Xometry helps DPI (Développement Projet Industriel) develop a sheet metal laser line for cutting coiled sheet metals into custom parts.

Франция

Steel, aluminium, carbon components (bonded to aluminium)

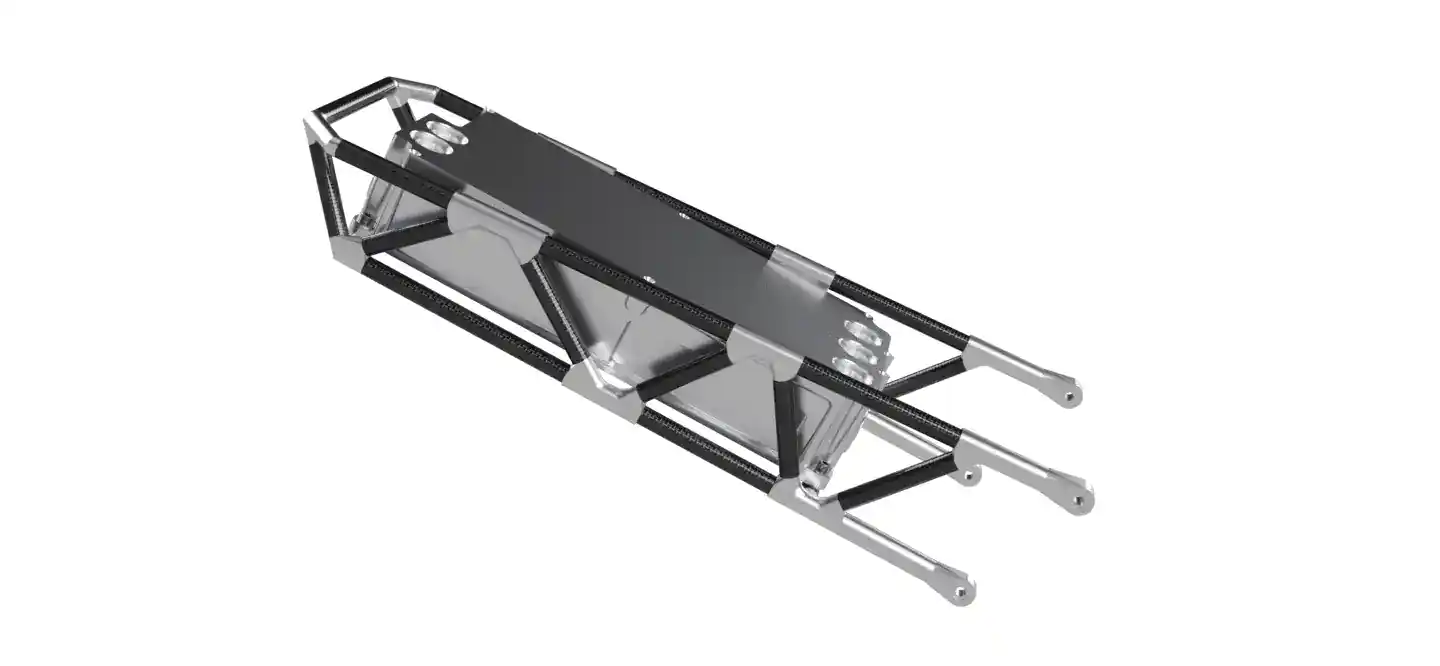

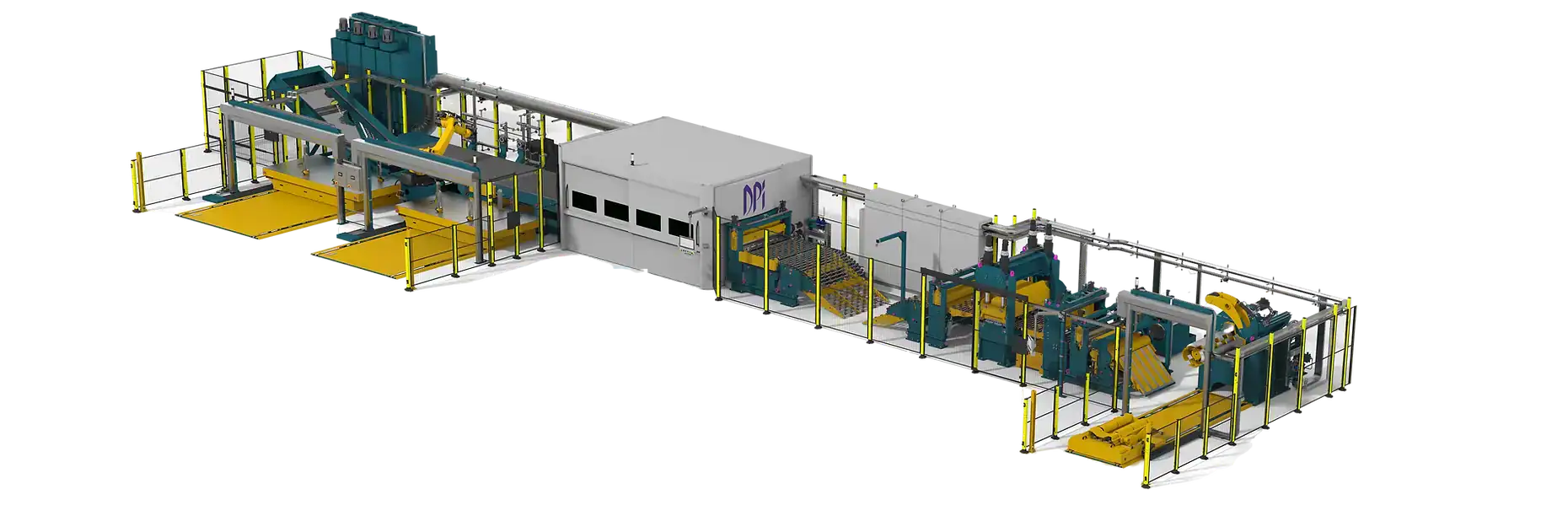

A 36-m-long, modular laser cutting line capable of processing coiled sheet metal into custom flat parts.

Xometry’s flexibility in managing small batch production has been a major asset for us, allowing us to respond quickly to changing market demands. This helps maintain high-quality components while meeting the demands for flexibility and responsiveness.

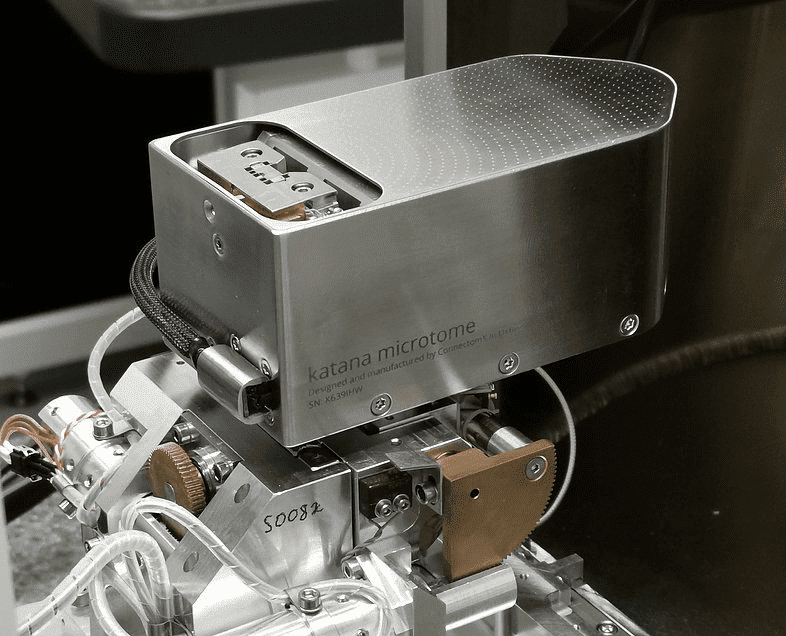

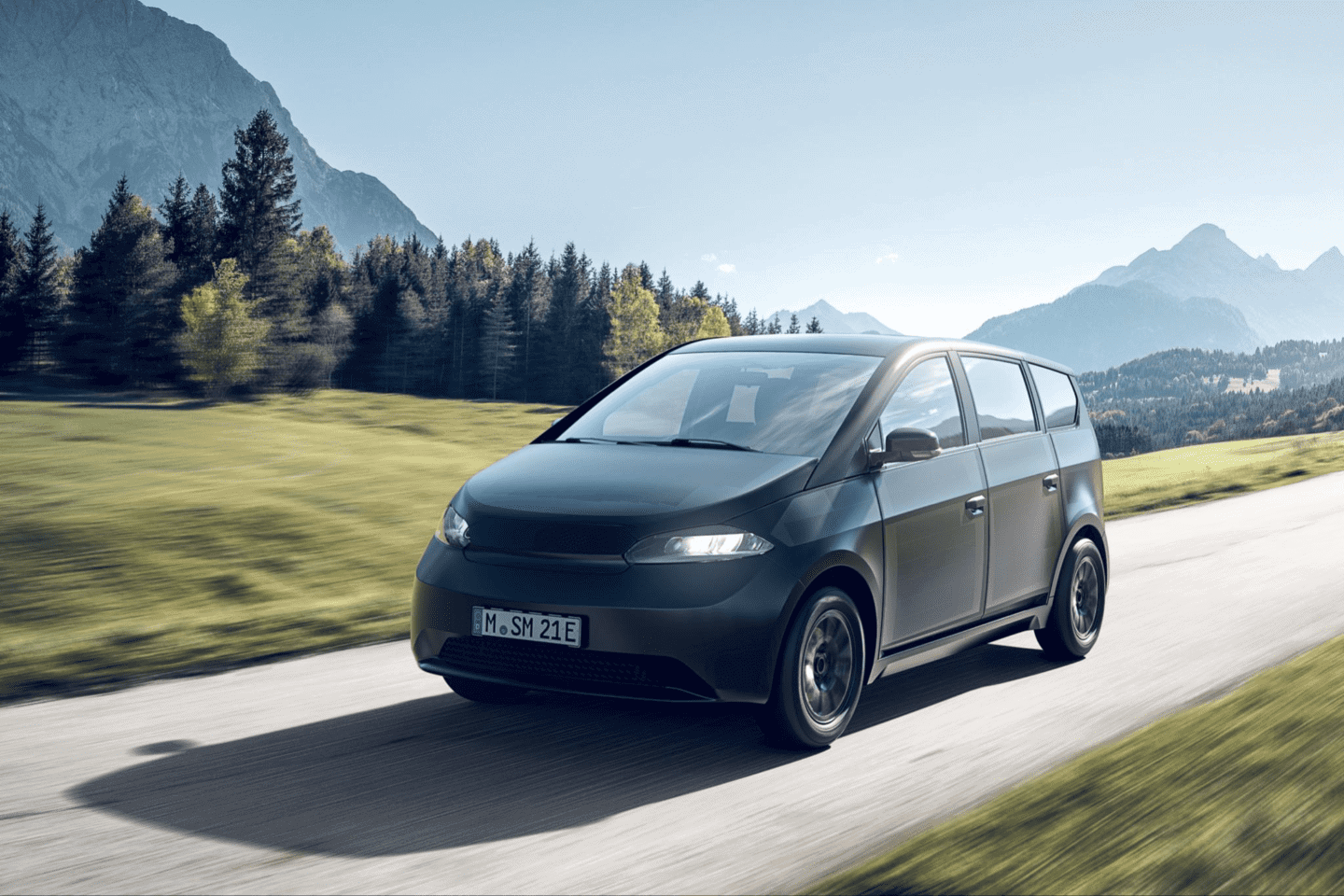

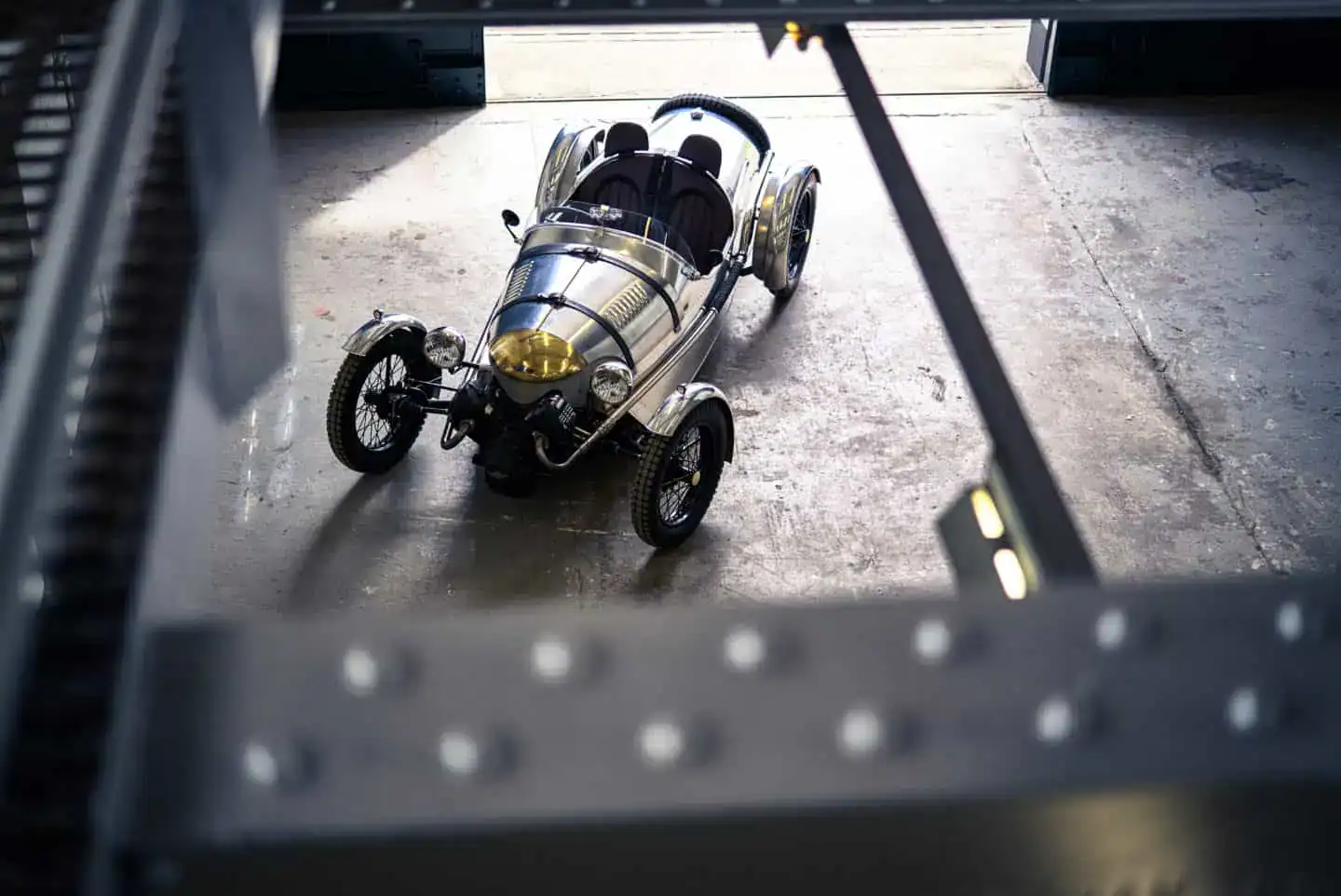

Développement Projet Industriel (DPI) is a French company specializing in the engineering of special industrial machines. They deliver turnkey projects combining mechanics, automation, and robotics, primarily for the automotive industry. DPI’s team sets itself apart thanks to its ability to create truly innovative solutions. One of their latest projects is a laser cutting line that processes coiled sheet metals into custom-cut flat parts for the automotive sector.

A Cutting-Edge Flexible and Modular Line

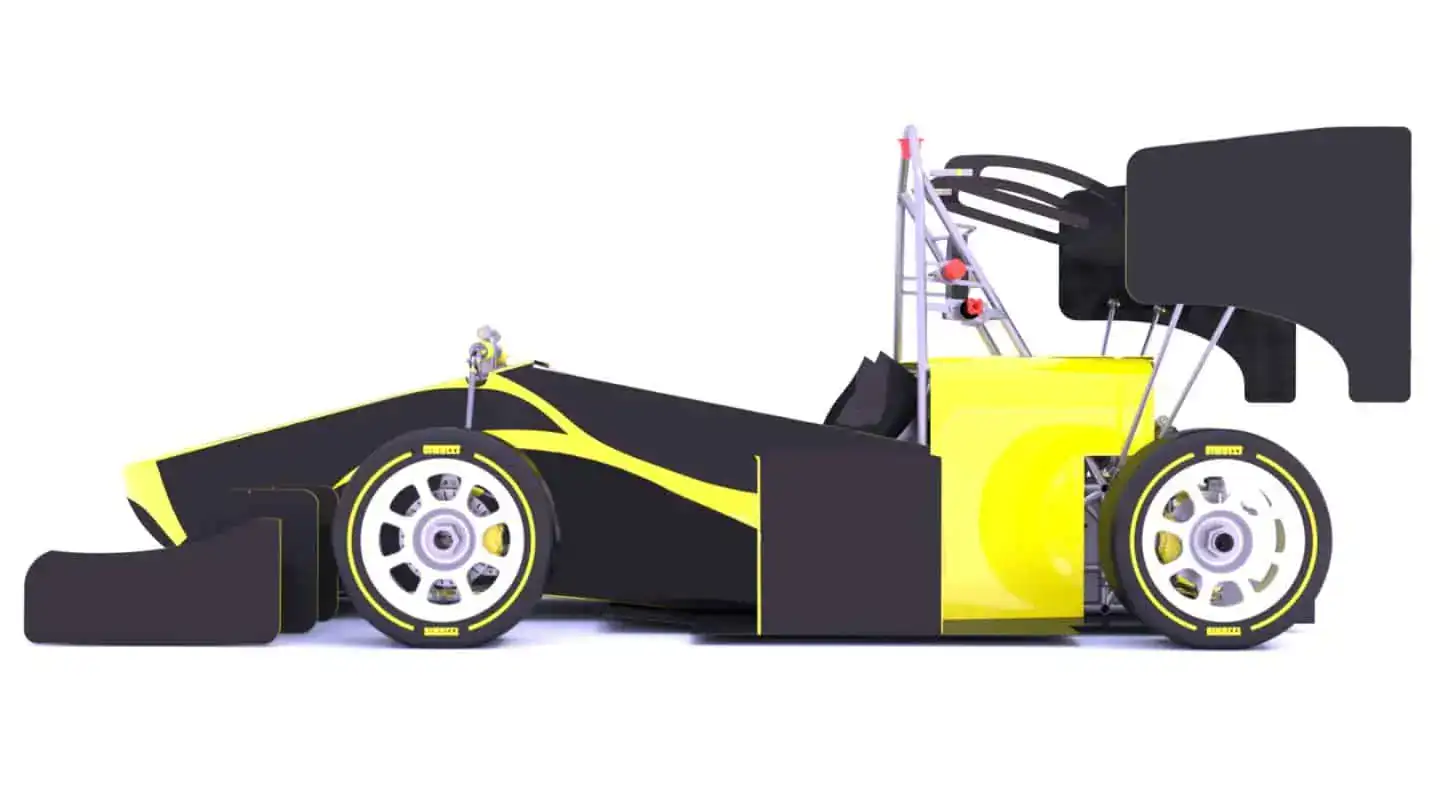

DPI is transforming industrial production with its new ultra-flexible laser cutting line. Initially designed to meet the specific requirements of an automotive manufacturer, this machine can easily be adapted to the needs of other industries. Unlike traditional production lines, which are often limited to large batches of identical parts, this system allows for the uninterrupted production of small, varied batches. While conventional solutions require hours of downtime for model changes, DPI’s line transitions between products in under a minute. This advantage significantly reduces in-process inventory and ensures unparalleled operational flexibility for manufacturers.

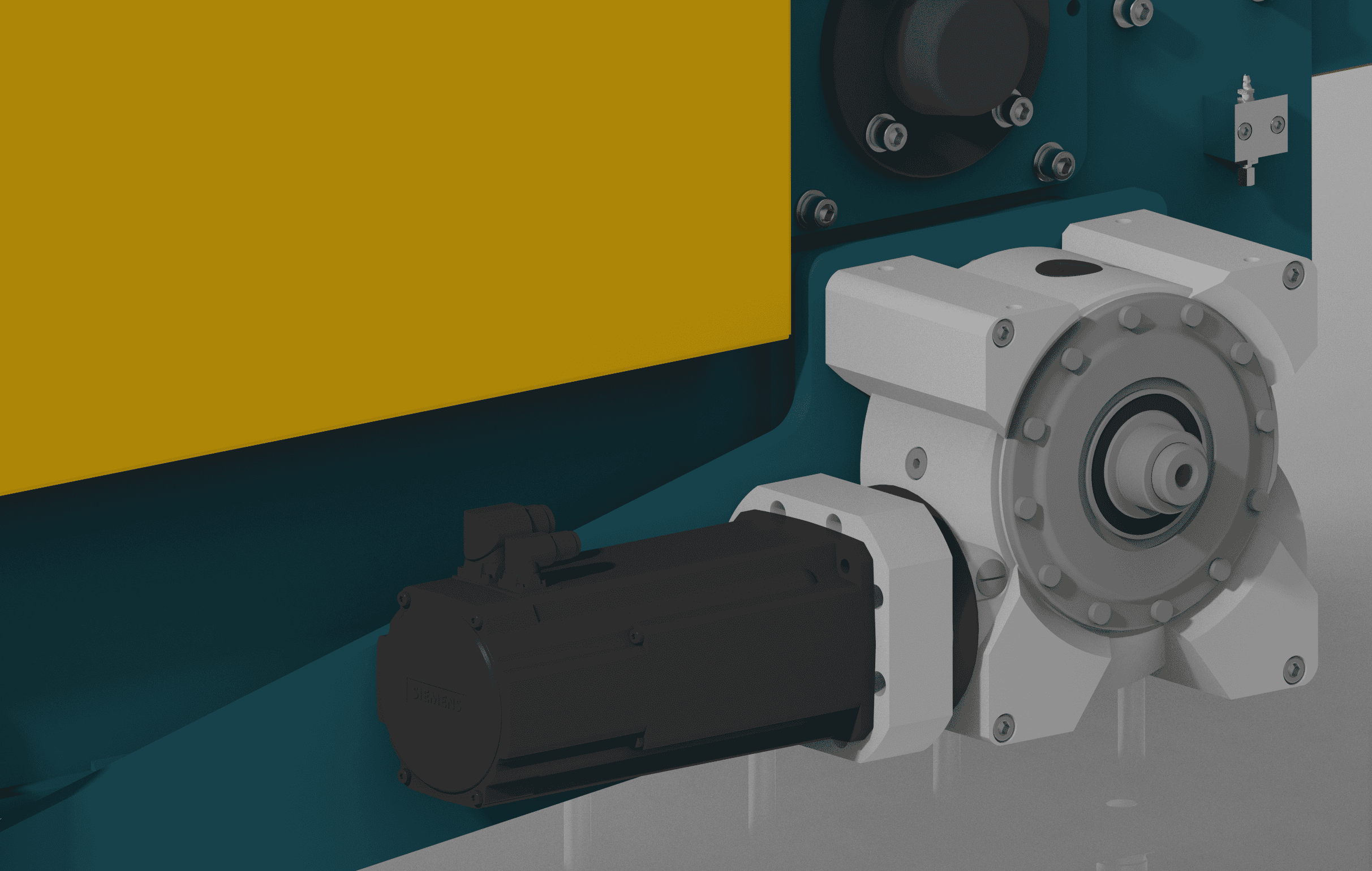

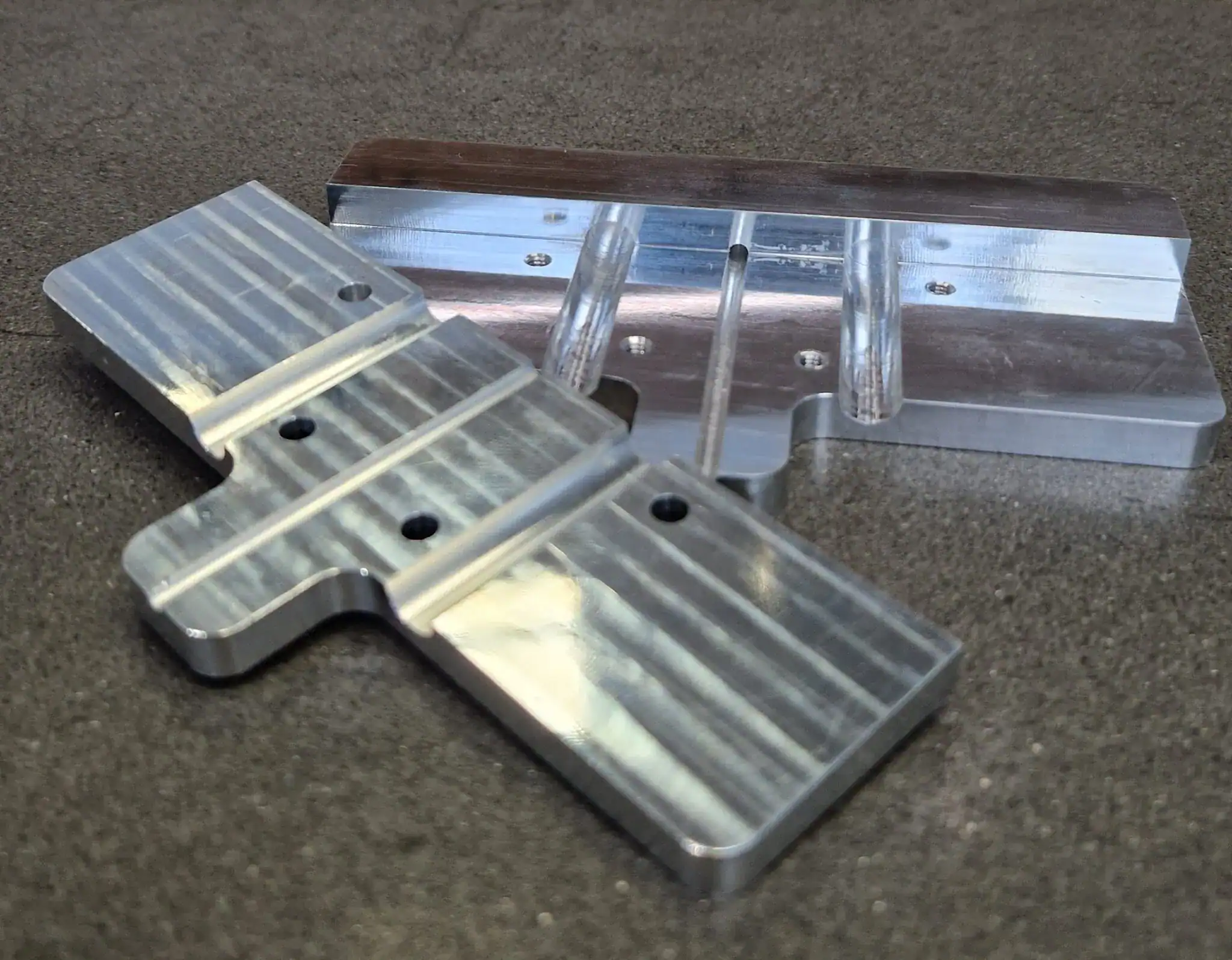

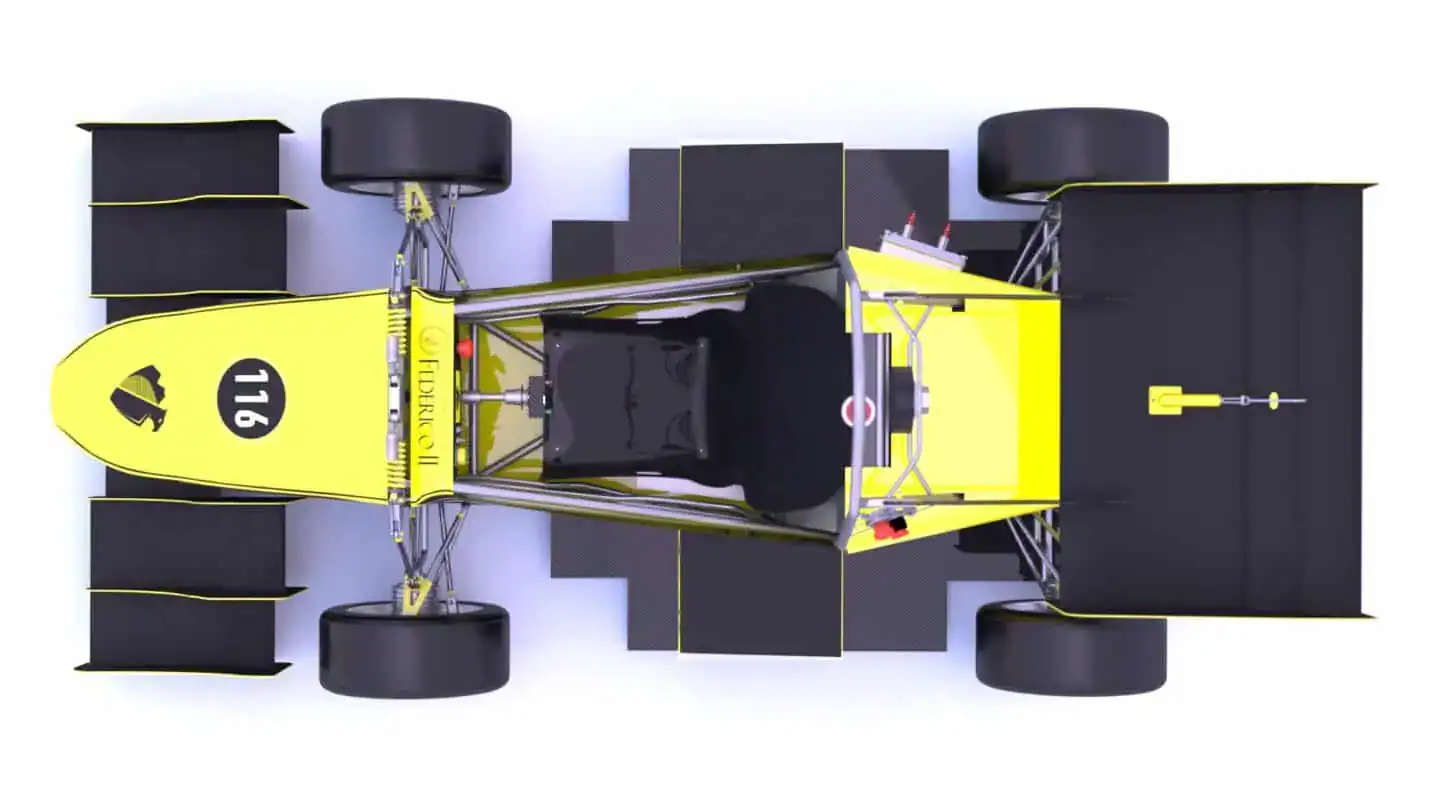

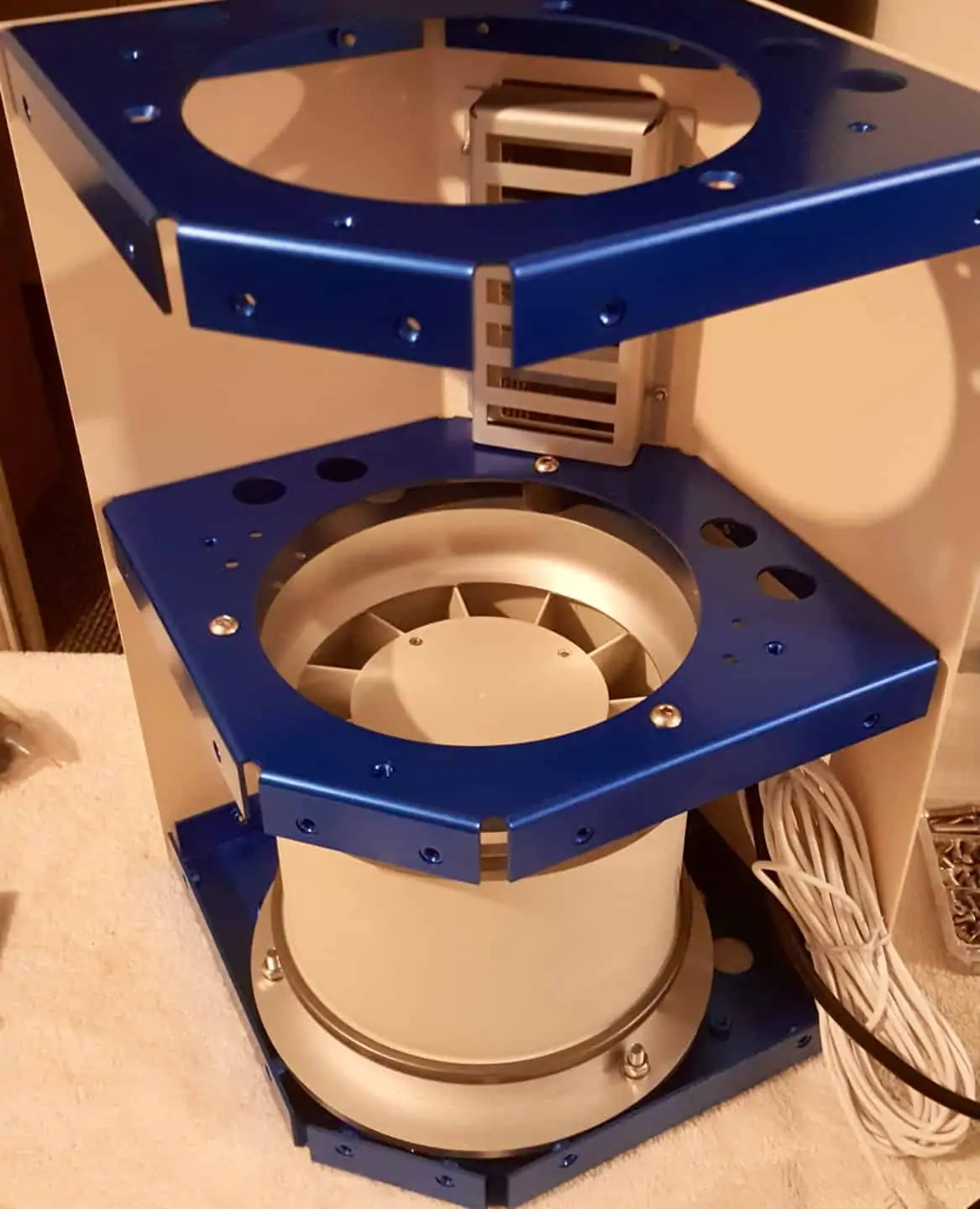

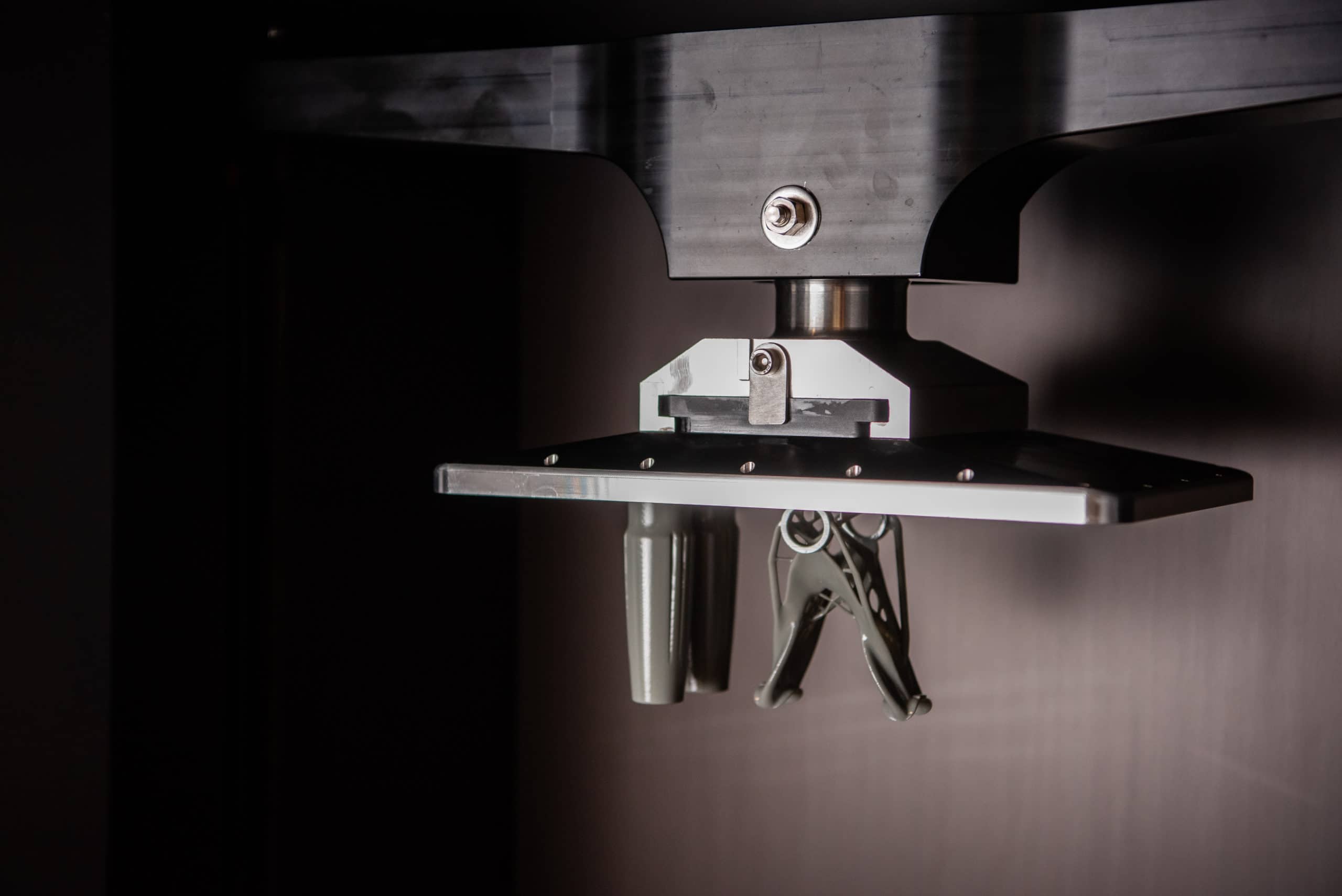

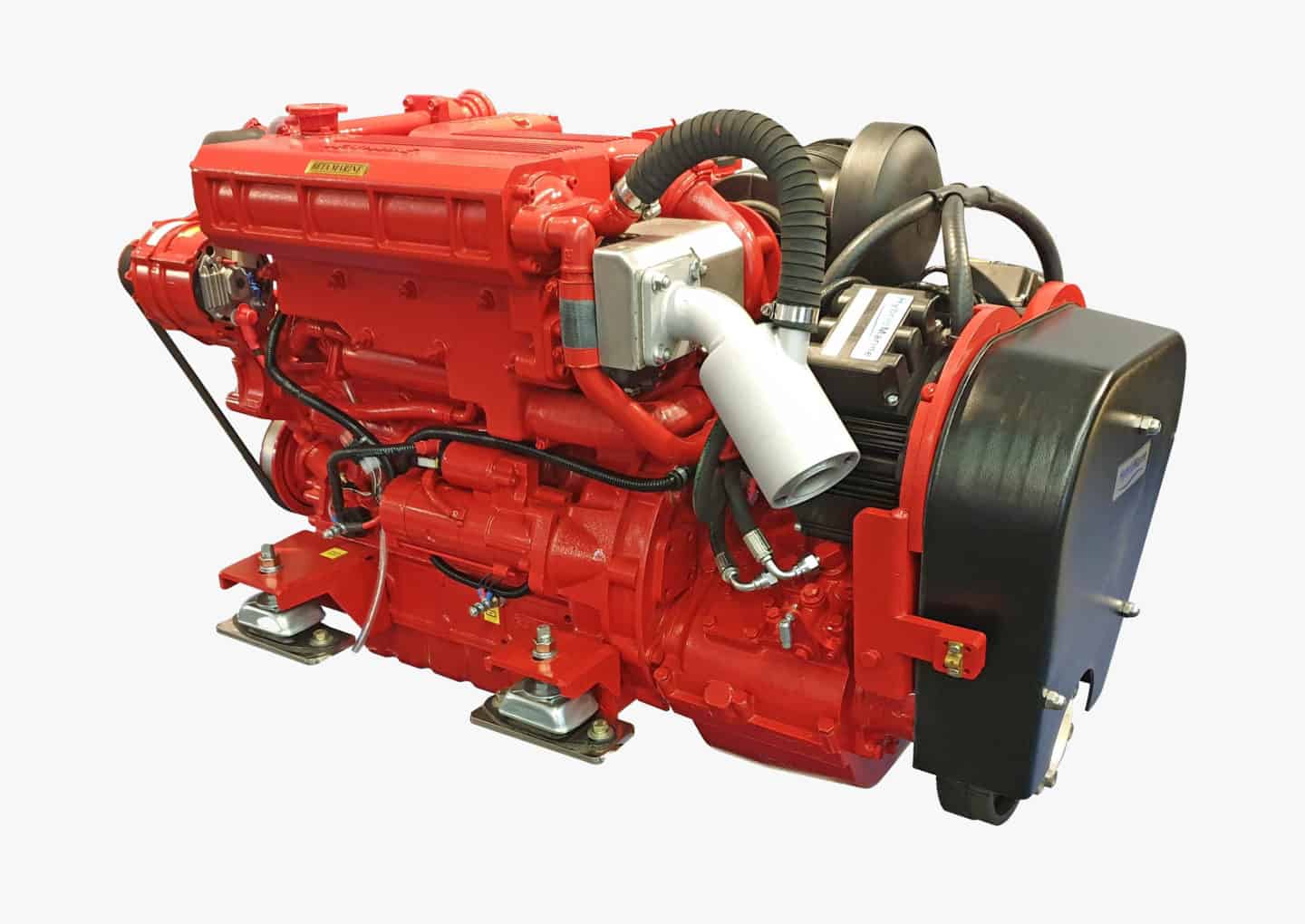

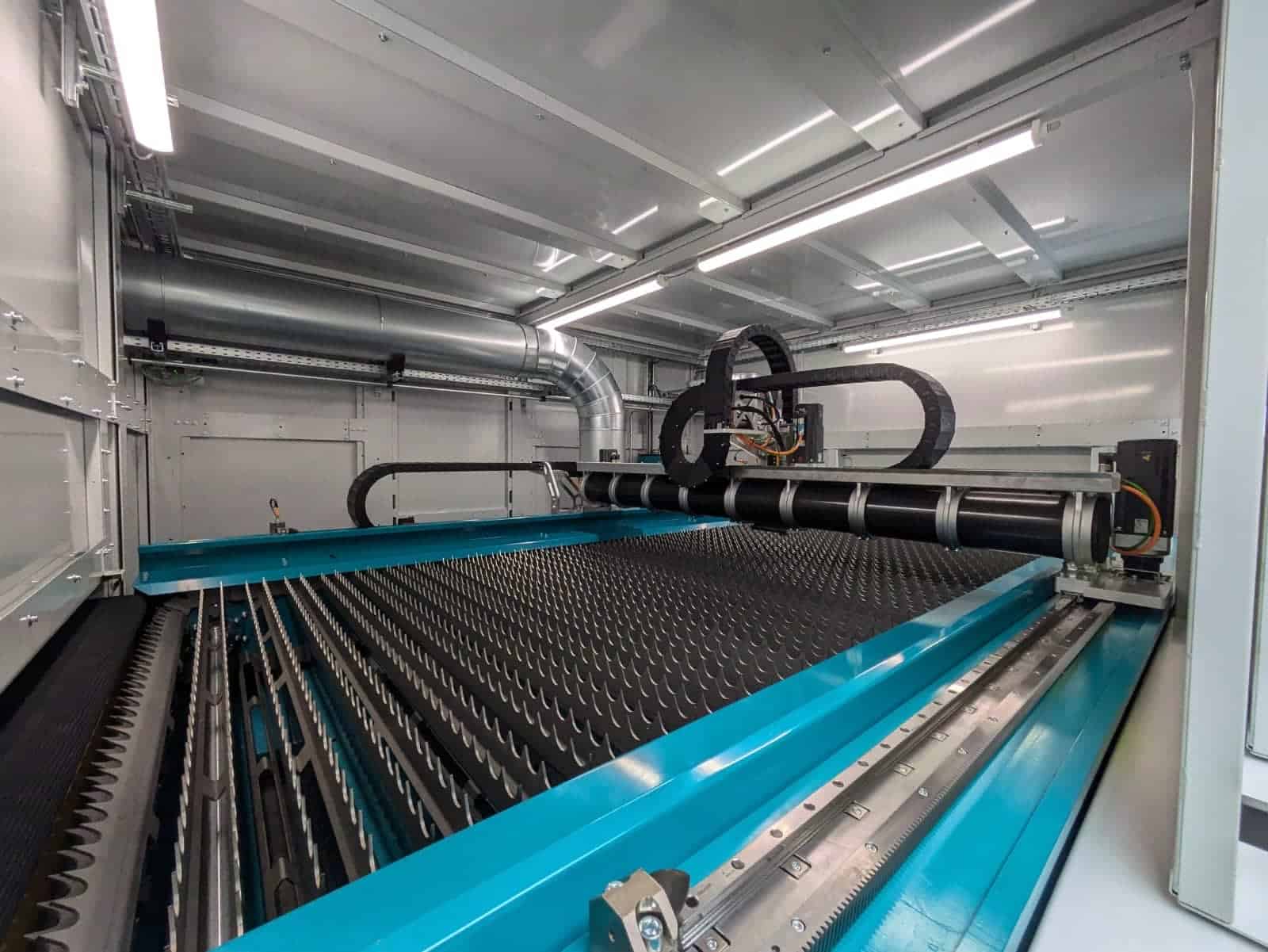

But flexibility isn’t the only strength of this production line. It spans 36 meters, weighs 80 tons, and is crafted from steel and aluminium, making it robust and reliable. Equipped with 36 high-performance servo motors and a Kuka robot, the machine is designed for optimal performance. Additionally, carbon components bonded to aluminium parts enhance cutting speed and precision, further maximizing productivity and efficiency.

DPI’s true innovation lies in its modular approach. Every component of the line, from the laser cutter to the shears, can be adjusted or replaced to meet specific customer needs. This architecture enables unique adaptability, making the machine suitable for various other industries. Thanks to this modularity, companies can make targeted adjustments without having to redefine their entire system, offering a flexible, competitive, and market-aligned solution.

A Precise Component Design Process

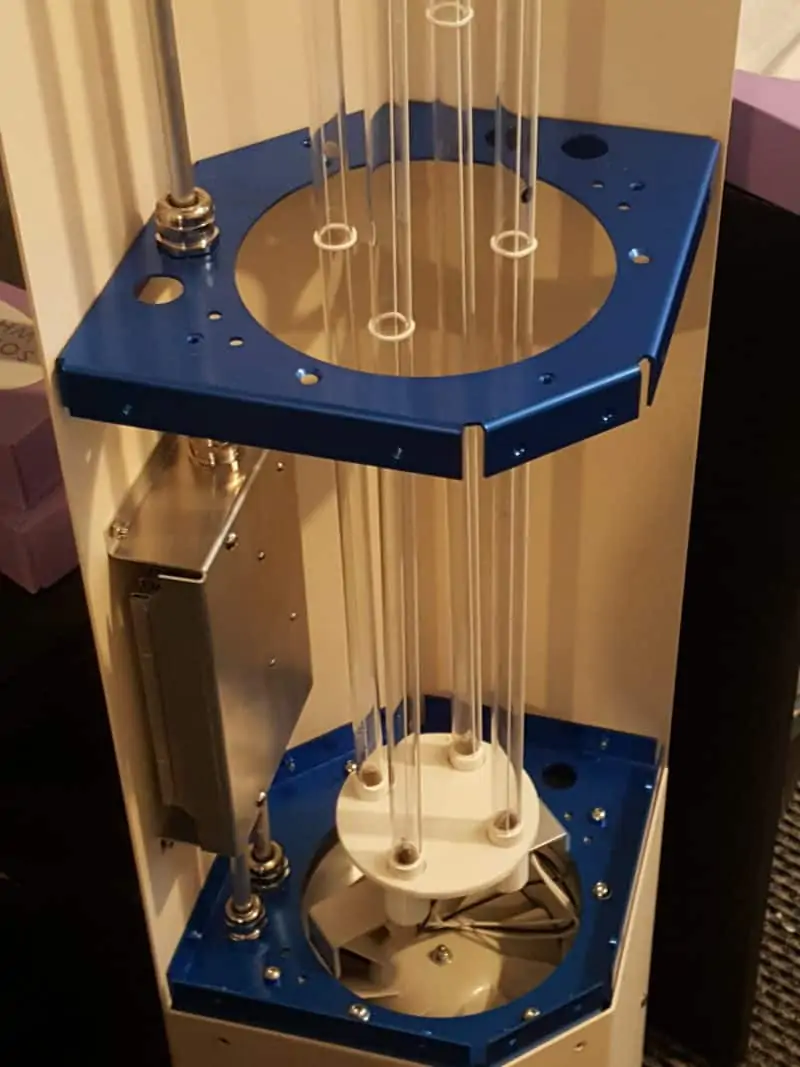

The creation of this line begins with the 3D modelling of all the parts. Assemblies of each component are then created to identify potential issues. After this stage, simulations, including structural and movement calculations, are performed using CAD software (PTC CREO) to ensure the parts are correctly dimensioned. Finally, 2D drawings with tolerances and STEP files are generated for manufacturing through machining or welding.

This meticulous design process has streamlined the production of traditionally costly and complex parts. For example, instead of using a large motor with a gearbox on the levelling machine, multiple smaller motors were installed, which resulted in substantial cost savings. If one breaks, it is far cheaper to replace a small motor than a large one. This approach not only simplifies maintenance but also improves cost management. Given the machine weighs about 12 tons and includes between 600 and 700 geometric parts, components such as rollers, shafts, and bearings have been simplified for more efficient manufacturing.

Smart Material Choices

In this large-scale project, DPI’s technical expertise guided the choice of materials and manufacturing processes. Advanced design software allowed for the simulation and optimization of each component. Among the notable adjustments, several parts initially designed in steel, such as bells and gearboxes, were redesigned in aluminium to reduce weight without sacrificing durability. Cost was also a factor in this decision, as aluminium machining is often simpler and less expensive than steel.

Leveraging Xometry’s Instant Quoting Tool for Efficient CNC Part Sourcing

Working with Xometry had some major advantages for DPI. The Instant Quoting Engine helped DPI by providing immediate cost estimates for parts but also by streamlining the overall project budget. A key requirement for this project was maintainability: the assembly line had to be easily repairable, with readily available off-the-shelf parts. Thanks to Xometry’s ability to provide competitive and accurate pricing for small and medium-sized parts, DPI can ensure continuous part availability while remaining competitive.

Promising Future Prospects: Expanding Commercial Reach

DPI is looking to expand in the future by attracting new customers interested in this production line. The enthusiasm shown by its current clients is already opening doors for future opportunities. The company is confident in its potential and plans to continue working with Xometry to produce new parts for upcoming projects.

While this revolutionary line was initially designed for the automotive sector, DPI does not intend to limit itself to this industry. DPI is leveraging the flexibility of its technology to attract a wide range of clients in various other sheet metal industries, such as signage manufacturing. Whether for manufacturing road signs or industrial components, the line’s modularity offers a broad range of applications, confirming its role in different production sectors.

Learn more about DPI: https://www.dpi-web.com/

Europe

Europe  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia  الشرق الأوسط

الشرق الأوسط