Video case

Video case

Turska

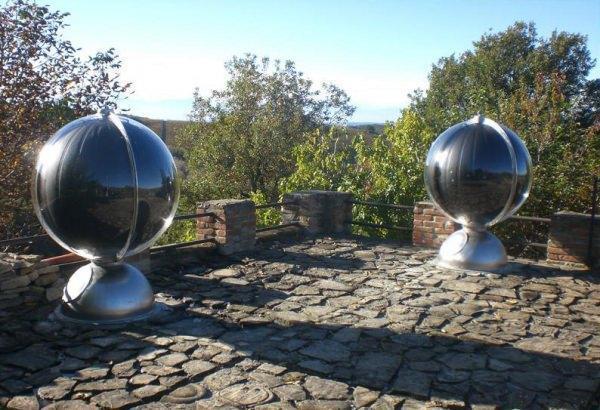

Electric vehicle charging station

Xometry is not just a supplier; it’s a true solution partner. In such specialized projects, challenges and delays are inevitable. However, we never faced any issues while working with Xometry.

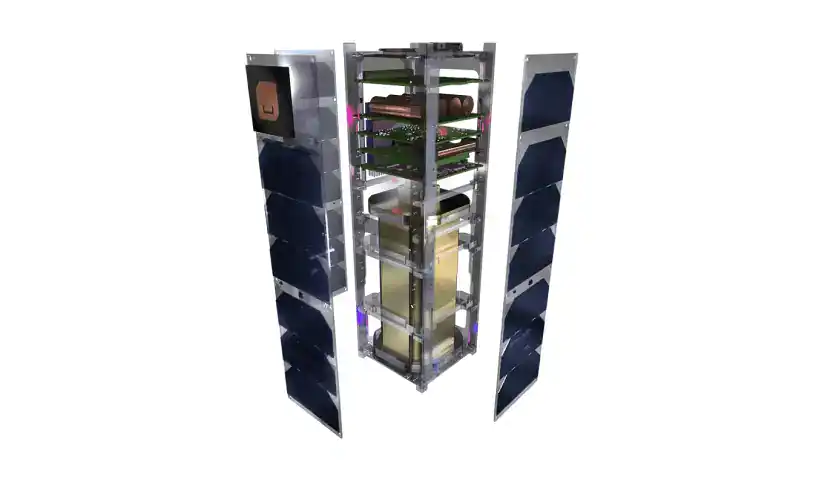

Orge Enerji, a leading Turkish company in electrical contracting and energy solutions, is celebrated for its innovative approach to sustainable energy projects. To develop its groundbreaking Round EV Charge Station, Orge partnered with Xometry to benefit from their expertise and comprehensive manufacturing solutions throughout the prototyping and production phases.

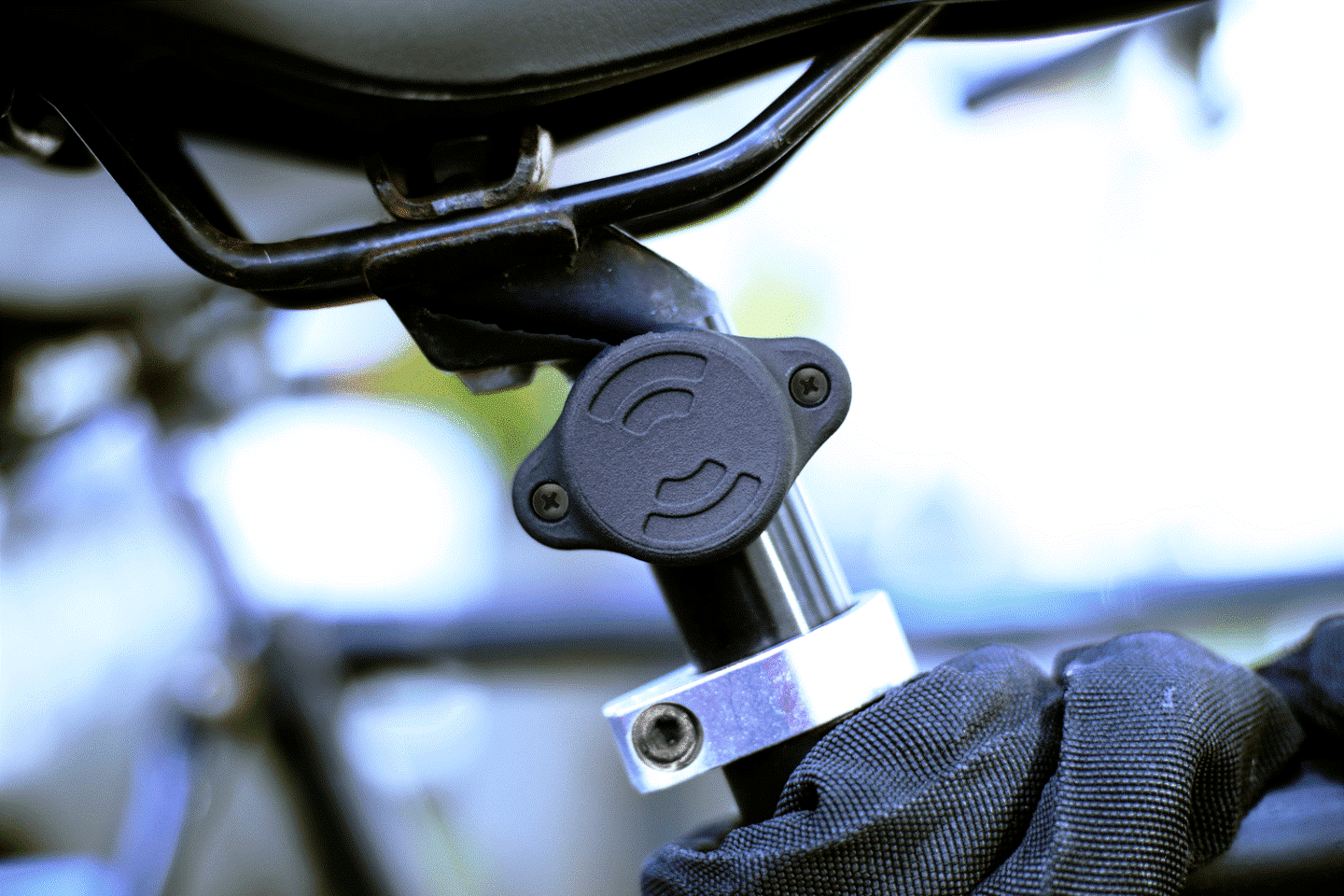

The Round stands out not only for its sleek design but also for its adherence to global standards such as IP 55/65 protection and OCPP 2.0.1 JSON compliance. Featuring cutting-edge technologies like bidirectional energy flow (V2G) and RFID/NFC-enabled secure operation, the Round offers a seamless user experience. Drivers can start and stop charging with just one command from their vehicles. Developing such a product required top-tier R&D and precision manufacturing.

A Prototype Engineered for Excellence

After six months of rigorous iterations, collaborative meetings, and production processes, the high-quality prototype of the Round EV Charge Station debuted at the EV Charge Show this November. The project’s prototyping phase presented several key challenges:

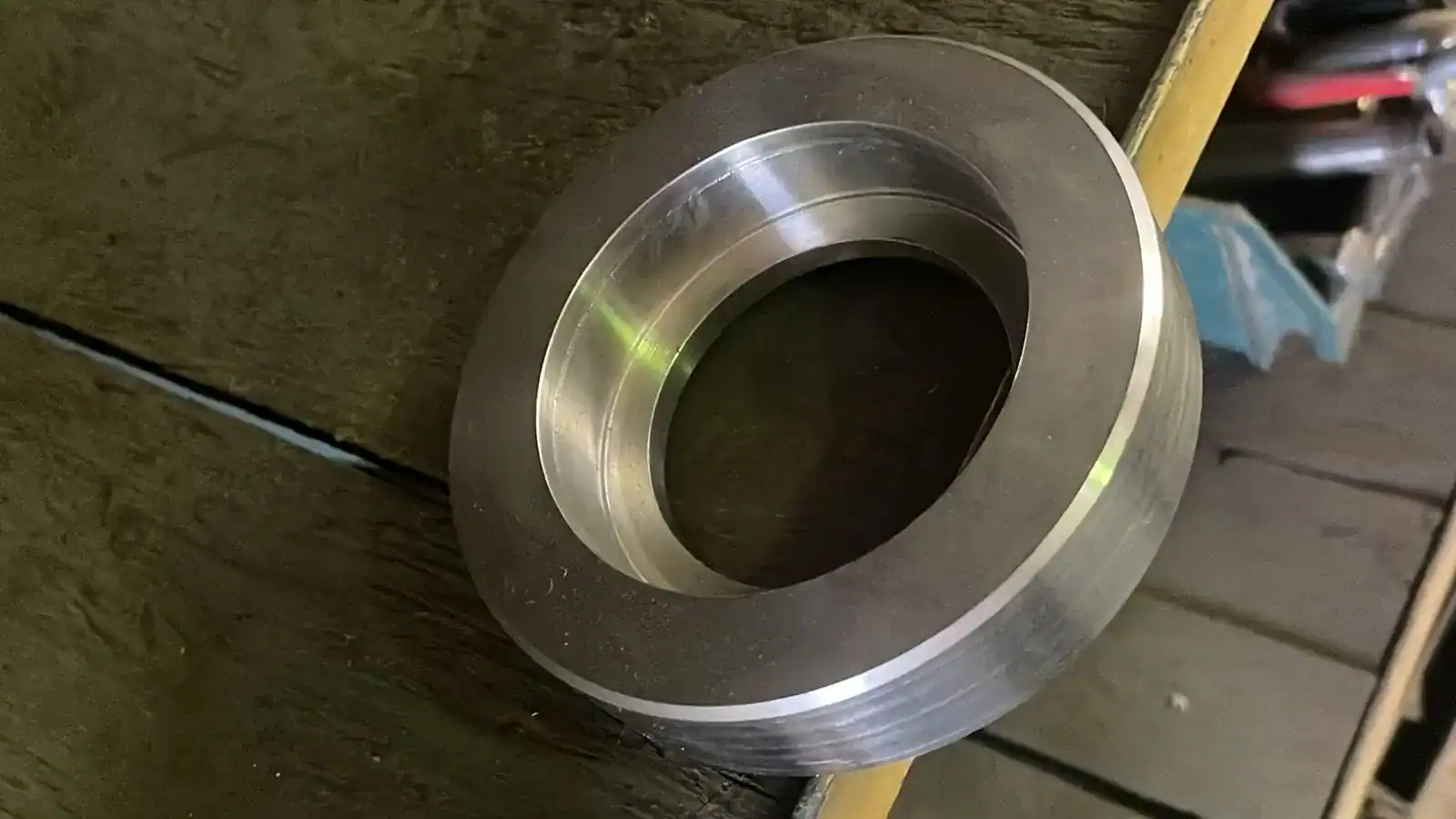

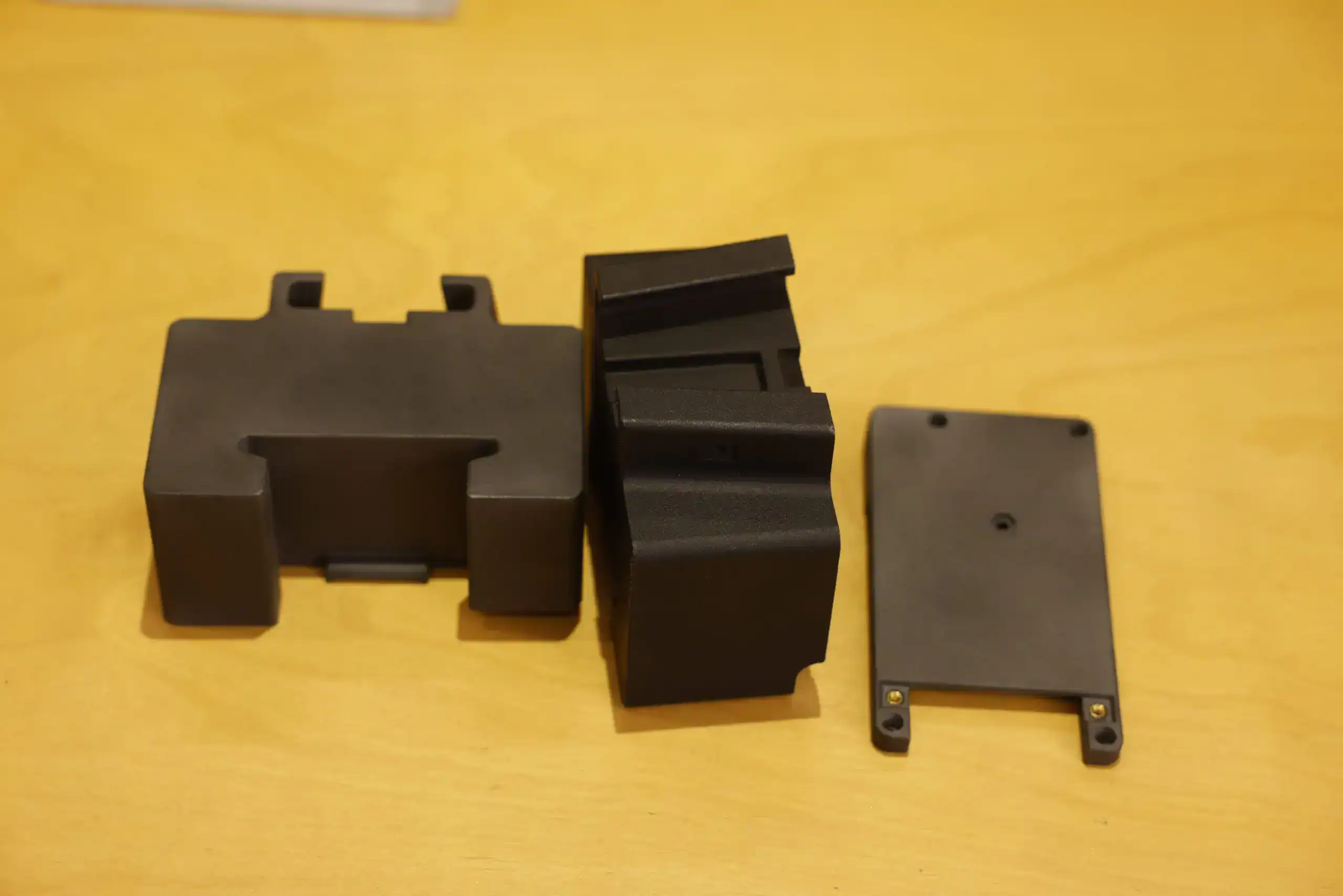

- Multidisciplinary manufacturing: Custom parts were crafted using Xometry’s vacuum casting and FDM 3D printing services.

- Aesthetic and functional perfection: The prototypes had to meet strict aesthetic and technical standards for international exhibitions.

- Design agility: The project demanded rapid adaptation to design changes and revisions.

- Flawless integration: Ensuring seamless compatibility among components was critical to success.

Precision Manufacturing in Action

Leveraging Xometry’s FDM 3D printing, vacuum casting, and advanced post-processing capabilities, the project delivered exceptional results. Key components—such as seals and the ORGE logo—were produced with FDM technology, while larger parts like the back cover, front panel, and diffuser were manufactured using silicone molding. Custom polishing treatments ensured a flawless finish, ready for global presentation.

Throughout the process, Xometry’s team conducted regular Design for Manufacturability (DfM) analyses, refining production methods and ensuring optimal design compatibility. Collaborative meetings allowed Xometry to quickly adapt to Orge’s evolving needs while preparing for mass production through mold manufacturing and injection molding.

Building the Future of EV Charging Together

Following the Round project, Orge plans to utilize Xometry’s injection molding and aluminum die casting services for its next-generation charging stations. This partnership underscores the synergy between Orge Enerji’s innovative vision and Xometry’s global engineering expertise, paving the way for future breakthroughs in sustainable energy solutions.

Learn more about Orge Enerji: https://www.orge.com.tr/

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط