Introduction

This editorial outlines the running principle and business value of Xometry. Robert then analyses Xometry using three of the most prominent business management tools: Porter’s Five Forces, Product-Market Matrix (Ansoff Matrix), and the Business Model Canvas (BMC). Lastly, the editorial shares highlight insights from an interview with one of the Xometry clients.

Running Principle and Business Value of Xometry

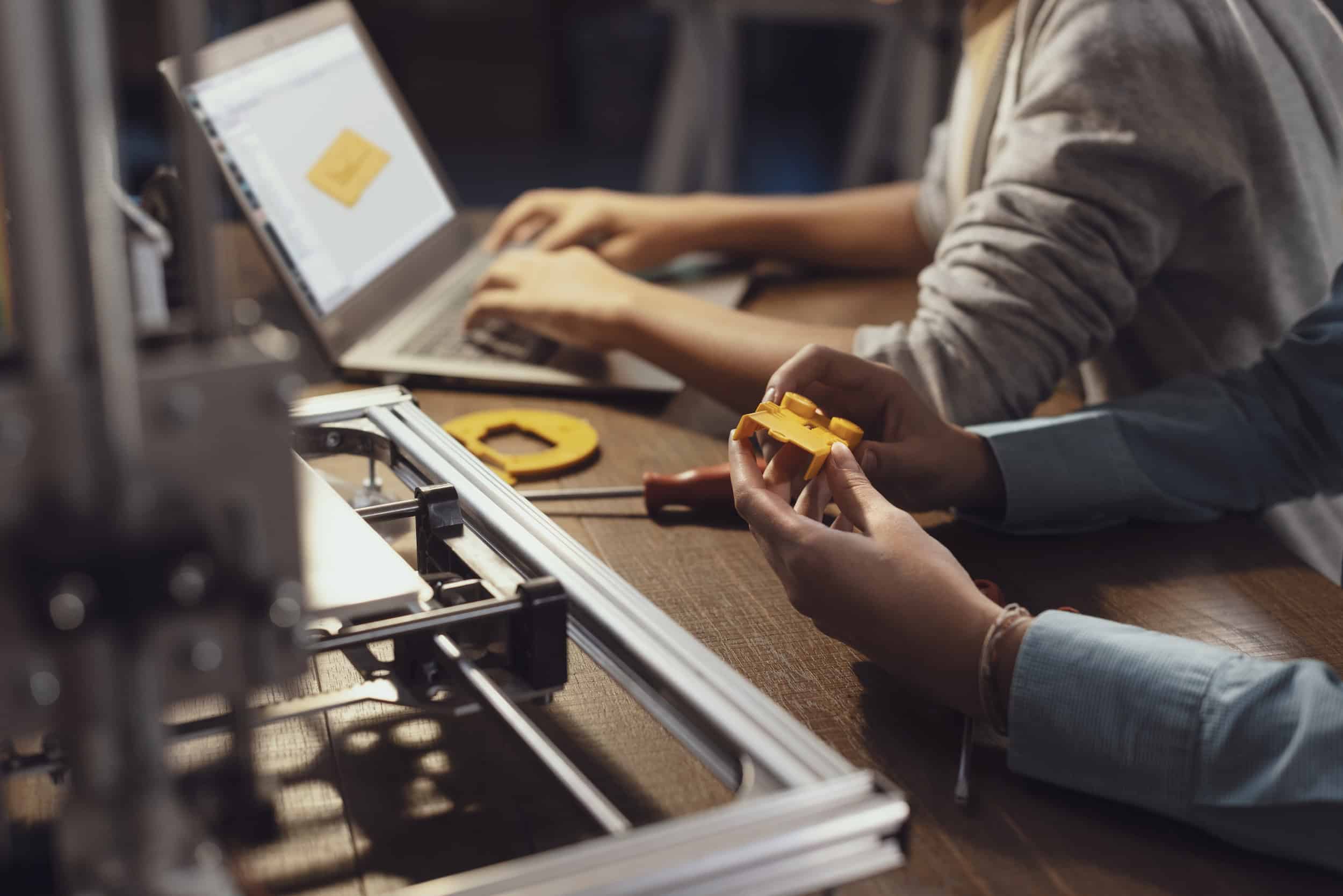

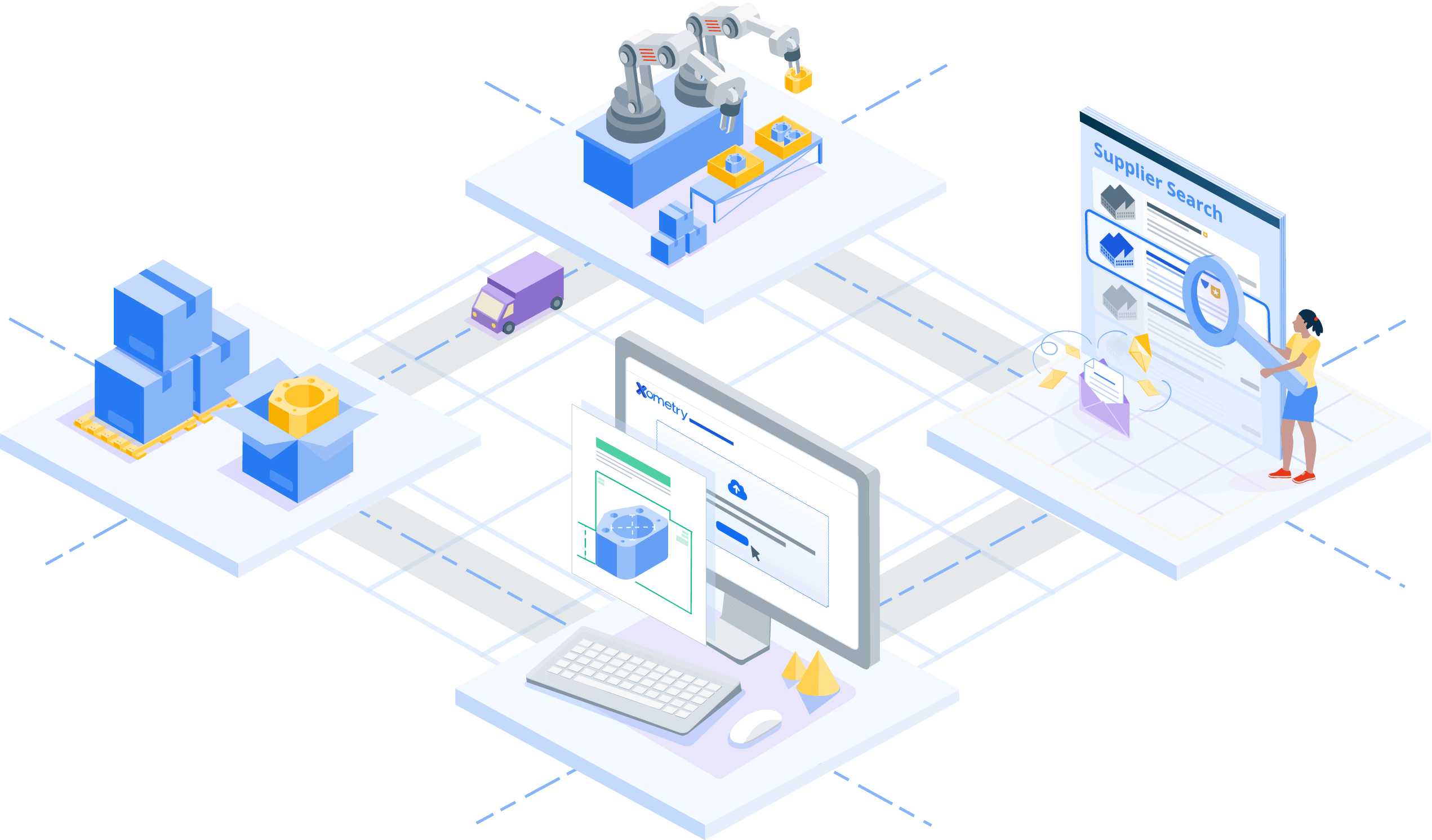

The following figure illustrates the running principle of the Xometry platform.

Essentially, the Xometry platform aggregates resources from various suppliers, as shown in grey rectangles at the bottom of the figure (e.g.: “Supplier A”). However, unlike a classic marketplace, Xometry adds value by building IT and logistical infrastructure, creating a flexible supply chain, and performing project and quality management. In short, Xometry created an environment where a customer gets parts made and a supplier gets manufacturing jobs.

Business values for customers:

- Fast and one-stop-shop access to the world’s largest manufacturing capacity

- Flexible and carefully vetted supply chain

- Time saved at quoting stage thanks to the Xometry Instant Quote Engine

- Production time saved through better use of manufacturing capacities

- Industry-leading price-quality ratio

Business values for suppliers:

- Efficient use of idle manufacturing capacity

- Access to new manufacturing jobs without having to invest in marketing

- No need to take care of logistics & communication

- Easy set-up

Analysing Xometry With Three Prominent Business Management Tools

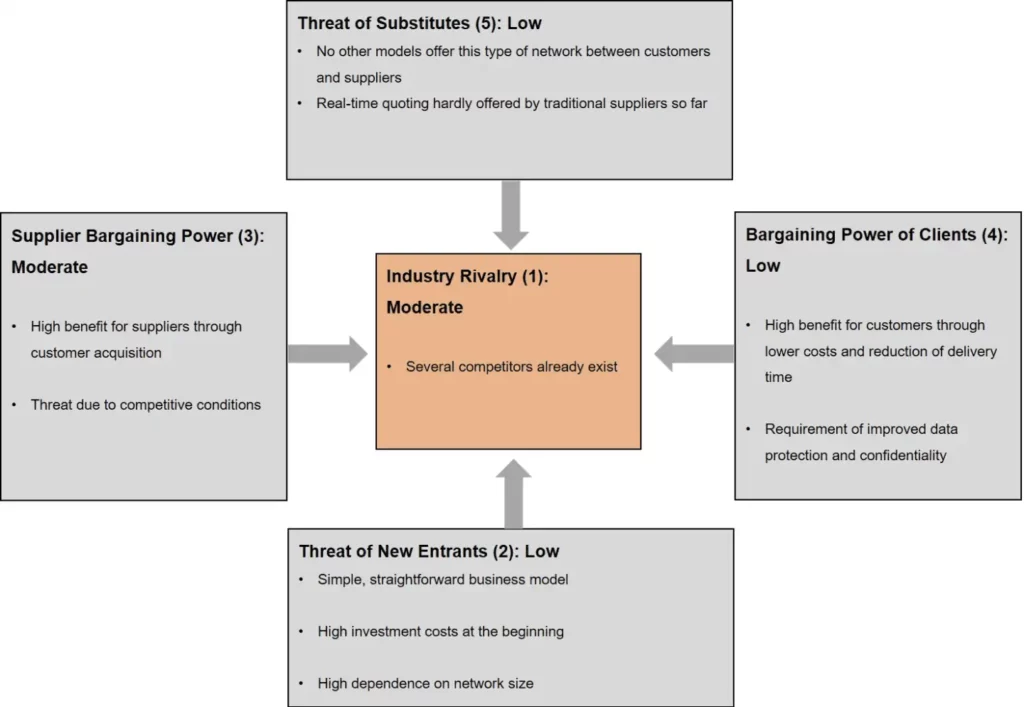

Porter’s Five Forces

In order to further illustrate the impact of Xometry on the Cloud Manufacturing market, an analysis of the company’s actual business environment is of major interest. To perform this analysis, I will use Porter’s Five Forces framework. It is a very helpful and easy-to-read tool for analysing a specific business strategy in a specific business environment by taking into account the competition of a firm.

The tool consists of five fields, namely the threats of new entrants (2), the bargaining power of suppliers (3), the threat of substitutes (5), the bargaining power of buyers (4), and the industry rivalry (1).

The following figure was created based on the analysis performed:

Each of the five fields describes the relationship of Xometry in relation to a specific field of business action and speculates about the distinctive impact resulting from this field, e.g. the “low” threat of substitutes.

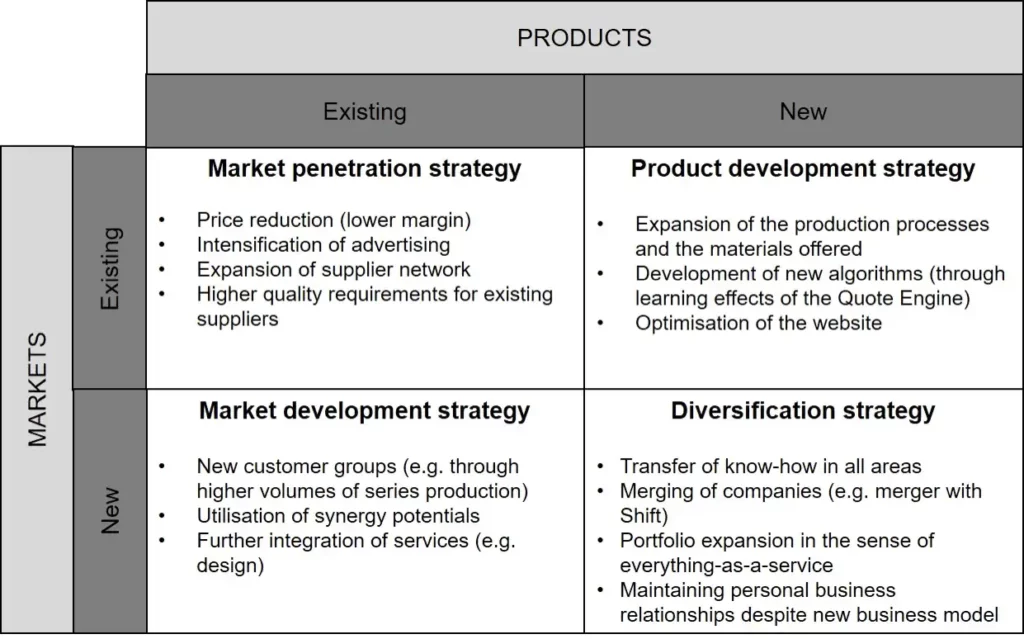

Product-Market Matrix (Ansoff Matrix)

The Ansoff Matrix is a popular business administration tool that helps companies analyse their possible strategies for growth. It consists of four fields, each assigned to a specific strategy that could be used to promote the growth of the corresponding company. Each strategy inhibits a different risk. Of the four strategies, market penetration is the least risky, while diversification is the riskiest.

More specifically, the four strategies in this tool are:

- Market Penetration focuses on increasing sales of existing products to an existing market.

- Product Development focuses on introducing new products to an existing market.

- Market Development focuses on entering a new market using existing products.

- Diversification focuses on entering a new market with the introduction of new products.

The Ansoff Matrix provides summarised information about the business growth strategies for a specific company (Xometry in this instance). The following figure (Fig. 3) is the result of my analysis.

Business Model Canvas

At this point, you should already have a reasonable understanding of the actual possible business impact of Xometry. Nevertheless, to be even more precise, I will now use the Business Model Canvas in the following figure to further illustrate Xometry’s market role:

The interpretation and usage of this business administration tool are actually self-explanatory – it is a descriptive tool for detailing the role of a specific firm in a given market.

Namely, in each of the corresponding fields (like “Customer segments” on the very right), you can clearly see the most important information for Xometry regarding this specific field of business action.

It aims to concentrate and condense the whole business model in a convenient format. To summarise, the business model canvas is a convenient tool to quickly assess a specific firm in a descriptive way.

Insights From an Interview With a Xometry Client: the Value of Xometry for Rapid Prototyping

Theory always sounds promising. But what about hard facts? In order to investigate this, I conducted a series of interviews with Xometry’s customers. Here’s an example of what I heard from one of the customers. To ensure privacy and adhere to common business regulations, the interviewee wished to remain anonymous.

Consequently, I will be referring to the company as “Company A”. I talked to a Product Manager involved in rapid prototyping projects and will refer to him as “Carl”. So, what does Carl have to say about all this?

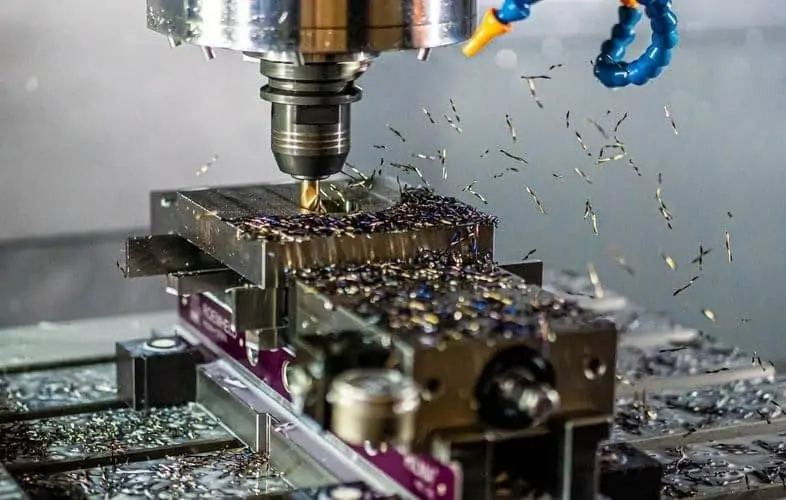

Company A deals with rapid prototyping on a daily basis. They use SCRUM methodology and as a result, they need a new prototype basically every three weeks.

Although some manufacturing capabilities are available in-house, they still need to use manufacturing resource providers to be able to carry out their work. Company A has to use a multitude of manufacturing processes and materials and contend with product variability.

I will now try to outline the situation for Company A before it started using the Xometry platform. Carl says:

- Step 1 – We created a design file:

1. Were we able to manufacture it on our own? If yes, job done.

2. If not, we needed a suitable provider, i.e. job not done. - Step 2 – If 1b, we would approach our own network of suppliers that we already knew

In doing so, we tried to either call or email them and send our corresponding design file without even knowing if they could produce it at all. - Step 3 – Then we waited…

1. On average, we got a few quotes from the companies we approached after several business days. This was a very uncertain phase for us.

2. After quoting and discussions, we had to wait for parts to be delivered. For example, simple 3D-printed parts took up to two weeks on average and more complex orders with CNC machining could have taken up to three or four weeks.

Even from this brief outline, the severe problems are already clear. For step two, it sounds way easier than it actually is – the cross-communication is very hard and time-consuming. This is because a mutual understanding has to be established for every order. According to Carl, this involves a “huge amount of cross-communication”, which is counterproductive to labour efficiency. In short, this cross-communication adds no value to your business.

Additionally, Carl mentioned another very severe problem: the high business uncertainty! Simply put, it is the uncertainty of not knowing exactly what is happening:

How many days/hours until we get a feasible quotation response?

How many days until our delivery arrives? What is the status of our order?

Uncertainty is a killer for every business. In particular, Carl experienced issues like unavailability of suppliers, late delivery, incomplete delivery, miscommunication, and ultimately bad product quality resulting from the issues just mentioned.

So, How Did Xometry Meaningfully Leverage This Upfront Situation?

“We now have a unified platform, which is far superior to a fragmented system of loosely connected mails, notes and memories of phone calls”, says Carl. “Working like this now is way more convenient”, he adds. The platform is transparent, easy to use and everything we need is in one place.

In addition, the second biggest difference is probably the instant quoting option – you can get a quote in almost real-time. Previously we had to wait on average several business days to receive quotes from all of the suppliers we contacted manually (regardless of geometry complexity). This is now the upper bound of time duration for very complex geometry.

Clearly, this is leveraging the business of Company A – Xometry is a time saver. Carl also believes that another big benefit of using the Xometry platform is the ability to choose from way more options than previously, as you can now specify your order in a more detailed way. As a result, there is less uncertainty regarding the final product.

Last but not least, Carl is very satisfied with the customer service he received when using the Xometry platform, “they know how to treat their customers – their service is excellent”.

To summarise this case study, what is actually different now with Xometry for Company A and Carl? Company A is now…

- …having to do much less administrative work for orders

- …able to know the status of their order at any given time

- …benefiting from a new upper bound of maximum time forgetting a feasible quotation for each kind of requested product,

- …benefiting from instant quoting for less complex geometry

- …able to specify their manufacturing order in a more detailed way, which results in less uncertainty about the final product

Conclusion

In this guest editorial, I initially outlined the running principle and business value of Xometry.

I then analysed Xometry using three of the most prominent business administration tools: the Business Model Canvas, the Ansoff Matrix and Porter’s Five Forces.

Lastly, I did an interview with one of Xometry’s clients and gathered their unique insights. By doing so, I was able to outline the huge business benefit for the customer’s rapid prototyping firm and thus demonstrate the tangible and undeniable business value of Xometry in the market.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Download

Download