Materials Library

Delve into our comprehensive library of materials used in various manufacturing technologies, complete with detailed properties and specifications.

-

CNC Machining (35)

-

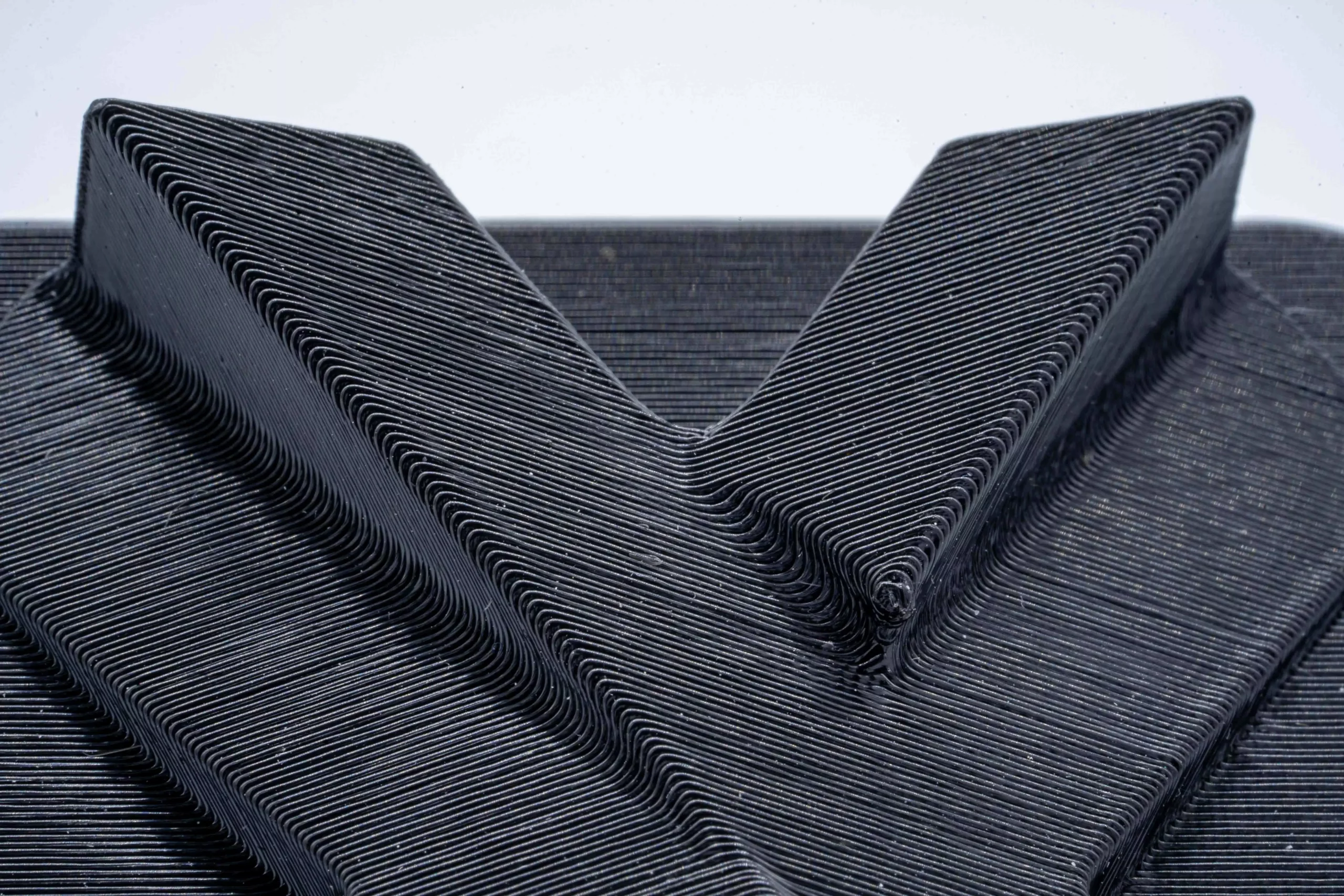

3D Printing (59)

-

Sheet Metal Fabrication (21)

-

Injection Molding (23)

-

Die Casting (8)

-

Vacuum Casting (19)

Material Types

Metals

Plastics

Elastomers

Special Properties

3D printing technologies

-

CNC Machining (35)

-

3D Printing (59)

-

Sheet Metal Fabrication (21)

-

Injection Molding (23)

-

Die Casting (8)

-

Vacuum Casting (19)

Material Types

Metals

Plastics

Elastomers

Special Properties

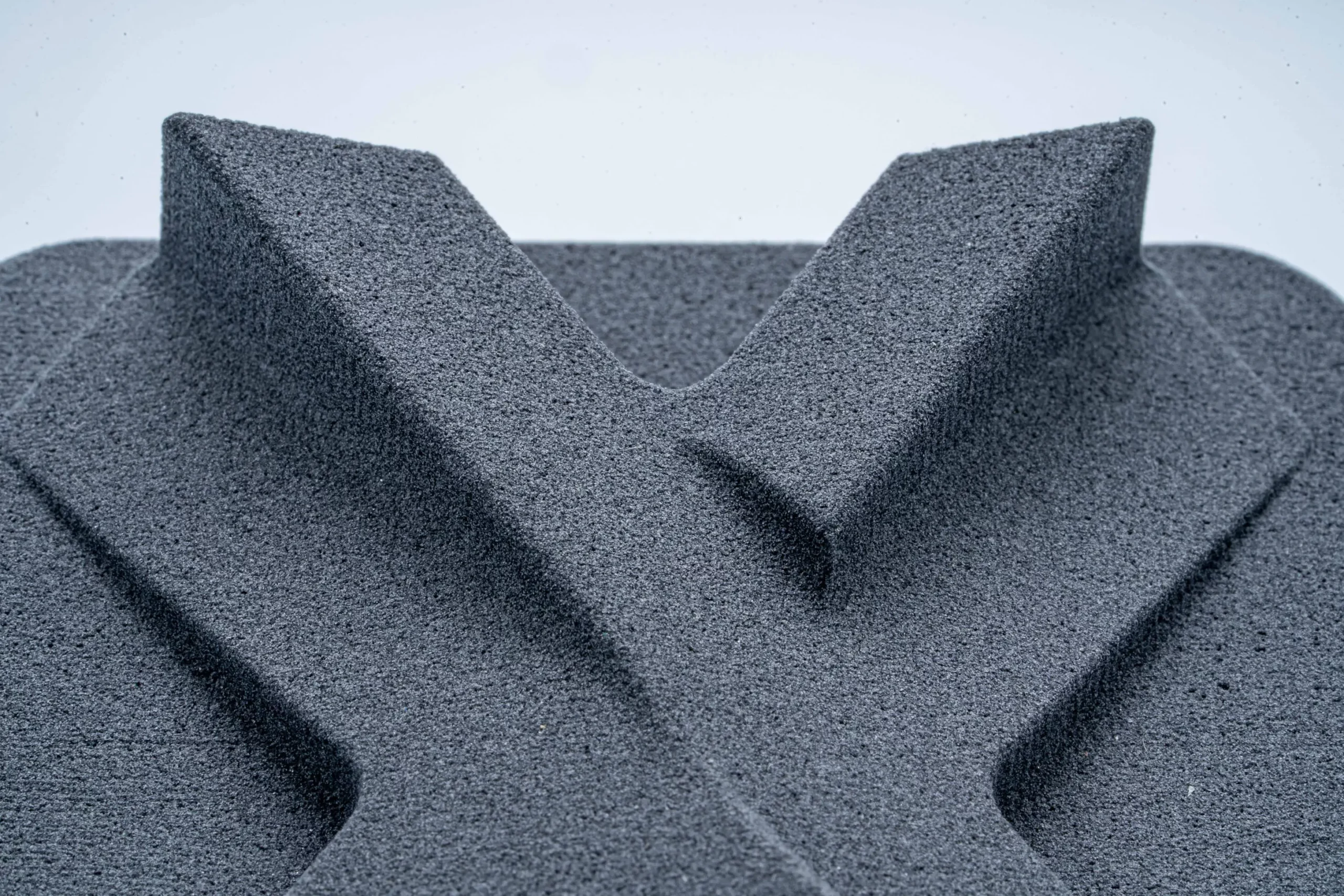

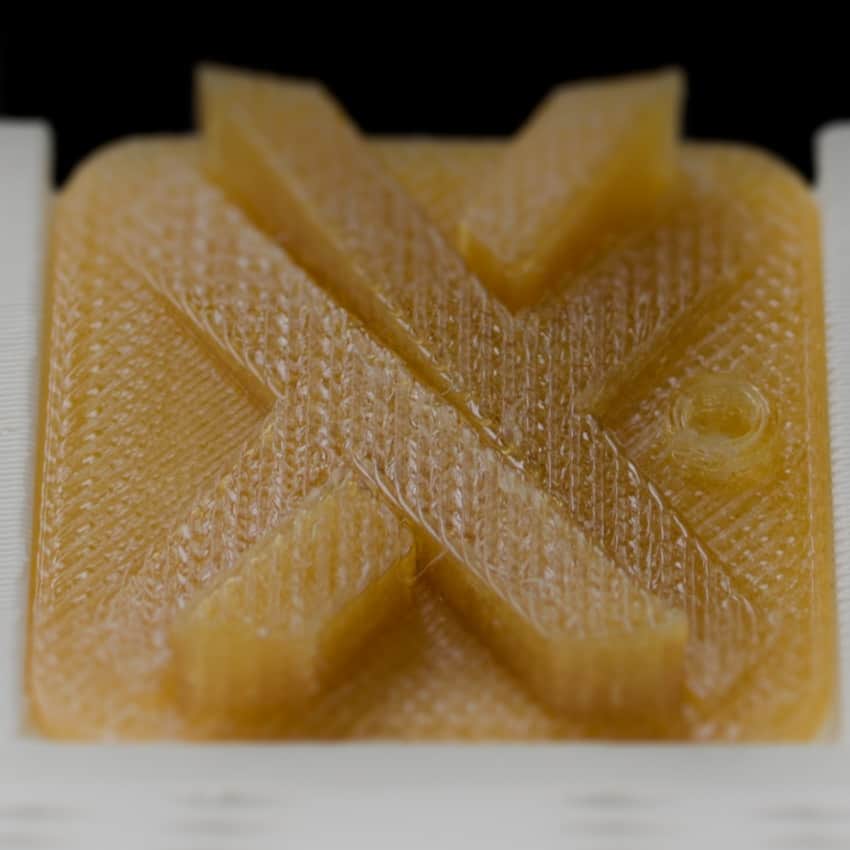

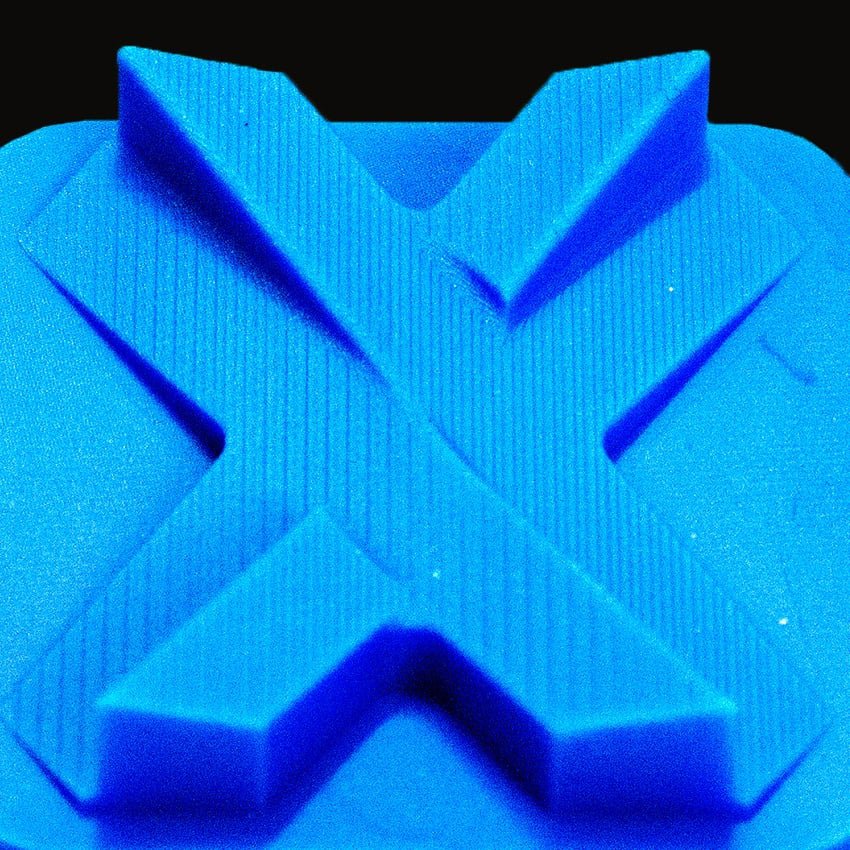

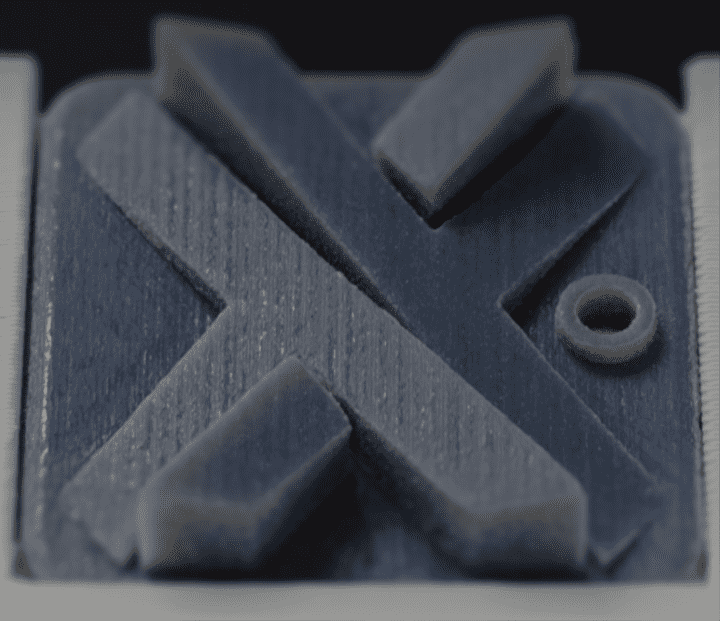

3D printing technologies

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account