Glaskeil is a classic plastic and glass processor, active in everything from simple cutting to complex complete solutions for private and industrial customers. The company supplies sectors such as wind power, yacht building, caravan construction, and switch cabinet manufacturing. The focus is on producing long-lasting, aesthetic products where precision and material expertise are essential.

Video case

Video case

Nemčija

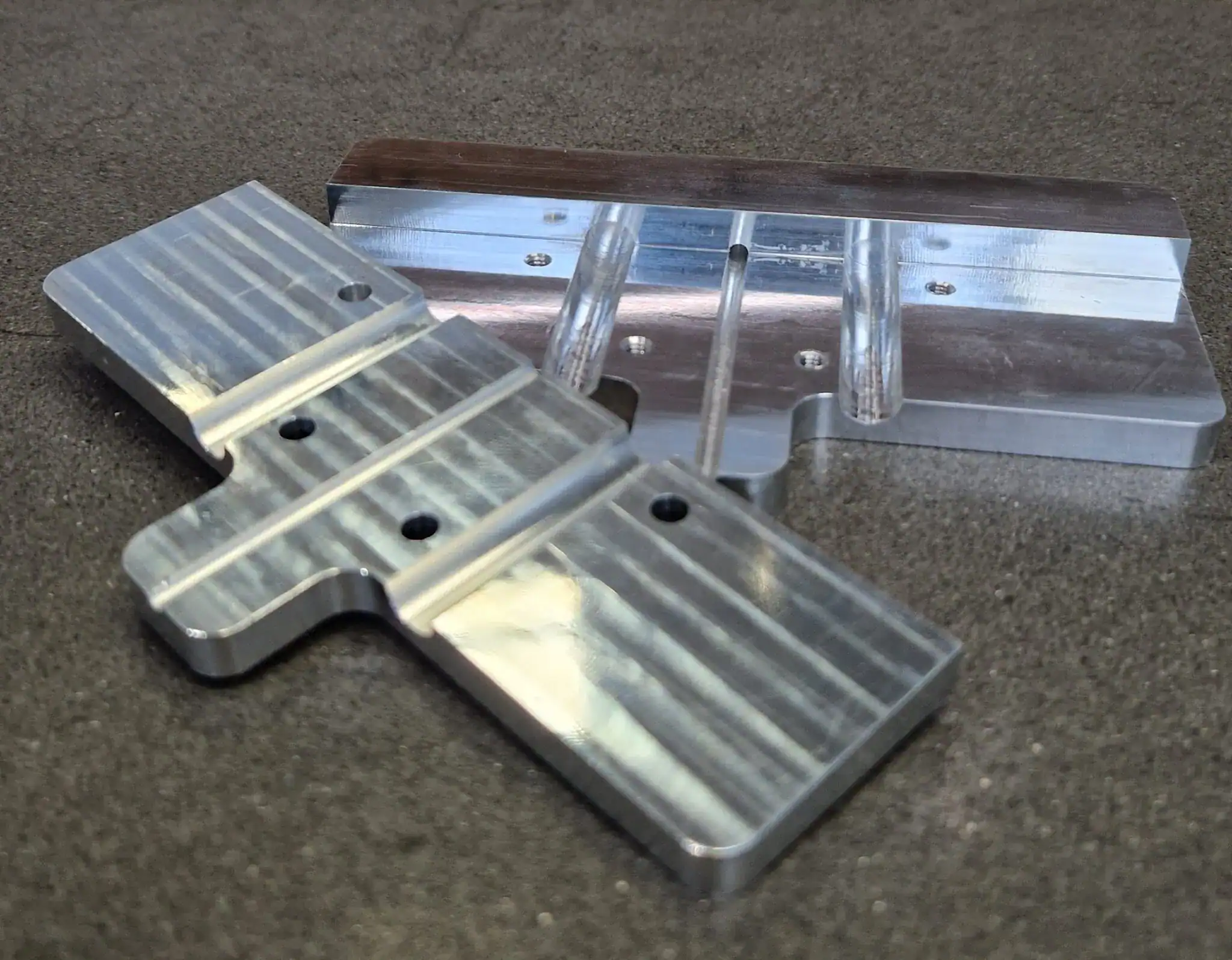

Aluminium

Polishing

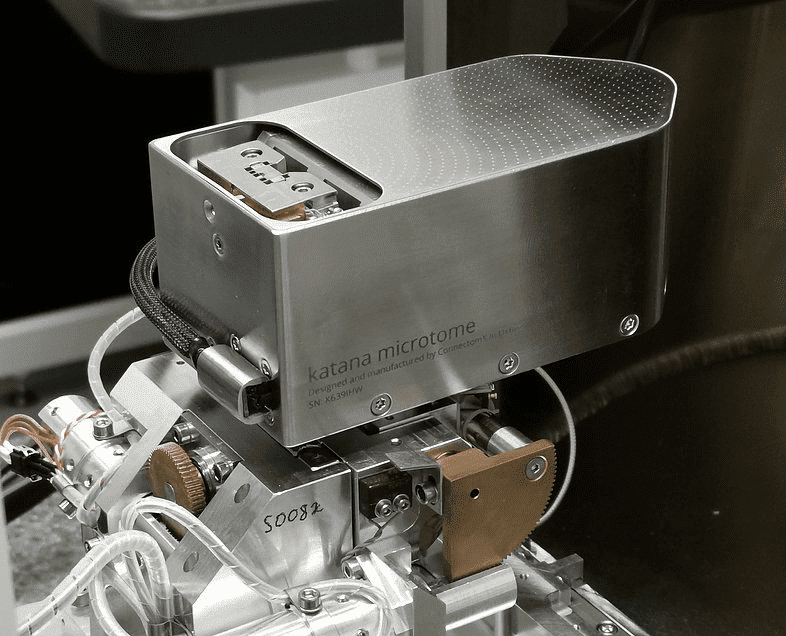

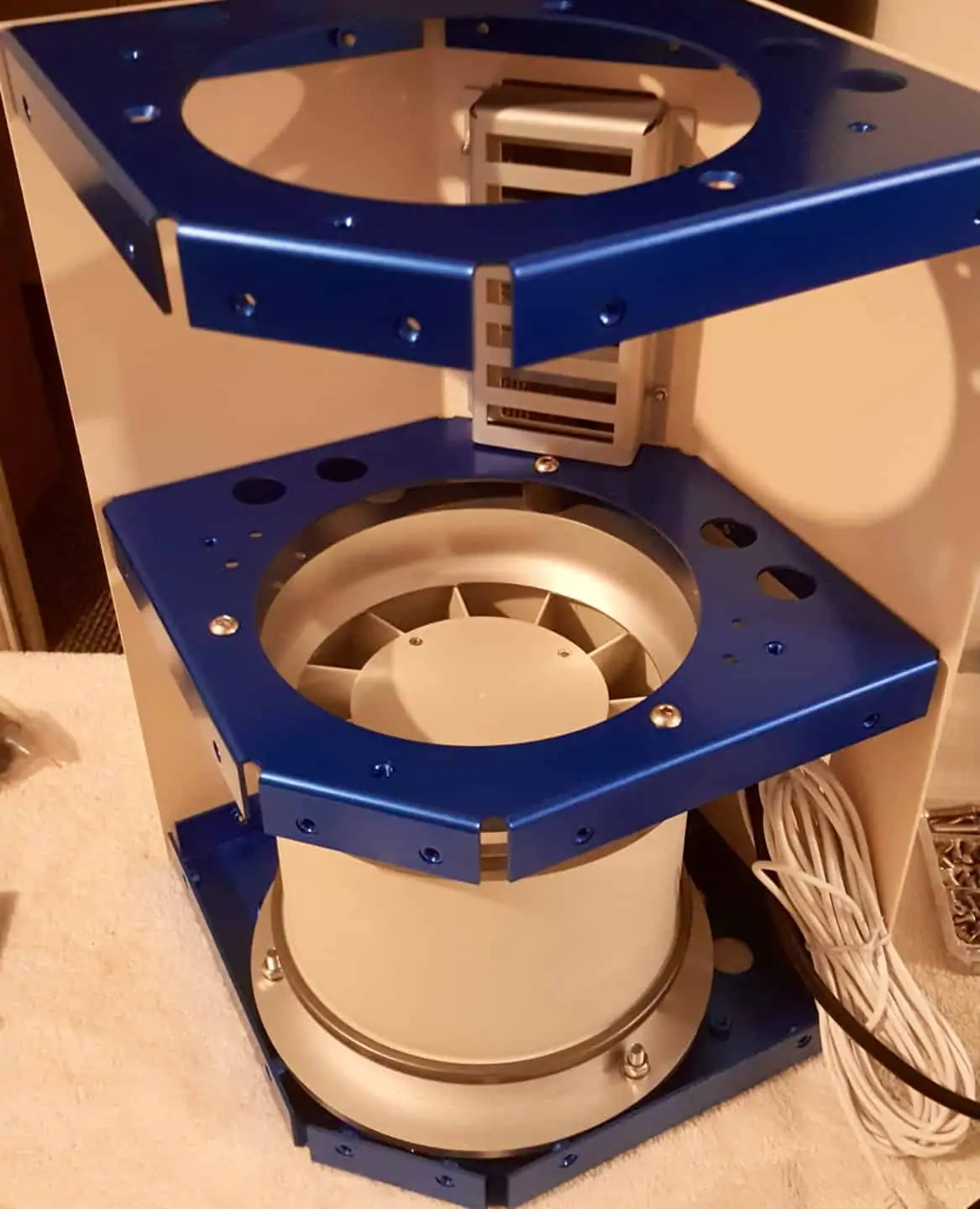

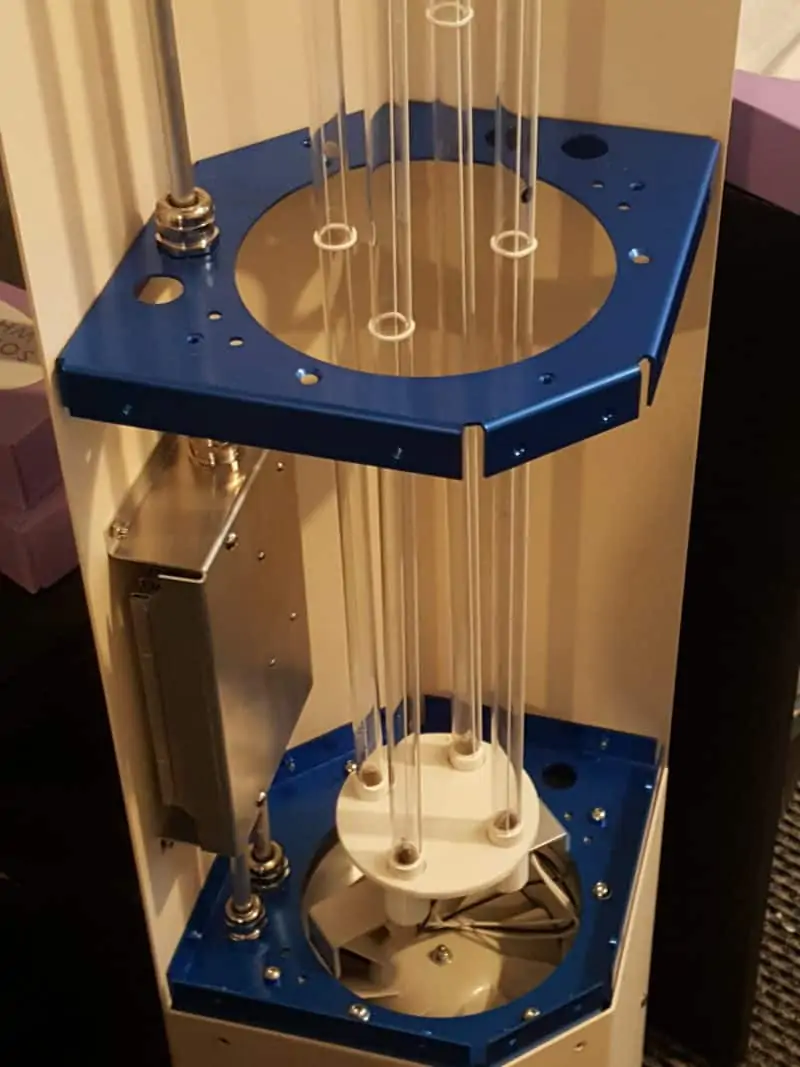

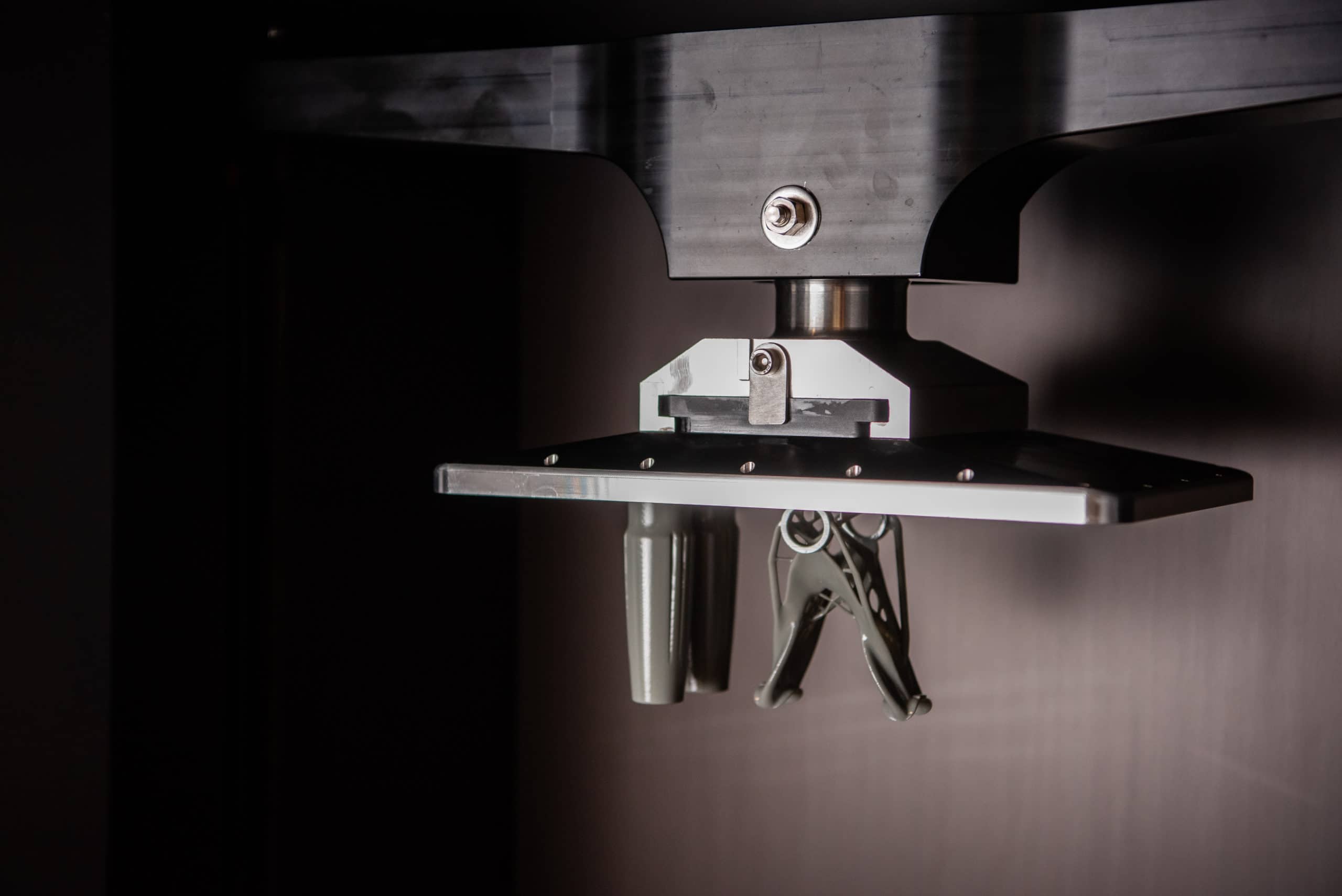

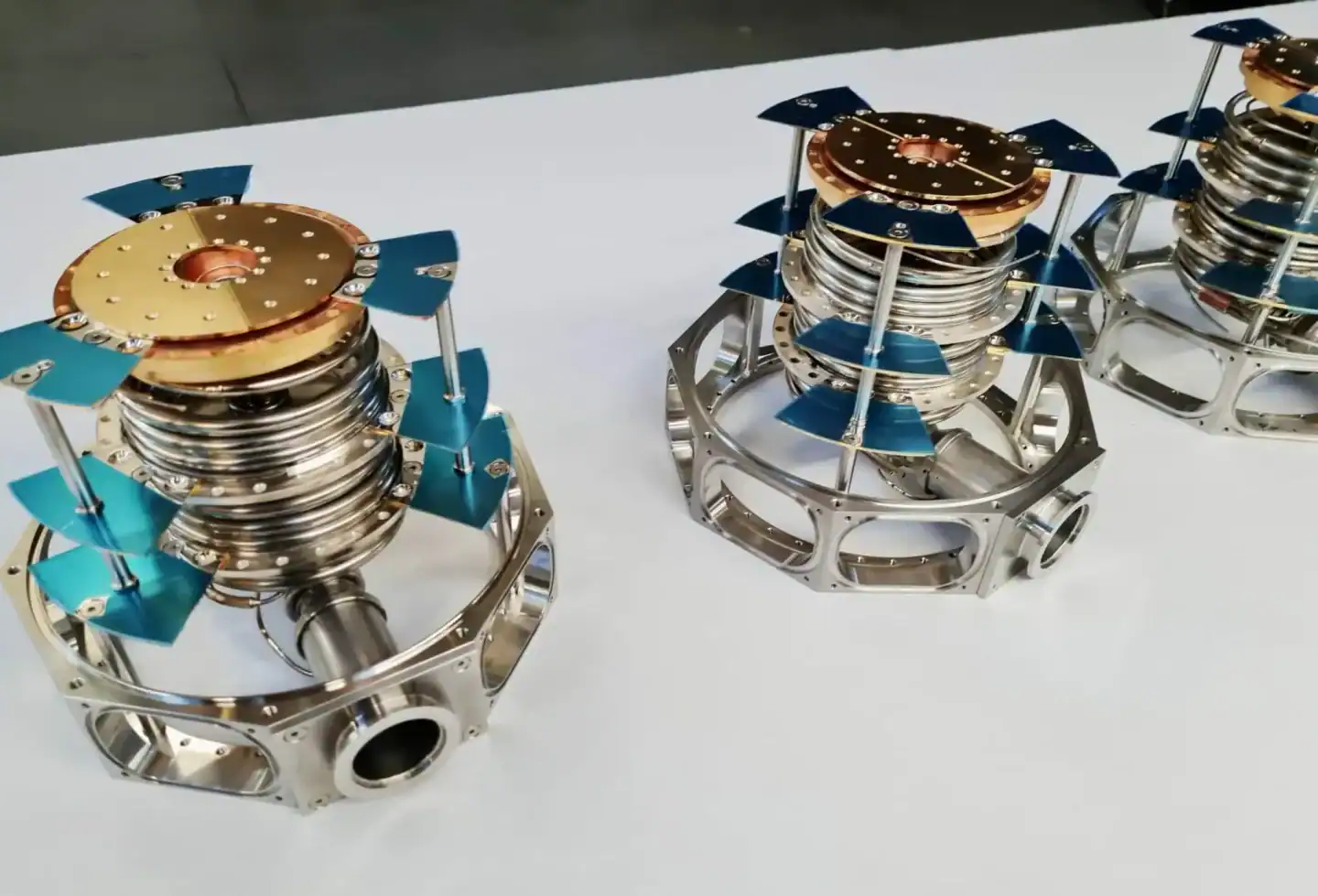

High-precision metal components used as integrated parts for complex glass and plastic solutions.

Without a partner like Xometry, you simply have to say that you constantly run into situations where you’re let down, delivery times are too long, and Xometry is quite simply more reliable.

Focusing on Core Competencies: Glass and Plastic

The specialization in glass and plastic demands the highest precision from Glaskeil. As the team emphasizes, both materials are highly unforgiving of errors: “A small mistake, a scratch, can lead to us having to scrap the component and starting over.” Longevity, resilience, and aesthetics are the ultimate goals.

However, for their complex projects, they often require parts made from other materials, particularly metal and aluminum. This is where Glaskeil reached the limits of its own production capabilities:

Especially when projects move quickly, the reliable procurement of these external materials becomes a challenge. Glaskeil sought a partner that could fill this gap and deliver the required precision.

Speed and Precision Through the Right Partner

Previous procurement processes for these external components were often characterized by a lack of reliability and overly long delivery times. With Xometry, Glaskeil has now found a manufacturing partner who eliminates these bottlenecks.

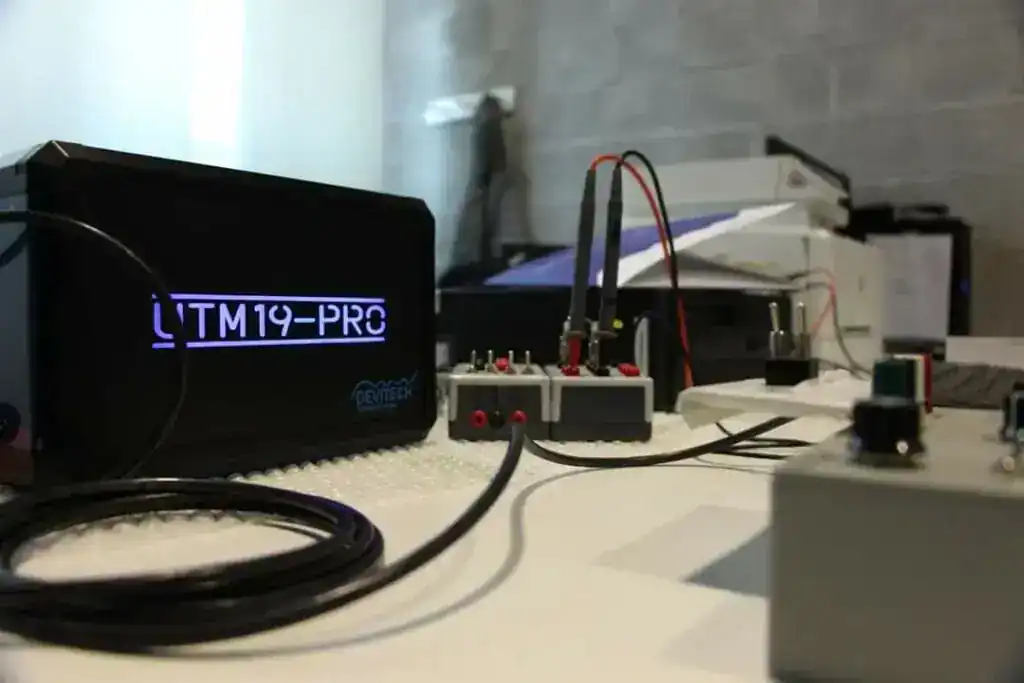

The parts manufactured by Xometry ensure the necessary precision, allowing Glaskeil’s final products to be manufactured safely, be long-lasting, and satisfy the customer. As professionals in surface finishing, the Glaskeil team pays close attention to the quality of the supplies: “When I see polished edges, I look at them, and if they’re well polished, I think that’s great.”

How Glaskeil Utilizes Xometry

The ordering process via the Xometry platform is a clear advantage for Glaskeil, as it saves time and enables a quick reaction to short-term needs.

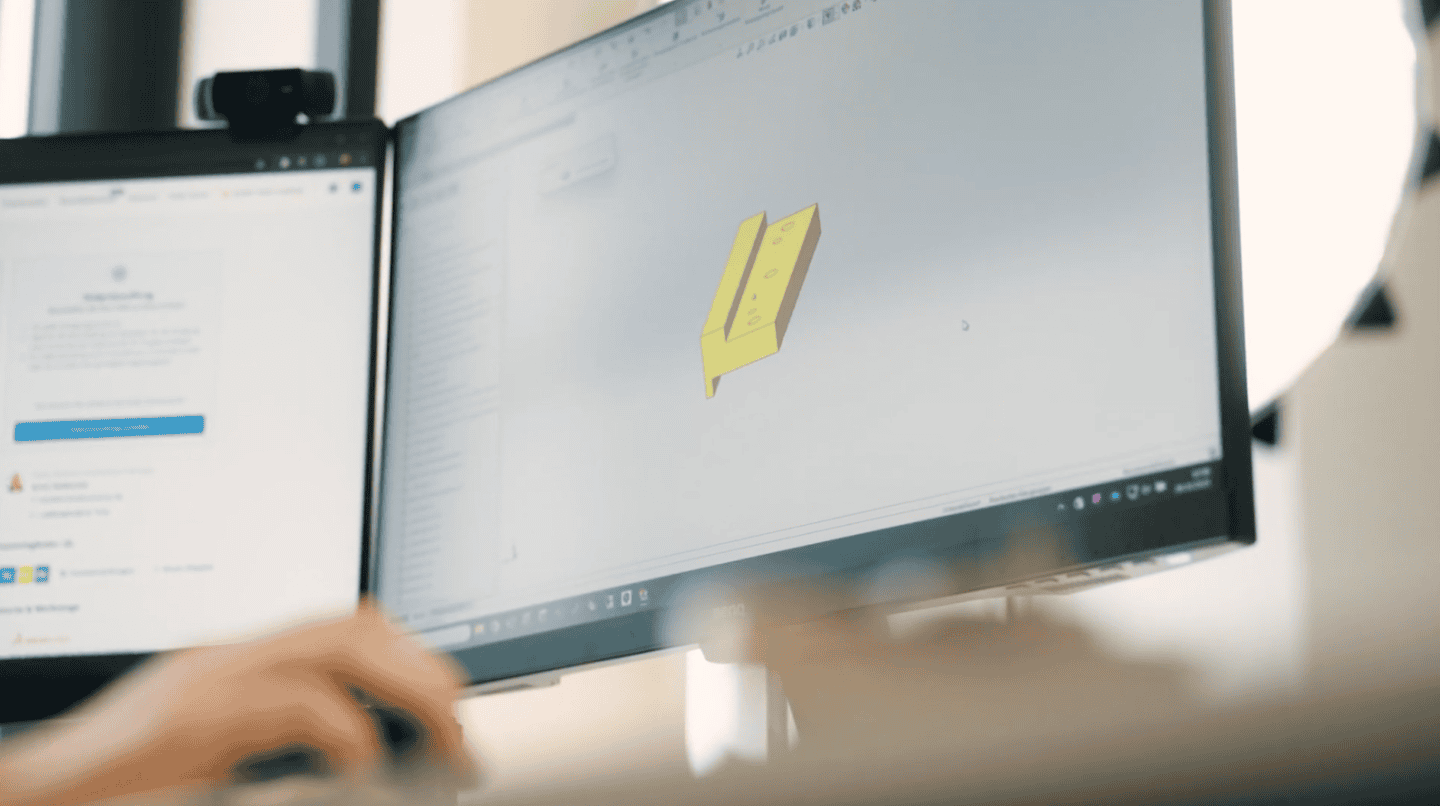

The process is straightforward: The component is uploaded with a simple drag & drop, the corresponding drawing is attached, and the material and quantity are selected. The quotation usually arrives within two days. Glaskeil also uses the option of Target Price Ordering to maintain high cost transparency.

For critical deadlines, Glaskeil can rely on express shipping.

Daily Relief and Focus on the Essentials

Thanks to the partnership with Xometry, Glaskeil has been able to resolve a significant bottleneck in parts procurement while ensuring the overall quality of its end products.

This relief allows the team to focus on their actual strengths and the complex tasks of glass and plastic processing.

Xometry delivers the components flawlessly, enabling Glaskeil to quickly manufacture its products and successfully complete projects. Xometry is the reliable manufacturing partner for Glaskeil for all non-core materials.

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط