AADS, a leading provider of specialised mobility solutions for defence and security, leveraged Xometry’s diverse industrial 3D printing capabilities to meet the unique demands of highly customised vehicle projects, particularly for rapid prototyping and low-volume production of complex parts.

Spojené království

Flexible HP MJF TPU Polyurethane Grey, FDM ASA Ivory, UltraLight Infill and Nylon PA12 Grey MJF

Customised defence and security vehicles

For our customers with small to medium volume specific requirements, high-volume injection moulding is typically used for manufacturing parts. However, in these cases, it often doesn’t make sense for us to pursue that option. Xometry’s diverse 3D printing can effectively fill this gap, as the tooling requirements for high-volume production are not justified for these smaller runs.

About AADS

AADS, established in 1904, specialises in custom vehicle conversions for military and government organisations. Born out of the Jeep J8 project in 2007, AADS transforms standard off-the-shelf vehicles into bespoke solutions, including troop carriers, ambulances, patrol vehicles, and command vehicles. Their mission is to provide comprehensive mobility solutions, encompassing integrated logistical support, parts supply, and extensive training for end-users, covering mechanical and driving skills, as well as after-sales support and warranty services through local partnerships. With a team of fifty, AADS delivers high-mobility, robust vehicles tailored to specific customer requirements, primarily for the US Department of Defence and direct government sales.

A significant portion of AADS’s business comes from the U.S. Department of Defence, which purchases vehicles on behalf of supported nations, often for counter-narcotics and counter-terrorism activities. They also engage in direct sales to governments, such as a recent contract with the Italian Ministry of Defence. The troop carrier vehicle is their biggest-selling single product.

The Challenge: Rapid Prototyping and Production for Bespoke Defence Vehicles with High Customisation Needs

AADS faced the challenge of rapidly prototyping and producing specialised niche parts for their highly customised defence vehicles for the Italian Ministry of Defence. The inherent need for bespoke solutions for military and government projects often meant small to medium production volumes, rendering traditional manufacturing methods like injection moulding, with their high tooling costs, economically unfeasible.

AADS J8 4×4″ vehicles to the Italian Ministry of Defence – National Armaments Directorate. These vehicles are used as part of the ‚Strade Sicure‘ operation, for the collaboration that the Esercito Italiano – Italian Army has been carrying out with the police forces since 2008 to safeguard the security of some of the most emblematic areas of the transalpine country.

The Solution: Xometry’s Agile Industrial 3D Printing Capabilities for Custom Defence Solutions

With the need for high customisation and quick iterations, AADS first discovered Xometry through one of their engineers who was searching for 3D printing services for rapid prototyping. Mark Jensen, Head of Technical and Production at AADS, recalled their initial encounter:

The instant quoting engine, which provided immediate feedback on pricing, material, and manufacturing processes, was a significant draw, allowing AADS engineers to quickly iterate on designs and assess production costs.

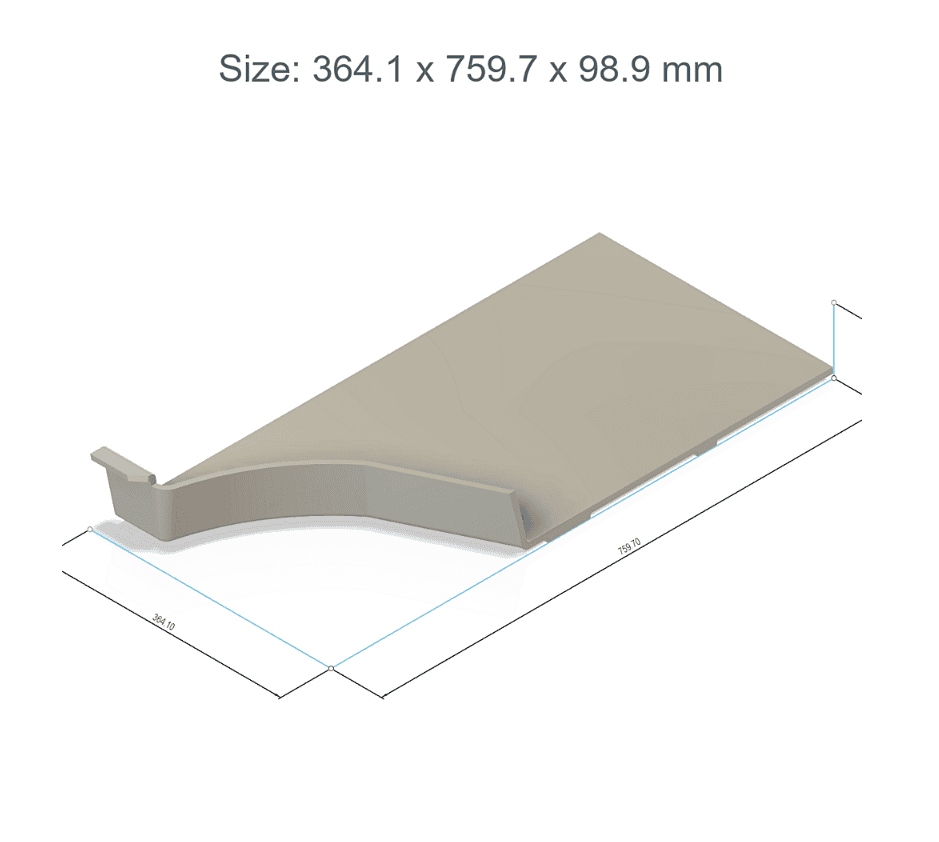

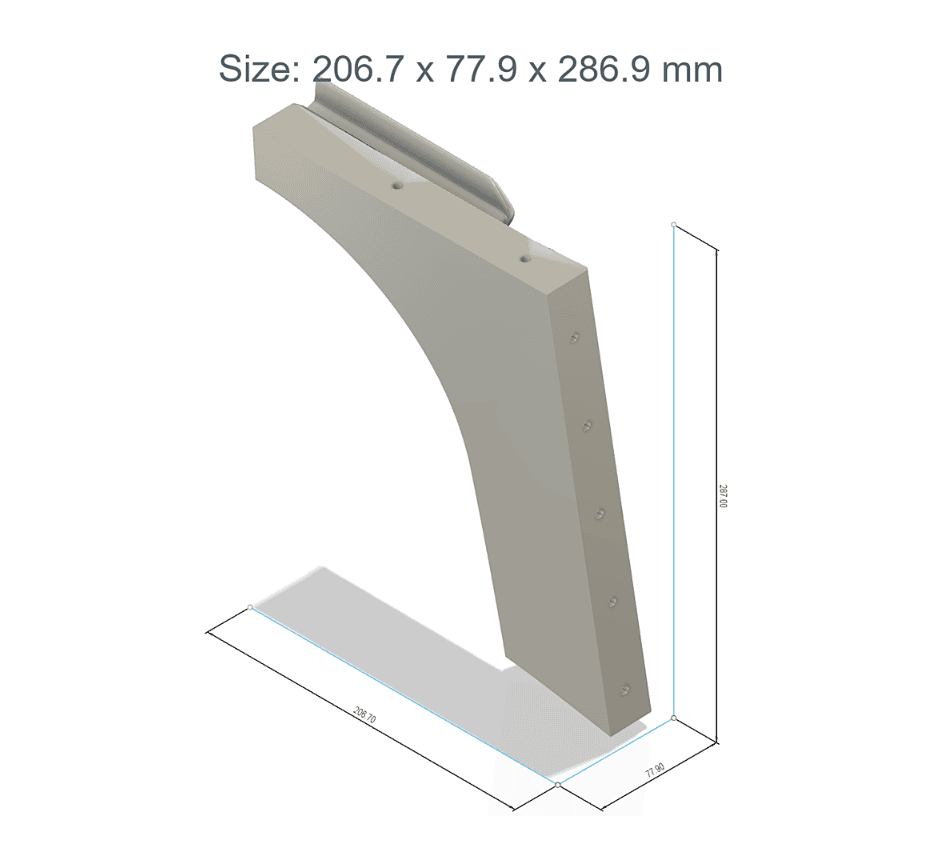

AADS first used Xometry for 3D printing, focusing on FDM with ASA Ivory for the UltraLight Infill Jeep Roof prototypes. They later expanded to producing low-volume, complex parts through Xometry, benefiting from reduced tooling costs. These parts were used in early prototyping of the interior fibreglass panels for AADS’ defence ambulance vehicles.

These projects include:

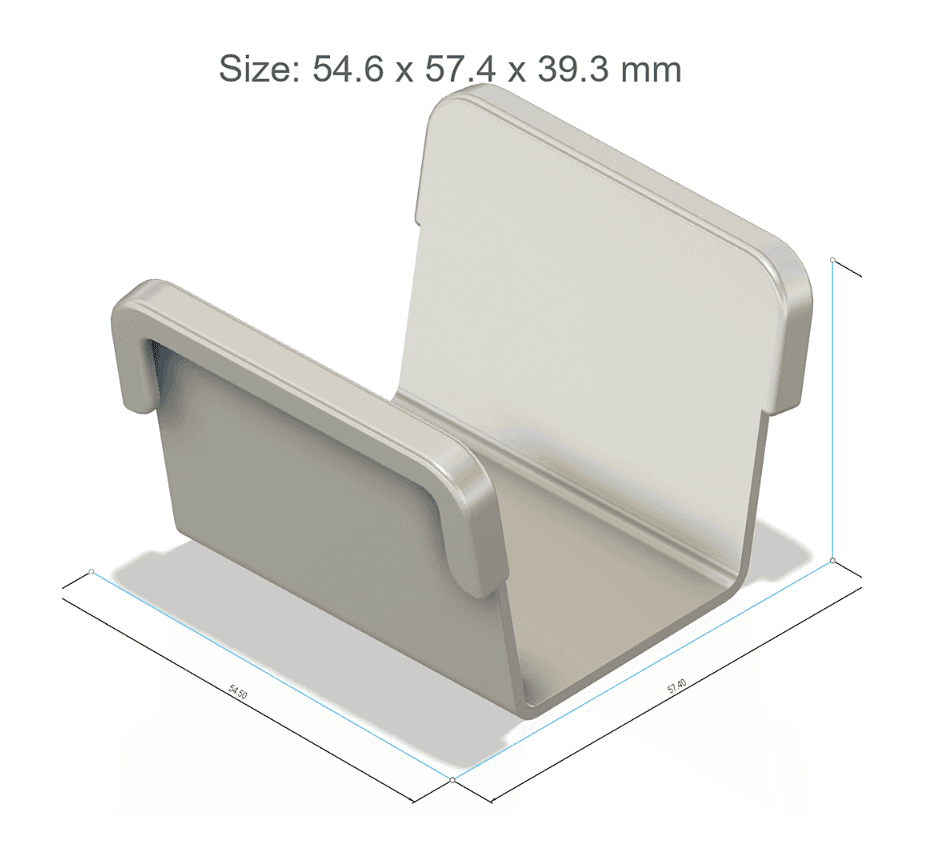

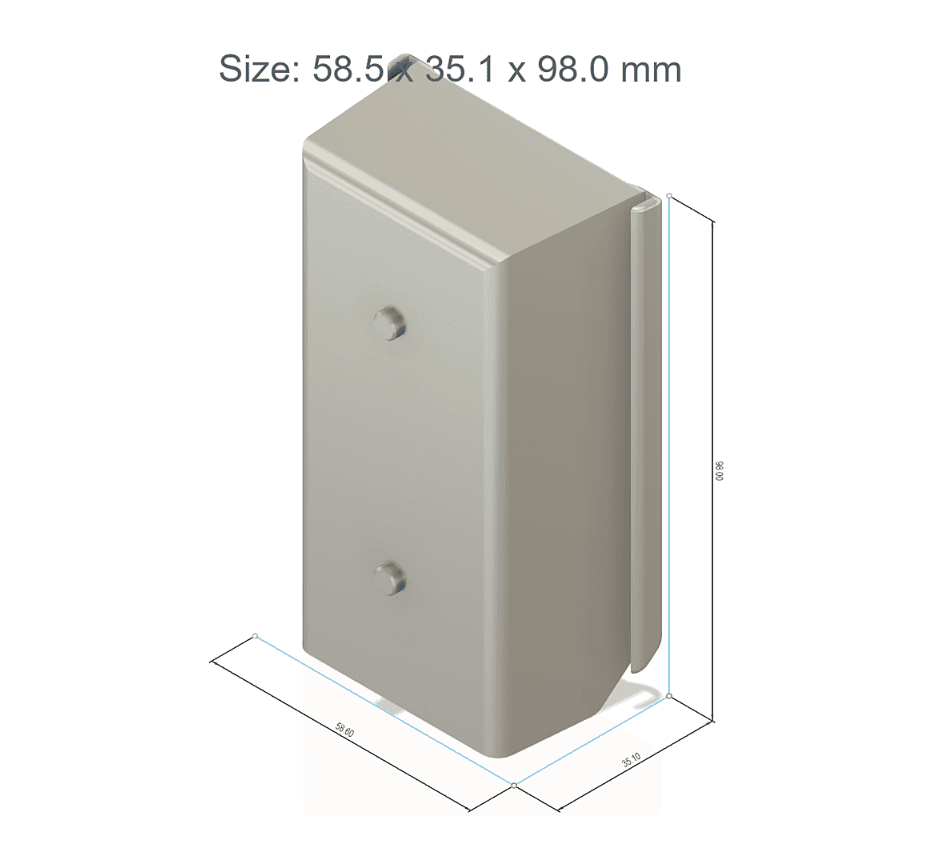

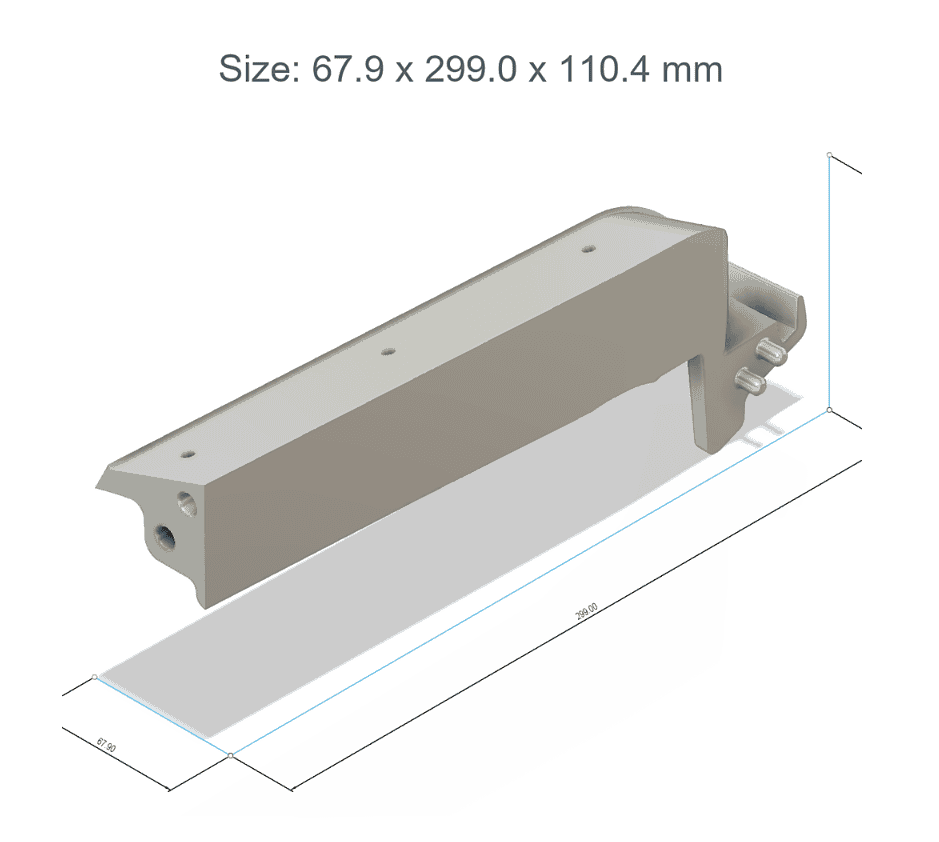

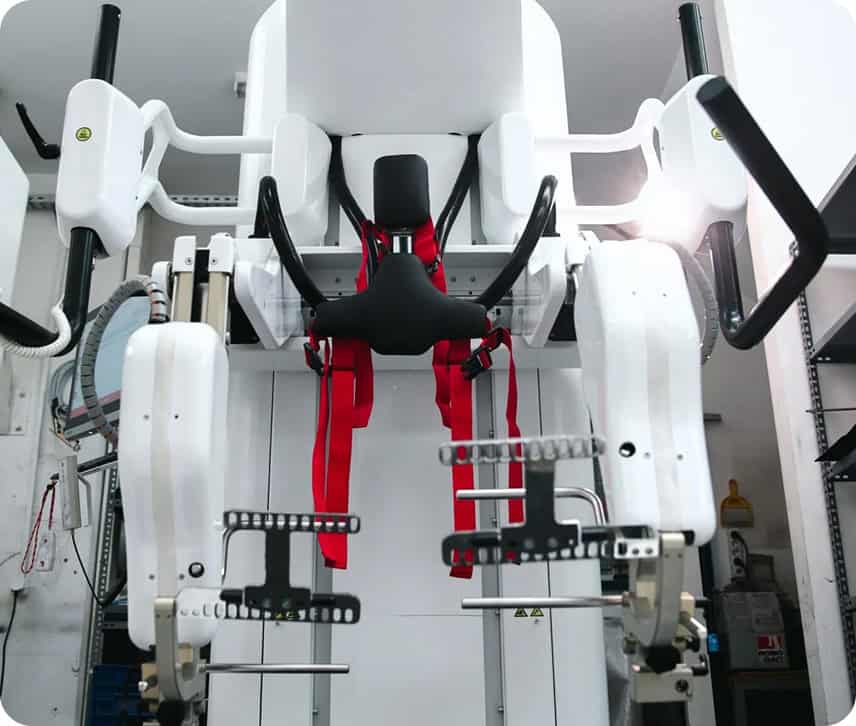

Flexible HP MJF TPU Polyurethane Grey inserts printed vibration isolation inserts for weapon mounts: Flexible TPU inserts were 3D printed to provide bespoke vibration isolation for weapon mounts on 300 troop carriers for the Italian Ministry of Defence. These were vital functional production parts that were directly installed within the vehicle interior. This application highlights 3D printing’s ability to produce highly specific, performance-critical components for immediate integration.

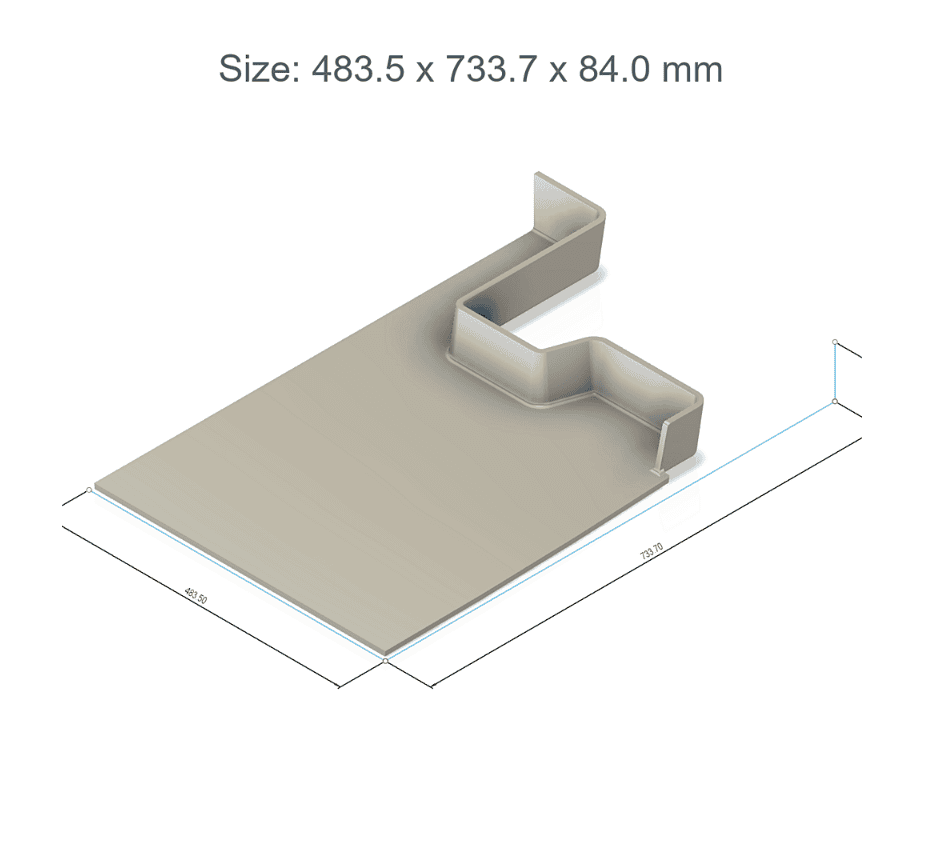

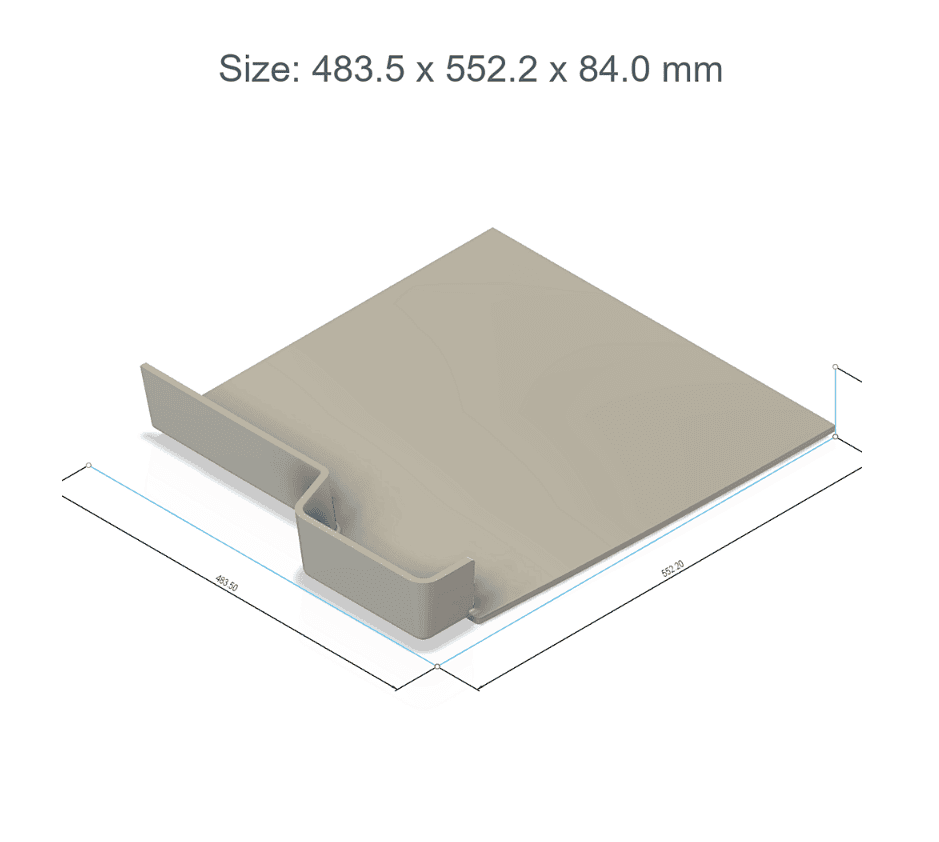

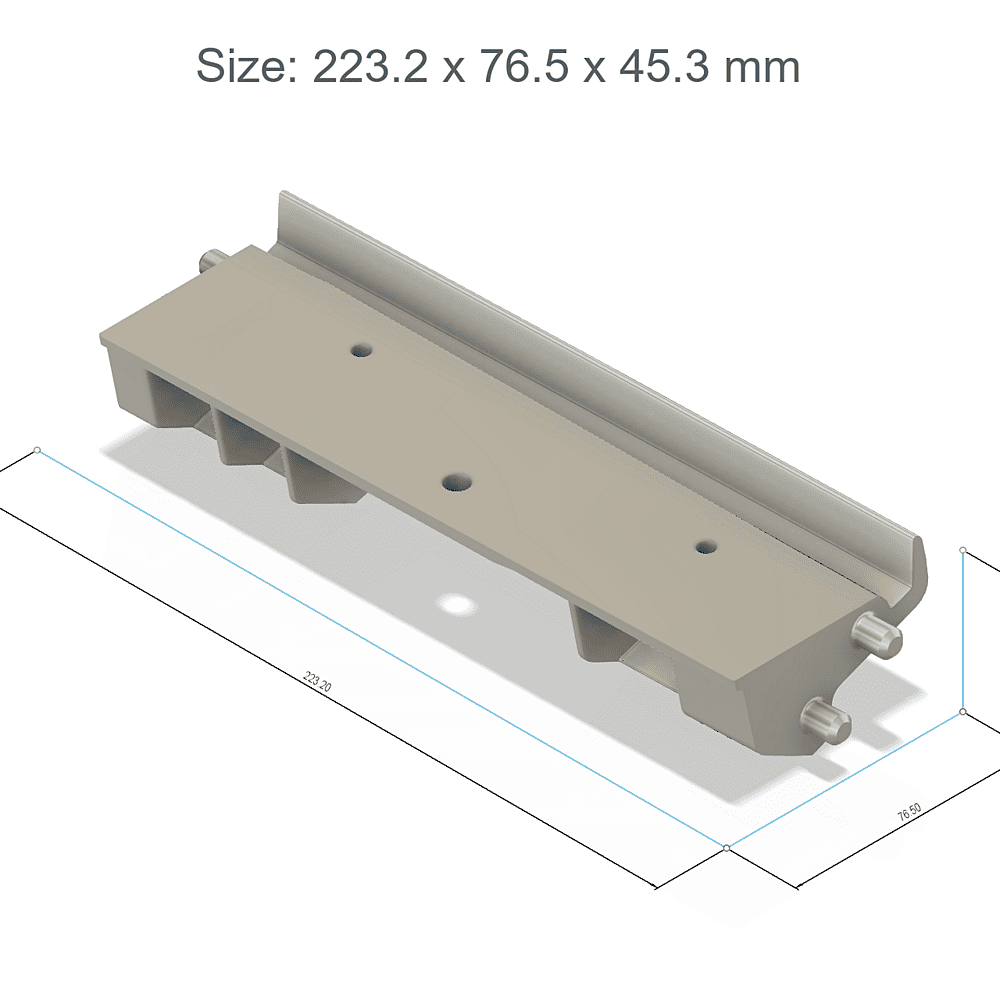

Nylon PA12 Grey MJF Jeep Roof Seals for Aluminium Hard Tops: Xometry produced 3D printed parts for an aluminium hardtop, specifically for complex geometries needed to create an effective seal around door frames. This was a prime example of using MJF 3D printing technologies for production where „more complex geometry“ was required but too difficult to make from low-volume aluminium.

Multi Jet Fusion produces highly detailed and intricate parts, with high resolution and precision, making it an excellent choice for designs with complex features and tight tolerances. By combining a relatively simple aluminium roof with these intricate MJF 3D printed components, AADS achieved a sophisticated design without the significant investment in injection moulding tooling, which would have been impractical for the required volumes.

Mark Jensen, Head of Technical and Production at AADS elaborated on the benefit of 3D printing for their volume needs:

AADS dramatically improved its supply chain and manufacturing capabilities by collaborating with Xometry. This partnership broadened their supplier network beyond local limits, offering access to a much wider array of manufacturing options. A key benefit was Xometry’s Target Price Orders feature, which proved invaluable for managing costs. It allowed AADS to set target prices early, and Xometry then connected them with suppliers who could meet those budgets. This capability is a significant advantage for forecasting in a fluctuating economic market, empowering AADS to maintain financial control and meet their project budgets consistently.

AADS on The Future: Product Diversification

AADS foresees continued partnership with Xometry as they aim to diversify their product portfolio and customer base, leveraging new vehicle platforms from the wider Stellantis group to offer more value to their customers.

Visit the AADS website to learn more: aads-gib.com

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط