Direct metal laser sintering (DMLS) belongs to the powder bed fusion (PBF) category of 3D printing and is similar to the SLS technology. In DMLS, however, metal powders are used instead of plastic powders to create metal parts that can be used both for functional prototypes and production parts.

Direct metal laser sintering technology is similar to Selective laser melting (SLM) technology, but the difference between both processes is the temperature used for metal powder fusion. SLM, as the name suggests, heats the metal powder until it fully melts into a liquid. DMLS does not melt the metal powder but sinters heat particles enough so that their surfaces weld together. Anyway, both terms (SLM and DMLS) are often used interchangeably in the 3D printing industry.

How Does DMLS Work?

The direct metal laser sintering process involves six basic steps:

- Step 1 – The DMLS process begins by slicing the 3D design CAD file data into single extremely thin layers, generating a 2D model for each layer

- Step 2 – The machine uses a high-powered optic laser, inside the build chamber area that contains inert gas

- Step 3 – There is a material dispensing platform and a build platform along with a roller used to move new powder over the build platform layer by layer

- Step 4 – On laying the powder on the build platform, the laser begins its path for this layer, selectively sintering the powder into a solid. The sequence of powder layer addition and sintering continues until the whole part is done

- Step 5 – After cooling, the surrounding loose metal powder is removed from the printer. The final steps include support structure removal and other post-processes

- Step 6 – DMLS parts can be treated like metal parts produced by conventional metal working for further processing. This may include machining, heat treatment, or surface finishing.

Materials for DMLS 3D Printing

Among the most generally used materials for DMLS, Xometry offers:

- Aluminium: such as AlSiMG

- Steel: such as Tool Steel MS1, Stainless Steel 17-4, Stainless Steel 316L

- Inconel: such as Inconel 718

Advantages of DMLS Technology

When coming to DMLS, these are the most important factors that make it standalone:

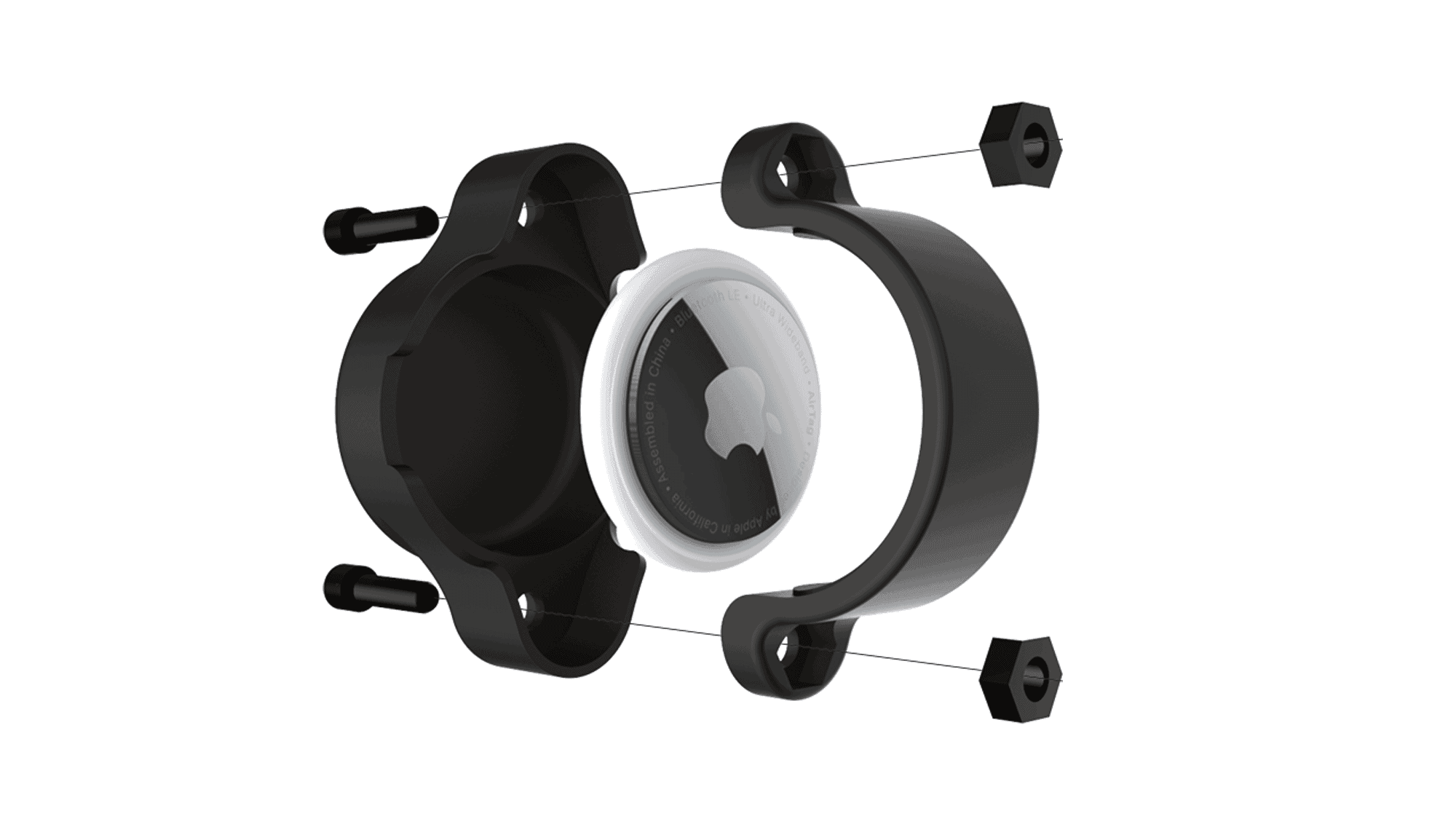

DMLS Allows Complex Designs

A main advantage of DMLS is the ability to manufacture parts that cannot be or are too expensive to be made using traditional manufacturing techniques. DMLS full potential can be seen when engineers design parts with complex geometries, such as integrated fastening features, long and narrow channels or mesh structures. DMLS facilitates all-in-one assemblies that reduce the number of parts, assembly time and rate for failures by combining multiple parts into a single design.

Quick Turnaround Time

The normal conventional process requires a lot of time to set the tool up before manufacturing which involves jigs and fixtures whereas, in DMLS, the part can be printed on-demand without any ramp up or tooling, resulting in shorter lead time compared to CNC machining. The combination of the reduced lead time and the efficient prototyping process reduces the turnaround time. This is one of the biggest advantages of DMLS.

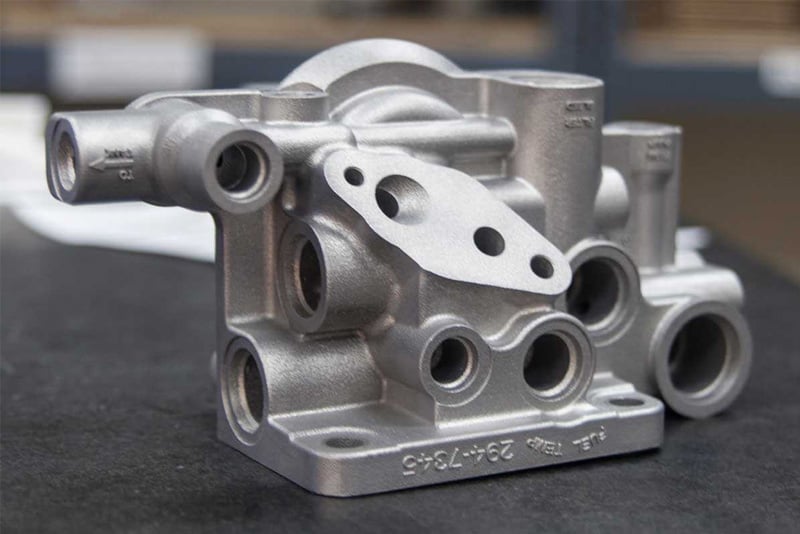

DMLS Use Lightweight and Durable Components

Parts manufactured from super alloys like Inconel 718, AlSi10Mg and Cobalt-chromium, are known to be lightweight compared to their conventionally machined counterparts. As an example, GE’s renowned 3D printed fuel nozzles for its LEAP family of engines used to be made from 20 discrete parts coming from independent suppliers but using direct metal laser sintering (DMLS) resulted in a single-piece component which is 25 per cent lighter and five times stronger than the original parts.

DMLS Allows Less Wastage

Metal powders that are untouched by the laser can be recycled and reused. Powder recycling also results in reduced prices. The waste produced is significantly less compared to a conventional process like CNC where a lot of waste is generated in the form of chips that are produced as a result of machining a metal according to a required design from a metal block and are very tough to recycle.

Considerations About DMLS Technology

Apart from the advantages of DMLS, there are a few considerations. The biggest competitor to DMLS would be the traditional machining technologies like CNC.

DMLS Needs Support Structures

Since DMLS belongs to the powder-based fusion category, support structures are inevitable and need to be removed in the end with the help of post-processing. During post-processing, the metal printed part is treated similar to a raw metal part manufactured conventionally and which means the part manufactured by DMLS is not ready to use and needs some work.

DMLS Parts Have a Grainy Surface Finish

DMLS printed surfaces won’t be as smooth as surfaces with CNC machining, and that it won’t be as easy to produce the desired surface textures. If post-processing needs to be done to enhance the finish and improve the aesthetics, the cost also increases accordingly.

Expensive Serial Production of DMLS Parts

Mass production is still a huge deciding factor across the industries and this is where DMLS lags behind compared to traditional techniques and the speed at which a 3D printer can assemble an object is no match to the conventional assembly line. Hence, DMLS is mainly recommended for a unit to a small batch.

Limited Material Selection

Generally, for metal 3D printing, the material selection is less, which can be a limiting factor when specific materials are needed for the required part and must be taken into consideration when deciding which technical properties you want your product to have.

Limited Build Volume

When a large part size is required, it’s always better to go with CNC machining. For instance, the standard part size that is recommended with DMLS is up to 250 x 250 x 325 mm and for CNC machining, it is up to 2000 x 800 x 1000 mm. The size comparison clearly shows the inability of 3D printing to manufacture huge parts due to its limited powder bed size.

Shrinkage and Limited Repeatability

With DMLS it is very hard to produce identical parts because of the natural shrinkage process. For example, a part printed for the first time and a similar part printed for the 10th time will have at least 2% error in the vertical direction (Z-direction), leading to shrinkage. The Dimensional changes are caused as a result of a combination of three sources: thermal shrinkage, sintering shrinkage, and expansion arising because the metal particles fall during the sintering.

Xometry’s DMLS 3D Printing Services

Xometry Europe offers DMLS service online, for on-demand 3D printing projects. With a network of more than 2,000 partners all over Europe, Xometry can deliver DMLS 3D printing parts in up to 3-5 days. Upload your CAD files to Xometry Instant Quoting Engine to get an instant quote with various manufacturing options available for DMLS 3D printing.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Download

Download