Injection molding, a modernised and far more advanced form of casting, is one of the manufacturing methods developed through the years that allows to speed up and enhance the production of different products. Speed and ease of production are critical considerations in manufacturing, especially bulk production, as these bring about numerous advantages. These advantages include lower development costs, greater forecasting accuracy, faster innovation, and larger market share.

What is Injection Molding?

Injection molding is a manufacturing process in which molten material is injected into an already prepared mold and left to cool. Upon cooling, the material solidifies and takes the shape of the mold, before being ejected. While this process may be used for one-off productions, it is usually used in the mass production of identical parts. Materials most commonly used in injection molding are plastics or elastomers.

Due to its high output rate and consistency of quality, injection molding is widely used across different industries to create parts such as electrical components, automotive parts, basic consumer plastics, furniture parts, and many others.

How Does Injection Molding Work?

A special-purpose injection molding machine carries out injection molding. The manufacturing process is divided into the various steps listed below:

Step 1 – Creation of the Mold

The first step in injection molding is mold creation. The mold for the part to be manufactured is designed according to the specifications of the part’s 3D model, using computer-aided design, following several injection molding guidelines. It is then manufactured in two parts, usually using CNC machining. Molds are made from metals (mainly steel or aluminium).

Step 2 – Injection

The separate halves of the mold are placed in and held together tightly by the clamping unit of the injection molding machine. In the form of granules or pellets, the raw material is introduced into a barrel where it is heated at a high temperature and pressure till it melts. Now in molten form, the material is immediately injected into the mold cavity, filling the entire space in the mold. It then cools down and solidifies, forming the shape of the mold.

Step 3 – Ejection and Finishing

After the material has completely cooled and solidified, the mold is opened by the clamping unit and the solidified finished part is ejected. The finished part is subjected to some post-processing operations. These operations include removing excessive material and support structure, surface finishing, and, if required, painting, electroplating, heat treatment, etc.

Other Injection Molding Processes

There are other forms of injection molding that vary from the process described.

Over Molding

Over molding is an injection molding process that allows a part to be created from two different materials. The first material is molded and, before cooling down, the overmolding material is introduced, creating strong bonds between the substrate and the overmolding material. This technique is used to create multi-material objects with improved aesthetics and functionality, while eliminating the need for secondary operations.

Insert Molding

Insert molding is similar to over molding. In this injection molding technique a preformed object is inserted into the mold before the molten material is poured. With the point being to have the preformed material inserted into the molded object. An application of insert molding is inserting metal screw holes into plastic parts.

Metal Injection Molding

In this process, finely powdered metal is combined with wax, polypropylene binders, or other polymers to form a feedstock mix. It is then injected into the mold and left to cool. Once it solidifies, a portion of the blinder is removed using methods such as the catalytic process and the use of solvents.

Die Casting

The die casting process, also known as high-pressure die casting, is the forcing of molten metal under high pressure into a mold cavity. The process is as follows:

- First is the preparation of the dies (molds), which entails the lubricating of the mold cavity to facilitate the easy removal of the casting and to control the temperature.

- After that, the cast is closed and injected with molten metals under relatively high pressure between 1500 psi and 25400 psi.

Die casting products are made from nonferrous metals such as copper, zinc, aluminium, and lead.

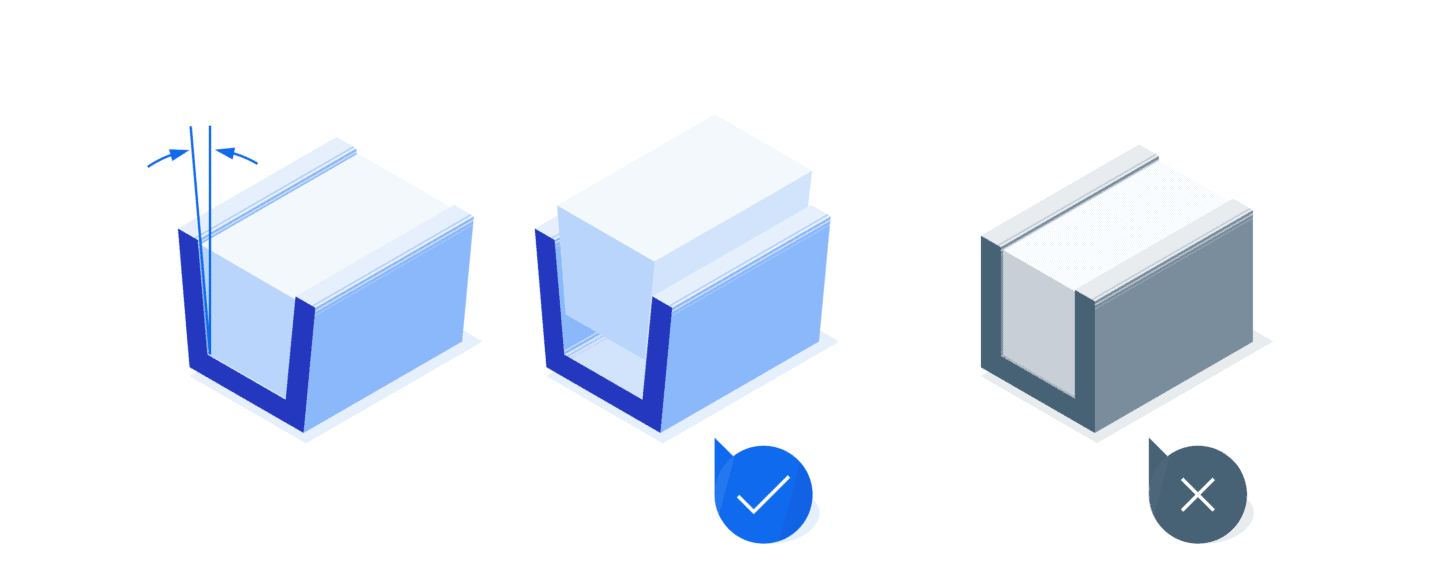

Thin-wall Injection

This injection molding process is used to create plastic parts with very thin walls such as food packaging, parts of equipment, and lab apparatus. The sizes of these parts are larger than their thickness. This process of creating thin walls is more difficult than other processes.

Micro Injection Molding

Just as the name implies, “micro injection molding” is a molding process used to produce tiny plastic parts with weights of about 1 to 0.1 grams. This facilitates the manufacture of micro parts of various complicated geometries with maximum precision and accuracy.

Gas-assisted Injection Molding

In the production of thick plastic parts with injection molding, there’s the risk of distorted parts caused during the cooling process of the molten plastic. This is prevented from happening in gas-assisted injection. As the molten plastics solidifies, gas is introduced into the mold by gas channels, producing smooth surfaces.

Benefits of Injection Molding

Injection molding, as a manufacturing process, has numerous benefits. Some of these are as follows:

High Production Output

This is one of the process’ most important advantages. The process takes 20-120 secs to complete a cycle, enabling it to create hundreds of parts per hour.

Minimal Cost of Labour

The injection molding process is fully automated and can be operated solely by one operator. Therefore, the production cost is cut due to the reduced number of heads.

Design Flexibility

Injection molding enables manufacturers to create various designs regardless of their complexity and intricacy.

Quality Consistency

This process follows a sequential pattern in the creation of identical parts. Therefore the quality of the first would be similar to that of the second, third, and the next.

Low Wastage

Unlike other production processes such as CNC machining cuts away substantial parts, injection molding produces very little scrap. The little unused materials can be gathered and recycled.

Compatibility of Multiple Materials

With this process, you can use multiple materials and colours simultaneously. And as the ejected part has a finished appearance, there is little or no work to be done after that.

Limitations of Injection Molding

Despite its multiple advantages, injection molding also has some of the following downsides.

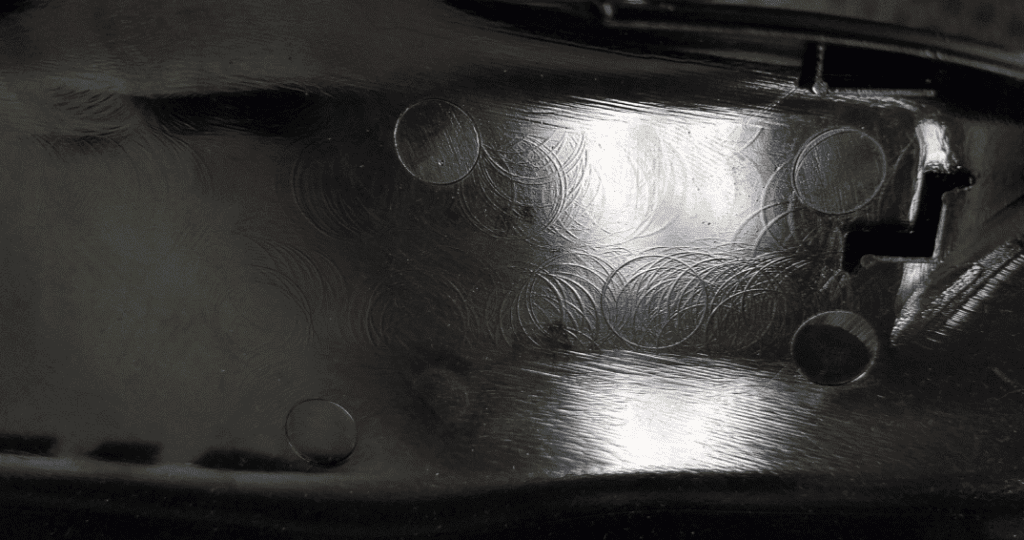

Visual Defects on the Parts

Though the process is precise, minor defects from the injection molding process may exist in the finished products. Take note that the defects are not such that would affect the workability of the parts. Some defects are warping, jetting, sink marks, flow lines, weld lines, short shots, and vacuum shots.

High Cost

The setup costs of injection molding are high. The machines and tools used are expensive. A prototype of the mold also needs to be created and tested. Plus, it takes very skilled workers to design the mold, to avoid future expenses in the part production.

Not Suitable for Large-sized Parts

The production of large parts of equal density is very difficult. This is because of the limitations of the mold. Large parts would have to be created as smaller parts and then combined.

Conclusion

The use of injection molding in various industries has brought about the seamless and precise production of parts in mass within a short period. Through our extensive network of manufacturers, Xometry Europe offers injection molding services for several dozens of materials including plastics and elastomers. Simply head over to our Instant Quoting Engine to upload your model and receive a quote to order parts.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0