Supporting KOPI Concepts from prototype right through to mass production, Xometry produces laser-engraved sheet metal bent parts, aluminium clear anodised parts and CNC turned stainless steel parts for food-safe coffee grinder accessories, in multiple batches of 200.

Birleşik Krallık

Aluminium, Stainless steel (food-safe CNC turned)

Clear anodising (aluminium), Media tumbling, Vibro-polishing

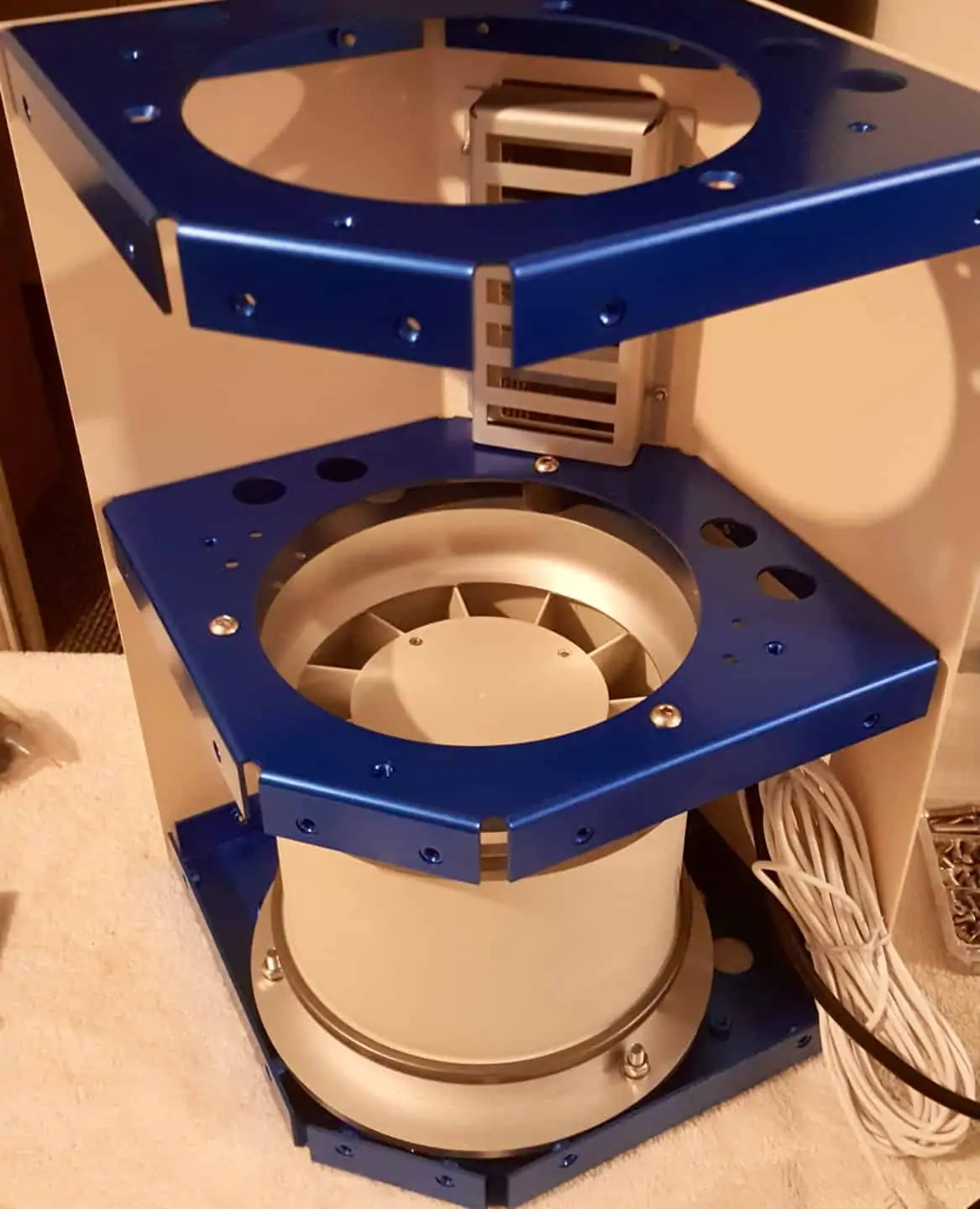

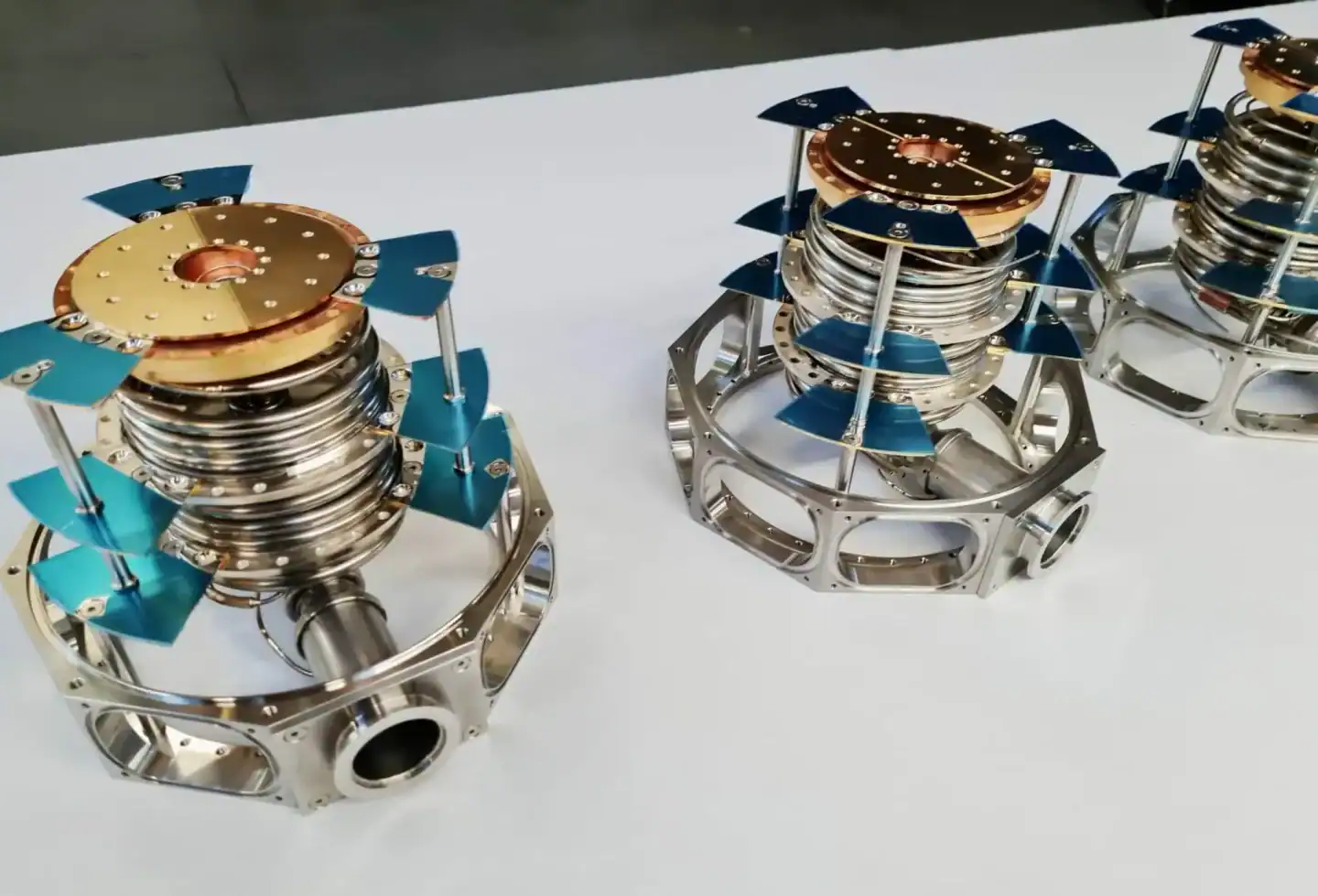

Single-dose coffee grinder (KOPI Deva) designed for consistent extraction and minimal waste

Xometry offered us a shortcut to the market. We leveraged Xometry’s massive manufacturing network to find capacities for small and medium sized machine shops that could produce parts in quantities we required.

KOPI Concepts was founded to bring quality coffee equipment into your home, reduce waste in your workflow, and help you get the best flavour profile from any brew method. Their aim is to provide you with the very best cup of coffee on demand, with every grind. Their solution was the stylish KOPI Deva, a single dose coffee grinder that provides consistency and quality, giving you the best flavour extraction out of every single coffee bean, whilst minimising waste.

Xometry speaks with Brandon Wong, CEO and Founder of KOPI Concepts, and Formula motorsport engineer, about his coffee vision and eye for precision.

The Journey with Xometry, From Prototype to Mass Production

Brandon Wong’s passion for exceptional coffee saw him utilise his skills as a Formula motorsport engineer to develop a premium and stylish coffee grinder that was a statement piece in anyone’s home.

The journey began back in London 2021, when KOPI Concepts started to develop unique designs for a coffee grinder prototype. Not just any coffee grinder, one that would fit seamlessly into your home with a sleek design and battery-operated functionality. After conducting some market research, Brandon Wong conceptualised the KOPI Deva coffee grinder and sought to produce his first prototype.

After searching for ‘online pricing for small batch manufactured parts’. KOPI Concepts discovered Xometry’s Instant Quoting Engine.

This was Brandon Wong’s first time product designing and developing, so the Instant Quoting Engine provided quick and transparent pricing options for his coffee grinder parts, allowing him to understand how much it would cost to create his premium prototype.

At this prototyping stage, KOPI Concepts found their coffee grinder to be well-received by the consumers, so they decided to develop it and scale-up to meet consumer demands. The challenge that KOPI Concepts faced was to understand the costs involved in manufacturing their coffee grinder in larger quantities. They knew the coffee consumer market wanted their KOPI Deva coffee grinder, but how many exactly was unknown – they needed flexibility!

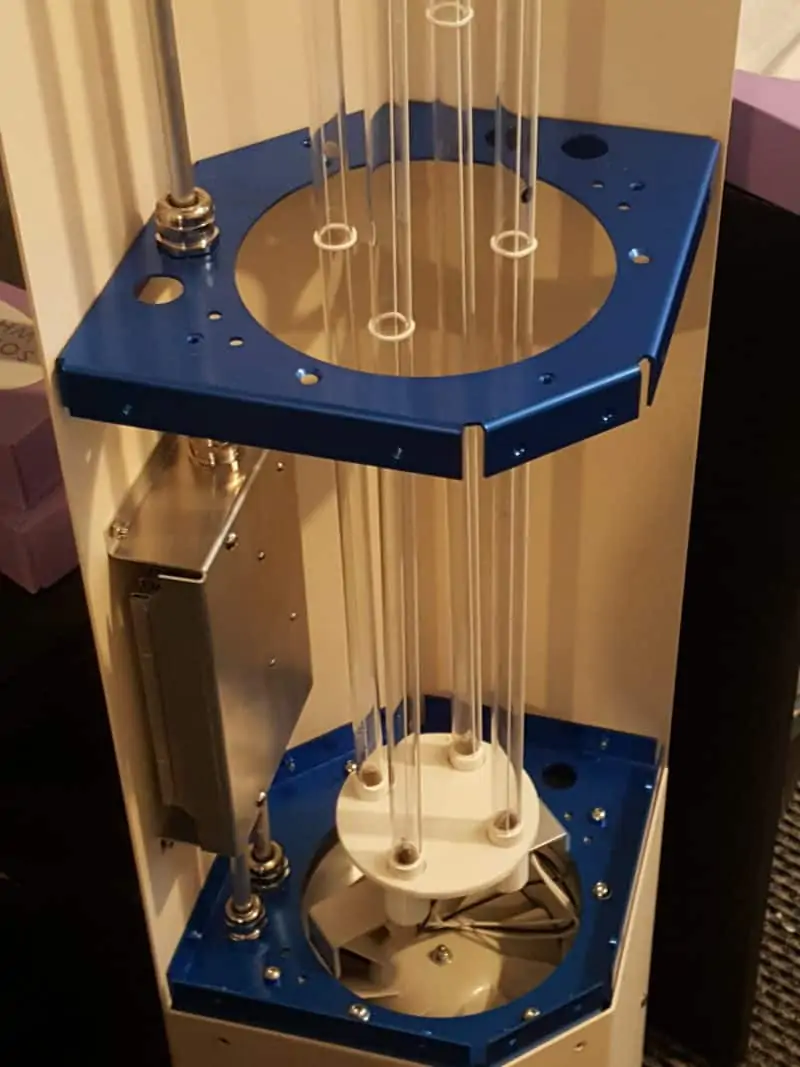

KOPI Concepts utilised Xometry’s Instant Quoting Engine often to seek pricing for their coffee grinder parts in different quantity breaks. The prototype went through five design development phases with Xometry supporting them throughout this process. Senior Key Account Manager, Dorien Sarsby, provided advice on selecting the best possible food-safe materials for their manufactured parts.

When it was time to scale-up, KOPI Concepts found instant access to manufacturers with flexibility to produce different quantities, a real benefit in working with Xometry. “Xometry offered us a shortcut to the market. We leveraged Xometry’s massive manufacturing network to find capacities for small and medium sized machine shops that could produce parts in quantities we required.” Brandon Wong explained.

As a small business , KOPI Concepts found real value in collaborating with Xometry as they were able to focus on the product design and development, whilst Xometry managed the logistics, quality control and communications with manufacturers. Brandon Wong adds “I really appreciate that Xometry has been able to support us through every stage of the process. That’s something that I don’t think is very common but was so beneficial for us as a small business.”

The Food-Safe Parts for a Premium Coffee Experience

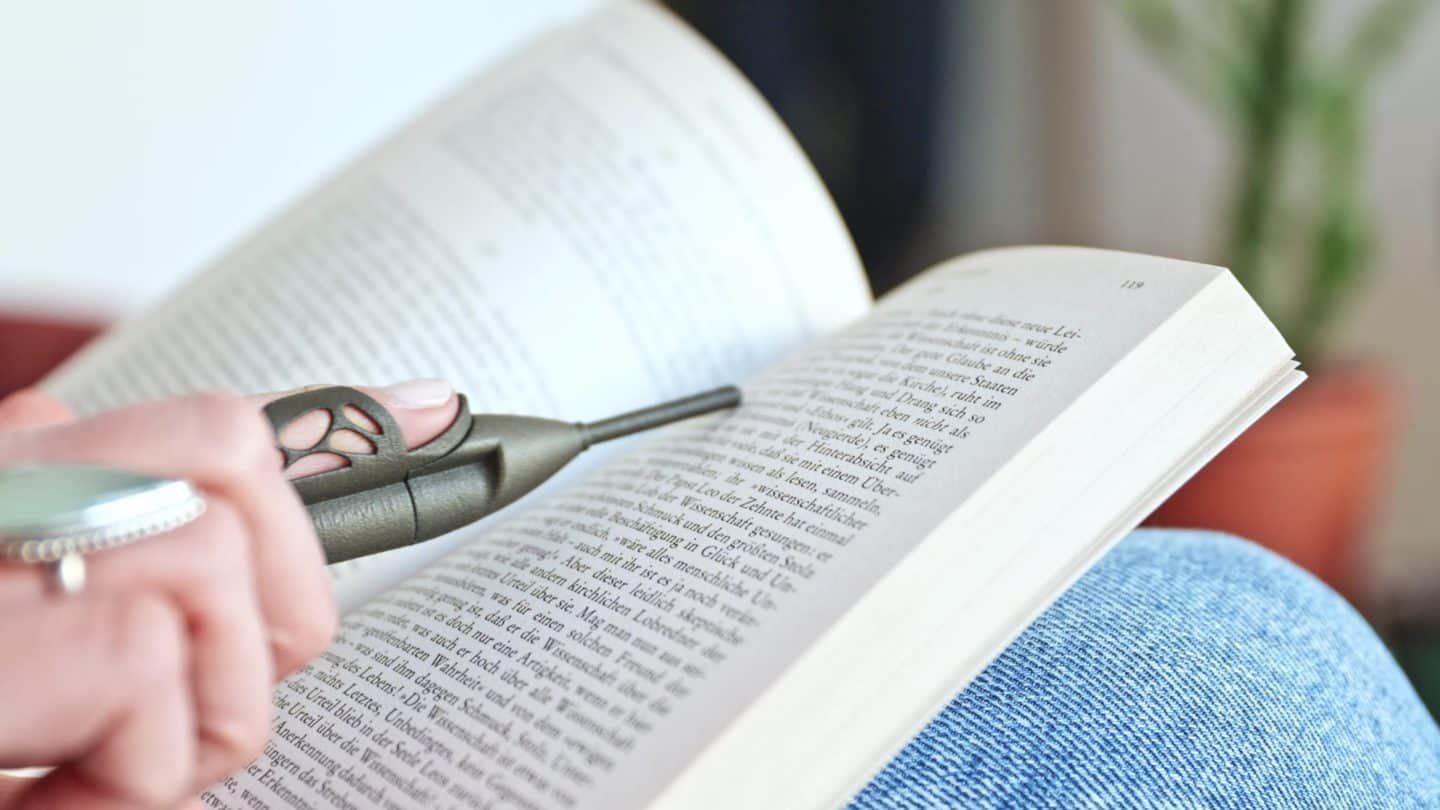

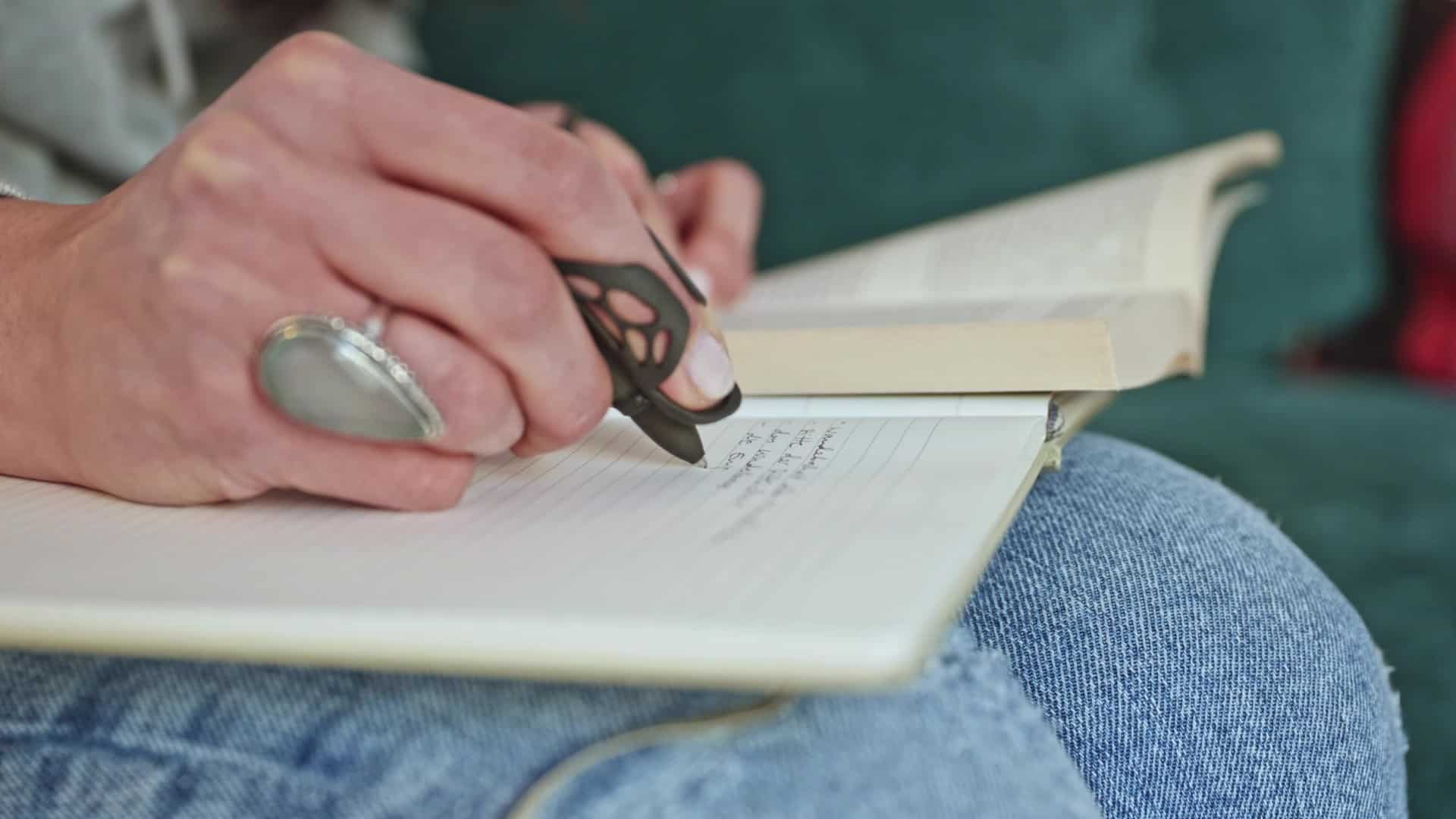

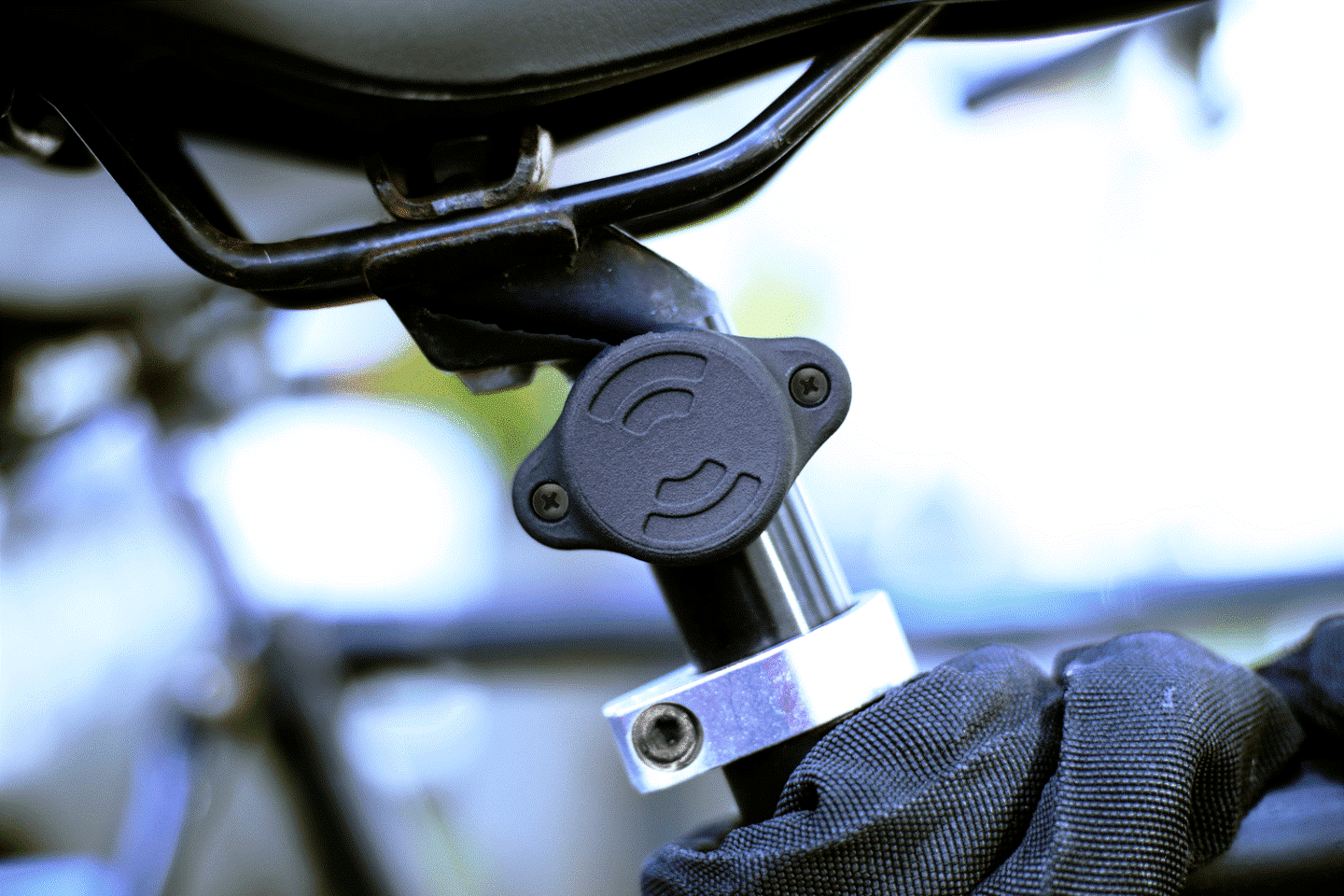

KOPI Concepts’ moved their prototype to mass production at lightning speed after being well received by coffee lovers, utilising Xometry’s precision manufactured parts throughout the process. These parts included a stainless steel food-safe holder that allowed users to grind into a cup that was designed to go directly into the coffee machine itself. These parts were on a CNC turned on lathe and then the media tumbled and vibro-polished to achieve a premium finish. Along with this, aluminium grade clear anodised parts were made.

Xometry also supplied laser-engraved sheet metal parts and CNC machined weight for a wood tamping station that enhances the consumer’s coffee experience. With these parts it was important that the laser engraving was of a consistently high quality due to it being a branded consumer facing element.

The Coffee Experience Continues

KOPI Concepts continue to expand their business into the drinks and beverage consumer market, now selling the unique KOPI Deva coffee grinder to larger distributors so that coffee lovers from around the world can enjoy a delicious full-flavoured cup of coffee in style!

Discover the coffee experience at KOPI Concepts website: https://www.kopiconcepts.com/

Avrupa

Avrupa  Birleşik Krallık

Birleşik Krallık  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط