Selective laser sintering (SLS) is an additive manufacturing technology that offers many advantages over traditional manufacturing techniques, such as the ability to create complex shapes with ease, reduced waste, and faster production times. This technology has found applications in industries such as aerospace, automotive, and healthcare, where precision and customizability are essential.

What is SLS 3D Printing?

Selective laser sintering belongs to the powder bed fusion (PBF) category. SLS printing involves a high power laser to sinter small particles of polymer powder into a product based on a 3D CAD model. Its high resolution, high productivity and easy availability of materials make SLS technology ideal for a range of applications from rapid prototyping to end-use parts with complex geometries.

How Does SLS 3D Printing Work?

The selective laser sintering process involves the fusion of layers of material powder (typically ~0.1 mm thick), spread evenly across the build area using a counter-rotating levelling roller. The part building process takes place inside a closed nitrogen gas-filled chamber (or any inert gas) in order to minimize oxidation and degradation of the powder.

Step 1 – Preheating the Powder

The powder in the build platform is preheated and maintained just below the melting point and/or glass transition temperature of the powdered material with the help of infrared heaters present above the build platform.

Step 2 – Printing the SLS 3D Parts at High Temperature

- As soon as the thin powder layer is formed and preheated, a focused CO2 laser beam is directed onto the powder bed and moved using galvanometers in such a way that it fuses the material thermally to form the cross-section layer by layer depending on the CAD design. How thick a layer should be is decided in the slicing software.

- Surrounding powder remains loose and supports the next layers, eliminating the need for support structures.

- After a layer is completed, the build platform is lowered depending on the layer thickness (slicing) and a new layer of powder is laid and levelled using the counter-rotating roller.

- The CO2 laser beam scans the subsequent cross-section of the layer. This process goes on until the whole part is built.

Step 3 – Cooling and Post-Processing the SLS 3D Parts

Finally, the completed parts are removed from the powder bed and the loose powder is cleaned off. Further post processing methods can be performed (dying, bead blasting, vapour polishing, media tumbling) to get a better surface finish or improve the part’s properties

Materials for SLS 3D Printing

Selective laser sintering technology can use a wide range of thermoplastic powders. The most commonly used thermoplastic powders for SLS include polyamide (Nylon), polypropylene, and thermoplastic elastomers (TPEs). The SLS materials can be classified into two main categories:

- Rigid materials: PA 12 (regular, glass-filled, flame retardant, food grade, filled with aluminium), PA 11 (regular, food grade) and Polypropylene (PP)

- Flexible materials: Flex TPU

Nylon PA 12 is one of the most popular 3D printing materials. This plastic material has good mechanical properties such as toughness, tensile strength and impact strength, making it a reference material for SLS technology.

Advantages of SLS Technology in 3D Printing

SLS is one of the most reliable, precise, and fast methods for prototyping, small batch production and also for industry grade applications. Selective laser sintering technology has a set of advantages that makes it unique.

SLS Prints Do Not Require Support Structures

Since selective laser sintering printing technology belongs to powder bed fusion, its designs do not need any support structures. While printing, all the empty spaces are filled with the unused loose powder, making SLS prints self-supportive.

Hence, designs with empty hollow spaces, overhanging features and very thin features which usually require support is no longer a problem printing with SLS, thus offering the product designers a large scope for design freedom.

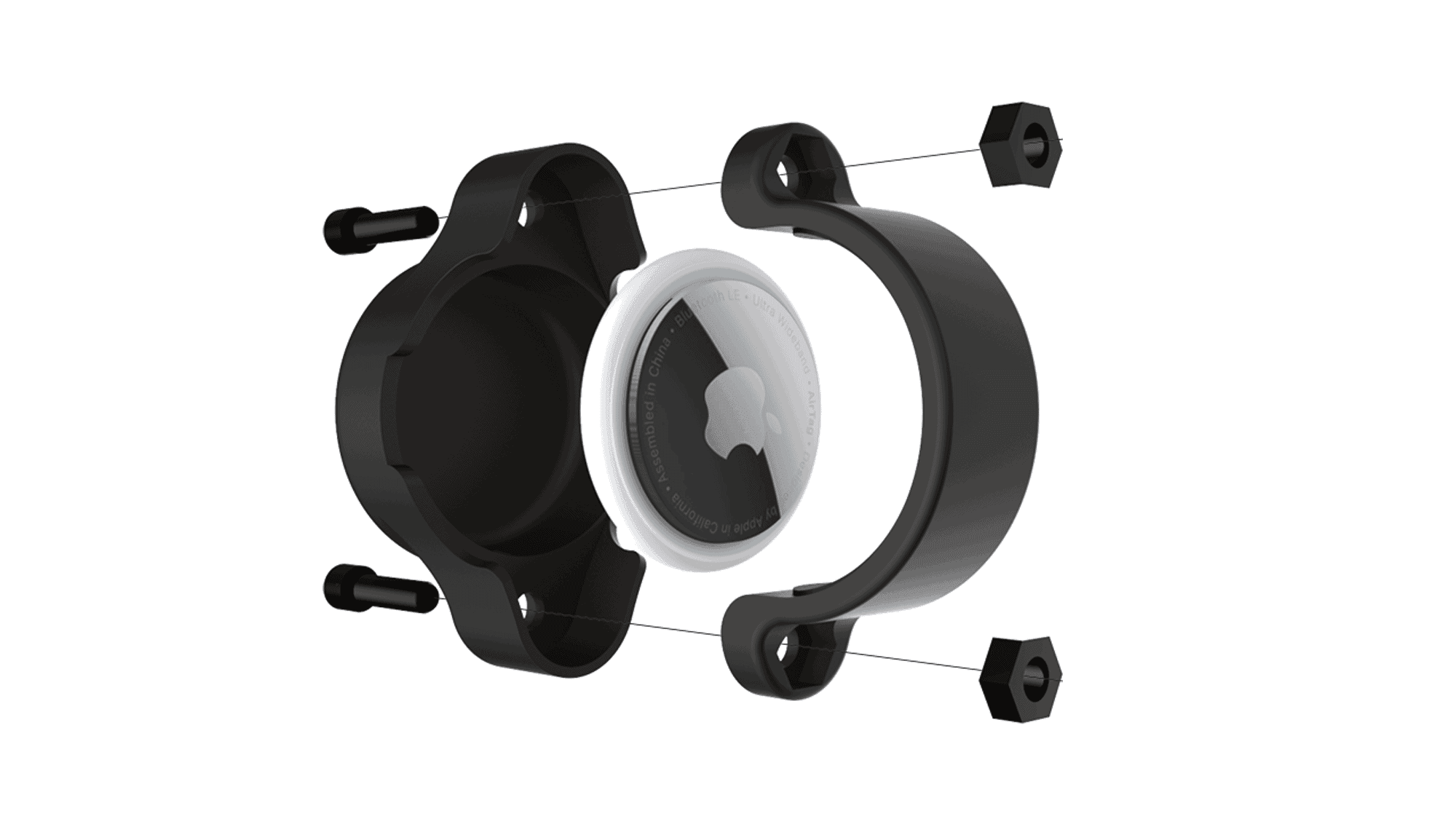

Parts with complex internal components, channels, can be built without compromising the design as there is no fuss of support structures. SLS can be the best solution for printing complex designs instead of printing in multiple parts which generally is an issue when the alternatives like fused deposition modelling (FDM) are used.

SLS is a Fast 3d Printing Technology

SLS is one of the fastest 3D printing technologies as the polymer powders used in SLS only require very little exposure to the laser in order to be sintered. In fact, speed has to be quantified with respect to the print resolution.

For example, an FDM printer can also print fast if it is set to print thick layers and compromising on the resolution. With SLS, there is no such compromise for resolution with faster print speed.

SLS Parts are Perfect for Dying and Colouring

SLS prints generally possess a porous surface making them excellent for the colouring. Also, dyeing using a hot bath process is very effective. Since the surface is porous, the colour sticking is also efficient.

SLS Has Excellent Mechanical Properties

SLS prints have very strong layer adhesion compared to its alternatives like FDM. Hence, SLS prints have isotropic properties which means that the tensile strength, mechanical hardness and elongation of the SLS printed part are almost equal along all directions (3 axes).

Due to the excellent mechanical properties, SLS printed parts are often used as an alternative for typical injection moulded plastic parts. SLS prints also offer decent chemical resistance (e.g. Nylon PA 12).

Disadvantages of SLS Technology in 3D Printing

Apart from the advantages it offers, there are also a few common disadvantages that Selective laser sintering technology possesses.

SLS Parts are Porous and Have a Brittle Structure

Although they have good tensile strength, SLS prints are less flexible and can undergo less deformation before failure. The same porosity that makes SLS prints excellent for dyeing also compromises their structural integrity. For this reason, SLS prints are best used as prototypes and not recommended as functional parts.

SLS Prints Have a High Shrink Rate

As per the working mechanism of SLS, the print powder needs to be exposed to elevated temperatures in order to sinter. As it starts to cool, contraction or shrinking takes place, resulting in a dimensionally inaccurate part. Shrinkage rate is as high as 3% to 4% which is comparatively more than the alternatives.

This needs to be considered in the design phase and the volume of the model is adjusted accordingly. The stress due to the contraction can also accumulate in sharp edges and corners, resulting in warping or distortion.

Higher Waste Production Due to SLS Powder Material

The powder inside the build chamber needs to be pre-heated so that it can be sintered with just the slightest exposure to the laser. Elevated temperature sintering of the powder surrounding a part being built can cause particle grains in the loose powder bed to fuse which compromises the quality of the powder.

Since you will always end up with a portion of unused powder with every single print, you will inevitably accumulate so much unused nylon powder that has to be discarded. With this single detail, selective laser sintering printing already generates more waste compared with HP multi jet fusion (MJF) that doesn’t preheat the powder. The loose nylon powder is also a respiratory hazard which you’ll need to protect yourself from.

Xometry’s SLS 3D Printing Services

Xometry Europe offers selective laser sintering services online, for on-demand 3D printing projects, for both prototypes and large batches. With a network of more than 2,000 partners all over Europe, Xometry is able to deliver SLS 3D printing parts in up to 3 days.

Upload your CAD files to Xometry Instant Quoting Engine to get an instant quote with various manufacturing options available for SLS 3D printing.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Download

Download