Filippi Lido, a world leader in racing rowing boats, turned to Xometry’s precision CNC machining and on-demand manufacturing services to produce custom components for its Olympic-class shells. The collaboration supported faster innovation, reliable small-batch production, and consistent part quality — contributing to the company’s performance at the 2024 Paris Olympics, where Filippi boats won 64% of all rowing medals.

意大利

High-performance racing rowing boats for Olympic, para-rowing, and coastal disciplines

We found a flexible company — fast in providing responses and feedback, highly professional, and offering an excellent price-to-quality ratio.

Founded in 1980 by Lido Filippi and now led by his son David, Filippi Lido has become a global benchmark in racing rowing. From its workshop in Donoratico, Tuscany, the company combines artisanal craftsmanship with advanced engineering to create boats designed for the highest levels of competition.

A Legacy of Craftsmanship and Innovation

Over the decades, Filippi has worked with elite athletes and national teams worldwide, uniting tradition with continuous research and innovation. This focus on performance and precision has made the brand a trusted partner in professional rowing. At the Paris 2024 Olympics, Filippi boats carried athletes to an exceptional 64% of all rowing medals, including nine golds, nine silvers, and nine bronzes — a result that confirms its leadership on the world stage.

Behind these achievements lies a commitment to constant improvement and strong partnerships. To meet the growing demand for precision components and shorter production cycles, Filippi collaborates with Xometry, using its digital manufacturing network to produce high-quality custom parts that keep each boat light, rigid, and perfectly balanced.

Engineering the Perfect Boat

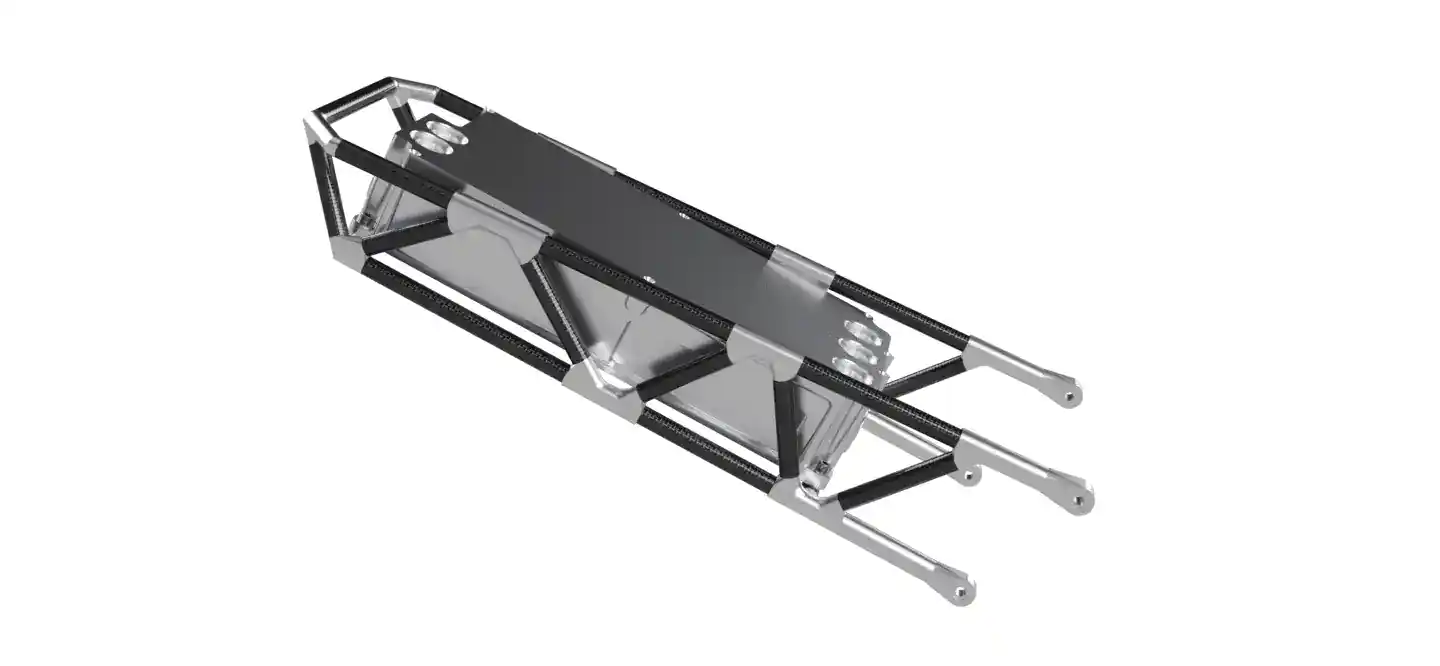

Each Filippi boat begins as an engineering study of the athlete’s interaction with the water. The design process focuses on ergonomics, balance, and the transmission of energy through the hull. Engineers analyze force patterns and structural stresses to optimize the geometry and internal reinforcement of every shell, ensuring maximum efficiency without adding weight.

In early 2024, Filippi launched its PERFORMANCE line — a major innovation in rowing shell construction. The new PERFORMANCE configuration introduced structural and material improvements that increased stiffness and enhanced power transfer. Despite being released just before the Paris Olympics, the PERFORMANCE line proved immediately successful: more than half of Filippi’s medal-winning boats were built using this configuration.

Precision and Speed Under Pressure

Designing Olympic-level boats means working to extremely tight tolerances and timeframes. Every part — from rigging pins to structural fittings — must meet exact specifications to guarantee durability, safety, and performance.

Because each Filippi boat is built for a specific crew, components must be custom-made and delivered quickly to fit the athletes’ training and competition schedules. This made it essential to find a manufacturing partner that could combine speed with precision and flexibility.

A Partnership Built on Precision

Xometry quickly met Filippi’s technical demands, producing key metal components for its Olympic-class shells. This partnership helped Filippi move from design to production within days instead of weeks — a crucial advantage when testing new configurations or preparing for major competitions.

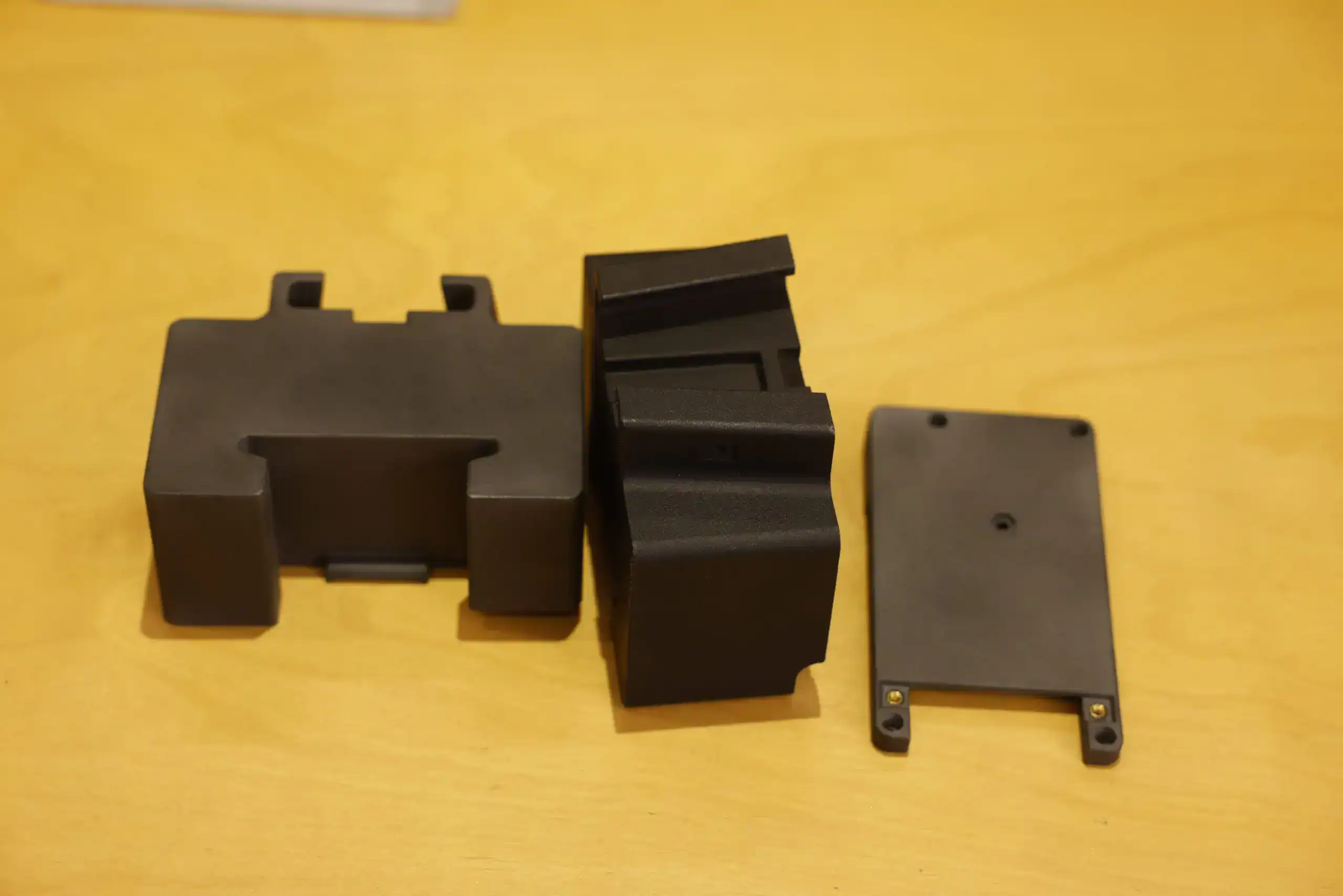

In particular, Xometry manufactures numerous metal/aluminum components for racing boats, such as rudder rockers, fifth tube ends, parts of the chassis, handles, handle holders and pins.

Each component was tested in real performance conditions, with the results shared back to Xometry for refinement of design accuracy and finishing. This iterative process ensured consistent quality and reliability across every production run.

Through its partnership with Xometry, Filippi reduced development time, improved component consistency, and achieved higher overall boat performance. The precision and repeatability of the manufactured parts contributed directly to the stiffness and efficiency of the boats.

Designing Tomorrow’s Champions

The company is expanding this configuration to new boat categories and developing AI-driven hull geometry in collaboration with European universities as part of an EU-funded research project.

As Filippi Lido continues to redefine what’s possible in racing rowing, its partnership with Xometry remains a vital part of that journey — combining precision, speed, and reliability to turn engineering excellence into Olympic success.

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط