Birleşik Krallık

High‑end mountain bike frame (“Chilli Dog”) designed for enduro use.

Xometry makes the process of sourcing custom and serial parts much easier. … Xometry helps me get fair prices for the CNC machined parts compared to when I would go to a random manufacturer I don’t have a relationship with.

mountain bikes and always wanted to build his own brand.

He initially started manufacturing the frames in Taiwan, but the lead times got longer and raw material shortages became an issue, so Kieran decided to re-think his strategy and manufacture the frame in the UK and the yoke in Germany.

So far, the company has focused on building high-quality frames rather than producing and assembling full-built bikes. To get the other components like suspension or wheels, they partner with other brands so their customers can order most of the components needed for a full build.

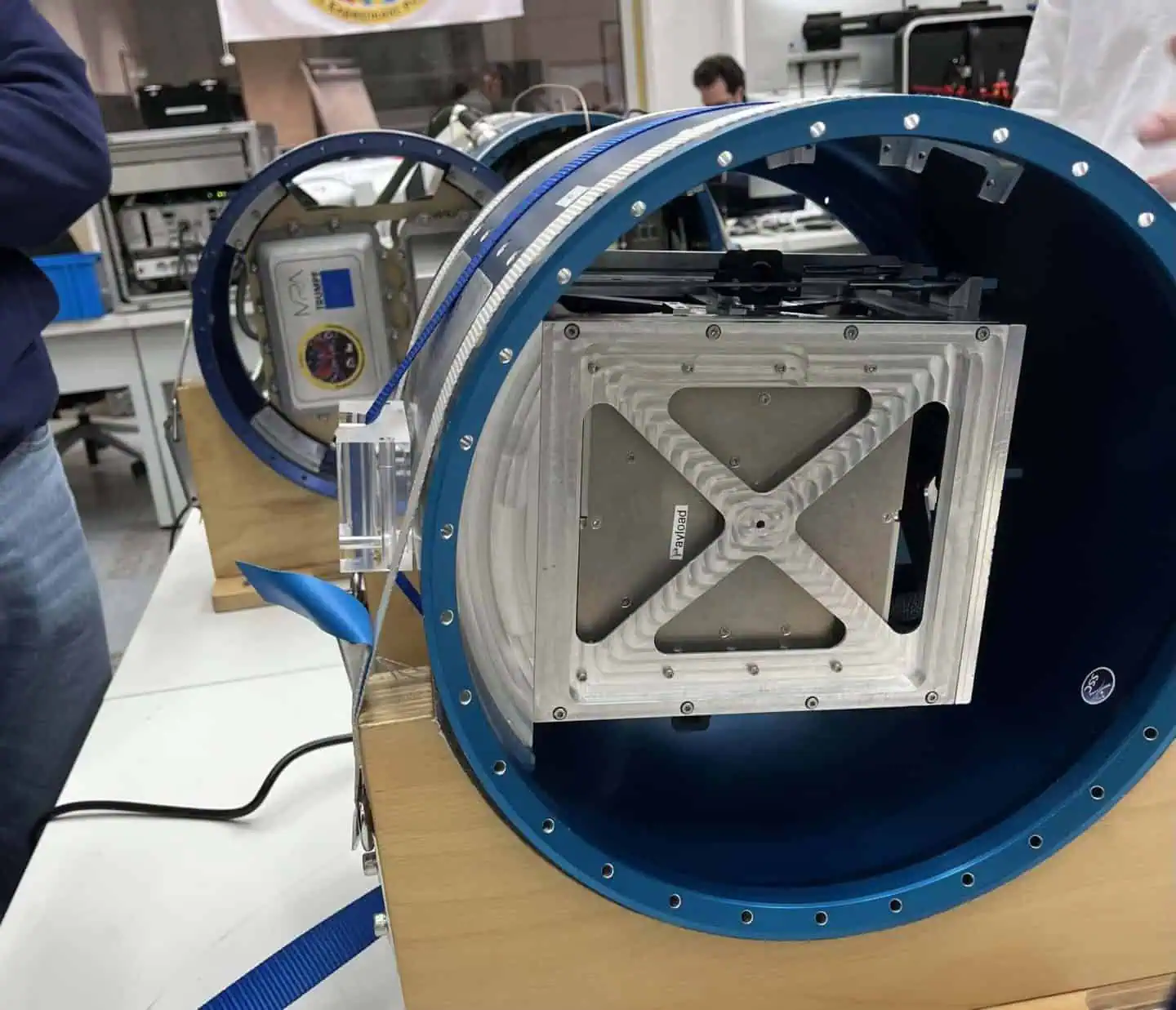

The Chilli Dog – A Perfectly Engineered Frame

Radical All Mountain Cycles is especially proud of its flagship frame for mountain bikes called the Chilli Dog, which is specifically aimed at the enduro market. Kieran focused on this specific frame because he personally rode and raced this category before he started the company, so he knows exactly what demands need to be met.

Engineering Components for Mountain Bikes

When approaching design, Kieran tries to respond to the needs of the bikes within this category. For example, there are various expectations for mountain bikes compared to road bikes, like the strength of their frames for hurtling downhills and taking big impacts. These are key things to consider when selecting production materials. For his frames, Kieran works with steel because of its strength, which allows the bikes to handle tough mechanical exposure. It also lets you draw the frame tube walls really thin to give you a smooth, compliant ride.

The geometry of the frame is also crucial and affects how the bike will ride. It is also dependent on the material selection if you eventually need to bend the tubes or use some special tooling.

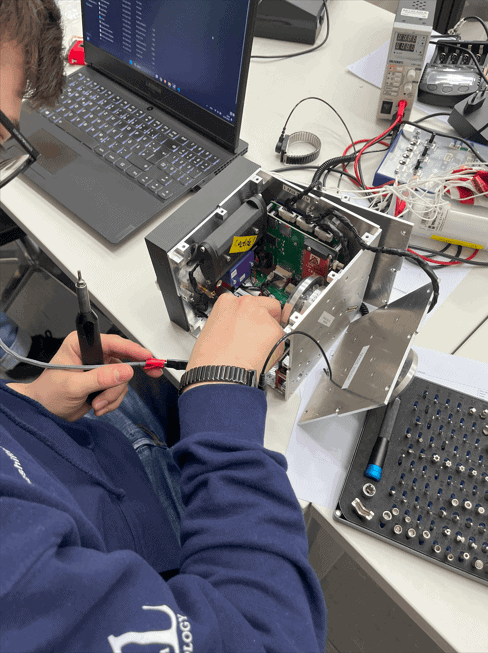

After performing some sketches of the geometry, a design engineer creates a 3D model, which helps them run various simulations and spot possible issues.

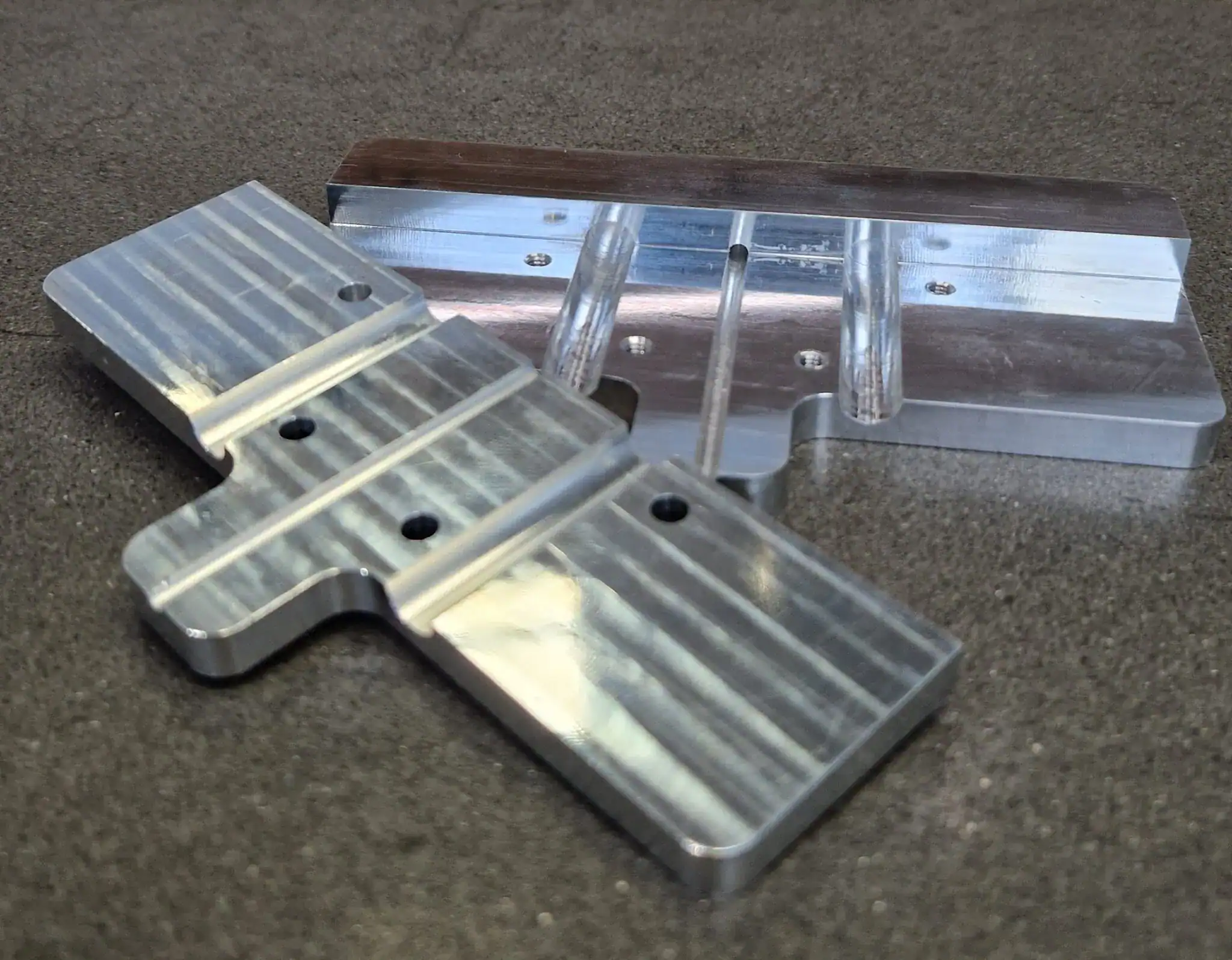

CNC Machined Yoke for Improved Energy Transfer

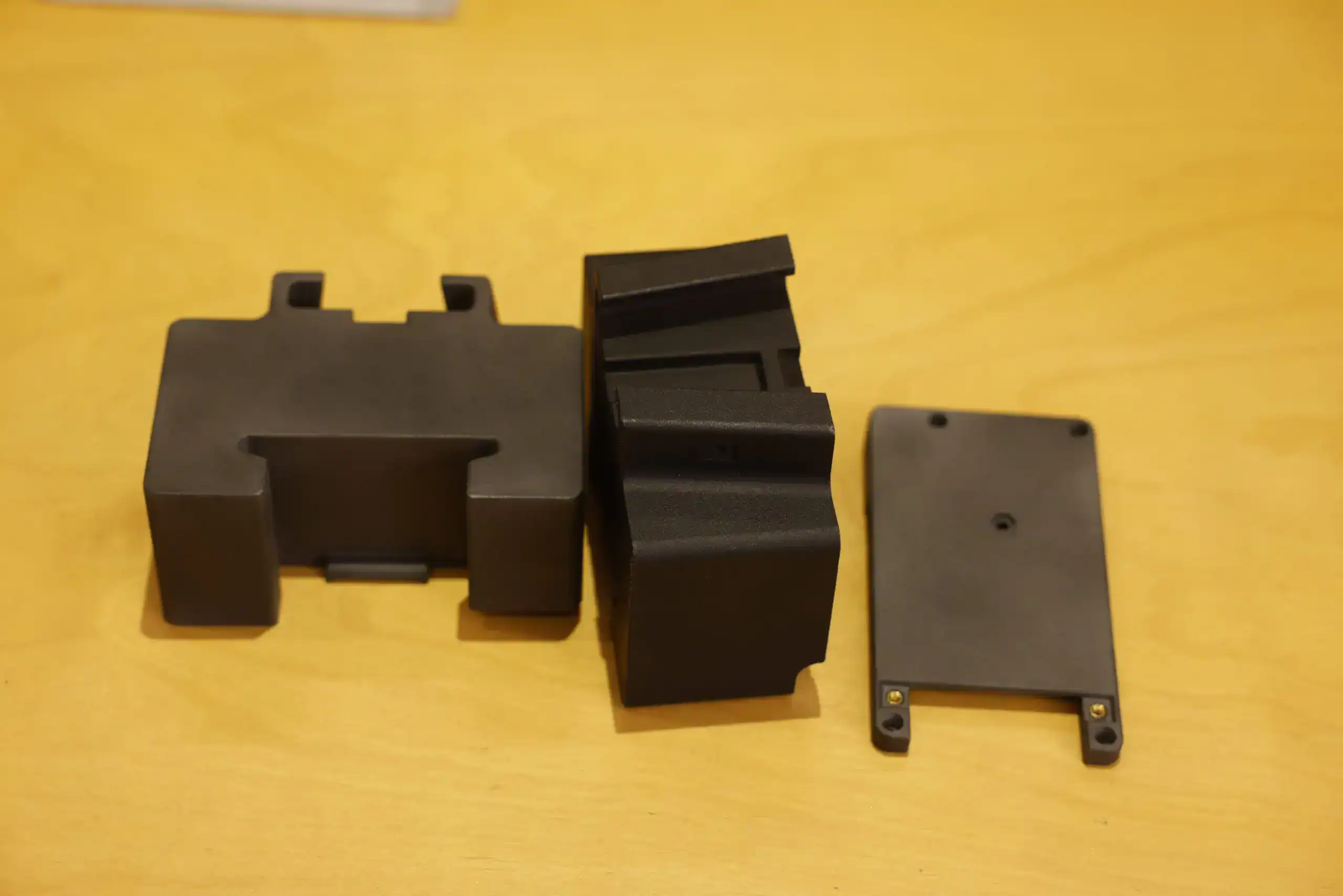

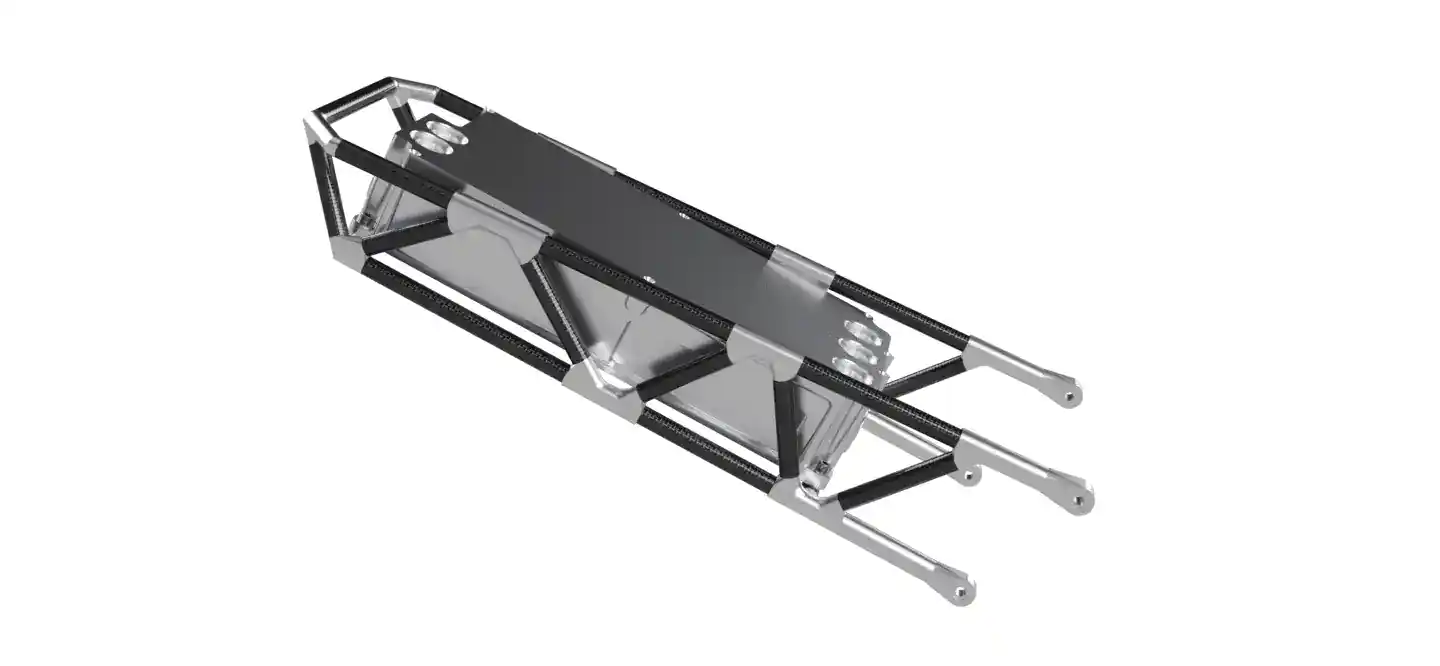

The yoke that Radical All Mountain Cycles designed and got manufactured via Xometry is a great example of how individual components affect the overall performance of the frame.

The yoke sits on the bottom of the frame and lets you increase your tyre or mount clearances. It also stops the rear end warping and twisting and gives you better energy transfer for the rear of the frame. This makes it more direct and improves rear-end control compared to welding the tubes holding the wheels directly to the frame.

Using Local Suppliers and on-demand Manufacturing to Overcome Supply Chain Disruptions

Kieran reports that material shortages and supply chain disruptions are major issues in the bicycle industry. Previously, when he was still dealing with the suppliers in Taiwan, he experienced lead times for producing frames of up to 2 years. This is simply not an option for a startup bringing a new product to the market. This made him turn to UK-based suppliers, which helped cut the lead times for the individual components from 12-24 months to having completely assembled frames in just 2.5-3 months.

In addition to this, Kieran enjoys Xometry’s on-demand manufacturing services. It can be quite difficult for a young company to know where to start or have established relationships with a manufacturer to work on your project. For him, Xometry makes the process of sourcing custom and serial parts much easier. He also adds that Xometry helps him get fair prices for the CNC machined parts compared to when he would go to a random manufacturer he doesn’t have a relationship with.

Plans

Currently, Radical All Mountain Cycles are working on another frame model specifically for smaller-sized wheels. They also have other products in the pipeline to help them grow the company.

Check out the website of Radical All Mountain Cycles: https://radicalallmountain.com or contact them via info@radicalallmountain.com

Avrupa

Avrupa  Birleşik Krallık

Birleşik Krallık  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط