Qinu’s dedicated team of scientists and developers are advancing quantum technology to support experimenters from industry and research with its unique cryostats.

Vokietija

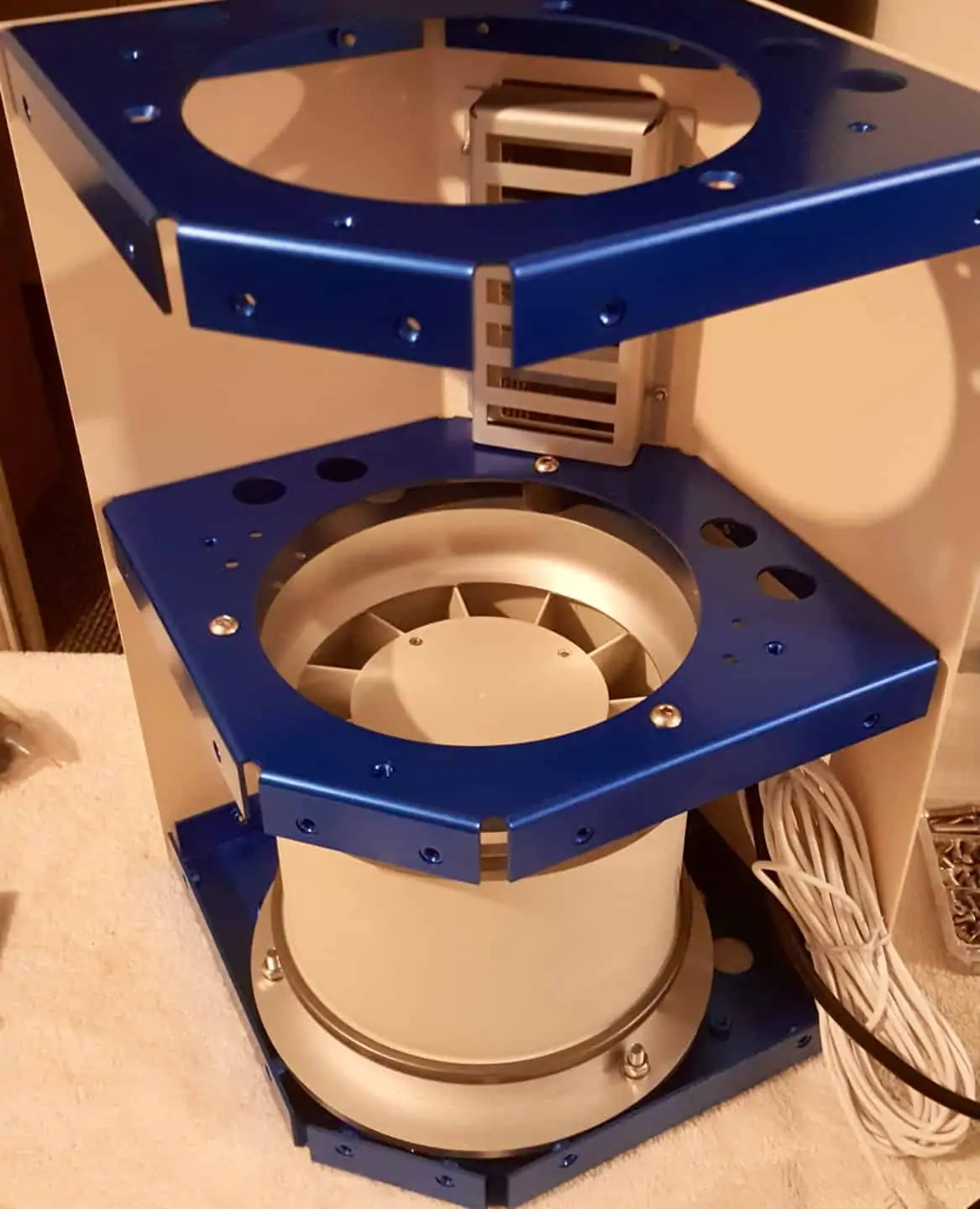

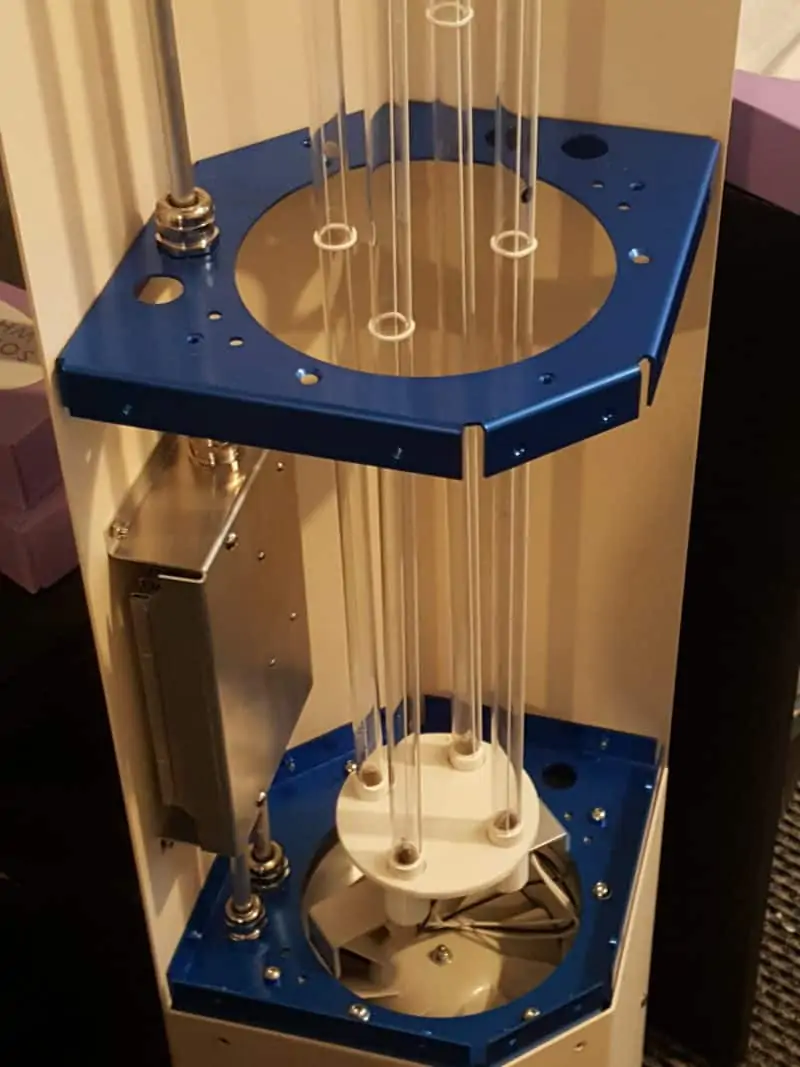

Qinu develops and manufactures high-tech cryostats and dilution cooling systems capable of producing extreme conditions

With regular manufacturers, you have to wait a week to 10 days before you even get a quote, but Xometry is usually already in the middle of production by then.

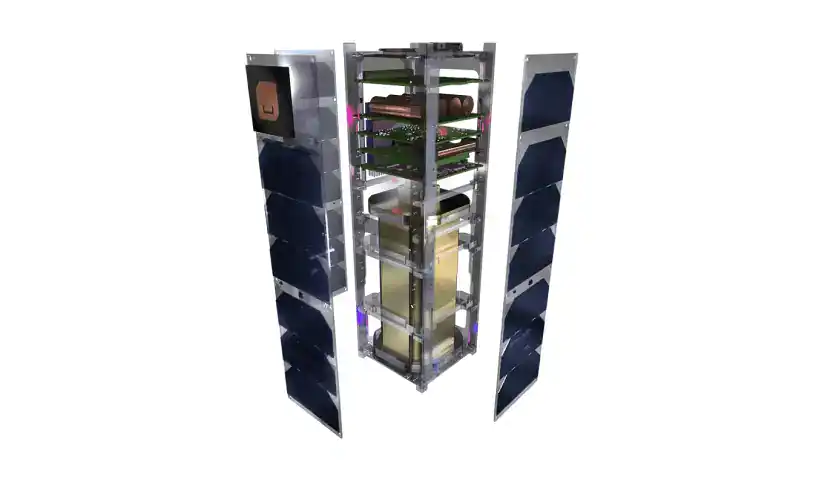

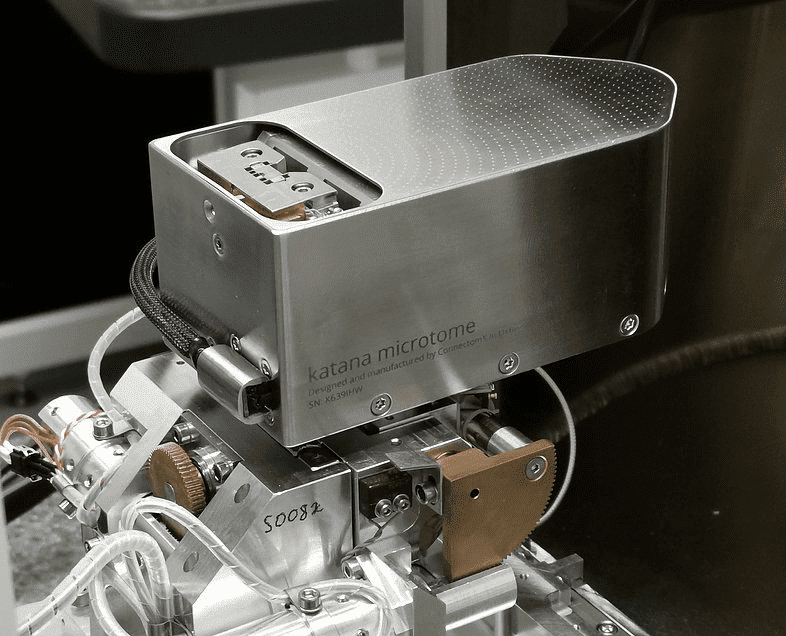

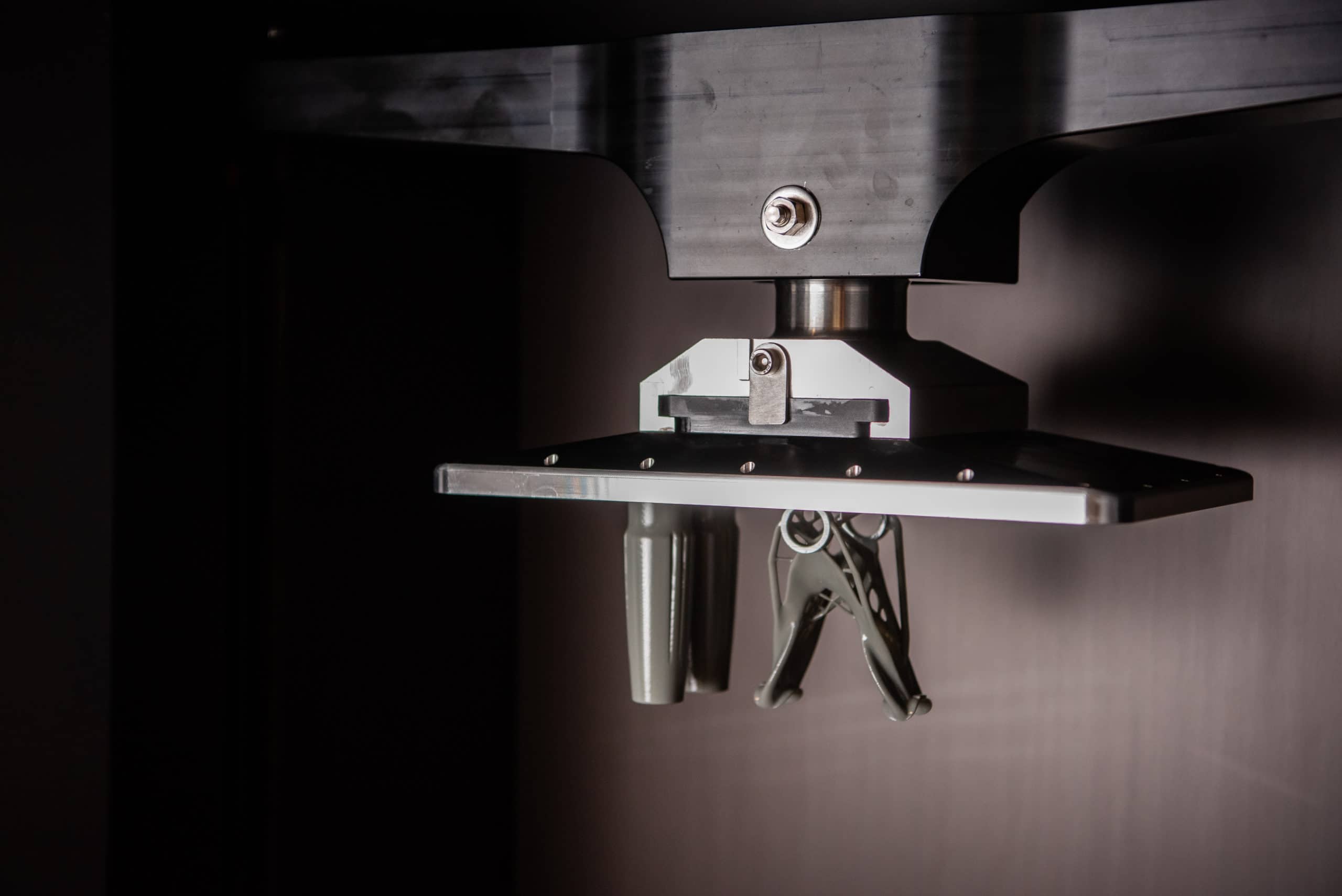

Qinu is an up-and-coming company that develops and manufactures high-tech cooling systems for industry and research. Their dilution cryostats can create extreme conditions like very low temperatures near absolute zero and vacuums, while also providing protection from electromagnetic radiation. Following the emergence of quantum technologies such as quantum computing and quantum sensors, the demand for these unique cooling systems is increasing in both basic research and the wider industry. Qinu strives to provide a platform for industry and research to optimise their individual technologies.

Looking for Solutions to Improve Manufacturing Speed and Efficiency

After its foundation in March 2021, Qinu was soon faced with the challenge of increasing production volumes and simplifying manufacturing processes to make production faster and more cost-effective. Qinu’s cooling systems are technologically advanced and require specific materials and manufacturing processes to meet the demanding specifications. In addition, the team also needs to take customer requests into account, as certain parts of the products can be customised.

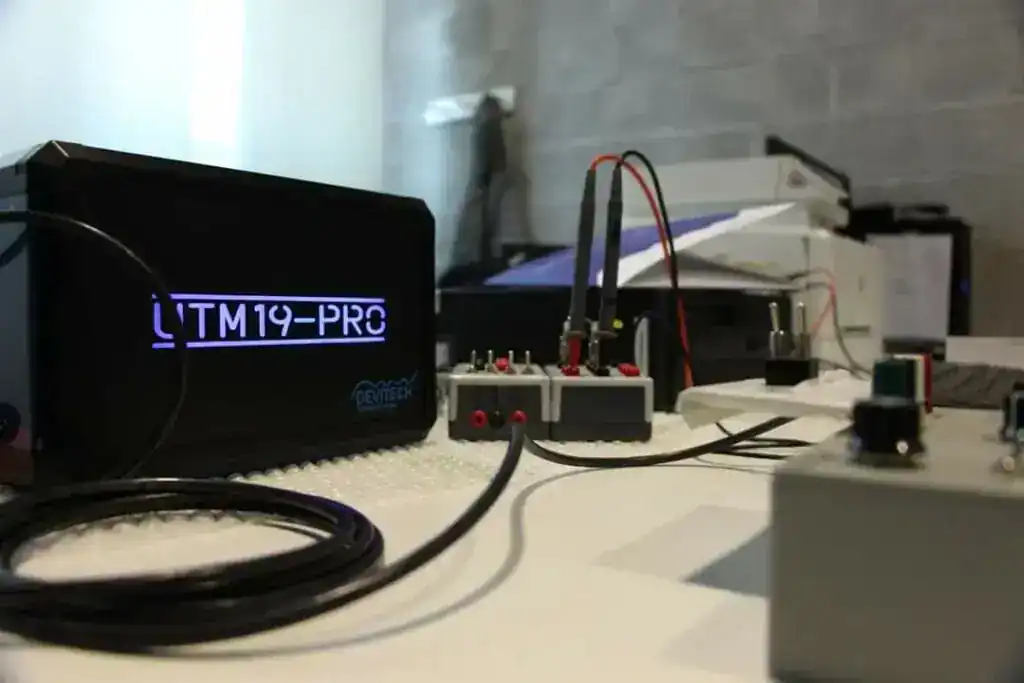

Instant Quoting Through Xometry Instead of Waiting for 10 Days

Xometry’s AI-supported Instant Quoting Engine meant that Qinu were able to get quotes for manufacturing solutions quickly and easily. Marcel Schrodin, Managing Director of Qinu, reports: “With regular manufacturers, you have to wait a week to 10 days before you even get a quote, but Xometry is usually already in the middle of production by then.” This system fast-tracked the process for Qinu and helped reduce delivery time significantly.

Fast Delivery of the Required Components

The partnership so far with Xometry has been extremely beneficial for Qinu. The price-performance ratio is competitive and the quality of the parts ordered was mainly rated as very good. “In general, we are very satisfied with the quality of the parts manufactured by Xometry,” says Schrodin. Even when there were several slight issues with surfaces, Xometry promptly resolved them for us.

Partnership and Goal-oriented Collaboration

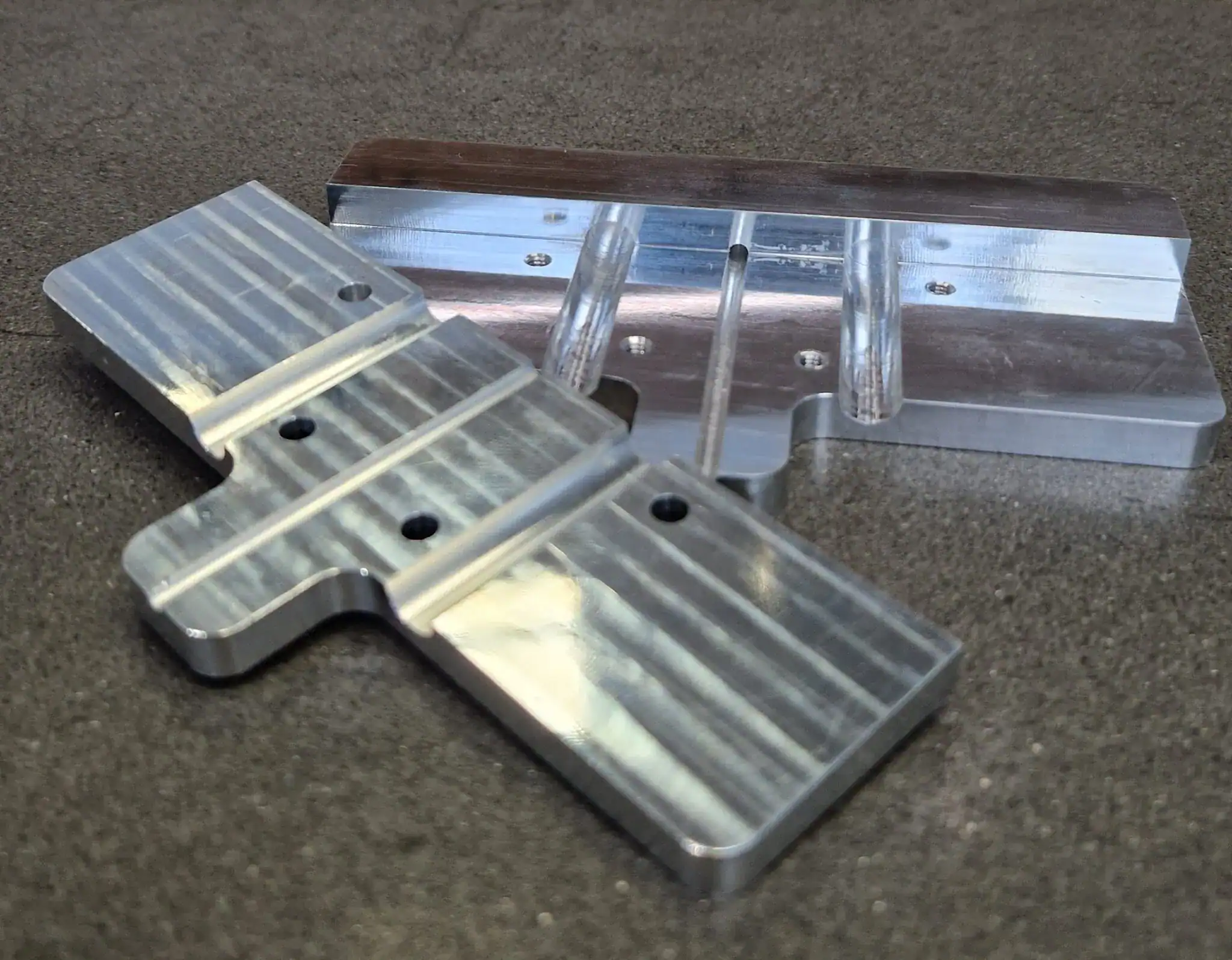

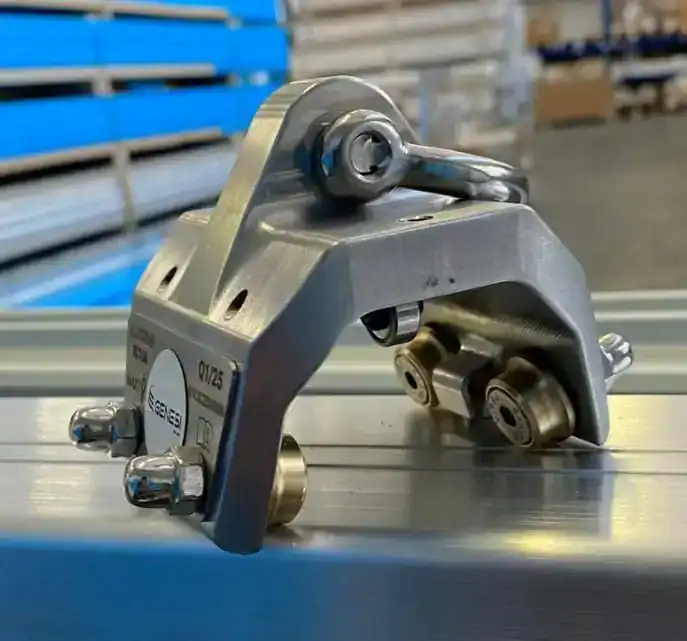

Qinu mainly uses CNC machining and also some sheet metal cutting to produce its high-tech cooling systems. These manufacturing solutions allow Qinu to meet specific material requirements while achieving complex geometries with high precision. The modular design of the cryostats enables the integration of various components, such as low frequency and RF cabling, optical fibres and windows. By using CNC machining, Qinu can reliably have standardised elements of their product mass-produced by Xometry.

During the collaboration, Gunar Simböck, Xometry’s Key Account Manager for Qinu, was able to use his in-depth expertise and years of experience in the manufacturing industry to understand Qinu’s specific requirements in detail and come up with solutions. Schrodin describes working with Xometry and Simböck in particular as follows: “I usually speak directly to our account manager or I can see in the comment column in the online order that there are still some points to clarify, because I have requested special material, for example—this type of situation can then also be resolved easily by getting a manual quote.”

This close collaboration meant that Xometry was able to efficiently implement the desired customisations and specialised manufacturing processes to produce the components for Qinu’s unique cooling systems.

What Does the Future Hold for Qinu?

In the future, Qinu plans to continue its collaboration with Xometry and use the platform for standard manufacturing. In addition, research and development will lead to further projects and components for which the company also intends to produce new parts and assemblies with Xometry. Schrodin is confident that Xometry will continue to provide valuable support for the production of its high-quality cooling systems in the future.

Website: https://qinu.de

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط