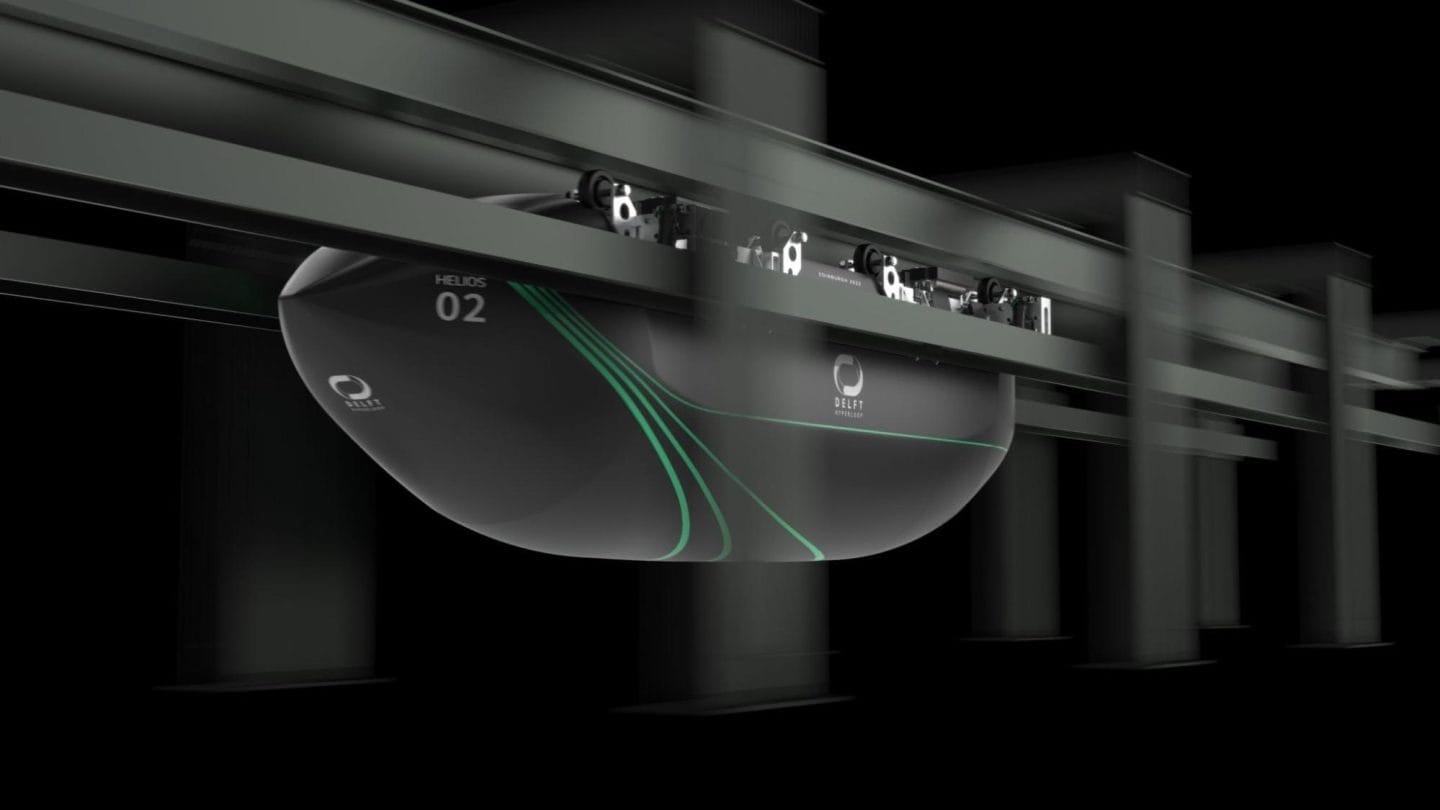

Delft Hyperloop, the student team from Delft University of Technology, is currently transforming sustainable travel with their Hyperloop concept. Teaming up with Xometry, they harnessed the power of efficient manufacturing techniques to quickly source and deliver a large volume of metal parts, thus allowing them to successfully develop the Hyperloop prototype. We spoke to Teije Nolen, Partnerships Manager at Delft Hyperloop, to discover the remarkable story behind the team’s game-changing innovation and how they leveraged precision manufacturing by working with Xometry.

Nyderlandai

Steel

Hyperloop prototype components, including a 50-metre steel “stator” track for the linear motor

We obtained around 3200 sheet metal parts and they were perfectly within tolerance. As a student team supplied entirely by partnerships, we were especially satisfied with the cost-quality ratio provided by Xometry

The Delft Hyperloop team is on a mission to revolutionise transportation with the Hyperloop concept. Inspired by the announcement of the SpaceX Hyperloop pod competition by Elon Musk, the team was founded in September 2015. Since then, they have been working hard towards making the Hyperloop a reality by pushing the boundaries of transportation and innovation.

Hyperloop’s Unparalleled Speed & Efficiency

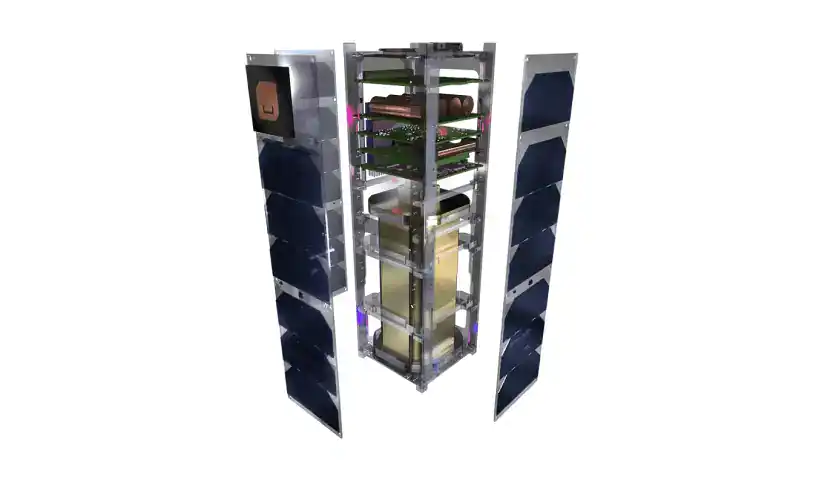

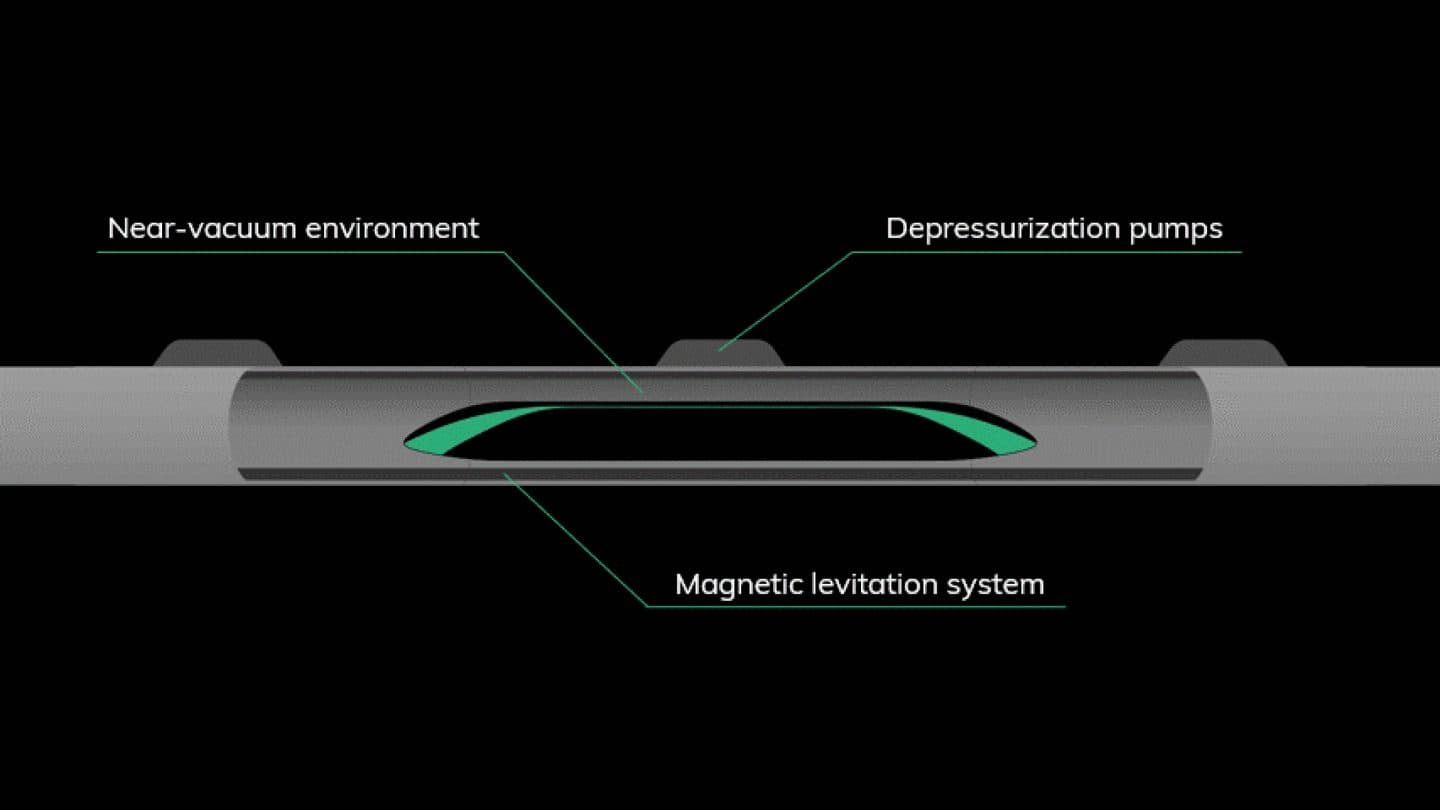

The Hyperloop, often referred to as the fifth mode of transportation, defies traditional classification. It travels through a near-vacuum tube, minimising air resistance, while magnetic levitation eliminates rolling resistance. This unique combination delivers unparalleled speed and energy efficiency, with the potential to reach speeds of around 1000 kilometres per hour. Delft Hyperloop operates as a D:Dream initiative and is currently represented by their seventh team, DH07. The team is participating in the European Hyperloop Week competition where they won the complete pod design award last year. Beyond the competition, their focus extends to conducting research, overcoming challenges, and collaborating with partners to develop and implement the Hyperloop concept.

DH07’s Collaborative Approach and Resourcefulness Drive Hyperloop Innovation

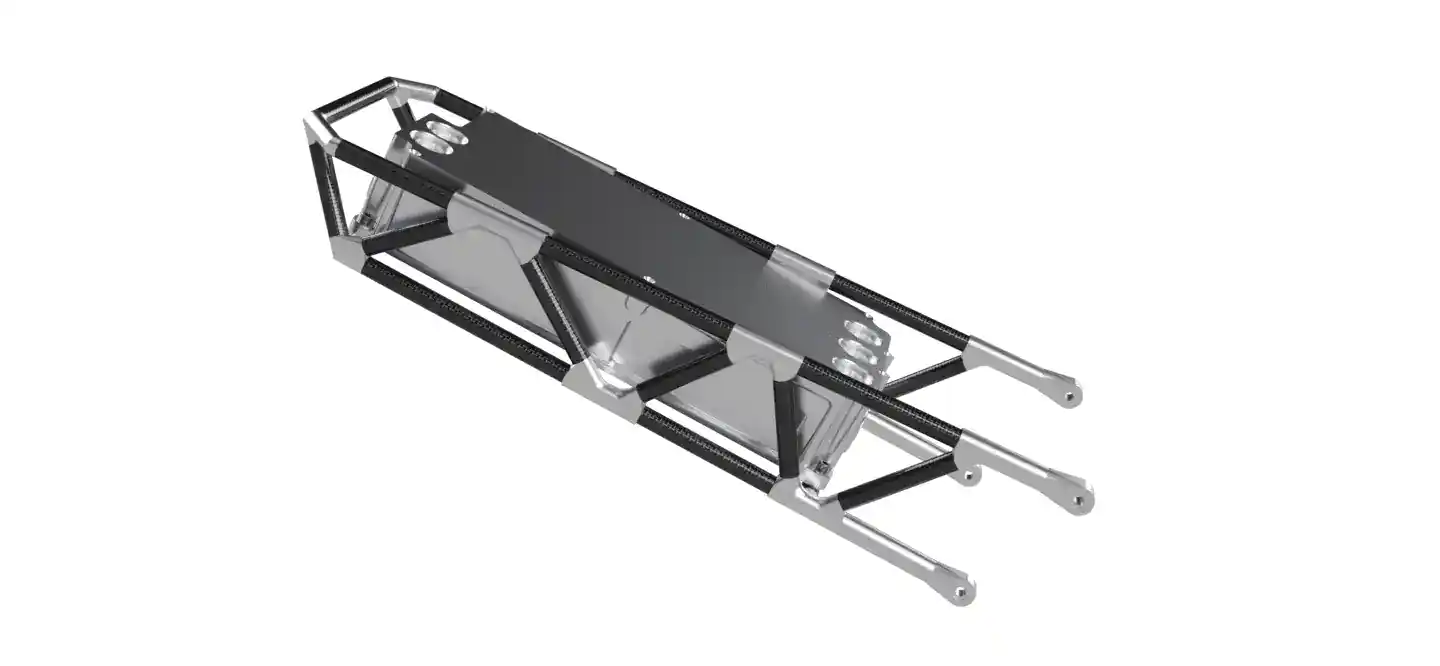

The DH07 team consists of 41 dedicated students. Each member plays a crucial role in various departments, including Management, Scalability, Propulsion, Levitation, Mechanical, and Sense & Control. With their diverse skill sets and shared vision, they work together to advance the Hyperloop technology and pave the way for a sustainable future.

The design and production processes involved in creating the Hyperloop and its components require a collaborative and resourceful approach. The team relies on partnerships and creative problem-solving to overcome challenges and meet project requirements. As DH07 starts their project journey, they follow a structured project timeline, starting with conceptual design and progressing through preliminary design, detailed design, production, and testing phases.

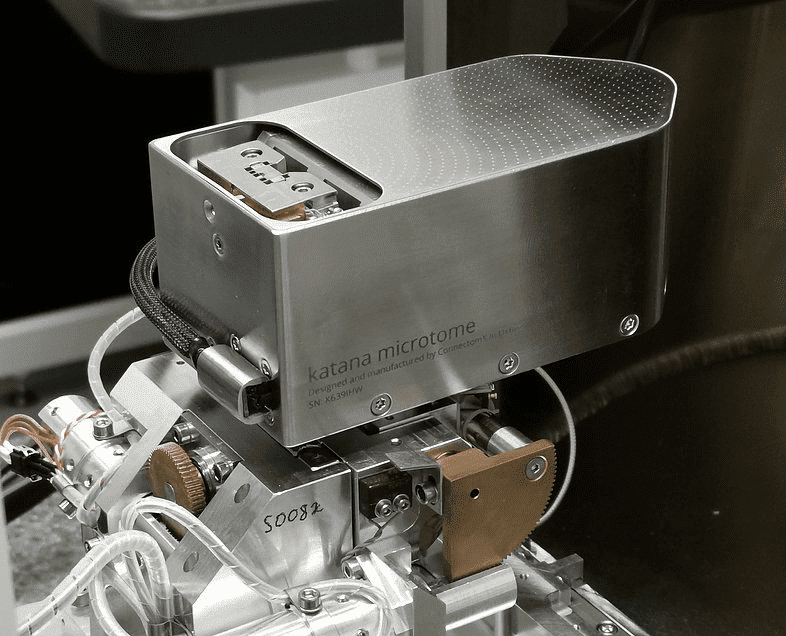

In the design and production processes of the Hyperloop and its components, the DH07 team demonstrates resourcefulness and adaptability, leveraging their partnerships to find innovative solutions. Recognising the time constraints involved, the team relies on the expertise and resources of their partners. “Since we don’t always have the time to design something ourselves, such as computer chips (waiting times could be months/years), we have to use the things we can source in a reasonable time frame. Sometimes this requires a very creative solution and manufacturers help us with that,“ says Nolen.

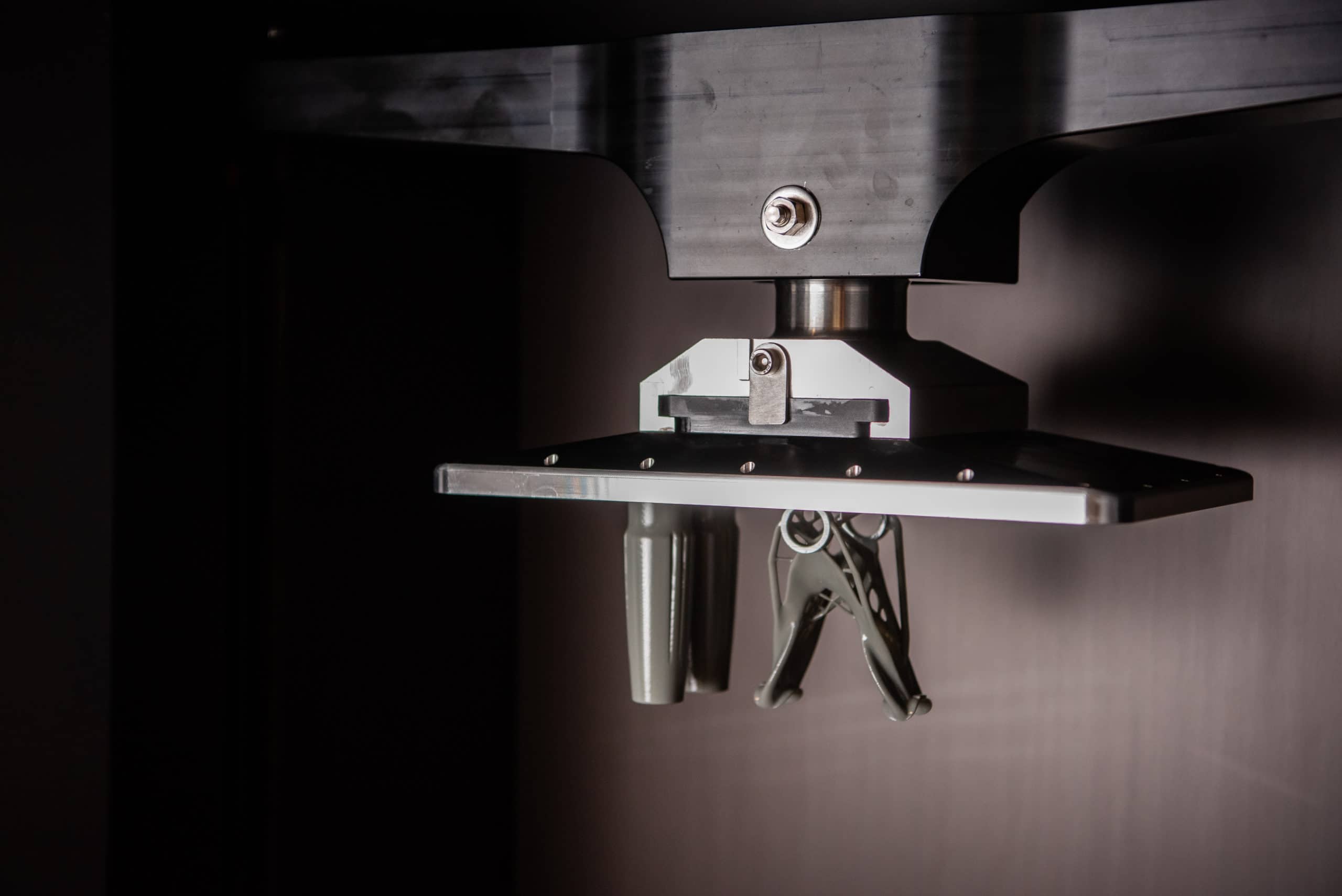

Xometry’s Precision Machining Delivers Hyperloop’s Stator Solution

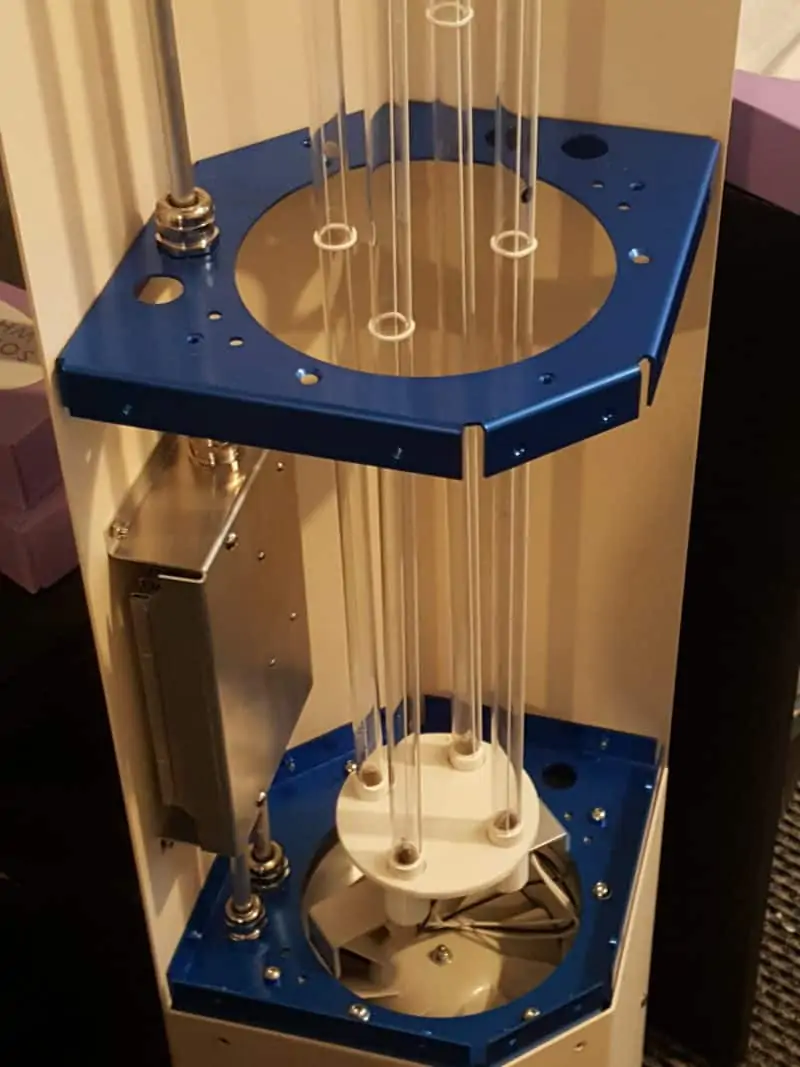

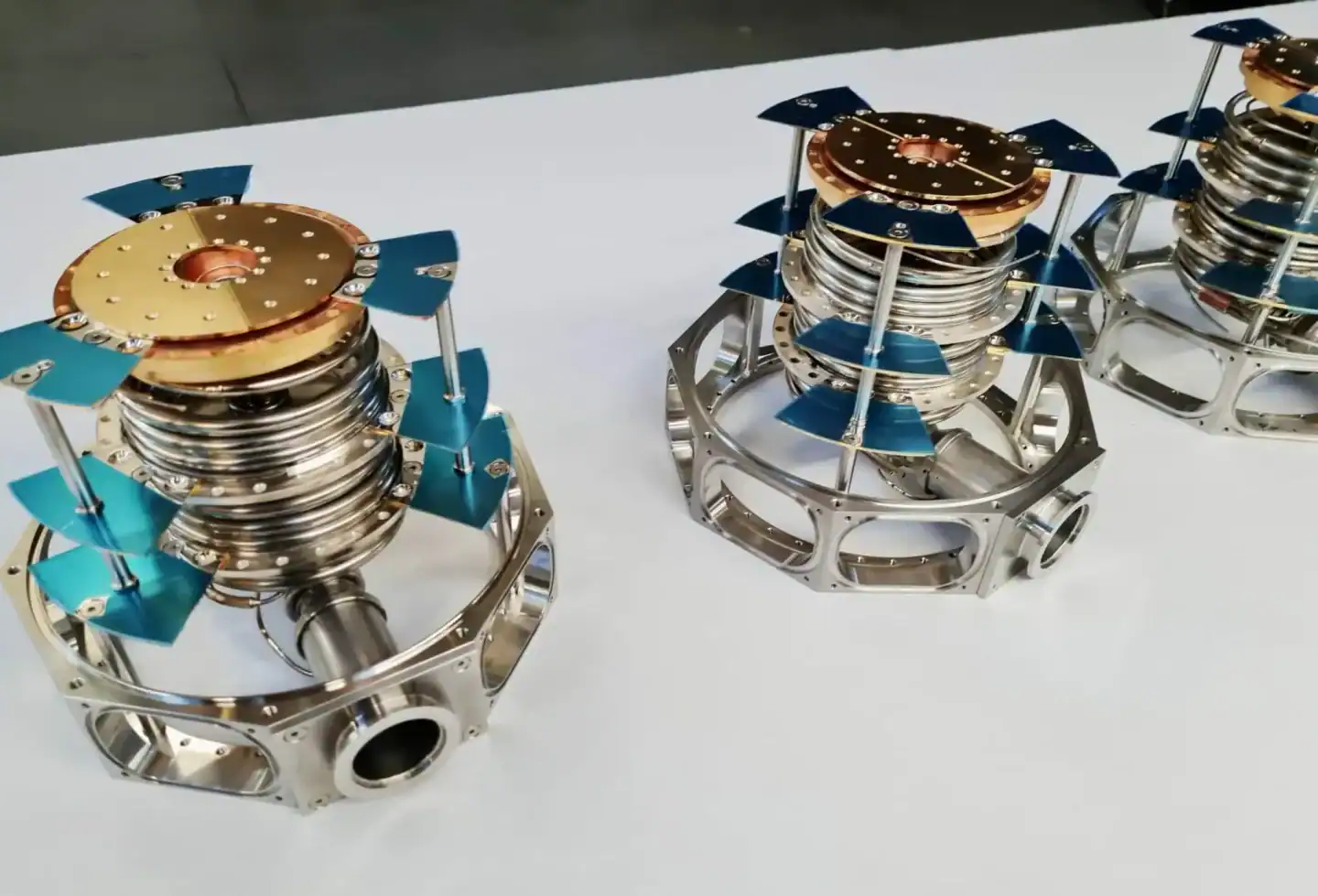

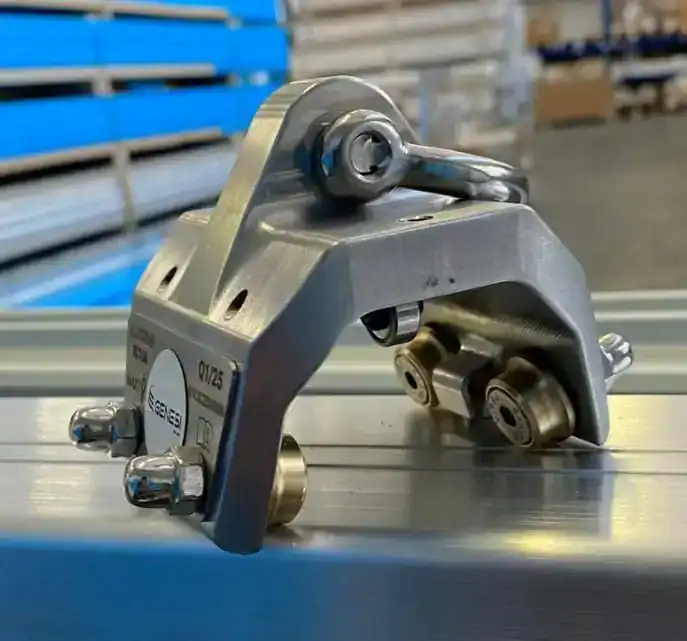

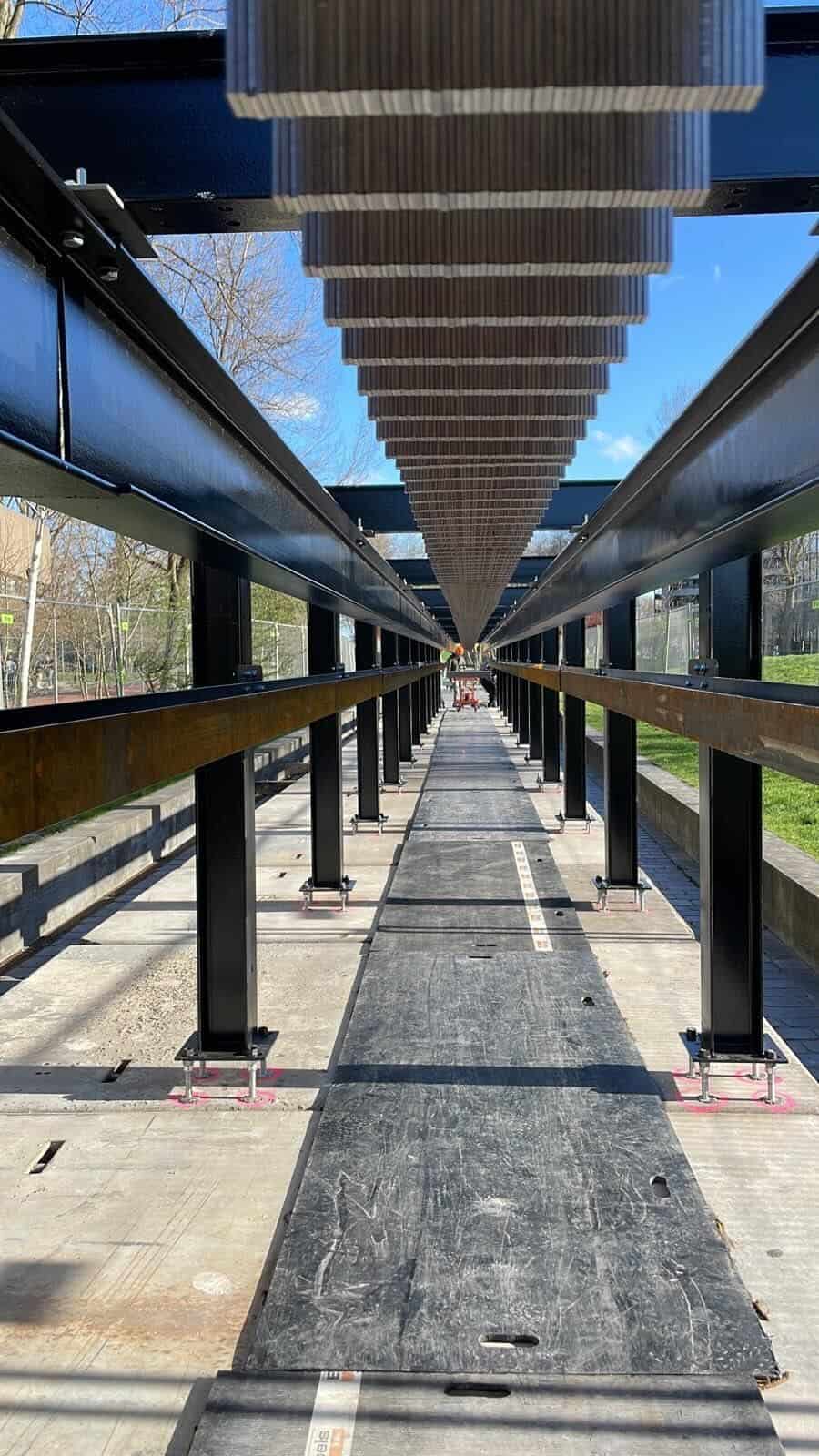

The development of the Linear Flux-Switching Permanent Magnet motor – a groundbreaking innovation for the Hyperloop – presented unique challenges for the team. Initially, traditional CNC machining was considered for manufacturing the complex track with over 500 precisely designed teeth, which serve as the primary acceleration mechanism for the pod. However, this approach proved to be incredibly expensive and unsuitable for large-scale production. The partnership with Xometry and their innovative manufacturing techniques demonstrated the team’s commitment to exploring innovative solutions and addressed the challenges posed by traditional production methods.

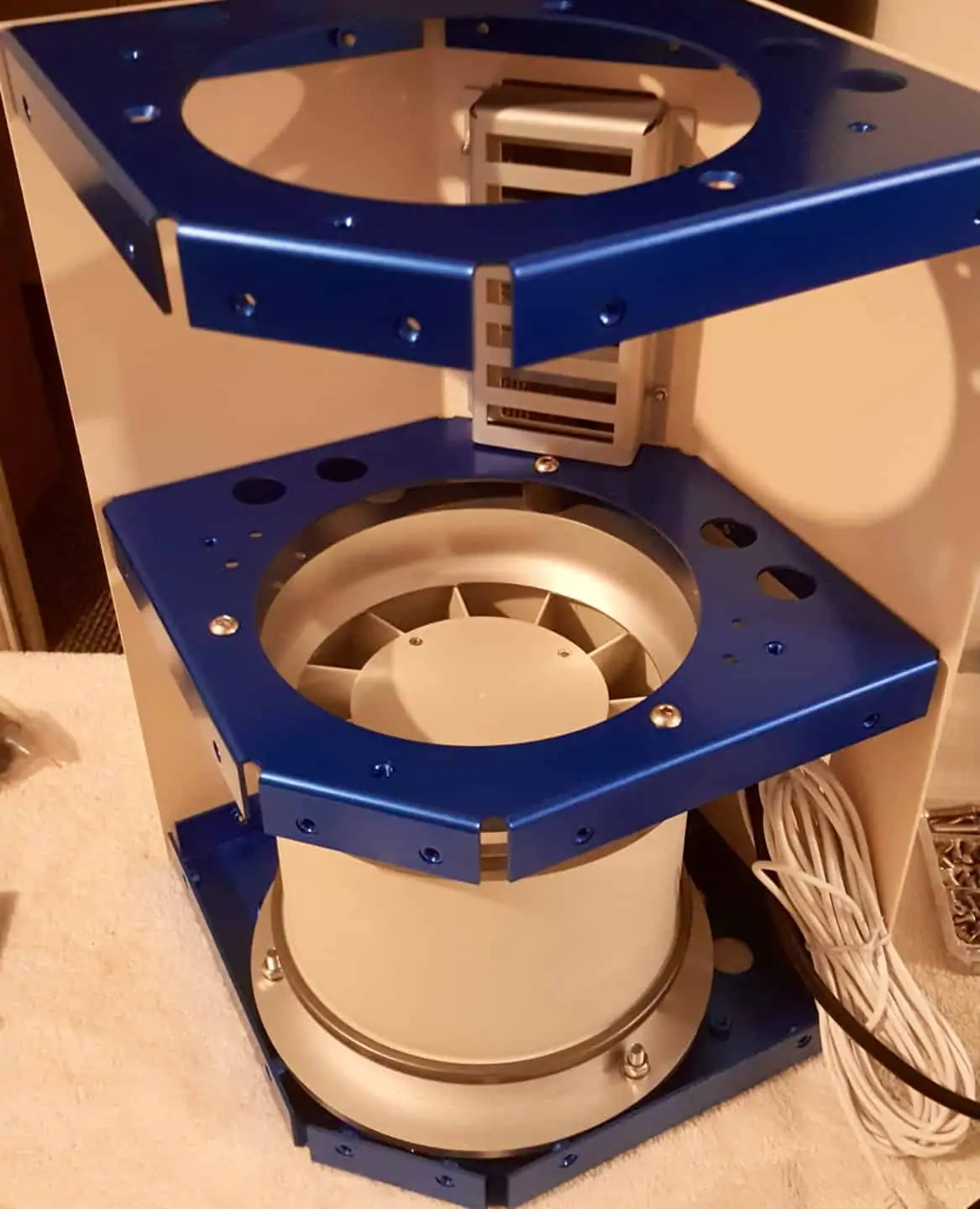

Xometry played a crucial role in the manufacturing process of the Hyperloop, particularly in producing the 50-metre motor track known as the “Stator”. Made entirely of steel, the stator is a fundamental component of the linear magnetic motor, enabling the pod to accelerate swiftly while levitating above the track. Through extensive discussions with the Xometry technical support team, the team devised a creative solution to produce the critical component in a cost-efficient and scalable manner.

“We obtained around 3200 sheet metal parts and they were perfectly within tolerance. As a student team supplied entirely by partnerships, we were especially satisfied with the cost-quality ratio provided by Xometry, “ explains Nolen.

The DH07 team were introduced to Xometry through the Instant Quoting Engine, which gave them an overview of the possibilities offered as their production partner. Sourcing their parts from Xometry had numerous advantages. Xometry’s commitment to quality and efficiency was evident, which also aligned with their expectations. However, it was Xometry’s exceptional project management and communication that truly impressed the team.

They faced the immense challenge of developing a fully operational hyperloop prototype within a year, with limited resources and various complexities. One of their critical components, the stator, exemplified the value Xometry brought to the table. Its production required straightforward techniques that were prohibitively expensive for the project. Nonetheless, Xometry stepped in, handling the production of 50 metres of the stator within weeks. Without Xometry’s efficiency and commitment, the project timeline would have been at risk, jeopardising the team’s participation in the European Hyperloop Week of 2023.

“The project management and communication at Xometry pleasantly surprised us…we were very pleased with the communication from Xometry and the efficient management of placing, producing, and delivering the order within time,” states Nolen.

DH07’s Exciting Future: Advancing Hyperloop Technology and Milestones

Delft Hyperloop has an exciting future ahead filled with ambitious projects and plans. They are on a mission to continue to revolutionise transportation and DH07 aims to accomplish several significant goals in the upcoming year. They will focus on achieving full levitation, implementing a new, highly efficient motor, and developing a vacuum-compatible thermal management system. These advancements will optimise their speed capabilities and energy consumption, driving the development of sustainable transportation solutions. Overcoming the challenge of lane switching is a key priority for the team.

They are actively exploring innovative solutions to ensure smooth transitions between tracks, which would enhance the efficiency and versatility of their hyperloop system. DH07 also plans to extend the length of their tracks to showcase the impressive speeds their system can reach—up to 1000 km/h. These extended tracks will demonstrate their engineering expertise and underline the immense potential of hyperloop technology. Creating a vacuum environment within the tube surrounding the tracks is another crucial objective. By eliminating air drag, DH07 aims to optimise speed and efficiency to keep pushing the boundaries of transportation technology.

While the current prototype may not require additional steel parts as they pass the project to the next team, DH07 is excited to announce that their future project, DH08, will have steel part requirements. Xometry is now the team’s go-to manufacturing partner for any new needs, highlighting the strong partnership developed between DH07 and Xometry in transportation innovation.

About Delft Hyperloop: Delft Hyperloop is a pioneering project led by a dedicated team of students from Delft University of Technology in the Netherlands. With a passion for revolutionising transportation, the team is at the forefront of Hyperloop technology innovation. Supported by esteemed institutions and government entities, Delft Hyperloop is committed to pushing the boundaries of sustainable travel.

Website: https://www.delfthyperloop.nl/

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط