Discover how Vivavis has developed Octopus IoT platform into mass production with Xometry’s MJF prototyping and injection moulding solutions.

Video case

Video case

德国

Polycarbonate (PC)

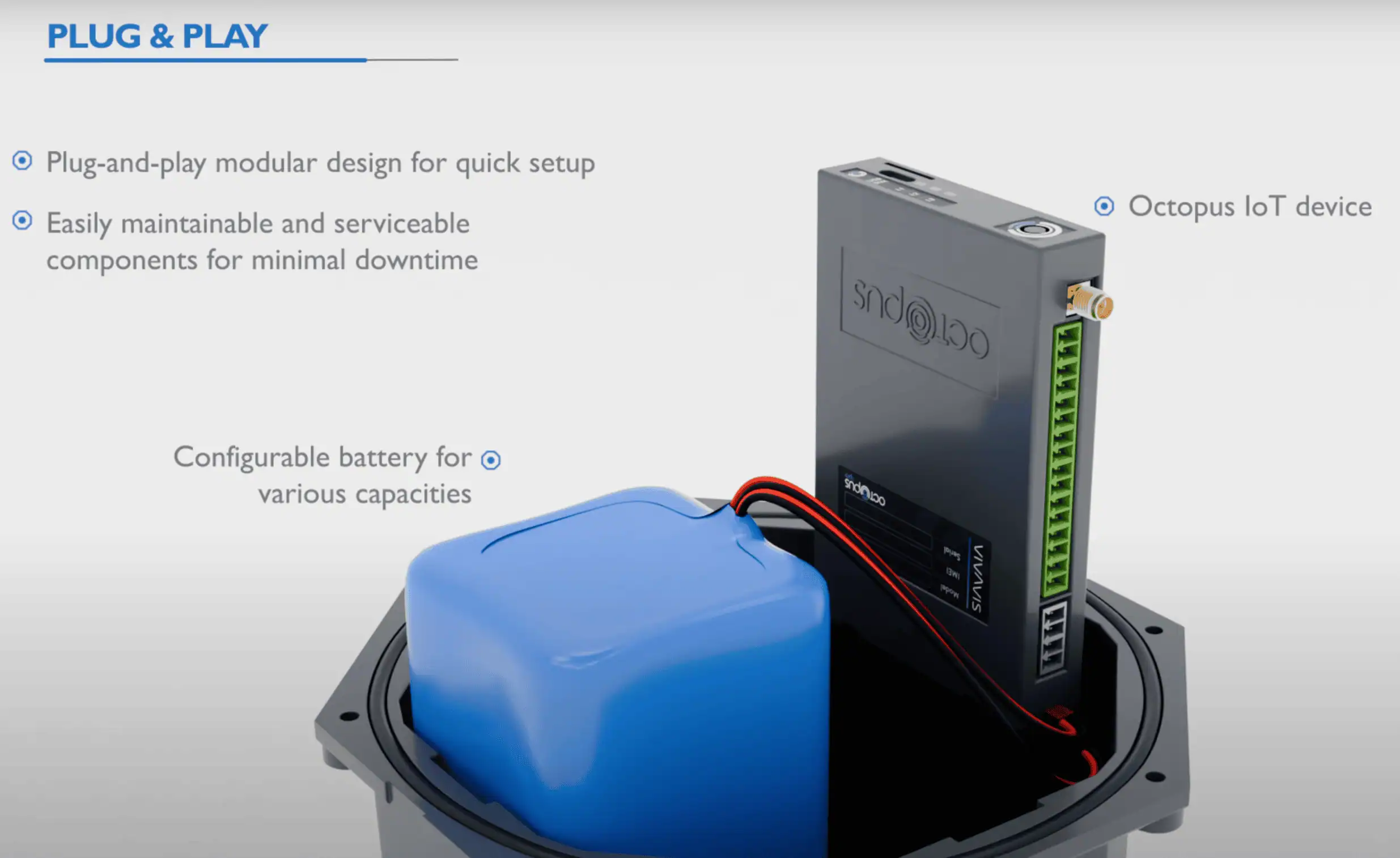

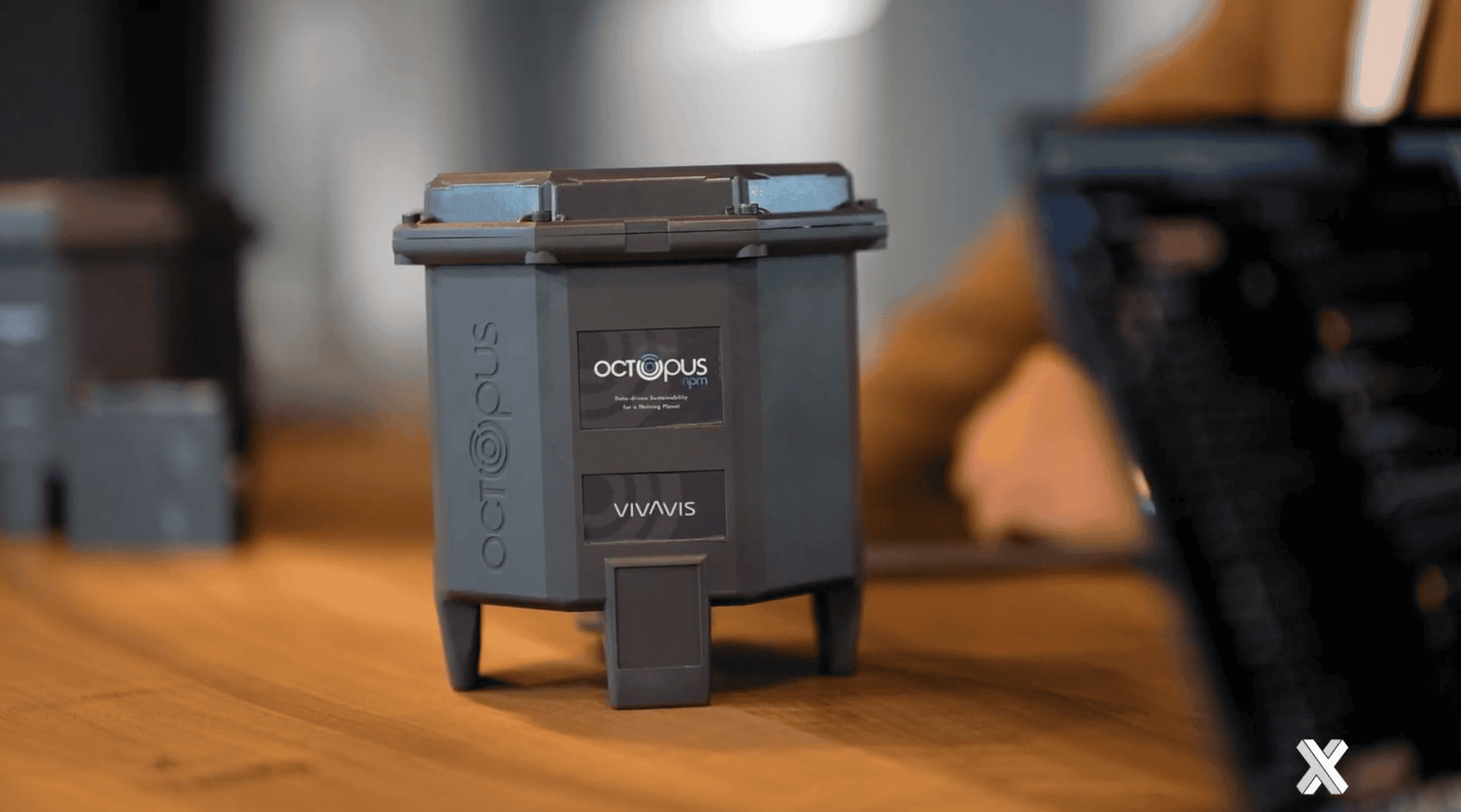

IoT device platform for infrastructure monitoring

We’re extremely satisfied with Xometry. Their technical capabilities and professional communication allowed our projects to progress seamlessly. The solutions provided for Octopus sped up our product development cycle and helped us achieve higher quality results. We look forward to working together again on new product segments.

Vivavis – A Pioneer in Digital Transformation and IoT Solutions

Based in Germany, Vivavis is one of the leading companies in digital transformation and IoT solutions for optimizing infrastructure systems. Within its Turkey operations, the firm develops innovative solutions for critical areas such as real-time monitoring and control of water and energy infrastructures.

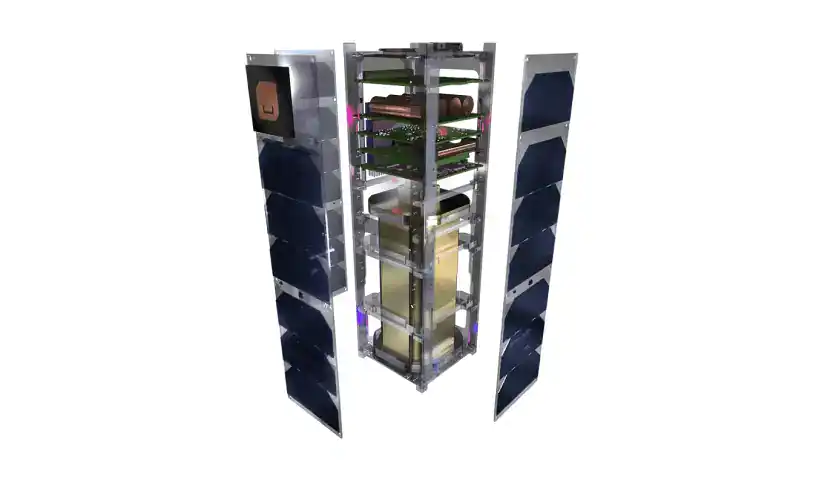

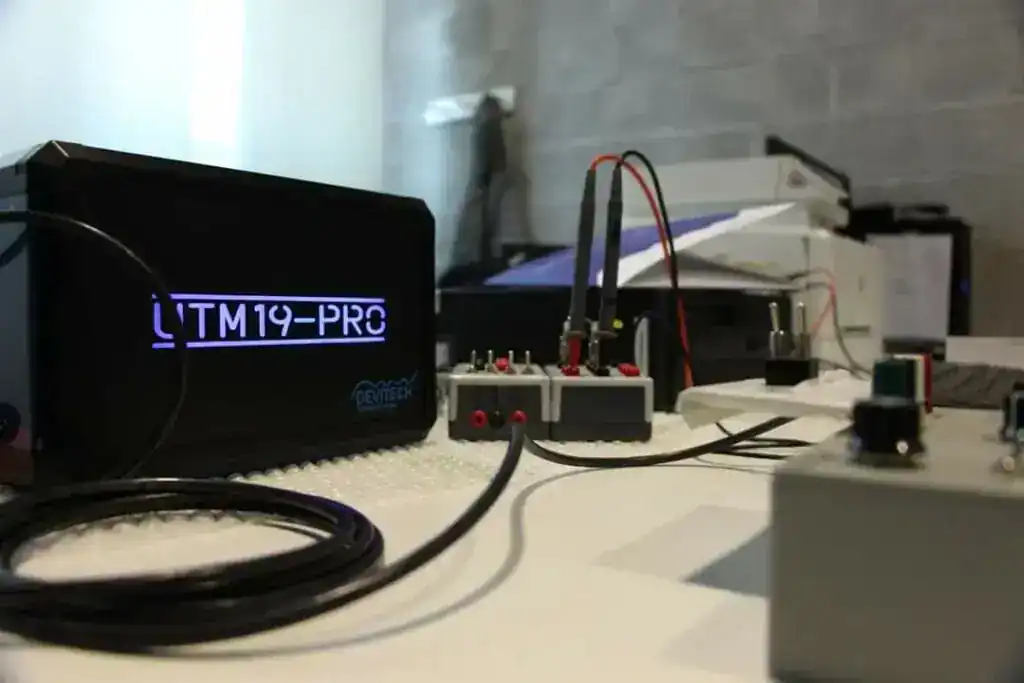

The IoT platform Octopus NPM, developed in this context, is a product that transfers data from sensors and meters spread over wide geographies, data at the endpoints of the networks to central systems over networks such as NB-IoT and LoRa, requiring high durability and precision.

Key Challenges – Developing Innovative and Durable Products

The Octopus NPM device operates between -20°C and +60°C and must maintain complete functionality in demanding environments. Because it remains installed for extended periods (often underground or in harsh surroundings), its design calls for high durability and IP68 standards. Additional project complexities included:

- Achieving the tolerances and surface quality required for harsh environmental conditions

- Choosing the right materials and manufacturing technologies during prototyping

- Optimizing injection mold design and production processes

- Evaluating local and global suppliers to find competitive pricing and the right manufacturing partner

- Balancing cost and quality across both prototyping and series production

In line with these requirements, Vivavis discovered Xometry’s digital manufacturing and procurement solutions.

Production Process – From MJF to Injection Molding

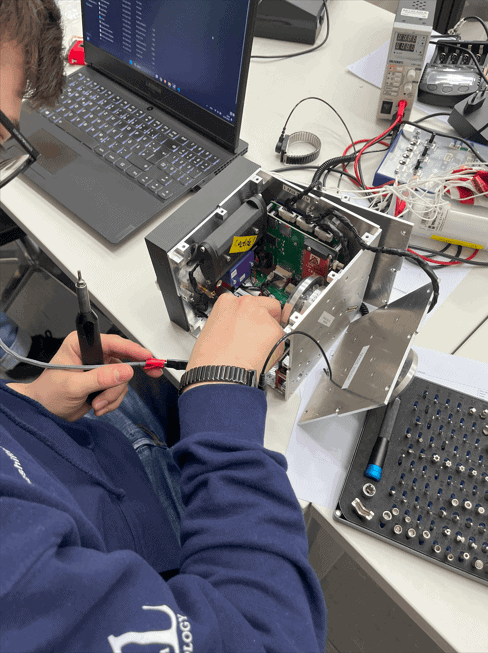

Vivavis collaborated with Xometry in three primary phases to bring the Octopus project to life.

1. Prototyping – Swift Testing with MJF 3D Printing

Initially, MJF 3D printing helped Vivavis quickly test the main design features of the Octopus’s outer shell. Regular meetings during this phase enabled fine-tuning of both the IoT product design and plastic injection molding requirements.

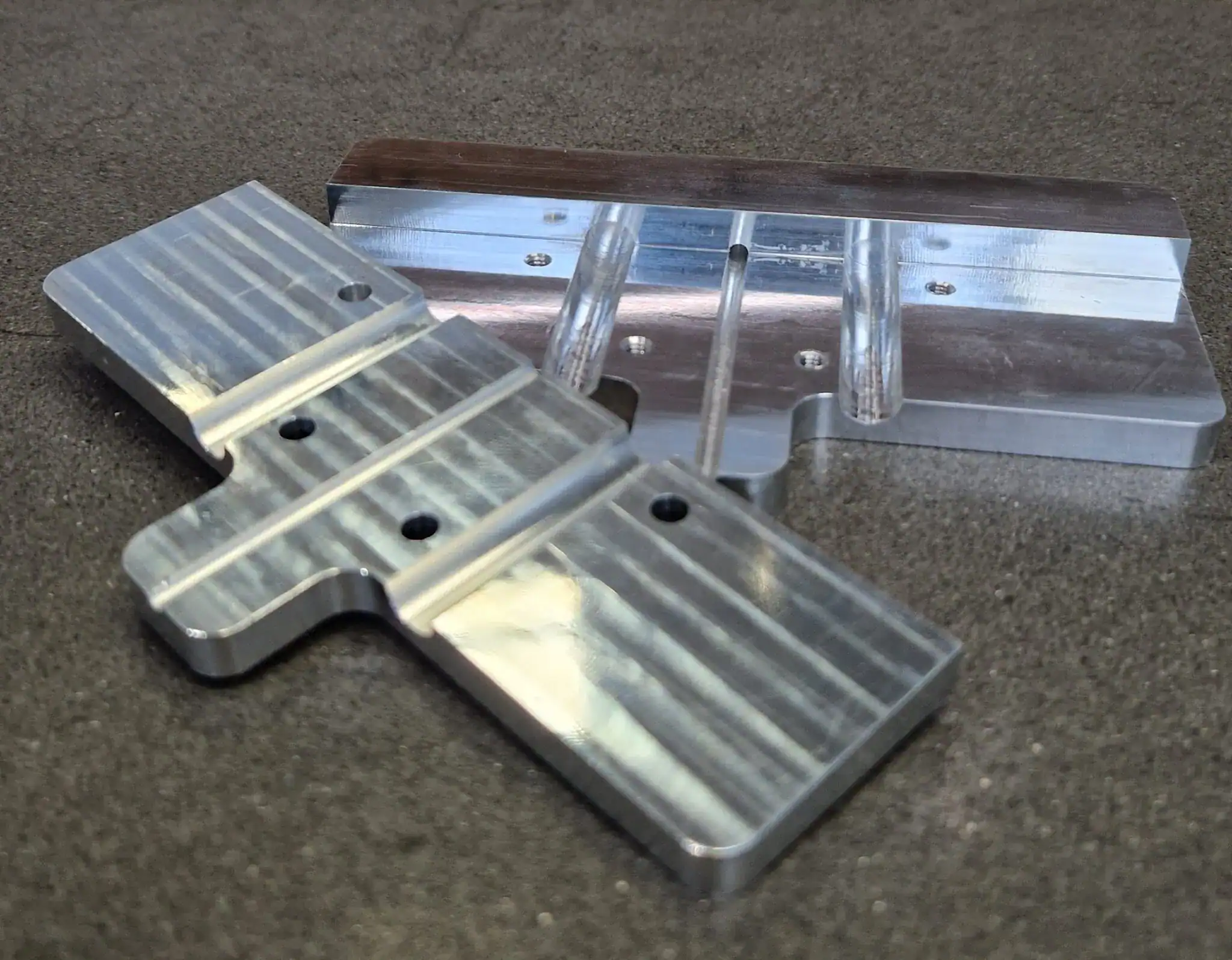

2. Injection Molding – Optimizing for Mass Production

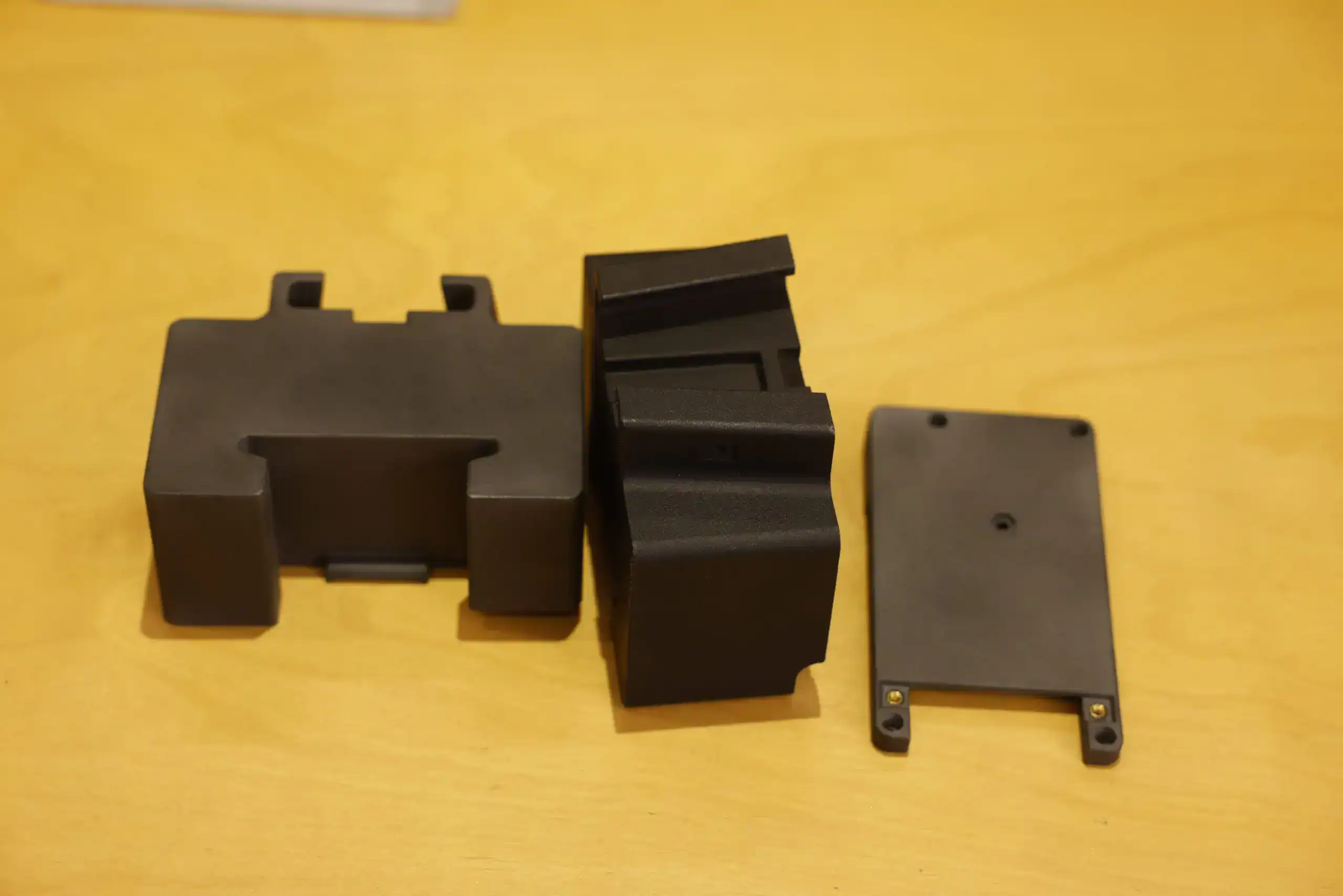

Octopus’s outer shell and PCB enclosure were produced using Xometry’s plastic injection molding solutions.

- Mold Manufacturing: Xometry’s engineering team planned the injection mold with close attention to tight tolerances and IP68 waterproofing.

- DfM Analysis: Through comprehensive Design for Manufacturability (DfM) evaluations, potential design flaws were identified early, preventing issues during serial production.

Material & Surface Quality: While several materials were considered to ensure durability and tight sealing, PC (Polycarbonate) was ultimately chosen for its superior surface finish and mechanical tolerance.

3. Project Management – Technical Support & Global Supply Solutions

Throughout the project, Vivavis worked closely with Xometry’s engineering team to streamline each step:

- Global Network: Xometry utilized its wide-reaching partner network to offer Vivavis multiple supplier options with competitive costs and high-quality standards.

- Logistics & Coordination: By managing logistics, customs, and delivery processes, Xometry reduced both the time and effort Vivavis needed to invest, making the entire project more flexible.

Result – A Dependable Partnership in Building Durable IoT Devices

The collaboration with Xometry enabled Vivavis to achieve remarkable outcomes for the Octopus project. Both the outer shell and PCB housing were built to function within -20°C to +60°C and to meet IP68 standards. Managing both 3D printing and injection molding within a single network minimized communication gaps and reduced revision cycles. Additionally, comprehensive DfM analyses and ongoing reviews paved the way for a faster time-to-market by eliminating unnecessary redesign work. Meanwhile, Xometry’s global network provided flexible supply chain solutions and competitive pricing, increasing overall efficiency.

Octopus NPM’s success exemplifies how innovative approaches to injection molding, rapid prototyping with MJF, and sealing solutions in IoT device design can transform a complex project into a genuine commercial success. Backed by the same level of quality and expertise, Xometry continues to serve as not just a supplier but a true end-to-end manufacturing partner for diverse industries.

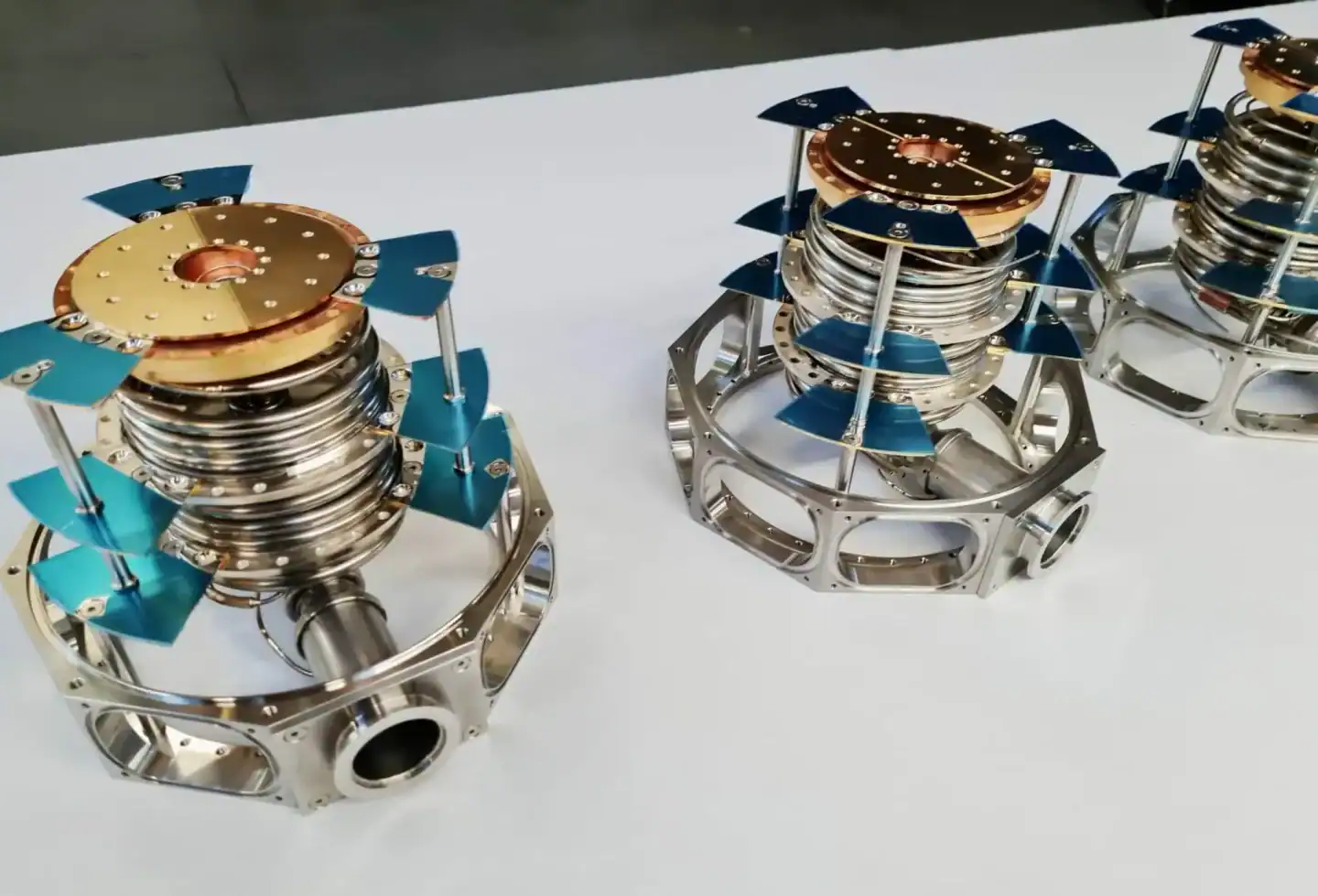

Advancing Innovation & Exploring New Product Segments

Building on the success of the Octopus IoT platform, Vivavis aims to collaborate with Xometry on upcoming projects. The company plans to expand into new product segments in the IoT industry, delivering cutting-edge solutions to a broader market.

For more information, visit Vivavis’ official website at https://vivavis.com.tr/en/ or contact them via info@vivavis.com.

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط