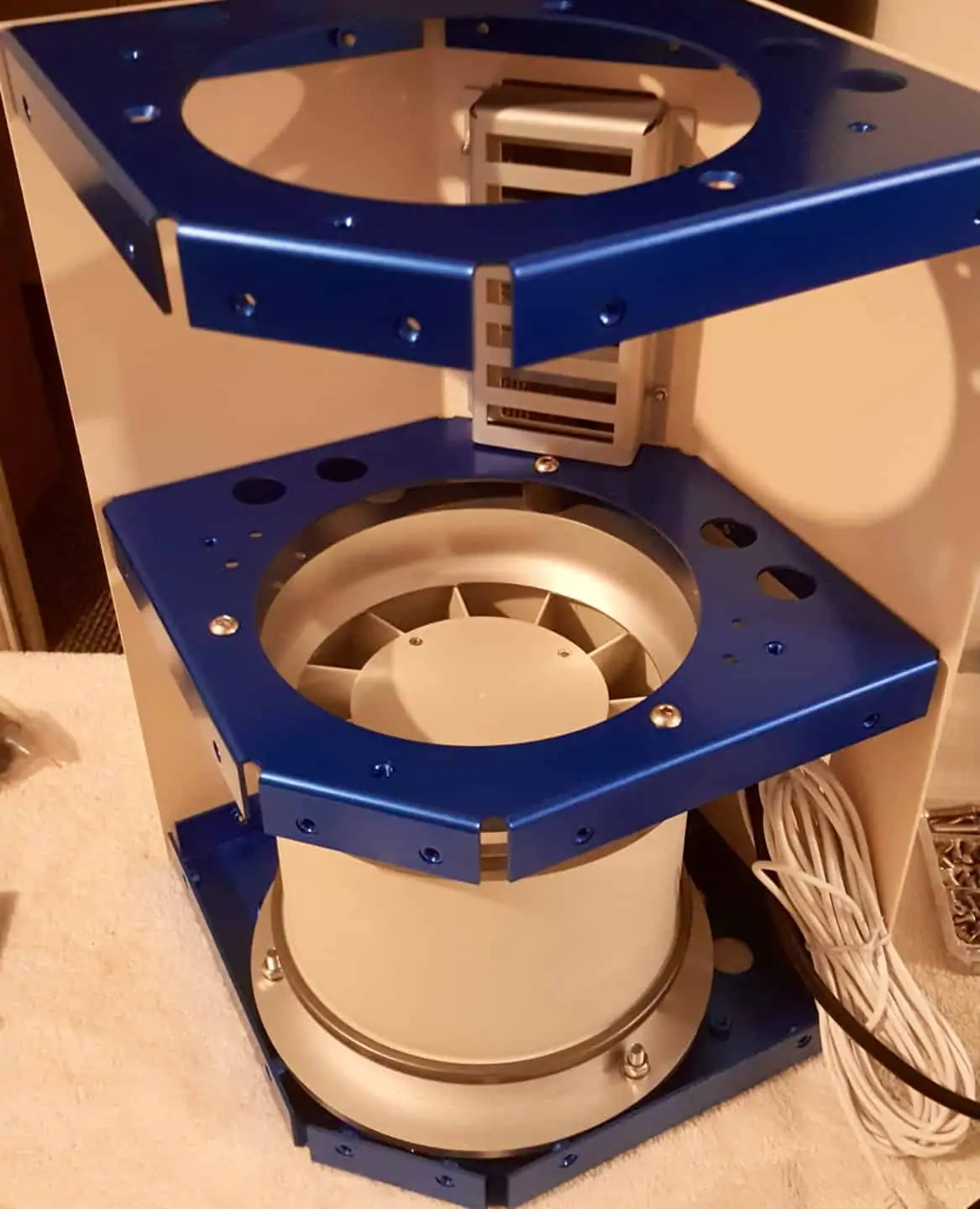

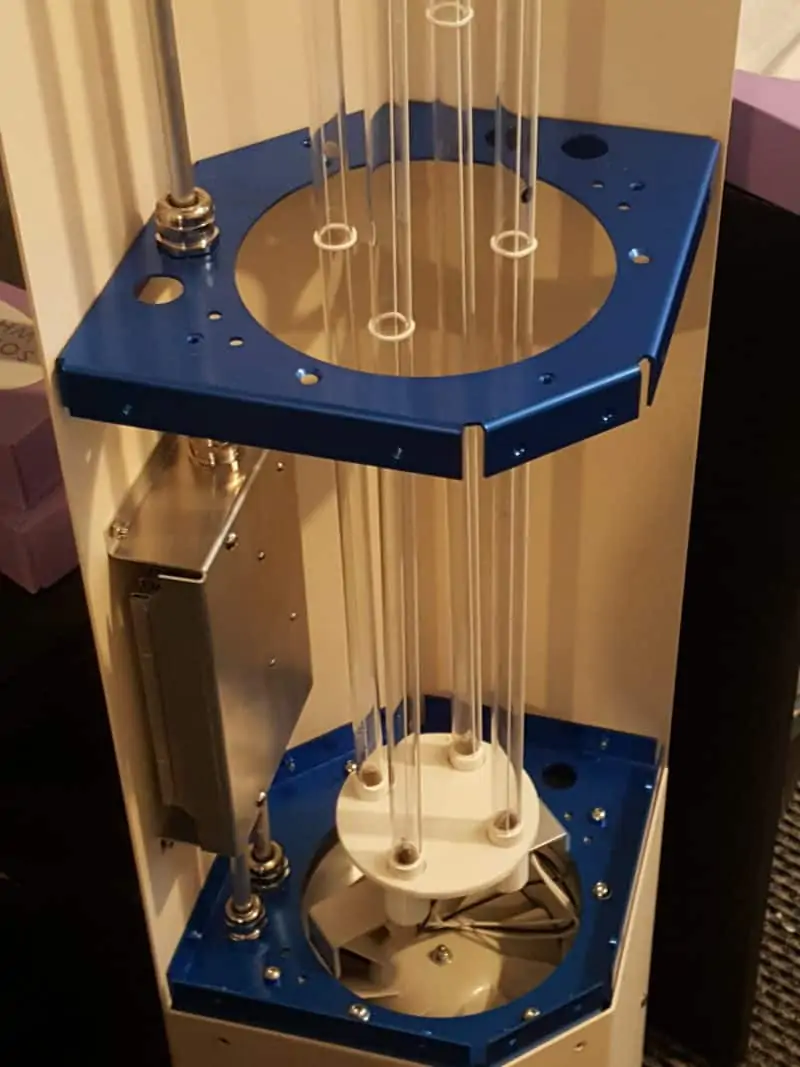

Andromeda high-power student rocket

Parts that were manufactured by Xometry are an excellent example … optimising the weight of these parts was crucial to be able to send the whole vehicle into targeted apogee with a limited weight.

SAT was founded in 2015 and is the first student team of its kind at the Aristotle University of Thessaloniki in Greece. The team currently has more than 60 members from different academic backgrounds working on two main disciplines — Aeronautics and Rocketry.

Andromeda: a High-power Rocket Designed by ASAT

One of the Rocketry team’s main goals is to design, manufacture and launch high-power rockets, thus introducing rocket science to Greece and its academic community. Six rockets have been designed since the ASAT Rocketry Department was established, including the latest one — Andromeda, a high-power rocket incorporating a deployable payload.

The team is proud to have participated in major international rocketry competitions for students, including the Spaceport American Cup (S.A.C.) and the European Rocketry Challenge (EuRoC). While at EuRoC 2022 in Portugal, Andromeda performed two successful launches and recoveries, reaching 3,446m and 4,076m with two types of motors. “The success of this mission makes this project extremely special, not only to us, but the whole academic society in Greece, as we managed to complete it at such high altitudes,” shares Koutsouras.

In-house Design Process and Simulating Flight Conditions

The team began by formulating scientific goals, creating a conceptual design and performing initial computer simulations to prove its hypotheses.

Since the legislation in Greece doesn’t allow test launches of the rocket on high altitudes, the team first had to get measurable data for passing all of the protocols before starting manufacturing and assembling parts. The team also needed to perform mathematical calculations to individually validate all rocket systems.

Before the official launch, the rocket had to pass numerous tests simulating real conditions as closely as possible. These tests include parachute dropping and testing all of the mechanisms used. This all had to be successfully completed before preparing for the competitions in Portugal and the USA where they could finally test the rockets in real conditions.

Challenges of the Aerospace Industry and Sourcing CNC Machined Parts With Xometry

For the Andromeda rocket, ASAT needed to source parts with very specific tolerances, materials and properties. Many of these parts have to withstand harsh aerospace conditions and resist extreme stress levels because of the supersonic speed that the rocket can reach.

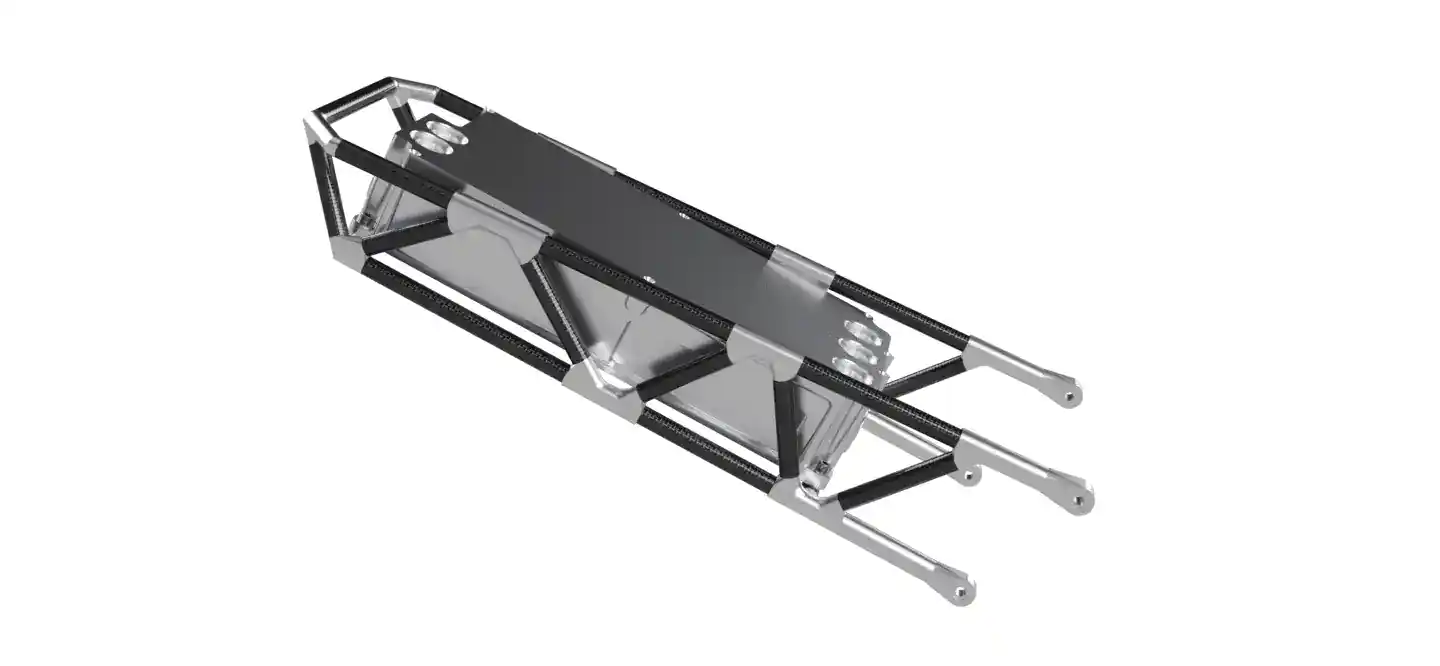

ASAT Rocketry used Xometry to manufacture several specific components, including the parts for critical systems like the rocket’s bulkheads that provide structural support. They are the components that join composite tubes and the frame of the rocket, as well as part of a bigger assembly of the parachute separation mechanisms.

One of the main challenges for the team was the tight tolerances (ISO 2768 (fine) or ISO 286 (grade 6)), as certain parts required a very specific calibration of the machine to be able to accurately manufacture rotational dimensions. This is precisely where Xometry made the difference compared to local Greek providers – Xometry uses its extensive network to find the right manufacturing partner with the capabilities to produce the complex parts.

Furthermore, Koutsouras admits that in the aerospace field many hours are dedicated to optimising parts from a strength-to-weight ratio point of view. “Parts that were manufactured by Xometry are an excellent example of this, as optimising the weight of these parts was crucial to be able to send the whole vehicle into targeted apogee with a limited weight.“ Along with the optimisation tool developed by the Rocketry team, this helped reduce the total weight of the structural components by approximately 2.5 kilograms.

The Andromeda rocket parts were manufactured using 5-axis CNC machines and were made from aluminum grade 6061, which is used in aerospace applications thanks to its corrosion- and stress-resistant properties. Koutsouras notes that Xometry’s wide range of alloys was extremely helpful.

He also states that working with Xometry was exceptional because of the strict adherence to deadlines throughout the entire manufacturing process: “The shipping times were amazing. This was an extremely important aspect for us because we only had two weeks or so before we had to travel to Portugal.”

Lastly, he adds that the Instant Quoting Engine makes the life of engineers much easier and the order process that once took days or even weeks, now just takes a couple of minutes. He also cites the huge capabilities available via the platform as being extremely useful for his applications.

Looking Into the Future of Aerospace Engineering

The ASAT Rocketry Department continues to develop at light speed, pursuing its existing goals and setting new ones. Koutsouras also shared with us that his team is continuing to optimise the Andromeda rocket’s performance by working on the apogee. In the near future, the team will also develop more complex and more powerful rocket engines for higher altitudes and larger cargo capacities. There are even plans to develop an autonomous parts landing system for the rocket’s payload and even for the rocket itself.

The team is also working on a humanitarian project called Phoenix. It is a solar energy-powered UAV (drone) for monitoring wildfires. The working prototype is estimated to be ready in Q3 2023.

During summer months, Greece faces a high risk of wildfires. Phoenix is designed to help respond to this ecological problem by detecting a fire early and informing the proper authorities about the situation. “We are going to implement machine learning algorithms, trained not only to detect if there is a fire in the forest, but also to monitor its further development in a specific location,” says Koutsouras. Equipped with cameras and an auto-pilot system, Phoenix should work autonomously while detecting the fire and providing updates on the situation.

About ASAT Rocketry

Aristotle Space & Aeronautics Team (ASAT) Rocketry — the first student Rocketry team in Greece for conducting research and experiments in the area of rocket science.

Learn more about ASAT Rocketry: www.asat.gr/projects/rocketry

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط